INPUT DATA FOR TORSIONAL VIBRATION CALCULATIONS (TVC)

advertisement

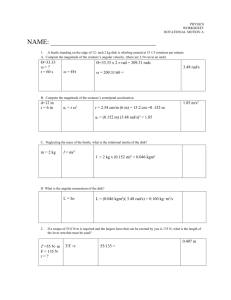

INPUT DATA FOR TORSIONAL VIBRATION CALCULATIONS (TVC) (POWER UNIT FOR MARINE INSTALLATIONS) Name of Vessel / New Building No. Name of Shipyard / Yard No. Name of Owner / Shipping Company Address of Owner / Shipping Company Volvo Penta engine type Purpose of engine drive system (e.g. propulsion, auxiliary, emergency, pump or alternator) Engine continuous power (kW) and speed (rpm), (for alternator the TVC is made with 110 % intermittent power) Classification Society for approval of the TVC (for classified installations only) Order No. of Volvo Penta importer/dealer/sales representative The input data on these sheets is issued by (Name, Company, sign.) Date For Volvo Penta Head Office use only Engine order No. TVC order No. Note I Suppl information under paragraphs 1.0 and 2.0 1 GUIDELINES The specified data on these sheets is required for carrying out torsional vibration calculations. It is extremely important that these data sheets, after the data has been filled in, are sent to AB Volvo Penta (under address below) together with the engine order form. A certain amount of time must be allowed for handling the TVC. Before delivery of the engine the TVC should be approved by the Classification Society. Figure I shows a SCHEMATIC lay-out of an engine drive system. The numbers indicated in the figure corresponds to the numbered headings in the text. Follow the numbered headings step by step (and this way proceed through the figure) and fill in the requested data where applicable. Delete or mark “not applicable” (N/A) for systems, components or data not applicable for the actual installation. ALTERNATIVE DATA asked for should be filled in when it is difficult to give the requested primary data. Should any of the configurations shown in Figure 1 not correspond to the actual installation, supply input data for the TVC by using the formats under applicable headings and refer to a supplied schematic lay-out of the actual installation. The data to be filled in can either be given in Imperial (English), US, metric (MKSA) or SI units. However, SI units are preprinted, so if other than SI units are used it should be noted what unit is being used. Please sent this form and other necessary documentation to: AB Volvo Penta Quality system & classification dept, 47870 Z1.1 S-405 08 Gothenburg SWEDEN or to fax no: +46 31 537447 “MASS MOMENT OF INERTIA” Data requested for “mass moment of inertia” can be given in different ways, as moment of inertia or flywheel mass. Moment of inertia is designated J and can be expressed in units of kgm2 (lb.ft2) or kpms2 (lbf.ft.s2). The latter units indicate that the quantity has been divided by gravity. It should also be noted to which axle the moment of inertia is referred (if it is not understood by the design, i.e. a symmetric axle). Flywheel mass is desionated mD2, GD2 or WR2 and expressed in units of kgm2 (lb.ft2), kpm2 (lbf.ft2) or lbf.ft2 (kpm2) respectively. The following relation applies: mD2 = 4J GD2 = 4gJ WR2 = gJ where g is the gravity (approx. 9.81 m/s2) 2 SCHEMATIC LAY-OUT OF AN ENGINE DRIVE SYSTEM (The numbers indicated in the figure corresponds to the numbered headings in the text.) Figure 1. 3 1. Power take-off (PTO) at front end (DAMPER SIDE) of engine 1.0 VOLVO PENTA will supply information under this paragraph! Continue to paragraph 1.1. For this order the following standard equipment will be delivered with the engine for connection to the engine’s front end (e.g. bilge pump, flush pump, hydraulic pump, extra drive, extra pulley, charging alternator, clutch, coupling, reduction gear, pto, etc.): 1.1 Disengageable coupling (clutch), rotating at engine speed Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , J: ......................................................................... _________ kgm2 J: ......................................................................... _________ kgm2 2 engine side, GD : ........................................................................ _________ kgm2 GD2: ........................................................................ _________ kgm2 pto-side, 1.2 Flange coupling, rotating at engine speed J: ......................................................................... _________ kgm2 or Flywheel mass for the complete coupling, GD2: ........................................................................ _________ kgm2 Moment of inertia for the complete coupling, Alternative data: Flange diameter: ........................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ........................................................................................................................................ _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.3 Flexible coupling, rotating at engine speed Make and type: For couplings supplied by Volvo Penta this data is not required. J: ......................................................................... _________ kgm2 J: ......................................................................... _________ kgm2 engine side, GD2: ........................................................................ _________ kgm2 GD2: ........................................................................ _________ kgm2 The data below are given for an ambient temp. for the engine installation of: ................................. ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 4 Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: ............................. ____________ ) Relative damping factor, Ψ : .......................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 1.4 Belt pulley (driving pulley), rotating at engine speed Moment of inertia, J: ................................................................................................................. 2 _________ kgm2 or Flywheel mass, GD : ................................................................................................................ _________ kgm2 Pitch diameter for the belt: ............................................................................................................ __________ mm Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.5 Shaft, rotating at engine speed Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 1.6 Disengageable coupling (clutch), rotating at engine speed J: ......................................................................... _________ kgm2 J: ......................................................................... _________ kgm2 engine side,GD2: ........................................................................ _________ kgm2 GD2: ........................................................................ _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 1.7 Flange coupling, rotating at engine speed J: ........................................................................ _________ kgm2 or Flywheel mass for the complete coupling, GD2: ....................................................................... _________ kgm2 Moment of inertia for the complete coupling, Alternative data: Flange diameter: .......................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ....................................................................................................................................... _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.8 Flexible coupling, rotating at engine speed Make and type: For couplings supplied by Volvo Penta this data is not required. J: ........................................................................ _________ kgm2 J: ........................................................................ _________ kgm2 engine side, GD2: ....................................................................... _________ kgm2 GD2: ....................................................................... _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 5 The data below are given for an ambient temp. for the engine installation of: ............................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ................................................................................................. __________ Nm Max torque of the coupling, Tkmax: ...................................................................................................... __________ Nm Max continuous vibratory torque at 10 Hz, TkW: ............................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ..................................................................................................... _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: ................................ _____________ Relative damping factor, Ψ: ................................................................................................................ _____________ Allowable energy loss, PkW: .............................................................................................................. __________ kW 1.9 Driven unit, rotating at engine speed Pump: Speed range for which pump is engaged: .................................................................................... __________ rpm Max load: ..................................................................................................................................... __________ kW Moment of inertia of the complete unit, _________ kgm2 J: ............................................................................. 2 or Flywheel mass of the complete unit, GD : ............................................................................ _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................ _______ Nm/rad Alternative data: Drawing of the main shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. pump gear etc.). Drawing no: .................................................................................................................................. No. ____________ Compressor: Speed range for which compressor is engaged: .......................................................................... __________ rpm Max load: ..................................................................................................................................... __________ kW To supply sufficient data for a complex compressor, the alternative data below is just an example. Contact Volvo Penta Sales Engineering in case of such an installation. Alternative data: Max gas pressure in the cylinders: .............................................................................................. ________ N/mm2 Moment of inertia for the complete unit, J: ............................................................................... _________ kgm2 or Flywheel mass for the complete unit, GD2: .............................................................................. _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................ _______ Nm/rad or Curve showing the gas pressure in the cylinders for one stroke. Curve no: ..................................................................................................................................... _____________ Drawing of the compressor crankshaft, indicating material and dimensions. Drawing no: .................................................................................................................................. Mass elastic – dynamic data of the compressor: Mass damper 6 Moment of inertia J (kgm2) _______________ Stiffness c (Nm/rad) ______________ gear _______________ ______________ cyl 1 _______________ ______________ cyl 2 _______________ ______________ .... _______________ ______________ flywheel _______________ ______________ _____________ Unbalanced masses: (or unbalanced forces, in N) ...................................................................... _____________ Total weight of the rotating masses per cylinder: ......................................................................... ___________ kg Total weight of the reciprocating (oscillating) masses per cylinder: ............................................. ___________ kg Alternator: Drawing of the alternator shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. fan, rotor etc.) Drawing no: .................................................................................................................................. No. ____________ 1.10 Belt pulley (driven pulley), rotating at driven unit’s (1.18) speed J: ................................................................................................................. _________ kgm2 or Flywheel mass, GD2: ................................................................................................................ _________ kgm2 Pitch diameter for the belt: ............................................................................................................ __________ mm Moment of inertia, Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.11 Jockey pulley J: ................................................................................................................. _________ kgm2 or Flywheel mass, GD2: ................................................................................................................ _________ kgm2 Pitch diameter for the belt: ............................................................................................................ __________ mm Moment of inertia, Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.12 Belts V-belts, Poly-V-belts, Toothed belts: Stiffness (in drag): ........................................................................................................................ _______ Nm/rad Number of belts in parallel: ............................................................................................................ ___________ qty Alternative data: Make and type of the belt: ............................................................................................................. _____________ Cross-section area of the belt: ...................................................................................................... __________ mm2 Modulus of elasticity of the material: ............................................................................................. ________ N/mm2 Damping (can be set to 0, if not available): .................................................................................... _____________ 1.13 Distance between the shafts of the driving and the driven pulley Distance between the shafts: ....................................................................................................... __________ mm 1.14 Shaft, rotating at driven unit’s (1.18) speed Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 7 1.15 Disengageable coupling (clutch), rotating at driven unit’s (1.18) speed J: ........................................................................... _________ kgm2 J: ........................................................................... _________ kgm2 engine side, GD2: .......................................................................... _________ kgm2 GD2: .......................................................................... _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 1.16 Flange coupling, rotating at driven unit’s (1.18) speed J: ......................................................................... _________ kgm2 or Flywheel mass for the complete coupling, GD2: ........................................................................ _________ kgm2 Moment of inertia for the complete coupling, Alternative data: Flange diameter: ........................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ........................................................................................................................................ _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 1.17 Flexible coupling, rotating at driven unit’s (1.18) speed Make and type: For couplings supplied by Volvo Penta this data is not required. J: ........................................................................... _________ kgm2 J: ........................................................................... _________ kgm2 engine side, GD2: .......................................................................... _________ kgm2 GD2: .......................................................................... _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, The data below are given for an ambient temp. for the engine installation of: .......................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: .................................................................................... ____________ ) Relative damping factor, Ψ: ........................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 1.18 Driven unit Speed of the driven unit: ............................................................................................................... __________ rpm or ratio of the belt drive, (speed of engine : speed of driven unit): ....................................................................................... 8 _____________ Pump: Speed range for which pump is engaged: ..................................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW Moment of inertia of the complete unit, J: ................................................................................. _________ kgm2 or Flywheel mass of the complete unit, GD2: ................................................................................. _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad Alternative data: Drawing of the main shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. pump gear etc.). Drawing no: .................................................................................................................................. No. ____________ Compressor: Speed range for which compressor is engaged: ........................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW To supply sufficient data for a complex compressor, the alternative data below is just an example. Contact Volvo Penta Sales Engineering in case of such an installation. Alternative data: Max gas pressure in the cylinders: ............................................................................................... ________ N/mm2 Moment of inertia for the complete unit, J: ................................................................................. _________ kgm2 or Flywheel mass for the complete unit,GD2: ................................................................................ _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad or Curve showing the gas pressure in the cylinders for one stroke. Curve no: ..................................................................................................................................... No. ____________ Drawing of the compressor crankshaft, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ Mass elastic – dynamic data of the compressor: Mass Moment of inertia J (kgm2) Stiffness c (Nm/rad) damper _______________ ______________ gear _______________ ______________ cyl 1 _______________ ______________ cyl 2 _______________ ______________ .... _______________ ______________ flywheel _______________ ______________ Unbalanced masses: (or unbalanced forces, in N) Total weight of the rotating masses per cylinder: .......................................................................... ___________ kg Total weight of the reciprocating (oscillating) masses per cylinder: .................................................................................................................................. ___________ kg Alternator: Drawing of the alternator shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. fan, rotor etc.) Drawing no: .................................................................................................................................. No. ____________ 9 2. Power take-off (PTO) at rear end (FLYWHEEL SIDE) of engine 2.0 VOLVO PENTA will supply information under this paragraph! Continue to paragraph 2.1. For this order the following standard equipment will be delivered with the engine for connection to the engine’s rear end: Reduction gear (Reverse gear): Make and type: Gear ratio (speed of input shaft : output shaft): Propeller shaft flange included: Coupling, engine – reduction gear: Make and type: Other equipment: (power take-off, clutch etc.) Make and type: 2.1 Coupling, engine – reduction gear Only to be filled in if not delivered by Volvo Penta! Make and type: For couplings supplied by Volvo Penta this data is not required. Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , J: .......................................................................... _________ kgm2 J: .......................................................................... _________ kgm2 2 engine side, GD : ......................................................................... _________ kgm2 GD2: ......................................................................... _________ kgm2 pto-side, The data below are given for an ambient temp. for the engine installation of: .......................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: ............................. ____________ ) Relative damping factor, Ψ : .......................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 2.2 Reduction gear (Reverse gear) Only to be filled in if not delivered by Volvo Penta! Make and type: ............................................................................................................................. _____________ Gear ratio: .................................................................................................................................... _____________ Drawing of the reduction gear, indicating material and dimensions of the shafts and wheels. Alternative data: (to be supplied on separate paper) Moment of inertia or flywheel mass for all shafts and wheels. Torsional stiffness for all shafts. Diameter of all shafts. Gear ratios. 10 2.3 Disengageable coupling (clutch), rotating at speed of engine or reduction gear output shaft J: ........................................................................ _________ kgm2 J: ........................................................................ _________ kgm2 engine side, GD2: ....................................................................... _________ kgm2 GD2: ....................................................................... _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 2.4 Flange coupling, rotating at speed of engine or reduction gear output shaft J: ......................................................................... _________ kgm2 or Flywheel mass for the complete coupling, GD2: ........................................................................ _________ kgm2 Moment of inertia for the complete coupling, Alternative data: Flange diameter: ........................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ........................................................................................................................................ _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 2.5 Flexible coupling, rotating at speed of engine or reduction gear output shaft Make and type: ............................................................................................................................. _____________ (data for the following flexible couplings, if of standard specification, are in the Volvo Penta TVC library and therefore data for these need not to be given below: Nor-Mex, Vulkan, Centa, Stromag, Holset and couplings of make RBD, Lord and Torflex used together with Twin Disc reduction gears) Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , J: ......................................................................... _________ kgm2 J: ......................................................................... _________ kgm2 2 engine side, GD : ........................................................................ _________ kgm2 GD2: ........................................................................ _________ kgm2 pto-side, The data below are given for an ambient temp. for the engine installation of: .......................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: .................................................................................... ____________ ) Relative damping factor, Ψ : .......................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 2.6 Belt pulley (driving pulley), rotating at speed of engine or reduction gear output shaft Moment of inertia, J: ..................................................................................................................... _________ kgm2 or Flywheel mass, GD2: ................................................................................................................ _________ kgm2 Pitch diameter for the belt: ............................................................................................................ ___________ nm Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 11 2.7 Shaft (intermediate shaft, countershaft, shaft included in propeller shaft transmission, etc.), rotating at speed of engine or reduction gear output shaft Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 2.8 Disengageable coupling (clutch), rotating at speed of engine or reduction gear output shaft J: ........................................................................ _________ kgm2 J: ........................................................................ _________ kgm2 engine side, GD2: ....................................................................... _________ kgm2 GD2: ....................................................................... _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, 2.9 Flange coupling (incl. split- or clamp-coupling), rotating at speed of engine or reduction gear output shaft J: ......................................................................... _________ kgm2 or Flywheel mass for the complete coupling, GD2: ........................................................................ _________ kgm2 Moment of inertia for the complete coupling, Alternative data: Flange diameter: ........................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ........................................................................................................................................ _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 2.10 Flexible coupling, rotating at speed of engine or reduction gear output shaft Make and type: For couplings supplied by Volvo Penta this data is not required. J: ......................................................................... _________ kgm2 J: ......................................................................... _________ kgm2 engine side, GD2: ........................................................................ _________ kgm2 GD2: ........................................................................ _________ kgm2 Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , pto-side, The data below are given for an ambient temp. 12 for the engine installation of: .......................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: ............................. No. __________ Relative damping factor, Ψ: ........................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 2.11 Driven unit, rotating at speed of engine or reduction gear output shaft Alternator: Drawing of the alternator shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. fan, rotor etc.) Drawing no: .................................................................................................................................. No. ____________ Compressor: Speed range for which compressor is engaged: ........................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW To supply sufficient data for a complex compressor, the alternative data below is just an example. Contact Volvo Penta Sales Engineering in case of such an installation. Alternative data: Max gas pressure in the cylinders: ............................................................................................... ________ N/mm2 Moment of inertia for the complete unit, J: ................................................................................ _________ kgm2 or Flywheel mass for the complete unit, GD2: ............................................................................... _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad or Curve showing the gas pressure in the cylinders for one stroke. Curve no: ..................................................................................................................................... No. ____________ Drawing of the compressor crankshaft, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ Mass elastic – dynamic data of the compressor: Mass Moment of inertia J (kgm2) Stiffness c (Nm/rad) damper _______________ ______________ gear _______________ ______________ cyl 1 _______________ ______________ cyl 2 _______________ ______________ .... _______________ ______________ flywheel _______________ ______________ Unbalanced masses: (or unbalanced forces, in N). Total weight of the rotating masses per cylinder: .......................................................................... ___________ kg Total weight of the reciprocating (oscillating) masses per cylinder: ............................................... ___________ kg Pump: Speed range for which pump is engaged: ..................................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW Moment of inertia of the complete unit, J: ................................................................................. _________ kgm2 or Flywheel mass of the complete unit, GD2: ................................................................................. _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad Alternative data: Drawing of the main shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. pump gear etc.). Drawing no: .................................................................................................................................. No. ____________ 13 2.12 Propeller shaft, rotating at speed of engine or reduction gear output shaft Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 2.13 Propeller, rotating at speed of engine or reduction gear output shaft The propeller rotating in water: Moment of inertia for the propeller, J: ........................................................................................ 2 or Flywheel mass for the propeller, GD : ....................................................................................... _________ kgm2 _________ kgm2 Alternative data: The propeller out of water (exclusive allowance for water rotating in the same direction): J: ........................................................................................ _________ kgm2 or Flywheel mass for the propeller, GD2: ....................................................................................... _________ kgm2 Moment of inertia for the propeller, or Drawing of the propeller, indicating: material, dimensions (diameter), number of blades. Drawing no: .................................................................................................................................. No. ____________ 2.14 Belt pulley (driven pulley), rotating at driven unit’s (2.22) or propeller’s (2.24) speed Moment of inertia, J: ................................................................................................................. 2 _________ kgm2 or Flywheel mass, GD : ................................................................................................................ _________ kgm2 Pitch diameter for the belt: ............................................................................................................ __________ mm Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 2.15 Jockey pulley J: ................................................................................................................ _________ kgm2 or Flywheel mass, GD2: ............................................................................................................... _________ kgm2 Pitch diameter for the belt: ............................................................................................................ __________ mm Moment of inertia, Alternative data: Drawing of the pulley, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 2.16 Belts V-belts, Poly-V-belts, Toothed belts: Stiffness (in drag): ........................................................................................................................ _______ Nm/rad Number of belts in parallel: ............................................................................................................ No. ____________ Alternative data: Make and type of the belt: Cross-section area of the belt: ...................................................................................................... __________ mm Modulus of elasticity of the material: ............................................................................................. ________ N/mm2 Damping (can be set to 0, if not available): .................................................................................... _____________ 2.17 Distance between the shafts of the driving and the driven pulley Distance between the shafts: ....................................................................................................... 14 __________ mm 2.18 Shaft, rotating at driven unit’s (2.22) or propeller’s (2.24) speed Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 2.19 Disengageable coupling (clutch), rotating at driven unit’s (2.22) or propeller’s (2.24) speed Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , J: ........................................................................ _________ kgm2 J: ........................................................................ _________ kgm2 2 engine side, GD : ....................................................................... _________ kgm2 GD2: ....................................................................... _________ kgm2 pto-side, 2.20 Flange coupling, rotating at driven unit’s (2.22) or propeller’s (2.24) speed Moment of inertia for the complete coupling, J: ............................................................................ _________ kgm2 or Flywheel mass for the complete coupling, GD2: ....................................................................... _________ kgm2 Alternative data: Flange diameter: ........................................................................................................................... __________ mm Flange thickness: ......................................................................................................................... __________ mm Hub outer diameter: ...................................................................................................................... __________ mm Hub length: ................................................................................................................................... __________ mm Overall length: .............................................................................................................................. __________ mm Material: ........................................................................................................................................ _____________ or Drawing of the coupling, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ 2.21 Flexible coupling, rotating at driven unit’s (2.22) or propeller’s (2.24) speed Make and type: For couplings supplied by Volvo Penta this data is not required. Moment of inertia, both halves, engine side, pto-side, or Flywheel mass, “ “ , J: ........................................................................ _________ kgm2 J: ........................................................................ _________ kgm2 2 engine side, GD : ....................................................................... _________ kgm2 GD2: ....................................................................... _________ kgm2 pto-side, The data below are given for an ambient temp. for the engine installation of: .......................................................................................................... ___________ °C Nominal torque of the coupling, TkN: ............................................................................................ __________ Nm Max torque of the coupling, Tkmax: ................................................................................................. __________ Nm Max continuous vibratory torque at 10 Hz, TkW: .......................................................................... __________ Nm Dynamic torsional stiffness, cTdyn: ................................................................................................ _______ Nm/rad (if not linear, it should be given as a function of load on the coupling, curve no: ............................. No. ____________ Relative damping factor, Ψ: ........................................................................................................... _____________ Allowable energy loss, PkW: ........................................................................................................ __________ kW 15 2.22 Driven unit Speed of the driven unit: ............................................................................................................... __________ rpm or ratio of the belt drive and reduction gear (speed of engine : speed of driven unit): ....................................................................................... _____________ Alternator: Drawing of the alternator shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. fan, rotor etc.) Drawing no: .................................................................................................................................. No. ____________ Compressor: Speed range for which compressor is engaged: ........................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW To supply sufficient data for a complex compressor, the alternative data below is just an example. Contact Volvo Penta Sales Engineering in case of such an installation. Alternative data: Max gas pressure in the cylinders: ............................................................................................... ________ N/mm2 Moment of inertia for the complete unit, J: ................................................................................. _________ kgm2 or Flywheel mass for the complete unit,GD2: ................................................................................ _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad or Curve showing the gas pressure in the cylinders for one stroke. Curve no: ..................................................................................................................................... No. ____________ Drawing of the compressor crankshaft, indicating material and dimensions. Drawing no: .................................................................................................................................. No. ____________ Mass elastic – dynamic data of the compressor: Mass Moment of inertia J (kgm2) Stiffness c (Nm/rad) damper _______________ ______________ gear _______________ ______________ cyl 1 _______________ ______________ cyl 2 _______________ ______________ .... _______________ ______________ flywheel _______________ ______________ Unbalanced masses: (or unbalanced forces, in N) Total weight of the rotating masses per cylinder: .......................................................................... ___________ kg Total weight of the reciprocating (oscillating) masses per cylinder: ............................................... ___________ kg Pump: Speed range for which pump is engaged: ..................................................................................... __________ rpm Max load: ...................................................................................................................................... __________ kW Moment of inertia of the complete unit, J: ................................................................................. _________ kgm2 or Flywheel mass of the complete unit, GD2: ................................................................................. _________ kgm2 Torsional stiffness of the main shaft: ............................................................................................. _______ Nm/rad Alternative data: Drawing of the main shaft, indicating: material, dimensions, the position of masses on the shaft, the moment of inertia for all masses on the shaft (i.e. pump gear etc.). Drawing no: .................................................................................................................................. No. ____________ 16 2.23 Propeller shaft, rotating at propeller’s (2.24) speed Drawing of the shaft, indicating: material, dimensions, the position of masses (belt pulleys, bearings etc.) on the shaft, the moment of inertia for all masses on the shaft if not given under another heading. Drawing no: .................................................................................................................................. No. ____________ Alternative data: Shaft diameter: ............................................................................................................................. __________ mm Shaft length: ................................................................................................................................. __________ mm Shaft material: ............................................................................................................................... _____________ 2.24 Propeller Speed of the propeller: .................................................................................................................. __________ rpm or ratio of the belt drive and reduction gear (speed of engine : speed of propeller): .......................................................................................... _____________ The propeller rotating in water: J: ....................................................................................... _________ kgm2 or Flywheel mass for the propeller, GD2: ...................................................................................... _________ kgm2 Moment of inertia for the propeller, Alternative data: The propeller out of water (exclusive allowance for water rotating in the same direction): J: ....................................................................................... _________ kgm2 or Flywheel mass for the propeller, GD2: ...................................................................................... _________ kgm2 Moment of inertia for the propeller, or Drawing of the propeller, indicating: material, dimensions (diameter), number of blades. 7733565-1 Note! Can not be ordered from publication store Drawing no: .................................................................................................................................. No. ____________ 17