4

dp5

dp1

3

1

W17

1

2

W4

5

3

W5

2

W19

W6

3

W28

TV

W7

dp8

1

W29

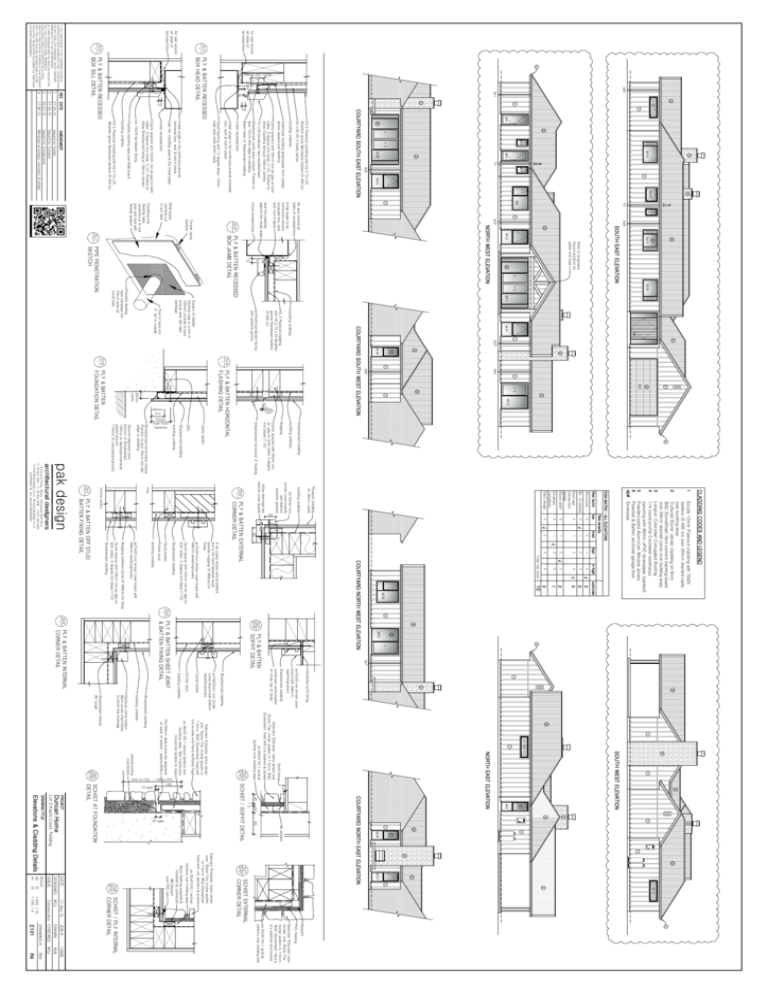

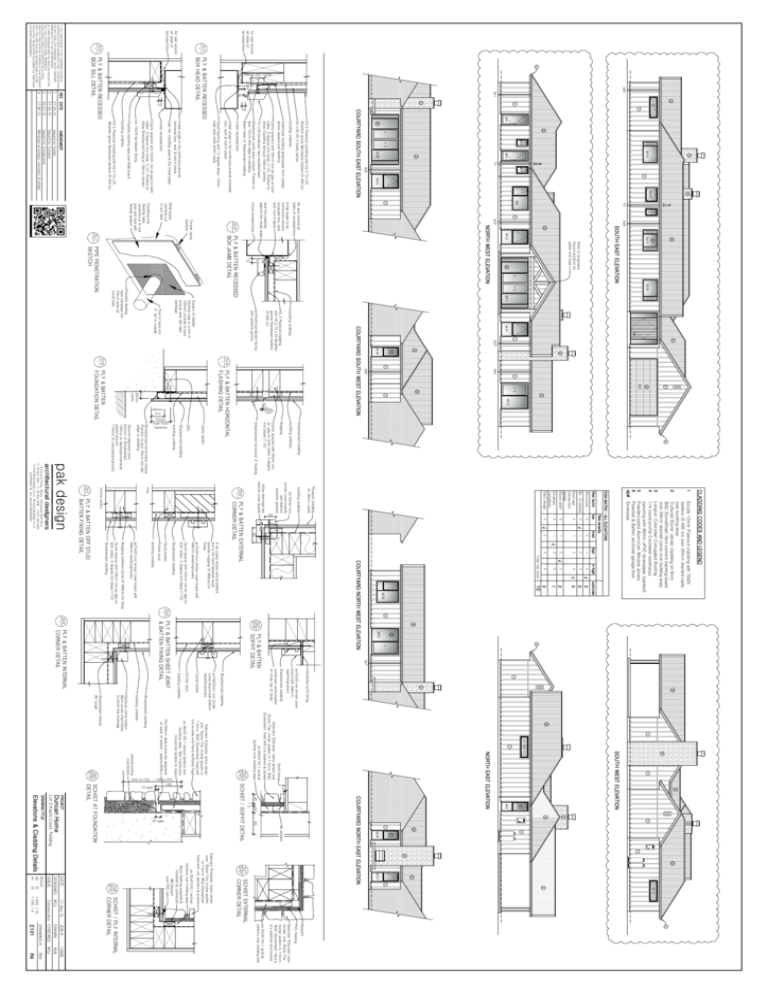

H3.2 Plywood cladding with H3.2 75 x 25

Weather grove Bandsawn battens @ 400 crs

20 x 50 H3.2 Cavity batten

building underlay

AMENDMENT

2

W20

TV

W9

1

1

3

3

5

W22

5

Refer to Engineers

Documentation for

gable end truss

10

NORTH WEST ELEVATION

W10

SOUTH EAST ELEVATION

dp6

dp2

metal recessed box

D16

-

Timber cavity

battens

RAB board

carefully cut

to suit pipe

W23

PIPE PENETRATION

SKETCH

W11

W31

W1

3

1

dp3

3

2

5

W30

D19

-

D18

-

1

dp4

dp9

1

1

6

W2

3

3

1

W15

COURTYARD SOUTH WEST ELEVATION

building underlay

H3.2 Plywood cladding

with H3.2 75 x 25 Weather

groove Bandsawn battens

@ 400 crs

ex70x25 bandsawn facing

with weather groove

Square of flexible

flashing tape to a min of

100mm outside of pipe,

ensure seal with pipe

bandage

Pipe to have min

5° fall to outside

Flexible flashing

tape bandage min

25mm wide all

round pipe.

PLY & BATTEN RECESSED

BOX JAMB DETAIL

seal the cladding

against the metal angle

metal angle to be

continuous around

recessed box, seal

and rivet in place

Air seal around all

sides of recessed box

W21

Cladding over

flashing tape,

carefully cut to suit

pipe and seal with

flexible sealant

D17

-

4

Shadowclad cladding

building underlay

Nogging

Cavity spacers with 50mm min

air gap on both sides. 5 degree

min slope (1:12)

Shadowclad horizontal 'Z' flashing

building underlay

Shadowclad cladding

DPC

Cavity batten

PLY & BATTEN HORIZONTAL

FLASHING DETAIL

20mm

cavity

PLY & BATTEN

FOUNDATION DETAIL

Shadowclad cavity base closure.

Position to give 10mm min drip

edge to cladding

1

med

2

1

high

4

6

√

√

10

0

2

1

2

0

5

subtotals

Ecoply 12mm Plywood cladding with 70x25

battens @ 400 crs over 20mm drained cavity

over building wrap

'Cultured Stone' veneer cladding on 9mm

BGC StoneSheet fibre cement backing board

over 20mm drained cavity over building wrap

Longrun Colorsteel Corrugated Roofing

1/4 round profile Colorsteel continuous

spouting with 80mm uPVC downpipes (painted)

Powdercoated Aluminium Window Joinery

Plywood & Batten sectional garage door

Downpipe

CLADDING CODES AND LEGEND

2

3

4

5

6

dp#

RISK MATRIX - ALL ELEVATIONS

low

1

0

5

3

6

W24

1

D23

-

3

D24

-

5

W25

4

dp7

1

2

3

Hardieflex soffit lining

ex75x25 min timber cover

board with 6x6mm

weathergrooves

Shadowclad cladding

continuies cavity batten

to close top of cavity

PLY & BATTEN

SOFFIT DETAIL

Shadowclad cladding

ex75x25mm min timber

cover board with 6x6mm

weathergrooves

Timber stud

Cavity batten

3

1

W3

1

2

1

3

W8

5

SOUTH WEST ELEVATION

40

20

2

3

1

2

1

3

1

5

W26

No sealant

90

SCHIST / SOFFIT DETAIL

7.5

1

2

3

3

W27

1

W18

3

SCHIST EXTERNAL

CORNER DETAIL

Selected 'Eldorado' stone veneer

over 'Stone-Tite' mortar system

to 7.5mm 'BGC Stonesheet'

fixed with s/s washers & screws

ex 50x25 H3.1 vertical

battens over building wrap

Back flashing supplied &

installed by contractor

MS Sealant

over PEF rod

4

Sealant

PVC flashing

Selected 'Eldorado' stone

veneer over 'Stone-Tite'

mortar system to 7.5mm

'BGC Stonesheet' fixed with

s/s washers and screws

ex 50x25 H3.1 vertical

battens over building wrap

JOB #:

WJA

15006

SCHIST / PLY INTERNAL

CORNER DETAIL

DRAWN:

D28

S101

MCJ

17-Sep-15

E101

DRAWING #:

R4

REV:

MCJ

DATE:

1:200, 1:10

1:100, 1:5

Construction CHECKED:

DESIGNED:

SCALE:

A3

@

A1

@

ISSUE:

PROJECT:

Elevations & Cladding Details

DRAWING TITLE:

Lot 2 Kapiti Court, Feilding

Duncan Home

SCHIST AT FOUNDATION

DETAIL

D27

S101

COURTYARD NORTH EAST ELEVATION

NORTH EAST ELEVATION

ex 50x25 H3.1 vertical

battens over building wrap

Soffit lining

Selected 'Eldorado' stone veneer over

'Stone-Tite' mortar system to 7.5mm 'BGC

Stonesheet' fixed with s/s washers & screws

D25

S101

Selected 'Eldorado' stone veneer

over 'Stone-Tite' mortar system to

7.5mm 'BGC Stonesheet' fixed with

s/s screws and Hard as Rocks Tags

ex 50x25 H3.1 vertical battens over

building wrap. Non-continuous

horizontal battens to nogs

D26

S101

waterproofing

membrane

10x100mm wide horizontal weephole

at base of rebate - approx 600c/c

Shadowclad internal

90° angle

Optional corner batten.

Back corner chamfered

to allow free drainage

building underlay

Shadowclad cladding

building underlay

PLY & BATTEN INTERNAL

CORNER DETAIL

PLY & BATTEN SHEET JOINT

& BATTEN FIXING DETAIL

D22

S101

COURTYARD NORTH WEST ELEVATION

Total risk score:

4

5

2

0

3

v-high

Risk factor

0

1

2

Risk severity

Wind zone

0

1

√

No. of storeys

0

√

Roof/wall

intersection

design

Eaves width

1

√

0

2

0

√

Envelope

complexity

Deck design

Plywood cladding

on 20mm cavity

building underlay

Ex 25mm min

timber cover boards

with 6x6mm

weather grooves

50

building underlay

Timber stud

Cavity batten

Shadowclad cladding

Cavity spacer with 50mm min air gap on

both sides. 5 degree min slope (1:12)

ex75x25 min timber cover board with

6x6mm weathergrooves

In all cases where vertical battens

are to be fixed between studs

provide nogging @ 480ctrs for

fixing

PLY & BATTEN EXTERNAL

CORNER DETAIL

Allow drainage slot

behind cover boards

D20

-

Plan

ex75x25 min timber cover board with

6x6mm weathergrooves

Nogging between studs @ 480ctrs for fixing

Shadowclad cladding

Cavity spacer with 50mm min air gap on

both sides. 5 degree min slope (1:12)

PLY & BATTEN OFF STUD

BATTEN FIXING DETAIL

Vertical section

D21

-

8 Connolly Place, Milson, Palmerston North 4414

P: 06 952 3584 F: 06 952 3586

C:027 204 9423

E:matt@pakdesign.co.nz W:www.pakdesign.co.nz

COPYRIGHT © ALL RIGHTS RESERVED

pak design

Ground clearance from

bottom of Shadowclad:

100min to decks/permanently

paved ground

175min to unprotected ground

50

Additional building wrap/paper from overlap

above lapped over flashing

Cavity spacers with 50mm min air gap on both

sides. 5 degree min slope (1:12). Position to

allow Cladding fixing at 150mm centers

75 x 25 bandsawn face weatherhead

Shadowclad cavity base closure. Position to

give 15mm drip edge to cladding

Bevel base of Shadowclad cladding

metal recessed box

DATE

Issued for Tender

Issued for Consent

Issued for Construction

Windows amended, removed, & added

20 gap

metal angle to be continuous around recessed

box, seal & rivet in place

Head flashing with 15 degree slope. 15mm

high stop ends within cavity

metal angle to be continuous around

recessed box, seal & rivet in place

seal the cladding against the metal angle

metal recessed box

Cavity spacers with 50mm min air gap on both

sides. 5 degree min slope (1:12). Position to

allow Shadowclad fixing at 150mm centers

ex 75x25 bandsawn facing

building underlay

Flexible flashing tape over RAB board

REV

27.05.15

27.05.15

20.07.15

17.09.15

H3.2 Plywood cladding with H3.2 75 x 25

Weather grove Bandsawn battens @ 400 crs

1

2

3

4

5

225 to FGL - 150 to FPL

100

10 gap

5mm

min

50mm

min

COURTYARD SOUTH EAST ELEVATION

10

PLY & BATTEN RECESSED

BOX HEAD DETAIL

8

PLY & BATTEN RECESSED

BOX SILL DETAIL

10

Air seal around

all sides of

recessed box

D14

-

Air seal around

all sides of

recessed box

D15

-

1) ALL DIMENSIONS TO BE CONFIRMED ON SITE BY

CONTRACTOR BEFORE MANUFACTURE / CONSTRUCTION.

DO NOT SCALE OFF DRAWINGS. NOTIFY DESIGNER

IMMEDIATELY OF ANY DISCREPANCIES.

2) THESE DRAWINGS MUST BE READ IN CONJUNCTION

WITH ALL SPECIFICATIONS, ENGINEER &

SUB-CONSULTANCE DOCUMENTATION & TRADE

RELATED PUBLICATIONS. CONSTRUCT IN ACCORDANCE

WITH THE NEW ZEALAND BUILDING CODE & OTHER

STATUTORY, REGULATORY DOCUMENTS & TERRITORIAL

AUTHORITY REQUIREMENTS.

75mm

max from

fastener

50mm min cover