Looking to Purchasing to Manage Costs at PPL

advertisement

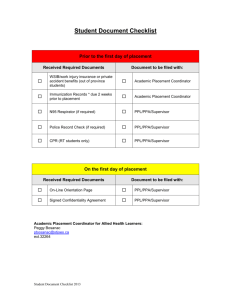

Looking to Purchasing to Manage Costs at PPL Imagine an industry where government regulation virtually guaranteed a return on investment. For most of our modern industrial era, this is how the U.S. electric industry has operated, usually resulting in a failure by most utilities to economize. Regulators routinely allowed electric utilities to earn a fixed rate of return on their assets, whether the assets involved a power generating station or the lush remodeling of a corporate boardroom. This may be the only industry where rules and regulations rewarded inefficiency by guaranteeing a fair return on assets. An executive at a major nuclear power utility remarked that cost overruns on their nuclear plants doubled our assets and doubled our earnings. Unfortunately for utility executives, the sense of security provided by regulation is disappearing. Utilities have entered an era of deregulated competition where consumers and businesses will select carriers similar to selecting phone services. Cost reduction and control is now the emphasis among utilities. Competition is becoming intense in Pennsylvania, which is at the forefront of electric deregulation. PPL, an electric utility with almost $3 billion in revenues headquartered in Allentown, Pa., concluded more than five years ago that it must reduce costs to succeed in an era of deregulated utility service. Procurement managers at this utility are keenly aware of the need to provide better service to internal customers while helping lower the utility’s average kilowatt per hour rate (KWH). This is motivating purchasing to develop systems and processes that reduce the effort and transactions required to process low value goods and services. Interestingly, how this utility defines a low value purchase differs dramatically from a typical manufacturing firm. Purchasing defines a small dollar purchase as less than $50,000 for services, and less than $3,000 for material purchases. This involves items or services not purchased regularly or covered by a corporate contract. A contract that exceeds $50,000 automatically involves purchasing. Given the nature of utility work (24 hours a day/seven day a week operation subject to emergencies and weather conditions), this definition of low value services and goods makes sense. Most internal purchasing customers are assigned to power generating plants or field warehouses that stock items for maintaining the utility network. Field engineers and mangers must have the ability to subcontract services or obtain needed materials quickly, which is one reason the decentralized purchasing systems featured here are important. PPL is noted for using aggressive approaches to using system technology, supported by other methods, to streamline the process for obtaining lower value goods and services. The company has developed four approaches for reducing the effort and transactions required to process low value purchases. These approaches include: User negotiated and issued service contracts Local purchase orders Blanket purchase orders and releasing Procurement cards The company also uses an online requisitioning system to notify purchasing of material needs that are not covered by one of these systems. Users contact purchasing through the online requisitioning system, for example, if they have a larger value requirement not covered by an existing contract. User Negotiated and Issued Service Contracts Granting users the authority to negotiate and issue service orders has greatly streamlined the process of obtaining low value goods and services, particularly during emergency conditions. With this approach, field users negotiate and issue orders for as much as $50,000 for a contracted service and $3,000 for materials. Price, scheduling, and the scope of work covered by the contract are the only topics users can discuss directly with suppliers. The utility has established a standard set of terms and conditions that apply to all service contracts. Service contracts do not apply to lower value goods inventoried at field warehouses. Users have access to a database for requisitioning commonly purchased items (e.g., safety items, tool crib items) covered by blanket purchase orders. PPL has determined that information systems technology must underlie any major effort to manage user-defined service contracts for low value purchases. The company has aggressively pursued a time-phased approach to develop Passport, a system that generates user-defined contracts for low value purchases. This system resembles an ERP (Enterprise Resource Planning) system. Field users generate material or service contracts with data captured and sent to the corporate system for accumulation and analysis. Service contract maintenance has evolved from a paper-based system to one that integrates electronically across multiple databases. The average service order contract value through the Passport system is $10,000, with 8,000 contracts generated annually. The process in place today bears little resemblance to the system initially developed to manage service contracts. Phase I featured the introduction of an informal, forms-driven process to manage service contracts. Phase II replaced these forms with a standardized contract within a structured program. During Phase II the company involved high-powered users throughout development to gain system buy-in. PPL also hired a training consultant to educate users on how to use the new systems and processes. Phase III, which began in the late1990s, involved the development of Passport to manage userdefined service contracts. A corporate reengineering effort, driven by the need to reduce costs company-wide in anticipation of deregulation, led to the development of the Passport system. A sub-team chartered during the reengineering effort was responsible for developing the system. The team’s primary task was to evaluate and select outside systems suppliers. Membership included information services, procurement, major users (such as power generating plants), and a consultant. Each sub-team had a leader who worked closely with the leaders of other reengineering sub-teams. The Passport system features client-server architecture using an Oracle platform developed externally. Using external developers was a logical way to overcome time and technical hurdles because PPL was familiar primarily with mainframe systems. The development effort also corrected the year 2000 coding problem for PPL. From a process standpoint, Passport is an integrated system that links workload management, inventory management, purchasing, accounts payable, and treasury databases. While workload management, inventory management, and purchasing are Passport modules, accounts payable and treasury operate under a system called PeopleSoft, also developed externally. Drastically reducing the number of service orders with no controls or accountability has been a major benefit from the systems developed in Phases I through III. Before the Phase I, no centralized controls were in place for initiating service contracts. Users often issued poor contracts that PPL had to honor. Field engineers frequently negotiated commercial issues with minimal contract management occurring. The service contract system has evolved from no controls, to “controlled chaos” with standard forms, to total control with integrated systems. PPL has created a system that allows field users to respond efficiently and quickly to internal and external customer needs. Another benefit from user-initiated service contracting is that purchasing can now commit time to areas that further reduce cost. For example, purchasing has negotiated a company-wide contract covering labor rates when emergency outages require the use of outside technicians. This contract, which was negotiated with a national union, applies to work at all company facilities and has resulted in major labor savings. Local Purchase Orders A second method employed to reduce the effort and transactions required to process low value purchases involves the use of local purchase orders. This approach is ideal for miscellaneous items that do not have a corporate contract or another method that covers the purchase. Local purchase orders are for use with local suppliers and have a maximum limit of $1,000. A manual system controls the use of local purchase orders, which is true of most local systems. Purchasing provides a pad of numbered forms to user groups throughout the corporation. If a user has a requirement that can be purchased with a local purchase order, he or she simply makes a purchase using the numbered form. The supplier sends the invoice directly to the user, who forwards a request for payment to accounts payable. This system is not widely used throughout PPL. During the reengineering effort mentioned earlier, a team recommended abolishing the local P.O. system because other systems were available or coming online that eliminated the need for a manual approach. Purchasing disagrees with this recommendation, arguing that the local P.O. system is ideal for voids left by other systems. Purchasing also argues that a user with only five requirements a year is unlikely to use computerized systems for requesting or ordering material. Purchasing has only indirect involvement with the local purchase order system. Using data supplied by accounts payable, purchasing determines if a supplier or item has enough volume to justify a blanket purchase order. Blanket Purchase Orders and Releasing One of the more successful approaches for reducing the effort and transactions associated with low value purchases at PPL involves the use of blanket purchase orders, which allows users to issue releases directly to suppliers. Purchasing is responsible for determining what items should be on a blanket purchase order. Of the 50,000 releases a year, approximately 40,000 are by users releasing against established blanket purchase orders. Blanket purchase orders are established in several ways. First, purchasing conducts regular reviews of purchases to identify which item or family of items should be part of a blanket purchase agreement. Second, users can request that purchasing establish a blanket order for an item or family of items. Users communicate via electronic mail when requesting purchasing to establish a blanket purchase order. Purchasing reserves the right to solicit competitive bids for all user-requested purchase orders. Many items on blanket purchase orders, particularly repetitively used warehouse items, are part of an automatic reorder point system. PPL transmits releases for these items primarily in two ways--EDI and FaxGate. Every supplier has an indicator on its data record instructing the proper method for transmitting a material release. PPL is attempting to release as many orders as possible through electronic data interchange. Before Passport came online, 40 percent of all releases passed through EDI. The new system has some technical issues with the communication software, which has reduced the volume of transactions passing through EDI. Releases sent by EDI move directly into the supplier’s order entry system with no manual intervention. The second transmittal method applies to suppliers that are not EDI capable. An autofax system, called FaxGate, transmits material releases automatically to suppliers once PPL’s reordering point system generates a material release. Unfortunately, while the faxing process at PPL is automatic, the process of receiving and entering requirements into a supplier’s order entry system is manual. This increases the possibility of a delay or an order entry error. Buyer/planners play a key role in establishing and managing blanket purchase order inventory. This affects the effort and transactions required to process low value purchases because a single individual manages the flow and maintenance of inventory, which helps avoid costly transferring of work or transactions between systems and personnel. The buyer-planner: Determines whether to stock an item Determines where to stock an item (Possible stocking locations include two major warehouses and 21 satellite warehouses) Determines how much of an item to stock Calculates an item’s forecasted requirements Establishes blanket purchase orders as required Determines an item’s safety stock or reordering levels Calculates the economic order quantity for items that are part of the automatic reorder point system (This eliminates spending time on routine and repetitive releases) Procurement Cards Since the mid-1990s, PPL has actively used procurement cards as part of its effort to reduce the costs and transactions associated with lower value purchases. During reengineering, a team member was responsible for recommending a bank and a card (Core States and VISA). This member made a pre-selection presentation to the team, which then made a final presentation. The procurement card program at PPL has a $3,000 limit per transaction, with a total limit of $15,000 a month. The bank suggested these limits, which PPL accepted. Users can request changes to these limits as needed. The card stripe is coded for travel and material uses by SIC code with dollar limits embedded in the stripe. If a cardholder uses the card, he or she receives an e-mail detailing the transaction. The bank sends a data tape to PPL, with users receiving details of individual transactions via e-mail. The cardholder prints the e-mail notification for reconciliation and payment. The use of procurement cards has streamlined the accounts payable process. In fact, accounts payable now has a third fewer employees, partly due to the introduction of procurement cards. Accounts payable receives a consolidated bill from the bank monthly with payment issued from a temporary corporate account. As cardholders reconcile their individual statements, accounts payable charges individual or department accounts. This replenishes the temporary account used to pay the monthly bill. Users must reconcile payment within 30 days or else accounts payable contacts them directly. Purchasing is the credit card administrator at PPL, requiring almost a full-time position. This position: Trains new cardholders in the proper use of the card, including reconciliation Keeps track of outstanding cards and credit limits Audits cardholder compliance and activity (For example, using the card for more than one cash withdrawal a day would generate an inquiry) Negotiates with the bank for usage rebates A major benefit from using procurement cards is reduced purchasing transactions costs. A preprocurement card study of transactions costs for items that did not have an established contract revealed an average transactions cost of $150. This includes the cost to requisition, place, receive and inspect, and process payment through accounts payable. A study after initiating procurement cards revealed an average transactions cost of $50, which includes user time for reconciliation. Furthermore, users appear satisfied with the procurement card system. Before full-scale launching of the card, purchasing conducted a six-month trial program with 300 users. After the trial period, purchasing surveyed these users concerning their satisfaction with the card program. More than 75 percent were positive about the procurement card program. Negative comments came from high- volume transaction users who were not prepared or organized to do a monthly reconciliation. Although PPL has currently issued over a thousand procurement cards, current usage levels are lower than what management anticipated during development. Part of this is due to certain supervisors not allowing subordinates to use cards. Others are reluctant to use the card for travel because they do not earn frequent flier miles like they would if they used their personal card and submitted an expense report. Other users sense a general lack of commitment to the expanded use of the card and are, therefore, reluctant to use the card. Another drawback cited by card administrators is insufficient data reporting for tax purposes. The system also cannot identify the use of small and disadvantaged suppliers. The card carrier is actively working on both issues. Future Enhancements Given the continuous pressure to reduce costs, it is not surprising that PPL plans to enhance its integrated Passport system. A major enhancement involves receiving advance-shipping notice (ASNs) from suppliers. This would reduce the effort required for receiving material into PPL’s inventory control system. ASNs could also link directly into the accounts payable system, allowing PPL to pay against the advance shipping notice as the company receives and posts material to the inventory. The company also expects to increase the number of material releases made through EDI. PPL plans to develop alliances with suppliers that require suppliers to perform all quality and inspection work. This would further streamline the process of obtaining lower value or repetitively purchased items. It also points out the value-added activities that are possible as purchasing shifts its attention from obtaining low value goods and services and focuses on strategic activities and responsibilities. Assignment Questions 1. What is a low dollar purchase system? Provide examples of systems or tools that support low dollar purchasing. 2. Discuss the advantages and disadvantages of a procurement card system. What is Purchasing’s role with P-Card systems? 3. Describe the main activities that occurred during PPL’s three-phase systems development. 4. What should be Pruchasing’s role during the development, implementation, and continuous use of low dollar purchase systems? 5. What are some of the unique operating requirements that PPL faces that most companies do not face? 6. What might make PPL’s system more efficient and effective in the future?