chapter

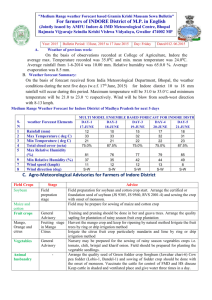

advertisement