Honors Thesis Proposal

advertisement

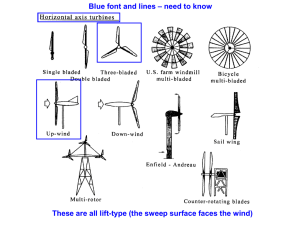

Honors Thesis Proposal Studying the Effect of Blade Pitch on Small Multi-Bladed Horizontal-Axis Wind Turbines By Mark Curtis Rector Advisor: Dr. Kenneth D. Visser Abstract During the past couple years, a study on the effects of solidity and blade number on small horizontal-axis wind turbines has been underway at Clarkson University. This thesis will study the impact of blade pitch angle on power extraction for the given wind conditions, in an effort to maximize the energy that can be produced. While similar studies have been conducted numerically and experimentally on scaled-down models in the on-site wind tunnel, the new data will be acquired from the Clarkson University Wind Turbine Test Site at the Potsdam airport. Introduction The general goal in optimizing the aerodynamic performance of wind turbines is to increase power extraction with a minimal increase to the overall cost of the system. For this reason, utility scale turbines are often optimized for least cost, since they are equipped with large, very expensive blades. It is believed, however, that the idea of aerodynamic optimization could play a larger role in the efficiency of small wind turbines, as these extreme costs do not apply on horizontal-axis wind turbines (HAWTs) more suited for the smaller utilities such as home use. The optimization of a wind turbine’s aerodynamic performance relies on many factors and variables, including blade number; rotor solidity, the ratio of blade area to swept area; blade pitch, the angle between the chord line and the plane of rotation; and tip speed ratio, the ratio of peripheral tip speed to wind speed. Past studies have shown that increasing blade number increases power output; however, most small wind turbines continue to utilize 3 blades. It is thought that this is because the smaller turbines are still based on the economic philosophy carried down from the larger utility scale turbines. Nybroe’s Windflower design, an increased blade-number concept developed in 1999, supports this theory [9]. This 12-bladed turbine with a 3.8 meter rotor diameter, seen in Figure 1, was found to operate at a competitive power coefficient, ratio of power extracted per the power in the wind (Cp), while at a much lower tip speed ratio, λ, than its counterparts. Figure 1: Windflower DK 4 kW [9] Figure 2 displays Johnson’s performance comparison of power coefficient versus tip speed ratio for some of the most common wind turbine designs [7]. Figure 2: Wind turbine Cp-λ comparison [7] Though the figure shows the two bladed rotor with tip speed ratios ranging between 4 and 7 producing the greatest power output, ideas such as the Windflower, producing a reported Cp = 0.47, have motivated the interests of further research here at Clarkson [8]. Previous Studies at Clarkson Aerodynamic performance of small horizontal axis wind turbines has been an active research topic at Clarkson over the past few years. Initial numerical studies investigated the implications of solidity, σ, and blade number, B, which were later tested experimentally in the Clarkson wind tunnel [1]. The results suggest that the greatest power coefficients result from increased blade number and greater rotor solidity, both of which contribute to the added torque that improves cut-in wind speed. Figure 3 displays the numerical results of the Expanding Wake Method (EWM), a performance analysis process based partly on the method of Gould and Fiddes with lifting line theory [5]. As shown, the theoretical results predict a 30% increase in Cp going from a 3 bladed rotor to 12, at equal solidities of 0.27. Even at σ = 0.14, an increase from 3 to 6 blades provides 10% greater Cp. These predictions are dynamic in suggesting the opportunity for significantly greater power extraction than comes from the two or three blade turbines most commonly in use. Figure 3: Numerical EWM results portraying the effect of blade number and solidity on Cp-λ characteristics [1] Figure 4 displays the experimental results for the performance analysis of varying blade number and solidity. Although the wind tunnel experiments failed to show the same results in regards to increased blade number, the experiments did coincide with the numerical results regarding solidity. This data suggests a much greater Cp at an increased solidity, when comparing the 3 bladed rotors with solidities of 14% and 27%. In conjunction with this increased power coefficient, is a reduction in tip speed ratio at maximum Cp. Though slight, this too, coincides with the results of the EWM theoretical study performed. Figure 4: Wind Tunnel experiment results portraying the effect of blade number and solidity on Cp-λ characteristics [1] More recently, full-scale experiments have been initiated to examine blade number and solidity at the Clarkson University Wind Turbine Test Site by comparing a Bergey XL.1 with a prototype six-blade turbine. Initial results agreed with the numerical study, suggesting the presence of increased power extraction at lower wind speeds, for increased blade number. The prototype has also shown that its greater torque results in lowered operational tip speed ratio, a decreased tip speed ratio at maximum Cp and reduced cut-in speeds [6]. Though it hasn’t been studied on a full-scale model until now, blade pitch angle, β, has been observed to be an important factor in both the numerical analysis and wind tunnel experiments, as it dramatically changes the tip speed ratio range of operation. While the two studies showed agreement that maximum Cp moved to smaller tip speed ratio, λ, with increasing pitch angle, they disagreed as to which pitch angle was optimum. Figure 5 displays the numerical Blade Element-Momentum (BEM) analysis results of Cp-λ characteristics for a 12 bladed rotor with solidity equal to 0.27, while Figure 6 displays that of the experimental case. Figure 5: Numerical BEM analysis of Cp-λ characteristics based on varying blade pitch with B = 12, σ = 0.27 [1] Figure 6: Wind tunnel experiment analysis of Cp-λ characteristics based on varying blade pitch with B = 12, σ = 0.27 [1] Both studies conducted analysis at 10°, 15° and 20°, however, the theoretical study indicated that β = 10° achieves the maximum power coefficient, while the wind tunnel experiment indicated 15° as optimum. Proposed Research Upon further analysis of the previous work performed at Clarkson, this thesis will examine the effect of blade pitch on a multi-bladed turbine to determine the optimum power and energy production for the given wind conditions. As a continuation of prior research regarding the aerodynamic performance of small horizontal-axis wind turbines, this study will be conducted on a full-scale level with the turbines already existing at the Clarkson University Wind Turbine Test Site. Data will be acquired at varying load and rotor speeds for multiple pitch angles to offer a complete comparison between the two turbines. Objective The ultimate goal in optimizing the aerodynamic performance of small horizontal-axis wind turbines is to work toward developing a machine more effective at reducing the costs of electricity and making wind a more affordable alternative to the pollutants currently used in energy production. Through the use of additional blades, increased solidity and optimized blade pitch, the intent is to improve the power coefficient at a lower tip speed ratio in an effort to make small HAWTs a more viable option for energy production. Of course, when evaluating the increased performance, it must be kept in mind that blades cost money, so an increase in blade number equates to a similar increase in turbine cost. Methodology Since this thesis is intended to complement the full scale research regarding the aerodynamic performance of small horizontal-axis wind turbines, it is important to keep the set-up and measurements consistent with studies done previously. Most of the necessary tools are already in place at the Clarkson University Wind Turbine Test Site, as the studies surrounding blade number and rotor solidity have been underway for almost a year. In fact, the data currently being recorded, at a blade angle of 15 degrees, will be used as the basis for which other blade angles will later be compared. The Clarkson University Wind Turbine Test Site is located at the Potsdam airport. The site includes a test silo, a meteorological tower and two fully operational 1 kW wind turbines. The meteorological tower, located approximately 20 meters (8 blade diameters) upwind of the two test turbines, uses anemometers to measure wind speed at heights of 6, 12 and 18 meters. Pressure, temperature and humidity are measured at 6 meters and corrected to the hub height of both turbines [6] The first of the two turbines, pictured in Figure 7a, is that of an unmodified Bergey XL.1, and is used as the control for the experiment. This 3 blade, horizontal-axis, upwind style wind turbine has a 6% solidity, blade diameter of 2.5 m, and approximate pitch angle of 10°. It is positioned at a height of 18 m, approximately 5 blade diameters away from the prototype, perpendicular to the prevailing winds. This turbine was chosen for study due to its simple design, small size and relatively inexpensive cost. The prototype, pictured in Figure 7b, is also a Bergey XL.1, purchased and modified to accept multiple blades at various pitch angles. In its current modified state, this turbine is a 6 bladed, horizontal axis, upwind style wind turbine having 12% solidity, blade diameter of 2.5 m, and blade pitch equal to 15°. A hub attachment was designed to enable the 6 blade configuration, which will remain throughout these studies, and variable pitch angles. Upon lowering the rotor to the ground, made-to-order metal shims are used to adjust the pitch. All other aspects of the prototype turbine have remained unchanged from the as-bought condition in an effort to maintain uniformity with the control. Both turbines have been installed as separate systems, each consisting of identical resistive load banks, length and grade of wire and safety equipment. a) b) Figure 7: Installed turbines at Clarkson University Wind Turbine Test Site [6] a) Control – Bergey XL.1, b) Prototype – 6 bladed rotor, 12% solidity Data from the turbines and meteorological tower is collected every second and stored in a computer housed inside the test silo. The data acquisition system, within, uses two National Instruments PCI-6024e DAQ boards with a BNC-2120 interface in conjunction with LABVIEW 6.0i. Current and voltage transducers located at the resistive load bank are used to determine Power, and RPM is calculated from the frequency in the voltage signal. The resistive load bank allows manual adjustment of the load from anywhere between 1 and 25 ohms, for a more controlled study. At midnight each day, the data stored in the test silo is transferred, via the internet, to a campus computer where it is stored for analysis. Analysis procedures follow the NERL performance test plans for a wind turbine very similar to the Bergey XL.1 used on site, along with the test procedures developed by Advanced Wind Turbines Incorporated [6]. The acquired data for each resistance is sorted according to wind speed into bins 1 m/s wide, with bin centers located at integer multiples of 1 m/s. From these averaged bins, power curves are then generated at each resistance value. Performance curves of power coefficient versus tip speed ratio and total energy can be created to compare and analyze the overall performance of the turbines. Schedule The following is a tentative schedule, outlining prospective dates for my thesis accomplishment: April 2004 Review previous data collected with blade pitch angle at 15 degrees May – November 2004 Run, collect and analyze data based on blade pitch angles of 10 and 20 degrees Early December 2004 Compile research into rough draft thesis form End February 2004 Submit Thesis final draft Mid March 2004 Present final Thesis References [1] Duquette, Mathew M. “The Effect of Solidity and Blade Number on the Aerodynamic Performance of Small Horizontal Axis Wind Turbines,” Master’s Thesis June 2002, Clarkson University, Potsdam, NY. [2] Duquette, Mathew M., Swanson, Jessica, and Visser, Kenneth D. “Solidity and Blade Number Effects on a Fixed Pitch, 50W Horizontal Axis Wind Turbine.” reprinted from Wind Engineering. Volume 27, No. 4, 2003. [3] Duquette, Matthew M. and Visser, Kenneth D. “Numerical Implications of Solidity and Blade Number on Rotor Performace of Horizontal-Axis Wind Turbines.” Journal of Solar Energy Engineering Vol. 125. November 2003: 425-432. [4] Gipe, Paul. Wind Energy Basics: A Guide to Small and Micro Wind Systems. Vermont: Chelsea Green Publishing Co., 1999. [5] Gould, J. and Fiddes, S.P. “Conputational Methods for the Performace Prediction of HAWTs.” J. Wind Eng Indust. Aerodyn., 39: 61-72. [6] Humiston, Christopher and Visser, Kenneth. “Full Scale Aerodynamic Effects of Solidity and Blade Number on Small Horizontal Axis Wind Turbines.” Clarkson University, presentation at World Wind Energy Conference, South Africa, 23-26 November 2003. [7] Johnson, Gary L. Wind Energy Systems: Electronic Edition. Manhattan, KS, 10 December 2001. [8] Manwell, J.F., McGowan, J.G., and Rogers, A.L. Wind Energy Explained: Theory, Design and Application. England: John Wiley & Sons, Ltd, 2002. [9] Nybroe, Klaus. “Windmission of Denmark.” 18 May 2002. <http://www.windmission.dk>.