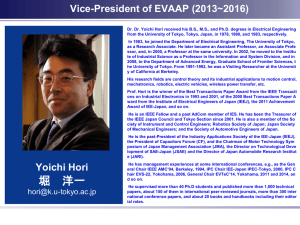

3 Technology Transfer

advertisement