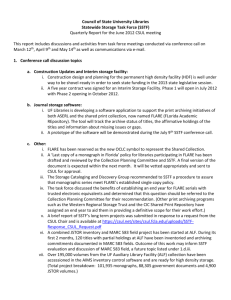

The basis of momentum criteria for flare system

advertisement

Upgrade Chemwork Discussions 1,188 members Members Search Manage Basis of Momentum Criteria for Flare System Learn Syan Lee Process Design Engineer Top Contributors in this Group Dear friends, Follow Learn Syan As per clause 6.5.1 of NORSOK Standard P-001 (Process Design), "all flare lines shall be designed to keep the rho.v2 < 200,000 kg/m.s2 criteria (where rho is the fluid density or mixed density for two phase conditions in kg/m3 and v is the velocity in m/s)." As per clause 13.5.1 of TOTAL GS EP ECP 103 (Process Sizing Criteria), "(flare) headers: 0.7 Mach max and rho.v2 < 150,000 Pa considering the maximum flow rate due to process limitations." Appreciate if anyone from the group can shed some light regarding the following queries: Ghasem Bashiri Process Lead Engineer at EIED Unfollow Ghasem See all members Your group contribution level Getting close! Reach the next level and you could get featured on the group homepage. • Basis of limiting flare system momentum to < 150,000 or < 200,000 kg/m.s2. Is it based on industrial experience or experimental results to maintain mechanical integrity of piping? • If the estimated momentum exceeds 200,000 kg/m.s2 (say 250,000 kg/m.s2) due to tie-in of a higher flare load to an existing system, what is the implication of exceeding the momentum criteria (e.g. excessive piping vibration)? Is it mandatory to increase the tie-in line size or can it be considered acceptable by providing proper supports/bracings since relief load to flare system is considered as intermittent service? Thanks in advance for sharing your experience and thoughts on this topic. Regards, Syan Like (1) Comment (4) Share Follow Reply Privately 12 months ago Add to Manager's Choice Close Discussion Comments Vinay Kumar likes this 4 comments S M Kumar Process Design Consultant SM Syan: Please google FIV Study + AIV Study. Flow Induced vibration/ Acoustic Induced Vibration and read all about it. Usually branch connections break and release HC inside the plant, rather than take it all the way to flare tip. Like (1) Reply privately Delete 12 months ago Azhar Ali likes this Mohd Fitri bin Mohd Lias Process Engineer at MMC Oil and Gas Engineering Sdn. Bhd hi, you may refer to aiv assesment and protection guideline by energy institute. its help Mohd Fitri Like (1) Reply privately Delete 12 months ago Azhar Ali likes this Building influence Ads By LinkedIn Members Fire Prevention Services Automatic sprinkler design, installation and maintenance services. SHEQ Software Manage your Quality, Environmental, Health and Safety performance Chemical Process Software Engineered for hundreds of industryspecific processes. Try CHEMCAD free. Latest Activity Feroz shaikh joined a group: Chemwork Chemwork Discussion Forum 11h ago Paramasivam CEng AMIE commented on a discussion in Chemwork. Ghasem Bashiri Parallel Flare Dear Experts Is it possible to have parallel Flare due to very large Relief Rate. Within a project we exposed to a very large Relief rate from upstream (1600 ton/hr). we know that such rate should be... more 12h ago Arun kumar Senior Process Engineer at Saipem Arun Hi, Syan The criteria holds good only for the single phase, not for two phase flow. More over if the rho.v2 is higher you will have to given more concrete support for the vibrationa and has a tremendours impact on the welded joints. As a good practise you can go upto 1 mach in tail Pipes, but not on the Sub-header and Main Headers. Check for the conditions at the main header and sub-header and speak to your piping department for the inputs on the cost of support, generally this has a huge financial Impact. For these reasons we recommend the limits. More over check for the generally Line sizing criteria. for the lines for two phase. PERVAIZ RIZVI commented on a discussion in Chemwork. Felipe D. Methanol as hydrate inhibitor - Regeneration and Recovery Process Dear all, Could anyone tell me more about the process of recovery and regeneration of methanol used as hydrate inhinitor on offshore natural gas platforms. I intend to run a simulation on hysys of... more 13h ago Like (1) Reply privately Delete 12 months ago See all activity Vinay Kumar likes this About Frank Petz research at Consultant Frank Privacy & Terms LinkedIn Corp. © 2014 as said by others these values are related to maximum stress and vibrations on lines, for single and two phase F = P*A + Rho*A*V^2 / g gives the force on a specified section, there is a static (P*A) and dynamic (Rho*A*V^2 / g) contribute, since you know the mass flow and conditions (for a PSV I simulate as isentropic nozzle with PRODE PROPERTIES) you can calculate density and velocity, for two phase I generally prefer the HEM model (i.e. gas and liquid traveling at the same speed and at equilibria), from the above you can calculate the maximum stress, for mach number you need the two-phase speed of sound, again you can calculate the speed of sound for two phase flow with a simulator (I use PRODE PROPERTIES) and then calculate the mach number Like (1) Reply privately Delete 11 months ago Vinay Kumar likes this Add a comment... Send me an email for each new comment. Feedback Add Comment