PhD RESEARCH PROPOSAL

advertisement

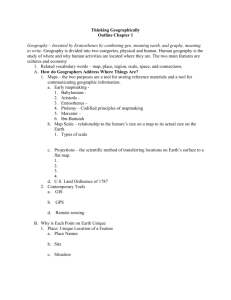

Managing Quality Performance in Supply Chains through Diffusion of Innovations Nadeem Kureshi Center for Advanced Studies in Engineering, Islamabad, Pakistan nadeemk@msu.edu 1. ABSTRACT Supplier Management is fast becoming one of the most critical determining factors in businesses as companies around the world are relying on outsourcing as a strategic tool to achieve competitive advantage. The growing trend of focusing on core competencies and letting the experts do their job has furthered the importance of Supplier Management. While the driving force behind any outsourcing remains increased competitiveness with a particular focus on reducing costs, it essentially requires certain strengths on part of the suppliers. Considering the fact that most of the suppliers around the world are SMEs, who are resource constrained by nature, the idea of outsourcing can potentially end up to be dichotomous;” competitiveness to be achieved through using resource constrained entities”. Such situations can be much more pronounced in developing economies and in situations where less liberty is available in choosing suppliers. Of the various initiatives undertaken to address this problem, Supplier development stands out. Contemporary literature however suggests that among the major Supplier Development activities, those carrying higher costs are seldom or never undertaken, and even the large firms tend to concentrate on activities involving less or no costs. This paper establishes a relationship between higher Supply Chain performances and the process of Diffusion of practices among firms, thus opening an avenue of no-cost improvement of suppliers, on the lines of buyers. An extensive literature survey is undertaken which forms a basis of an ongoing empirical research on the subject. Keywords: SMEs, Supplier Management, Supply Chain Integration, Diffusion of Innovations. Introduction Supply Chain Management is continuously evolving as a faculty, with the ever changing business trends. Supply Chain Integration (as opposed to arm-length market contracting relationship; where only very essential information such as price is exchanged with suppliers) consists of establishing relationships among the members of a supply chain that ensure smooth flow of logistics and information. The growing increase of the importance of Supply Chain integration can be attributed to many factors (Gélinas and Bigras, 2004) such as; (a). Using partial approaches to Supply Chain problems creates and increases the potential for inconsistency in the decision-making process. (b). One can not expect to achieve optimization in a process involving inputs from players extraneous to ones own firm by controlling variables in own firm alone. (c). Some of the more advanced manufacturing practices can work only when all the participating member of a supply chain are onboard (delayed differentiation is a good example). Supply Chain Integration presents a unique problem when we consider that most firms find their upstream supply chain partners to be predominantly SMEs. The established fact that SMEs are resource constrained by nature requires that firms are expected to make efforts to strengthen their weak supply chain partner so they can indirectly perform well. The Diffusion Process The conditions and mechanisms underpinning the flow of social practices among members of a large system have been of interest to researchers. Encarta defines diffusion as “the spread of tools, practices, or other features from one culture to another”. In Roger’s (2003) widely cited definition diffusion occurs when “an innovation is communicated through certain channels over time among the member of a social system”. Diffusion is often described as a rational process. Learning from the experiences of others appears a sensible and even optimal strategy where means-ends (Newell & Simon, 1963) relationships are not feasible for either being costineffective, or being unsolvable by the available resources. Relational models suggest that the rates of diffusion should vary with the rates of interaction between prior and potential adopters. When adoption is socially meaningful, it is common to think of actors as making different choices cognitively available to each other, developing shared understandings, and exploring the consequences of innovation through each others’ experience. (Strang, D. and Meyer, W.; 1993) Theories of diffusion emphasize the rationalities involved. This occurs in part through attention to the characteristics of practices that spread widely. A core idea is that practices are adopted to the extent that they appear more effective of efficient than the alternatives. (Fliegel & Kivlin; 1968). A number of analyses treat diffusion as a spatial process, where the probability of transmission is some function of geographical distance (Hagerstrand.; 1967). Others have used diffusion processes to examine social structure, greatly conceived as a network of social relations (For example; Kathleen; 1990, and; Knoke; 1982) Diffusion of Innovation: Theoretical and empirical work on the diffusion of innovations has been conducted mainly by geographers and anthropologists. Overwhelmingly this literature concentrates on the spatial and temporal aspects of spread of new ideas, customs, laws and technology among individuals and social organizations. A fundamental assumption underlying most approaches is that the adoption of innovations is primarily a learning process. Knoke (1982) has identified the number of adopting units, the number with potential to adopt, and their distributions in social and physical space; as the critical variables that affect the growth process. In the landmark and wholesome work, Rogers (1995) has outlined the mechanism of the mechanism of diffusion process, which lead to confirmation of a process which is to be diffused. He has shown a logical link of adoption and risk attitude. The work then goes on to outline the efforts which are most successful in encouraging the spread (or diffusion) of an innovation. The figure shown below is an adoption from Rogers (1995), summarizing the whole model. Diffusion of Innovation Model: Adopted from Rogers (1995) Two basic generalizations reflect the influence of non-random communications and networks: (a). Neighborhood Effect: The closer a potential adoption unit to the source of innovation or to another unit that had already adopted the innovation, the greater the probability that it will adopt before potential adopter that are further away. (Cohen, 1972). Knoke (1982) has observed that social interactions involving communication, persuasion and imitation tend to follow a spatial gradient. This is a very important finding for the proposed research because variables such as communication, persuasion and imitation can be considered fundamental to the process of quality diffusion among member firms of a supply chain. (b). Hierarchical Effect: The higher the ranking of a potential adoption unit in a hierarchy, the greater the chance of adoption before unit that are lower on hierarchy (Cohen, 1972) Diffusion has been shown to be halting where practices are identified solely with specialized theorists. For example Cole, RE (1985) has compared the rapid diffusion of Quality Circles in Japan and Sweden with slow diffusion in the U.S. He argues that Quality Circles were adopted in Japan by centrally placed corporations for expanding productivity and by labor organizations in Sweden as a mean of work-floor democracy. Where-as in contrast, the proponents of the Quality Circles in the U.S. isolated foundations, management consultants and academicians. Work on importance and nature of SMEs The importance of SMEs as one of the most important vehicle of industrial development, industrial employment and export growth is widely accepted. Light (1993) and Acs (1992) have shown that SMEs are major economic agents for industrialized countries. Schwenk and Shrader (1993) have pointed out that small businesses have become one of the mainstays of US economy. European Commission website shows that more than 99% of enterprises in the EU are SMEs, and provide 65 million jobs. Similarly the ESP (2005-06) shows that SMEs form more than 99% of Pakistani businesses and have thus tremendous effect on employment and exports. It interestingly observes that “Nothing portrays the reality of Pakistani business environment better than ... its SME sector”. While the survey provides interesting statistics showing the importance of SME sector, particularly of the manufacturing SMEs, it has not commented on the performance of this sector, and there is no mention of the quality of products produced by manufacturing SMEs. It also has no mention of interaction between businesses, at any level. Pointing out resource scarcity and conservative organizational structure, Lee (1998, 2004) has recommended only minimal adoption of TQM, starting from the easiest (or cheapest); simply for the benefit of that particular program. It can be inferred from Lee’s studies that a complete adoption of TQM is likely to be infeasible for adoption because of the inherent constraints that SMEs have. He thus suggests only beneficial adoptions of quality practices. He has also pointed out improvement in Supplier’s Performance for companies adopting TQM, suggesting the presence of quality diffusion phenomenon across to suppliers. He has however not investigated that the factors that influence such diffusion. Work on the process of Integration; both internal and external to a business Despite the popularity of the integrated logistics concept and its many applications and tremendous impact it can have on the performance of a business, very few publications have discussed it from the standpoint of SMEs. Indeed, since the early 1990s, only a dozen or so scientific papers published in journals with reading committees have dealt directly with logistics issues for SMEs. (Gélinas and Bigras, 2004) In context of development of working relationships among businesses, particularly SME subcontractors, (though not necessarily among businesses of a single supply chain or a supply chain network) Wynarczyk and Watson (2005) have observed that the development of embedded relationships between firms is clearly facilitated when the interacting employees believe that they share a common economic situation, ethnic identity and/or value system. By engendering mutual trust, resource sharing and innovation, such embedded ties have the potential to create a viable and less costly alternative to formal governance systems based upon contracts. Many researchers (see for example, Bagnasco and Sabel, 1995; Freel, 2000; Collinson, 2000) have addressed the possibility that firms that adopt an explicit strategy of relying upon such partnership arrangements are able to innovate, remain competitive and improve their business performance relative to other firms. This work however is broader in nature and has no focus on businesses partnering for a particular product or businesses that are essentially in a buyer-supplier relationship. They have also not addressed peculiarities of a Supply Chain, and have not addressed the impact of such relationships on quality performance of the interacting firms. Pegels (1991) stresses the importance of integrating the functional areas for improved productivity and quality in manufacturing organizations. The objectives to be achieved from enhanced functional areas integration are improved communication and co-operation between the various functional areas involved in developing a product from the point of concept to delivery of the product to the customer. Pegels has however not discussed such integration across to suppliers, whose performance can arguably have more critical impact on the finished good than some functional areas within a company such as accounting. Work on critical importance of Quality in a business One of the more important aspects of information and logistics flow is the quality of the flowing products. Quality is considered as a critical basis of competitive advantage. Holbrook and Corfman (1981, in Rowley, 1988) suggest that quality acts as a relatively global value judgment. Some authors have even equated the concepts of perceived quality with perceived value and often use the terms interchangeably. (Caruana et al., 2000; Klaus 1985, in Snoj, 1992). Many authors have suggested that Quality is more congruent with long-term attitude of a business (Bolton and Drew, 1991; Parasuraman et. al., 1988, in Stafford et al., 1998). Lee and Yang (2001) have suggested that producers must focus on assuring highest possible objective and perceived quality to provide highest possible value. Many studies have shown that QM practices are associated with superior organizational performance. (Kureshi and Sajid 2005; Ahire, Golhar, and Waller 1996; Emery Summers, and Surak 1996; Lee and Crouch 1996; Freddenhall and Robbins 1995). Lee (2004) has shown TQM influencing improvements in organizational performance measurement standards such as (a) Financial Performance; (b) Quality Performance; (c) Manufacturing Performance; (d) Inventory Performance; (e) Supplier Performance. Similarly Tzelepis et. al. (2006) have shown quality certification as reducing productive inefficiencies in a firm. There has been a convergence of opinion that positive quality perception lead to improved value attributions (nominal price + costs of product acquisition and its use; Zeithaml, 1988) One reason for the keen attention placed on product quality is because of its critical relevance for delivering superior customer value (Lee and Yang, 2001), which is the cornerstone of competitive advantage (Day and Wensley, 1994) and thus a focus must be placed on quality as it can be considered a reliable; albeit general; standard for such diverse measure like Competitive Advantage, Value Judgment, Customer Satisfaction and Performance Measurement. From the perspective of a developing country, Hoang et. al. (2005) have investigated the relationship among TQM implementation constructs and a firm’s innovation; as described by the level of newness and the number of new products. They have observed positive a relationship for 3 constructs. This study however has the limitation of assessing the constructs within the company boundaries. The authors have suggested measuring the newness for entire industry as future possible research. Adoption of Supplier development Activities Kureshi et al. (2006) have presented a discussion on the criticality of strategic reliance buyer firm places on a supplier firm. The possibility of going out of business even when performing as good as ones competitor has been discussed, if the supplier do not perform well. The paper goes on to discuss the factors which should be strengthened if good quality practices are to be diffused from large buyers to small suppliers. In outsourcing decisions where suppliers are limited in number; a scenario, where the supplier provides a ready-for-integration business function, the quality of service provided by the supplier essentially determines the outcome in terms of quality of the final product a buyer produces. In an alternate scenario, where the buyer can actually alter the supplier business function, the quality of service provided by the supplier will be the determinant of how much, if at all, the buyer needs to alter the business function before it is integrated in the final product. A corollary of the above argument is that the more a supplier does in terms of quality, the less the buyer needs to do. The results are inevitably lower costs and thus higher competitiveness. Considering outsourcing decisions where enough number of suppliers is actually available for a particular business function, selection of the best supplier remains a critical decision to be made. Such decisions have to be based on initiatives such as Supplier Evaluation and subsequently Supplier Development. Watts and Hahn (1993), based on the results of a cross-industry mail survey of 81 purchasing practitioners, have reported that supplier development was performed primarily by large firms. Krause 1997 has discussed the variety of activities used by buyer firms for developing the capabilities and performance of their suppliers. The results indicate that most of the buyers have used supplier development activities such as “Providing supplier with feedback about the results of its evaluation “, “Inviting supplier’ s personnel to your site to increase their awareness of how their product is used” and “Site visits by your firm to supplier’s premises to help supplier improve its performance”. As a corollary, activities like “Investment in the supplier’ s operation“, “Use of 4 or more suppliers for this purchased item to create competition among suppliers” and “Training/education of the supplier’s personnel“ have been used seldom or never. Krause has reported reduced incoming defects and cycle times; and improved on-time deliveries and orders received complete as a result of these Supplier Development activities. However, mixed response has been received from suppliers when asked if their product/service costs have decreased or their sales have increased. Similarly, the ability of suppliers to improve product design as a result of Supplier Development activities was reported as mixed. Krause has mentioned that supplier development effort can incur fairly high expenditures to the host company, thus it has been suggested that such activities should be undertaken only when they are expected to yield maximum benefits. Kureshi & Sajid (2008) have empirically established that firms generally undertake supplier development activities that incur minimal or no costs. The Relationship Having established the fact that outsourcing has to go to an SME, as per the law of averages, and that an average SMEs is by no means resourceful enough to provide the requisite competitiveness; it is but natural that suppliers must be integrated into the parent firm, and strengthened to achieve optimality that is critically required to remain competitive. Moreover, the reluctance of larger firms to invest in suppliers’ business operations and training the suppliers’ workforce, it is only logical to find a least cost solution to this situation. “Diffusion of Innovations” in this context offers a solution that can potentially be free, if strategic focus is placed to integrate the quality delivery of suppliers into own firm. Kureshi (2007) has studied the factors that influence the diffusion process, from a Quality Management perspective, between supply chain partners. The work has gone further to validate the findings through fuzzy logic. Conclusion and Discussion Diffusion remains a core faculty in management sciences with the work of Bass (1969) being selected as the fifth most cited work in the history of Management Sciences. The predominant use however is found in marketing management. Similarly, the relationship of diffusion and the cost incurred on it remains little researched. With the tremendous potential the diffusion process carries in business decision making, particularly from the perspective of Supply Chain Management, the research conducted so far on the subject has remained humble. The fact that diffusion process is inherently culture dependent makes the subject more intriguing. While this paper provides a broad literature review of the diffusion process in context of managing small suppliers, attempts need to be made to explore the variation of the process across cultures. This becomes even more important when we consider extensive outsourcing being done by businesses in US and EU to the developing economies for achieving cost and quality optimization. While it can be said that all diffusions are bound to take place if the are given unlimited time to do so, such a model will contribute little to business decision making. Factors that speed up diffusion process of practices that a firm would like to transmit to its suppliers (or adopt from them) need to be investigated in greater details with analyzing cultural biases. Similarly, the practices that are not intended to be diffused need to be studied for retarding factors across businesses. References Acs, Z. J. (1992). “Small Business Economics: A Global Perspective,” Challenge (November– December), 35(6), pp. 38–44. 2. Ahire, S.L.., D.Y. Golhar and M.A Waller (1996). “Development and Validation of TQM Implementation Constructs,” Decision Sciences 27(1), pp. 23-56. 3. Bass, F (1969). "A new product growth model for consumer durables". Management Science 15 (5): p215-227. 4. Bagnasco, A. and C. Sabel (eds), 1995, Small and Mediumsize Enterprises, Pinter: Cassell Academic. 5. Bolton, R.N. and Drew, J.H. (1991), “A multistage model of customer assessment of service quality and value”, Journal of Consumer Research, Vol. 17, pp. 375-84. 6. Caruana, A., Money, A.H. and Berthon, P.R. (2000), “Service quality and satisfaction – the moderation role of value”, European Journal of Marketing, Vol. 34, pp. 1338-52. 7. Cohen, Yehoshua. (1972). “Diffusion of Innovations in Urban Systems”, Term paper (140), Geography Department, University of Chicago. 8. Cole, RE (1985) "The macropolitics of organizational change: A comparative analysis of the spread of small group activities." Administrative Science Quarterly, 30: 560-585. 9. Collinson, S., 2000, ‘Knowledge Networks for Innovation in Small Scottish Software Firms’, Entrepreneurship & Regional Development 12, pp. 217–244. 10. Day, G.S. and Wensley, R. (1994), “Assessing Advantage: a framework for diagnosing competitive superiority”, Journal of Marketing, Vol. 52 pp. 1-20. 11. Economic Survey of Pakistan, 2005-06, Ministry of Finance, GOP. 12. Emery, C.R., T.P. Summers, and J.G. Surak (1996). “The role of organizational Climate in the Implementation of Total Quality Management”. Journal of Managerial Issues 8(4). pp. 484-496. 1. 13. Fredenhall, L.D., and T.L. Robbins (1995). “Modeling the role of Total Quality Management in the Customer Focused Organization,” Journal of Managerial Issues 7(4). pp. 403-419. 14. Freel, M., (2000). “External Linkages and Product Innovation in Small Manufacturing Firms”, Entrepreneurship & Regional Development 12, 245–266. 15. Fliegel, FC & Kivlin, JE (1968). “Attributes of innovation as factors in diffusion”, American Journal of Sociology, 72, pp. 235-248. 16. Gélinas, R., and Bigras Y (2004) “The Characteristics and Features of SMEs: Favorable or Unfavorable to Logistics Integration” Journal of Small Business Management 42(3), pp. 263–278. 17. Hagerstrand, T (1967) “Innovation Diffusion as a Spatial Process”. Chicago, Ill.: University of Chicago Press. 18. Hoang. D.T., Igel. Barbara and Tritos. L, (2005). The impact of total quality management on innovation – Findings from a developing country”. International Journal of Quality and Reliability Management, 23(9). pp. 1092-1117. 19. Holbrook, M.B. and Corfman, K.P. (1981), “Quality and value in the consumption experience. Phaldrus rides again”, in Jacobi, J. and Olson, J. (Eds), Perceived Quality, Lexington Books, Lexington, MA, pp. 31-57. 20. Kathleen, C. (1990). "Structural Constraints on Communication: The Diffusion of the Homomorphic Signal Analysis Technique through Scientific Fields." Journal of Mathematical Sociology 15 (3-4): pp. 207-246. 21. Klaus, P.G. (1985), ‘Quality phenomenon: the conceptual understanding of quality in face-to-face service encounters”, in Czepiel, J.A., Solomon, M.R. and Surprenant C.F. (Eds), The Service Encounter, Lexington Books, Lexington, MA. 22. Krause, D.R (1997). “Supplier Development: Current Practices and Outcomes”. International Journal of Purchasing and Materials Management, Spring. pp. 12-19. 23. Knoke, David 1982 "The spread of municipal reform: temporal, spatial, and social dynamics." American Journal of Sociology 87: pp. 1314-39. 24. Kureshi N, Sajid A (2005), “SWOT analysis as a tool for formulating quality strategy of a company”. Proceedings of the Sixth International Conference of Quality Managers, Tehran 2005. 25. Kureshi, N., Qureshi, M.F. & Sajid, A. (2007) “Using Fuzzy Logic to Investigate and Improve Quality Diffusion among Less Resourceful Supply Links”. “Proceedings of the 3rd International Symposium on Management, Engineering and Informatics: MEI 2007; In the Context of The 11th World Multi-Conference on Systemics, Cybernetics and Informatics: WMSCI 2007, July 8-11, 2007, Orlando, Florida (USA). 26. Kureshi N, Sajid A (2008), “How Critically is the “Small” quality affecting the “Big” quality? Supplier Development in a Developing Economy Context”, Proceedings of the 2 nd MEQA Annual Congress, Dubai, 2008. 27. ”. Proceedings of the Sixth International Conference 28. Lee C.Y. (2004). “Perception and Development of TQM in Small Manufacturers: An exploratory study in China”, Journal of Small Business Management, Vol 42, No. 1. pp. 102-115. 29. Lee C.Y., and H.L. Crouch (1996). Quality Management in Korea: An Empirical Investigation,” Proceedings of Pan-Pacific Conference, XIII Chiba, Japan, May 28-31, pp. 144-146. 30. Lee, C.C. and Yang, J. (2001). “The knowledge value of customers and employees in product quality”. Journal of Management Development, Vol. 20 No. 8. pp. 691-704. 31. Light, L. (1993). “Small Businesses: The Job Engine Needs Fuel,” Business Week, March 1, 78. 32. Newell, A. and Simon, H. (1963). GPS: A program that simulates human thought. In Computers and Thought, ed. Feigenbaum and Feldman. McGraw-Hill, New York. 33. Parasuraman, A., Zzeithaml, V.A. and Berry, L.L. (1988), “SERVQUAL: a multiple item scale for measuring customer perception of service quality”, Journal of Retailing, Vol. 64, pp. 12-40. 34. Pegels, C.C. (1991), ``Integrating functional areas for improved productivity and quality'', International Journal of Operations & Production Management, 11(2), pp. 27-40. 35. Rogers, E.M. “The Diffusion of Innovations”. (Simon and Schuster, 2003). pp. 14. 36. Schewenk, C.R., and C.B. Shrader (1993). “Effects of formal strategic planning on Financial Performance on Small Firms: A meta analysis,” Entrepreneurship – Theory and Practices 17, pp. 53-64. 37. Snoj, B., Korda, A.P. and Mumel, D (2004) The relationship among perceived quality, perceived risk and perceived product value”. Journal of Product and Brand Management, 13(3). pp. 156-67 38. Strang, D, and John W. Meyer. (1993). "Institutional Conditions for Diffusion." Theory and Society 22: pp. 487511. 39. Tzelepis, D., Tsekouras, K., Skuras, D., and Dimara, E. (2006) International Journal of Operations & Production Management, Vol. 26. pp. 1146-1165. 40. Wynarczyk. P. and Watson. R (2005). “Firm Growth and Supply Chain Partnerships: An Empirical Analysis of U.K. SME Subcontractors”. Small Business Economics Vol. 24: pp. 39–51. 41. Watts, C.A. and Hahn, C.K. (1993). “Supplier Development Programs: An Empirical Analysis,” International Journal of Purchasing and Materials Management, vol. 29, no. 2, pp. 11-17. 42. Zeithaml, V. (1988), “Consumer perceptions of price, quality and value: a means-end model and synthesis of evidence”, Journal of Marketing, Vol. 52, July, pp. 2-22.