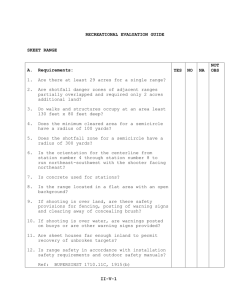

- (AMDO) Association

advertisement