Report4-Rev3.doc

advertisement

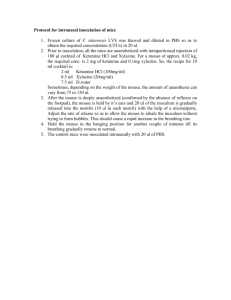

2.875 – Fall 2001 Annabel Flores, James Katzen 2.875 - Fall 2001 Mechanical Assembly and Its Role in Product Development Term Project: Report #4 DESIGNING ASSEMBLY WORKSTATIONS TO PRODUCE COMPUTER MOUSE ASSEMBLY November 21, 2001 Annabel Flores James Katzen Photos taken from: http://www.petergof.com/x-ray/Mouse.htm http://www.Mousemorf.com/images/Mouse2b.jpg Page 1 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen DESIGNING ASSEMBLY WORKSTATIONS TO PRODUCE COMPUTER MOUSE ASSEMBLY Introduction The Microsoft Mouse Version 2.21 is an ergonomic, dual-button Mouse. The simple, eleven-part design provides an opportunity to analyze the product’s assembly characteristics. Previous reports developed for this class have analyzed either individual parts or the interface between a subset of parts of the mouse. The most recent report consisted of an in-depth analysis of the assembly of the product. This report will focus on the design of a particular workstation for assembly. A specific workstation, involved in the assembly of components critical to the function of the mouse, will be examined in detail. The layout of this station, the movements of the actuator and support personnel, the placement of subassemblies, and the movement of the parts through the station will be addressed. In addition, the cost for procurement, and the time required to complete the needed assembly steps will be estimated. Our assembly analysis is based on one major assumption; the product is assembled using robot assembly. The product’s large production volume, as well as the flexibility in adjusting the assembly process for the scope of the product, led us to believe that robotic assembly would be the most likely assembly method. In addition, this assumption allowed us to develop our understanding of the additional complications that surface in assembly using automation. An earlier report listed the primary steps involved in assembly of the mouse as: 1. 2. 3. 4. 5. 6. Place Mouse Base (Part #8) onto Primary Fixture. Place Wheel (Part #10) onto end of Spring (Part #9). Assemble Wheel and Spring Subassembly with Mouse Base (Part #8). Assemble Circuit Board (Part #11) with Mouse Base (Part #8). Attach Plug of Cord (Part #6) to Circuit Board (Part #11) Route Cord (Part #6) through slot in Mouse Base (Part #8) and secure Strain Relief to Mouse Base (Part #8). 7. Attach Horizontal Gear (Part #7) to Mouse Base (Part #8). 8. Attach Vertical Gear (Part #7) to Mouse Base (Part #8) 9. Attach Mouse Cover (Part #5) to Mouse Base (Part #8). 10. Invert Assembly and place into Secondary Fixture. 11. Place Ball (Part #2) into Ball Holder (Part #1). 12. Place Ball and Ball Holder Subassembly into Mouse Base (Part #8). 13. Secure Mouse Base (Part #8) and Mouse Cover (Part #5) by inserting and tightening Screw (Part #4). 14. Attach top Sticker Pad (Part #3). 15. Attach bottom Sticker Pad (Part #3) This list did not address the material handling needs of the assembly process, or the need to allocate and balance assembly steps among different stations to meet cycle time targets and machine complexity and cost constraints. In planning an complete assembly line to produce the 1 Refer to Appendix A and Appendix B, respectively, for Bill of Materials and Exploded View for part naming and numbering conventions. Page 2 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Mouse assembly, the above list must now be expanded to include support operations, such as those involved in the loading of parts into the initial fixture, the testing and inspecting of parts, subassemblies, and the finished product, and finally, the packing of finished assemblies. It was decided that these operations would logically be grouped into five workstations: one manual station, followed by three robotic stations, followed by one final manual station. Using this allocation, the complete list of the stages required for assembly the mouse is shown below: Station 1 (Manual): o Step 1: Place Mouse Base (Part #8) onto Primary Fixture o Step 2: Place Wheel (Part #10) onto end of Spring (Part #9) o Step 3: Assemble Wheel and Spring Subassembly with Mouse Base (Part #8) o Step 4: Transfer pallet between Station 1 and Station 2 Station 2 (Automatic): o Step 5: Locate Pallet on Locating Pins o Step 6: Assemble Circuit Board (Part #11) with Mouse Base (Part #8). o Step 7: Attach Plug of Cord (Part #6) to Circuit Board (Part #11) and attach strain relief of Cord to Mouse Base (Part #8) o Step 8: Attach Horizontal Gear (Part #7) and Vertical Gear (Part #7) to Mouse Base (Part #8) o Step 9: Attach Mouse Cover (Part #5) to Mouse Base (Part #8) o Step 10: Transfer between Station 2 and Station 3 Station 3 (Automatic): o Step 11: Invert Assembly and place into Secondary Fixture. o Step 12: Transfer between Station 3 and Station 4 Station 4: o Step 13: Place Ball (Part #2) into Ball Holder (Part #1) o Step 14: Place Ball and Ball Holder Subassembly into Mouse Base (Part #8) o Step 15: Secure Mouse Base (Part #8) and Mouse Cover (Part #5) by inserting and tightening Screw (Part #4) o Step 16: Attach top Sticker Pad (Part #3) o Step 17: Attach bottom Sticker Pad (Part #3) o Step 18: Plug in Cord’s connector into Test Fixture Connector Block o Step 19: Functional Test o Step 20: Remove Cord’s connector from Test Fixture Connector Block o Step 21: Attach Hologram Sticker o Step 22: Transfer between Station 4 and Station 5 Station 5: o Step 23: Bundle Mouse Assembly with Product Documentation and Software o Step 24a: Pack into OEM packaging OR o Step 24b: Pack into aftermarket packaging The middle assembly station (Station 2) was chosen for in-depth analysis. This workstation was selected because the assembly stages completed at this station predominantly determine the proper function of the finished product. Therefore, proper completion of each assembly step of this station must be achieved, and therefore close analysis must be used in the design and layout of this station. A preliminary design for this workstation is shown below: Page 3 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Hopper for Mouse Covers Pick And Place Robot Conveyor Belt Direction of Rotation Direction of Rotation Gear Hopper Figure 1: Proposed Layout of Workstation #2 The remainder of this report will focus on the necessary product redesigns to facilitate robotic assembly and a thorough description of the workstation including material flow and required motions. In addition, a first attempt is made to estimate the cost of the workstation. PRODUCT REDESIGNS In the previous report, we identified a number of assembly problems in the product design. In order to design a workstation, and consequently an entire product assembly layout, we needed to identify the product feature redesigns we believe are needed for efficient robot assembly. Page 4 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Spring and Wheel Previously, we recognized that the Spring and Wheel presented the most difficult components to assembly. We proposed a linear spring design to replace the need for a Spring and Wheel manual assembly. However, additional investigations are needed to evaluate the feasibility of the Linear Spring. Until a better design is finalized, the Spring and Wheel subassembly design in the 1999 model will continue to be used. Circuit Board and Cord A number of additional problems were identified in the assembly of the Circuit Board and the Cord and the Mouse Base. Recall that attaching the Circuit Board to the Mouse Base requires a number of adjustments, translations, and rotation in various different directions in order to clear assembly features used by the Mouse Base to mate to the Mouse Cover and to retain the Circuit Board. Currently, undercuts in the Mouse Base serve to secure the vertical position of the Circuit Board. However, it is these undercuts that force the reorientation of the Circuit Board. The decision to assemble the product using robotic assembly leads to a necessary simplification of the process. Primarily, the Mouse Base can be simplified to eliminate the undercuts as well as other unnecessary features. The previous report identified a mystery part in the vicinity of the gears. This mystery part is one of the protrusions that prevent the Circuit Board from simply dropping into the Mouse Base. Unless the purpose of these features is discovered, they should be eliminated to simplify the assembly process. In addition, the cutouts on the Circuit Board that provide clearance between the Circuit Board and Mouse Base should be enlarged to be able to position and lower the Circuit Board in its nominal position to the Mouse Base. In the current design, routing the Cord around the side of the Mouse Base from the connector in the Circuit Board to the front of the Mouse Base and then inserting the strain relief feature would be difficult to automate given the flexibility of the part. Instead, we will take Professor Whitney’s suggestion to relocate the Plug from the rear of the Circuit Board to the front as shown below: Switches Reoriented Gear Relocated Electronics New Location Of Connector Block Figure 2: Circuit Board Redesign Shortening the length of the Cord that resides within the mouse facilitates assembly. In order to clear up the necessary real estate in the front of the Mouse Base assembly, the Gears and Sensors must be reoriented. The strain relief feature on the Cord should also be redesigned so that assembly can occur from the vertical direction. Currently, the strain relief feature must be positioned inside the mouse and then pushed out through the corresponding hole. Using the suggested redesigns, a short Cord and strain relief could be inserted into the Mouse Base in one Page 5 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen motion. As mentioned in an earlier report, the Plug should be redesigned to prevent the robot from incorrectly inserting the connection rendering the mouse unusable. In our original assembly sequence, we assumed the Circuit Board and Cord would enter the assembly area as a subassembly to allow testing of the Circuit Board and Cord during its production stage. However, inserting the Circuit Board into the Mouse Base becomes significantly more challenging if the robot must also control the motion of the Cord during the same step. The Circuit Board can still be tested after its production stage through the use of a test cord that mimics the interface between the Circuit Board and the Cord. This allows the two components to be assembled individually, greatly simplifying the process. Cover The Mouse Cover and Mouse Base interface will also need to be redesigned to facilitate robotic assembly. The current interface design has one function, to fasten the front end of the Mouse Cover to the Mouse Base. The rear portion of the Mouse Cover is fastened to the Mouse Base through a single threaded Screw. In an earlier analysis, we mentioned the possibility of eliminating the Screw from the Assembly, efficiently eliminating the need to invert the product. However, until an evaluation of the product redesign is completed and all of the product requirements are met, the removal of the Screw will be postponed. Therefore, the front end of the Mouse Cover and the Mouse Base interface must still be able to fasten the components together. The current design of the Mouse Cover necessitates a complicated assembly process to engage the Mouse Base fastening features. This process requires a rotation as shown, as well as several independent translations to properly align and mate assembly features. Figure 3: Current Mouse Base and Mouse Cover Interface Ideally, redesigning the interface should allow the Mouse Cover to be assembled onto the Mouse Base by a single translation along the vertical axis. A viable option is to modify the interface to include spring tab snap-fit fasteners as shown below: Page 6 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Figure 4: Spring Tab Redesign for Mouse Cover to Mouse Base Interface The above product redesigns greatly simplify the assembly steps and motions required to achieve complete assembly. The remainder of this report will assume that these redesigns have been incorporated. ASSEMBLY STEP ANALYSIS Each assembly step will now be described in detail. For each step, the required operation time will be calculated. In addition to the time calculations, the in-flow and out-flows of all assemblies and parts will be discussed. Finally, the required motions of the robot, as well as the human operators that are needed to load parts, will be choreographed. Based on recommendations from lecture, it was decided that batch sizes of four components would be used to produce the Mouse assemblies. This was decided upon to minimize the impact that tool changes would have on overall cycle time. The drawing below shows the planned pallet that will be used in the assembly process: Page 7 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Cavities Boss to Fit into Mouse Base Hole Figure 5: Proposed Pallet Design That Will Fixture Four Assemblies At Once Step 5: Locate Pallet on Locating Pins Step Description Before assembly steps can commence, it is critical that the pallet containing the prior assembled parts (Mouse Base, Wheel and Spring) be oriented and located in a fixed and known position. This requires that all degrees of freedom of the pallet be constrained. It is assumed that automated conveyors will be used to move the pallet from Station 1 into Station 2. Therefore, as is typically done in industrial automation, a pneumatically-actuated lift cylinder should be used to raise the pallet slightly off the conveyor. The upwards movement should be sufficient enough so the moving belt no longer touches the pallet, and therefore does not act to shake the pallet as the parts contained are being worked on. The air cylinder should act to push the pallet up against alignment features, and these locating pins should be used to orient the pallet. A typical pin-hole and pin-slot combination could be used to constrain the pallet in all directions, while avoiding an over-constrained condition. In-flow and out-flows of all assemblies and parts A pallet, containing four sets of Mouse Base/Wheel/Spring sub-assemblies will enter this step by being moved along a conveyor belt. Time-controlled gates will hold one pallet on the conveyor belt above the pallet lift while other time-controlled gates meter the flow of pallets into the station. The pallet lift will then raise the pallet into position. No other in-flows or out-flows of assemblies and parts will be present. Required Motion of Robot A simple vertical motion of an air cylinder is required in this step. Since the required motion is quite small, (the clearance between the pallet and the conveyor belt does not need to be any more than one inch), a small air cylinder, with a stroke of approximately two inches is all that is needed at this step. Hard stops, rather than the end of the air cylinder’s stroke, should be used to achieve a precise vertical positioning of the pallet. The air cylinder must be capable of applying Page 8 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen a resistive force at least equal to the force needed to press the four sets of Horizontal and Vertical Gears into their position in their respective Mouse Base. This ensures that the pallet will not be pushed down, which could result in jarring contact with the conveyor belt. This resistive force could be achieved by using a coil spring. Required Motion of Human Operators Since this is an automatic station, no human operators will be required under normal conditions. However, since the potential for mis-positioned parts and pallets exists, it is important that an access panel be included to allow a human operator to clear parts and restart the operation. Electrical interlocks must be included on this access panel, so the assembly station is immediately shut down when the panel is opened, in order to limit safety risks to the operator. Time Calculations As no assembly operations are being conducted in this step, operation time will be relatively short. However, care must be taken to ensure that the starting acceleration and the finishing deceleration, as well as the steady state speed of the upwards motion is not so great that it jars the held parts out of position. If this occurs, there is a risk of damage to the parts, the pallet, the fixtures, as well as the tooling. The locating of the Pallet on Locating Pins is estimated to take 0.75 - 1.5 seconds. Note that experiments could easily be conducted to determine the minimum time that can be used to position the parts, while ensuring the parts remain properly seated in the pallet and fixtures. Step 6: Assemble Circuit Board (Part #11) with Mouse Base (Part #8). Step Description It is assumed that the electronic Circuit Boards will be supplied to the Mouse assembly location in pallet form. These pallets will contain multiple circuits boards, placed in a specific orientation and a fixed spacing. In this step, one Circuit Board will be picked up from a pallet of parts and placed into the Mouse Base. This will be achieved with a standard pick and place robot. The redesigned assembly features on the Mouse Base will properly locate and constrain the Circuit Board. In-flow and out-flows of all assemblies and parts The prior assembly step will have properly positioned the fixture containing four sets of Mouse Bases, Wheels, and Springs. There will be no additional movement of these parts during this operation. Since the Circuit Boards are assumed to be packaged on a pallet, a complete pallet of Circuit Boards will be automatically moved into place once all Circuit Boards have been removed from the cavities of one pallet. The moving of the pallets will be achieved by using a standard pallet feed system. The frequency of pallet cycling will be dependent on the number of Circuit Boards that are held by each pallet. Required Motion of Robot At the beginning of this assembly step, the robot end-effector must select the proper gripper set from its magazine of tools. Once this has been completed, the robot should move using gross motions, from its default tool-change position, in the horizontal plane until the gripper is above the Circuit Board pallet, directly above a Circuit Board in that pallet. A simple counting algorithm can be utilized to keep track of which cavities of the pallet contain a Circuit Board. Page 9 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Gripper Motion Direction Once in position, the robot should move downward in a gross motion, so that the gripper fingers (shown below as hatched gray rectangles) would be aligned with the internal edges of the Circuit Board, as shown in the picture below: Figure 6: Gripper Finger Placement For Circuit Board Note that if the workspace if free from obstacles, the two motions can occur simultaneously, which would save valuable cycle time. The gripper should then be opened, and sufficient spreading force should be applied to securely hold the Circuit Board, but damage to the delicate Circuit Board must be avoided. Once the Circuit Board has been gripped, the robot end-effector should move upward in the vertical axis, and then in the horizontal plane, until the end-effector is above the Mouse Base. Fine motions should be used for this motion, as there is some risk of damage to the Circuit Board, even if the robot trajectory is properly planned. The end-effector should then be moved downward so that the hole and slot in the Circuit Board engage the peg features of the Mouse Base. Once this motion is complete, the gripper fingers should close, releasing the Circuit Board. Then, the end-effector can move in a gross motion, in the vertical axis, as well as in the horizontal plane, so that the gripper fingers are again place at the part presentation area, this time directly above the next occupied cavity of the Circuit Board pallet. The new Circuit Board should be gripped and inserted in the second Mouse Base, using the motions just described for the first set. This operation should then occur two more times, so that in all, four Circuit Boards have been placed. Upon completion of this, the end-effector should then be moved in a gross motion back to the tool change location. Required Motion of Human Operators Again, since this is an automatic station, little human motion or intervention will be needed under normal conditions. Human operators will be needed to load pallets of Circuit Boards. The frequency of human interaction will depend on the number of Circuit Boards that are placed on each pallet by the Circuit Board supplier. In addition, since the potential for mis-positioned parts and pallets exists at this station as well, it is important that an access panel be included to allow a human operator to clear parts and restart the operation. Electrical interlocks must also be included on this access panel, so the assembly station is immediately shut down when the panel is opened, in order to limit safety risks to the operator. Time Calculations Page 10 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Using the Boothroyd and Dewhurst2 data charts for robotic assembly, we were able to estimate the cycle time for this assembly step. At this step, the Circuit Board requires a special tool for handling and assembly. Since the decision was made to assemble four products at the same time, the time required for tool changeovers can be effectively neglected. Since the Circuit Board is not easily aligned, but is added and secured immediately using motion along the vertical axis requiring simple manipulation, the Boothroyd-Dewhurst chart estimates that 3.3 seconds is required to assemble the Circuit Board and the Mouse Base. Four Circuit Boards inserted into four Mouse Bases results in a cycle time of 13.2 seconds. Note that this time is based on Boothroyd and Dewhurst’s empirical studies of typical robotic assembly times, rather than based on speed capabilities of a particular robot. Since fine motions are suggested (see below), due to the fragileness of the Circuit Board, the actual assembly time for this step may be greater than that estimated by Boothroyd and Dewhurst. Step 7: Attach Plug of Cord (Part #6) to Circuit Board (Part #11) and attach strain relief of Cord to Mouse Base (Part #8) Step Description In this step, two distinct operations will be completed. The first operation is the connection of the Cord to the Circuit Board. This is achieved by mating the connector block halves on the Cord and the Circuit Board. The second operation is the attachment of the Cord’s strain relief to the Mouse Base. Note that due to the product redesigns mentioned at the beginning of this report, these two operations are now much simpler. The need to route the Cord around the side of the Mouse Base is eliminated, and the strain relief no longer has to be pushed through a small hole in the Mouse Base. Both of these operations will be completed simultaneously by using a two-part gripper, mounted to a pick and place robot. In-flow and out-flows of all assemblies and parts The first assembly step in this workstation will have properly positioned the fixture containing four sets of Mouse Bases, Wheels, and Springs. The prior assembly step will have added the Circuit Board. Since all these parts are completely constrained, there will be no additional movement of these parts during this operation. It is assumed that the Cords will be produced by a subcontractor. Because of this, it is reasonable to assume that the subcontractor can be required to place the Cords carefully on a pallet, in a fixed orientation. If this is the case, a pick and place robot can easily pick off one Cord at a time. Since we will be using pre-filled pallets, a complete pallet of Cords will be automatically moved into place once all Cords have been removed from the cavities of one pallet. The moving of the pallets will be achieved by using a standard pallet feed system. The frequency of pallet cycling will be dependent on the number of Cords that are held by each pallet. Required Motion of Robot At the beginning of this assembly step, the robot end-effector must select the proper gripper set from its magazine of tools. Once this has been completed, the robot should move using gross motions, from its default tool-change position, in the horizontal plane until the gripper is above the Cord pallet, directly above a Cord in that pallet. A simple counting algorithm can be utilized to keep track of which cavities of the pallet actually contain a Cord. Once in position, the robot should move downward in a gross motion, so that one set of gripper fingers would be aligned 2 Product Design For Assembly, G. Boothroyd & P. Dewhurst, Boothroyd Dewhurst Inc., Wakefield, RI, 1991 Page 11 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Gripper Motion Direction Gripper Motion Direction with the edges of the Cord’s connector block and one set of fingers would be aligned with the strain relief, as shown in the picture below: Figure 7: Gripper Finger Placement For Cord Note that if the workspace if free from obstacles, the two motions can occur simultaneously, which would save valuable cycle time. The grippers should then be closed, and sufficient clamping force should be applied to securely hold the connector and the strain relief, but damage to the delicate connector must be avoided. Once the parts have been gripped, the robot endeffector should move upward in the vertical axis, and then in the horizontal plane, until the endeffector is above the Mouse Base. Fine motions should be used for this motion, as there is some risk of damage to the Cord, even if the robot trajectory is properly planned. The end-effector should then be moved downward so that the connector block halves mate and the strain relief slides into the Mouse Base. Once this motion is complete, the gripper fingers should open, releasing the Cord. Then, the end-effector can move in a gross motion, in the vertical axis, as well as in the horizontal plane, so that the gripper fingers are again place at the part presentation area, this time directly above the next occupied cavity of the Cord pallet. The new Cord should be gripped and inserted in the second Mouse Base, using the motions just described for the first set. This operation should then occur two more times, so that in all, four Cords have been placed. Upon completion of this, the end-effector should then be moved in a gross motion back to the tool change location. Required Motion of Human Operators Once again, since this is an automatic workstation, little human motion or intervention will be needed under normal conditions. Human operators will be needed to load pallets of Cords. The frequency of human interaction will depend on the number of Cords that are placed on each pallet by the Cord supplier. In addition, since the potential for mis-positioned parts and pallets exists at this station as well, it is important that an access panel be included to allow a human operator to clear parts and restart the operation. Electrical interlocks must also be included on this access panel, so the assembly station is immediately shut down when the panel is opened, in order to limit safety risks to the operator. Time Calculations Using the Boothroyd and Dewhurst3 data charts for robotic assembly, we were able to estimate the cycle time for this assembly step. At this step, the Cord requires a special tool for handling and assembly. Since the decision was made to assemble four products at the same time, the time 3 Product Design For Assembly, G. Boothroyd & P. Dewhurst, Boothroyd Dewhurst Inc., Wakefield, RI, 1991 Page 12 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen required for tool changeovers can be effectively neglected. Since the Cord is not easily aligned, but is added and secured immediately using motion along the vertical axis requiring simple manipulation, the Boothroyd-Dewhurst chart estimates that 3.3 seconds is required to assemble the Cord and the Circuit Board. Four Cords inserted into four products results in a cycle time of 13.2 seconds. Note that this time is based on Boothroyd and Dewhurst’s empirical studies of typical robotic assembly times, rather than based on speed capabilities of a particular robot. Gripper Motion Direction Gripper Motion Direction Step 8: Attach Horizontal Gear (Part #7) and Vertical Gear (Part #7) to Mouse Base (Part #8) Step Description In this step, the Horizontal Gear and the Vertical Gear are gripped at the same time by a robot gripper. The Horizontal Gear and Vertical Gear are carefully oriented. After being gripped, the Gears are pressed into their respectively assembly features in the Mouse Base. To facilitate simultaneous insertion of the two Gears, the Gears must be carefully oriented with respect to the robot gripper and the Mouse Bases held in the pallet. This orientation is shown below: Final Orientation in Mouse Assembly Page 13 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen This enables the Gears to be picked up from the part feeder and placed into the Mouse Base without the need of a rotational orientation (about the vertical axis). In-flow and out-flows of all assemblies and parts Since specific orientation of the Gears are required, it is suggested that vibratory bowl feeders which feed self-aligning tracks be used. A material handler is required to simply dump a large quantity of Gears into a hopper. One bowl feeder would supply Gears for the Horizontal Gear. Another identical bowl feeder, rotated at 90 degrees with respect to the first bowl feeder, would supply Gears for the Vertical Gear. Because the Vertical Gear and the Horizontal Gear are identical, the hopper can feed each bowl feeder. The self-aligning tracks would allow a small inventory of parts to be present, in case the vibratory bowl feeder jams. The layout of the bowl feeders, and the self-aligning tracks is shown below: Hopper Direction of Rotation Direction of Rotation Required Motion of Robot At the beginning of this assembly step, the robot end-effector must select the proper gripper set from its magazine of tools. Once this has been completed, the robot should move using gross motions, from its default tool-change position, in the horizontal plane until the gripper is above the part presentation location. Then, the robot should move downward in a gross motion, so that the gripper fingers would be aligned with the shafts of the Gears. Note that if the workspace if free from obstacles, the two motions can occur simultaneously, which would save valuable cycle time. The gripper should then be closed, and sufficient clamping force should be applied to securely grip the Gears, but damage to the Gears must be avoided. Once the Gears have been gripped, the robot end-effector should move upward in the vertical axis, and then in the horizontal plane, until the end-effector is above the Mouse Base. Gross motions can be used, Page 14 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen since there is little risk of damage to the Gears, if the robot trajectory is properly planned. The end-effector should then be moved downward so that the Gear shafts engage the assembly features of the Mouse Base. At this point, fine motion in the vertical axis should be used to fully seat each shaft and ensure each snap fit has been completed. Once complete, the gripper fingers should open, releasing the Gears. Then, the end-effector can move in a gross motion, in the vertical axis, as well as in the horizontal plane, so that the gripper fingers are again place at the part presentation area, with the gripper fingers aligned with the shafts of another set of the Gears. The new set of Gears should be gripped and inserted in the second Mouse Base, using the motions just described for the first set. This operation should then occur two more times, so that in all, four sets of Gears have been placed. Upon completion of this, the end-effector should then be moved in a gross motion back to the tool change location. Required Motion of Human Operators There is little required motion of human operators at this assembly step. Humans would only be needed for two tasks. The first task is the periodic dumping of Gears into the part-feeding hopper. This is a simple task, as the parts would likely be delivered by the supplier in cardboard boxes or plastic bags, with the Gears simply randomly piled in the container. The second task, which would again be periodic, would be the clearing of part jams in the vibratory bowl feeders. Part jamming is an inherent limitation of bowl feeders, yet the occurrence of jamming can largely be reduced by adjusting the vibration profile of the feeder. However, as part jams will never be completely eliminated, occasional human interaction will be required. Time Calculations Using the Boothroyd and Dewhurst data charts for robotic assembly, we were able to estimate the cycle time for this assembly step. At this step, the Gears require a special tool for handling and assembly. Since the decision was made to assemble four products at the same time, the time required for tool changeovers can be effectively neglected. Since the two Gears are not easily aligned, but are added and secured immediately using motion along the vertical axis requiring simple manipulation, the Boothroyd-Dewhurst chart estimates that 3.3 seconds are required to assemble each set of gears. One set of Gears inserted into four products results in a cycle time of 13.2 seconds. Note that this time is based on Boothroyd and Dewhurst’s empirical studies of typical robotic assembly times, rather than based on speed capabilities of a particular robot. Step 9: Attach Mouse Cover (Part #5) to Mouse Base (Part #8) Step Description In this step, one Mouse Cover will be picked up from a table and placed onto the Mouse Base. This will be achieved with a standard pick and place robot. The redesigned snap-fit assembly features on the Mouse Base will properly locate and constrain the Mouse Cover. The complex shape of the Mouse Cover complicates the part presentation at this assembly stage. First, the part is asymmetrical. Next, protruding snap-fit features cause the parts to hook onto each other, making separation more difficult. Finally, the rounded edges of the top surface makes it difficult to positively locate the Mouse Cover in a fixture. Therefore, a more complicated system, incorporating a vision system, will be needed to position and orient Mouse Covers correctly. Numerous systems that perform pattern recognition are commercially available, such as the Adept® version shown below: Page 15 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Figure 8: Commercially Available Pick and Place Robot That Performs Pattern Recognition4 In-flow and out-flows of all assemblies and parts To address the complexity issue of the Mouse Cover part presentation, the use of a vision system with pattern recognition and a parts recirculator is suggested. This system would operate in the following way. First, a hopper of parts would be filled periodically by a human operator. Then, the hopper would occasionally spill a few parts onto a table. An overhead camera would the scan the parts on the table, looking for any parts that are oriented with the top of the Mouse Cover facing up, and any of those parts that are not touching other parts or edges of the table. If any of these parts are present, the position and orientation of an acceptable part is sent to the control strategy for the pick and place robot. The robot will then move to that location, rotate its gripper about the vertical axis and the grip the part. The assembly steps will then be completed. Once the steps are completed, another acceptable Mouse Cover will be chosen for assembly. This cycle will continue until there are no more acceptable parts on the table. Once this occurs, the parts on the table will be automatically cleared and redeposited in the hopper. New parts will then be deposited on the table, and the cycle repeats. Required Motion of Robot At the beginning of this assembly step, the robot end-effector must select the proper gripper set from its magazine of tools. Once this has been completed, the robot should move using gross motions, from its default tool-change position, in the horizontal plane until the gripper is above the Mouse Cover table, directly above a Mouse Cover that is in an acceptable orientation. The vision system controller would instruct the robot gripper to rotate about the vertical axis so that the gripper will be aligned with the Mouse Cover of interest. Once aligned with the Mouse Cover, the robot should move downward in a gross motion. Note that if the workspace if free from obstacles, the two motions can occur simultaneously, which would save valuable cycle time. The gripper should then be closed, and sufficient clamping force should be applied to securely hold the Mouse Cover, but damage to the Mouse Cover must be avoided. Once the Mouse Cover has been gripped, the robot end-effector should move upward in the vertical axis, and then in the horizontal plane, until the end-effector is above the Mouse Base. Gross motions 4 Photo taken from http://www.adept.com/Main/products/machine_vision/vis_guid.html Page 16 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen would be used for this motion, as there is little risk of damage to the Mouse Cover, even if the robot trajectory is properly planned. The end-effector should then be moved downward so that the snap-fit assembly features of the Mouse Base engage the snap-fit features of the Mouse Cover. Once this motion is complete, the gripper fingers should open, releasing the Mouse Cover. Then, the end-effector can move in a gross motion, in the vertical axis, as well as in the horizontal plane, so that the gripper fingers are again place at the part presentation area, this time directly above another Mouse Cover that is in an acceptable orientation. The new Mouse Cover should be gripped and attached to the second Mouse Base, using the motions just described for the first set. This operation should then occur two more times, so that in all, four Mouse Covers have been placed. Upon completion of this, the end-effector should then be moved in a gross motion back to the tool change location. Required Motion of Human Operators There is little required motion of human operators at this assembly step. Humans would be needed for periodic dumping of Mouse Covers into the part-feeding hopper. This is a simple task, as the parts would likely be delivered by the supplier in cardboard boxes or plastic bags, with the Mouse Covers simply randomly piled in the container. The frequency of human intervention depends on the number of Mouse Covers that are contained in each container, and on the size of the part-feeding hopper. Since the size of the Mouse Cover is relatively large (compared to other parts of the Mouse), it is expected that either the part-feeding hopper for this part will be quite large in order to balance the levels of line side inventories. Time Calculations Using the Boothroyd and Dewhurst data charts for robotic assembly, we were able to estimate the cycle time for this assembly step. At this step, the Mouse Cover requires a special tool for handling and assembly. Since the decision was made to assemble four products at the same time, the time required for tool changeovers can be effectively neglected. Since the Mouse Cover is not easily aligned, but is added and secured immediately using motion along the vertical axis requiring simple manipulation, the Boothroyd-Dewhurst chart estimates that 3.3 seconds is required to attach the Mouse Cover to the Mouse Base. Four Mouse Covers attached to four Mouse Bases results in a cycle time of 13.2 seconds. Note that this time is based on Boothroyd and Dewhurst’s empirical studies of typical robotic assembly times, rather than based on speed capabilities of a particular robot. Step 10: Transfer between Station 2 and Station 3 (Automatic) Step Description Once the assembly steps at this workstation are completed, the pallet lift will lower to it bottom position. This will allow the bottom surface of the pallet to rest on the conveyor belt. The timecontrolled gates that held the pallet on the conveyor belt above the pallet lift will now be opened, allowing the pallet to move along the conveyor and onto the next workstation. The upstream time-controlled gates will then open, allowing another pallet into this workstation, and the assembly sequence is repeated. Page 17 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen In-flow and out-flows of all assemblies and parts This step will commence with the lowering of the pallet onto the conveyor belt. The pallet will then exit this step by being moved along the conveyor belt. No other in-flows or out-flows of assemblies and parts will be present. Required Motion of Robot The same air cylinder that was used to lift the pallet into position will be used to lower the pallet onto the conveyor, thereby allowing the pallet to move to the next station. Refer to the earlier description of the required motion of this air cylinder for more details. Required Motion of Human Operators As was stated before, since this is an automatic station, no human operators will be required under normal conditions. However, since the potential for mis-positioned parts and pallets exists, it is important that an access panel be included to allow a human operator to clear parts and restart the operation. Time Calculations Similar with the raising of the pallet lift at the start of this workstation, no assembly operations are being conducted in this step. Therefore, operation time will be relatively short. However, care must still be taken to ensure that the starting acceleration and the finishing deceleration, as well as the steady state speed of the downwards motion is not so great that it jars the held parts out of position. If this occurs, there is a risk of damage to the parts, the pallet, the fixtures, as well as the tooling. The lowering of the Pallet lift is estimated to take 0.75 - 1.5 seconds. Note that experiments could easily be conducted to determine the minimum time that can be used to lower the pallet, while ensuring the parts remain properly seated in the pallet and fixtures. PRODUCT TESTING There are two types of tests that need to be performed for functionality, electrical performance and mechanical interface. The electrical performance test consists of verifying the functionality of the Circuit Board and its individual components. The mechanical interface tests verify that the Mouse Cover made contact with the Circuit Board switches and that the movement of the Ball is properly translated through the Gears and to the Circuit Board optical encoder sensors. In our earlier analysis of the product assembly, we imbedded most of the testing into the assembly process. The electrical performance would be tested off line while the mechanical interface would be tested immediately after the components involved in the interface were assembled. A reevaluation of the assembly process led to a restructuring of the assembly sequence. As mentioned earlier, the Circuit Board will still be tested off line through the use of a test cord, however a full functional test will now be conducted after assembly is completed. The mechanical interface tests present a more difficult decision. Testing the interface between the Mouse Cover and the Circuit Board switches can be done at the end of Workstation 2 since all the components are in place. However, doing so would mean the testing responsibility would fall on the robot and would add additional complexity and cost in the workstation. More critically, the testing process could impact the ability to balance the lines and potentially cause additional delays during assembly. Page 18 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Testing the interface of the Ball and Gears requires that the Ball be inserted into the Mouse Base. Currently, this is not accomplished until the end of Workstation 4. Quality principles recommend that tests should be performed as early in the assembly process as possible to minimize the wasted assembly effort on defective parts. The assembly sequence could be reorganized to insert the Ball and Ball Holder into the Mouse Base earlier in the process. Unfortunately, this effort to ensure quality early in the process is a direct tradeoff with Design for Assembly principles that dictate product reorientations should be eliminated or at least minimized in the assembly process. Utilizing a robot to initiate, control and perform the test would be difficult. Specifically, plugging in the Cord to a simulation tool would require human interaction. However, an automated simulation would provide a base test to accurately calibrate the performance of the Mouse. The mouse could be fixed onto a testing table that would fix the lateral position of the product while a conveyor belt underneath could activate the Ball to test the interface. It is important to note that the product must be inverted once again to allow gravity to push the ball onto the conveyor belt. The operator that plugged the Mouse into the simulation could also position it onto the test surface in the proper orientation. In addition to functional tests, it is suggested that sensors be used to ensure that by the each part required in this operation is actually present and properly gripped. Sensors that monitor either the clamping force or position of the grippers’ fingers can achieve this inspection capability. Additional sensors, such as a vision system, can be used to ensure the presence and proper positioning of the parts after they have been mated to the Mouse subassembly. However, as each of the parts involved in this assembly station (Circuit Board, Cord, Horizontal and Vertical Gears) are crucial to the function of the Mouse, the improper placement, or the absence of these parts will very likely be caught at the functional test station in Station 4. Therefore, the added cost of a vision system could be eliminated. But, since each assembly stage should not rely on downstream operations to catch its mistakes, the vision system is recommended. CYCLE TIMES Using the Boothroyd-Dewhurst data charts for robotic assembly, we were able to estimate the cycle time for assembly at Workstation 2. Each component that enters the workstation, Mouse Base, Circuit Board, Cord and Gears, requires a special tool for handling and assembly. The robot tooling head will need to accommodate all four tools. In order to minimize tool changeover, we propose assembling four products at the same time, effectively negating the time required for tool changeovers. Since all four parts are not easily aligned, and are added and secured immediately using motion along the vertical axis requiring simple manipulation, the chart estimates that 3.3 seconds are required to assemble each part. Four parts inserted into four products results in a cycle time of 52.8 seconds. (3.3 seconds*4 parts*4 products). If we assume that between 0.75 and 1.5 seconds will be needed to have the pallets enter the workstation and be properly positioned, and that another 0.75 to 1.5 seconds will be need to have the pallets leave the workstation, an overall cycle time of 54.3 to 55.8 seconds, or simply 55 seconds, is estimated. This equates to roughly 14 seconds per Mouse assembly. Page 19 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen The Gantt chart included below outlines each assembly step and the time required for each step for a complete assembly cycle. The blue shaded boxes represent the time during which a specific operation is taking place. The green shaded box represents the next commencement of the next cycle. Note that all tasks are sequential, and no tasks can be done in parallel. Elapsed Time (seconds) 0.0 1.5 4.8 8.1 11.4 14.7 18.0 21.3 24.6 27.9 31.2 34.5 37.8 41.1 44.4 47.7 51.0 54.3 57.6 Operation Step 5 Tray Enters Workstation #2 Step 6 Pick & Place Circuit Board in Mouse 1 Pick & Place Circuit Board in Mouse 2 Pick & Place Circuit Board in Mouse 3 Pick & Place Circuit Board in Mouse 4 Step 7 Pick & Place Cord in Mouse 1 Pick & Place Cord in Mouse 2 Pick & Place Cord in Mouse 3 Pick & Place Cord in Mouse 4 Step 8 Pick & Place Gears in Mouse 1 Pick & Place Gears in Mouse 2 Pick & Place Gears in Mouse 3 Pick & Place Gears in Mouse 4 Step 9 Pick & Place Mouse Cover in Mouse 1 Pick & Place Mouse Cover in Mouse 2 Pick & Place Mouse Cover in Mouse 3 Pick & Place Mouse Cover in Mouse 4 Tray Leaves Step 10 Workstation WORKSTATION COST ESTIMATES Page 20 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen One of the most important aspects of a manufacturing system, particularly in robotic assembly, is to determine the cost associated with each workstation. Each assembly robot is priced differently depending on its performance requirements and capabilities. In order to determine baseline costs for the robot, the general performance requirements were defined. The conceptual design of the workstation require the robot to lift a small payload, have pick and place capabilities, and have the ability to carry and use four different gripper tools with minimal changeover. Since these are not advanced requirements, it is believed that a standard robot could be purchased from a major robot manufacturer, such as Denso® or Adept®. After researching these and a number of other different companies on-line, we were unable to find a book price for robotic assembly. However, outlining the different costs associated with installing, purchasing and operating the robot can still be used to develop cost estimates of the workstation. The largest percentage of costs is associated with the physical equipment needed such as the robot, tooling (special grippers), and material handling equipment. In order to automate the assembly process, material flow is also accomplished through automation. Primarily, a conveyor-type belt is needed to transfer completed work between workstations. Pallets, trays and shakers will also be needed to control the orientation and the flow of the individual components into the workstation. In addition, a system, potentially an automated one, will need to replace empty pallets and trays with new, filled pallets into the workstation as needed. In addition to the cost of the robot, a significant portion of time and money will have to be devoted to developing software that effectively runs the workstation. It is important to note that installation costs should also be considered in determining the feasibility of a new workstation. If either the equipment or software is new, operators that interface with the workstation will have to be trained in use and maintenance. The cost of equipment was estimated to be between $100,000 and $125,000, the cost of installation at approximately $15,000 and between $25,000 and $35,000 for software development. In order to determine the cost of running the workstation for one full cycle, the fixed costs and the variable costs must be separated. All of the capital required to create one workstation is a fixed cost. The variable costs associated with one cycle are the raw material costs (estimated at $2.00) and labor costs. However, there are no direct labor costs associated with this workstation. There is some indirect labor costs associated with this workstation, such as the operator needed to fill part hoppers with components. However, it is assumed that this operator will have responsibilities other than material handling, and his/her labor costs can be allocated proportionally among those responsibilities. The chart below outlines the labor requirements to meet the production volume of 800,000 products in one year. (The production volume was based on Microsoft’s claim that 2 million products were in the market and our assumption that a production run lasted 2.5 years.) 7 hours/shift 25200 seconds/shift 477.27 products/shift 2 shift/day Page 21 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen 250 days/year 238636 products/year 800000 products/year 3.35 lines required Page 22 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen TABLE OF FIGURES Figure 1: Proposed Layout of Workstation #2................................................................................ 4 Figure 2: Circuit Board Redesign ................................................................................................... 5 Figure 3: Current Mouse Base and Mouse Cover Interface ........................................................... 6 Figure 4: Spring Tab Redesign for Mouse Cover to Mouse Base Interface ................................... 7 Figure 5: Proposed Pallet Design That Will Fixture Four Assemblies At Once ............................ 8 Figure 6: Gripper Finger Placement For Circuit Board ................................................................ 10 Figure 7: Gripper Finger Placement For Cord .............................................................................. 12 Figure 8: Commercially Available Pick and Place Robot That Performs Pattern Recognition ... 16 Page 23 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen APPENDIX A: Bill of Materials Bill of Materials Mouse Assembly Mouse Base Subassembly Mouse Base Spring/Wheel Subassembly Spring Wheel Circuit board Gears (2) Cord Ball Holder Subassembly Ball Holder Ball Mouse Cover Screw Sticker Pads (2) Part No. 8 9 10 11 7 6 1 2 5 3 4 Page 24 of 25 2.875 – Fall 2001 Annabel Flores, James Katzen Page 25 of 25