Case History 102

Industry:

Automotive-Lighting manufacturers

Components/Products:

Tail, stop, indicator, fog and headlights for all types of vehicles.

Background:

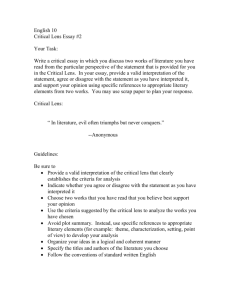

Plastic lens covers for tail light assemblies come in all shapes, sizes and colors; clear, red,

amber, silvered or a combination of each. Suppliers of lighting products have opened

manufacturing plants in countries around the world to satisfy the local content

requirements of the automotive manufacturers.

Normally three major parts make up any lighting unit; the reflector lens which is also the

rear housing, the lens cover (shown above) and the electrical components. There are at

least three potential applications common to lighting manufacturers depending on the

“local styles” and manufacturing process, but there can be more.

EXAIR Corporation, 11510 Goldcoast Dr., Cincinnati, OH 45249-1621, Phone (513) 671-3322, Fax (513) 671-3363

Copyright ©2007 EXAIR Corporation. All Rights reserved.

The Problems:

The lens cover and reflector lens/housing are made from various plastics and during

manufacturing, dust is attracted to these surfaces due to the build up of static electricity.

Lens cover. In the above photograph there is a black edge to the lens cover (could also be

red). This is paint which is applied to the underside of the cover to make a neat edge. For

good paint adhesion and minimal overspray the cover must be static free and the dust

removed. If not, the part is reworked or scrapped.

Reflector lens/rear housing. The reflector lens is produced by applying a

silver coating to the inside of the reflector lens/housing using a vacuum

plating process. Before the coating is applied, the cover must be static

free and the dust removed. Otherwise the lens will magnify the

imperfections, the silver coating will have poor adhesion and the light

beam will be irregular, resulting in scrap.

Lens cover joined to reflector lens/housing. Dust on the outside of the

finished lamp unit can easily be removed, but dust on the inside is totally

unacceptable. Depending on the manufacturing process, both the lens

cover and the reflector lens/housing may need static and dust removed

before they are ultrasonically welded together. If not, a distinct haze or

mist will be seen when the unit is illuminated causing the lamp assembly

to be scrapped.

The Solution:

Based upon the part configuration and manufacturing process both Ion

Air Cannons and Super Ion Air Knives from EXAIR have been

successfully used in the USA and UK to remove the static charge and

dust particles. Problems solved.

Vivek Engineers

#22, 1st Floor, 1st Cross

Bilekahalli Industrial Area,

Adj. IIMB Compound

Bannerghatta Road

Bangalore-560076. India

Tel: 00-91-80-32970358

Fax: 00-91-80-4217 6243

EXAIR Corporation, 11510 Goldcoast Dr., Cincinnati, OH 45249-1621, Phone (513) 671-3322, Fax (513) 671-3363

Copyright ©2007 EXAIR Corporation. All Rights reserved.