RAKO_Villa Tugendhat (doc, 135 kB)

advertisement

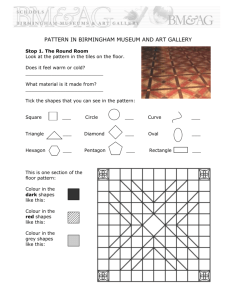

PRESS INFORMATION Icon of modern architecture reopened after extensive renovation Rako reproduces tiles for the „Villa Tugendhat“ by Mies van der Rohe Famous buildings are often ahead of their time. But there could not be a building that is as much ahead of its time as the „Villa Tugendhat“ in the Czech city of Brno . Erected according to the plans of Ludwig Mies van der Rohe and by now refurbished accurately in every detail, this luxurious, finished in 1930 residence impresses with its clear generosity and visionary building services engineering up until today. Also tile brand Rako was involved in the two years of restoration measures, which were finished in the spring of 2012, for this icon of modern architecture. Flooded with light and variable in room arrangements, as much functional as valuable in its furnishing and visionary in its technical possibilities – a fascinating combination of futuristic design concepts is what characterises the „Villa Tugendhat“. A single-family home with incredible 1.250 square meters of usable space. Built for the Brno textile manufacturers Fritz and Grete Tugendhat for a back then horrendous amount of money (it was then considered the most expensive one-family house), but also with remarkable courage for a at that time completely new architectural concept. However, history didn't mean well with this gem of exemplary architecture: For only eight years its owners were granted to make use of their precious domicile. When the Sudentenland was annexed by the German Reich in 1938, the jewish family fled and that was followed by decades of misappropriation and lasting decay for the villa Listed as UNESCO World Cultural Heritage Only in the recent past the house has found the way back to its well deserved attention: In 1995 the villa was declared National Cultural Monument, in 2001 even designated UNESCO World Cultural Heritage as one of very few modern buildings on that list. But P r e s s c o n t a c t Informationsbüro Ingrid Bork, Schwalmstr. 27, D 41564 Kaarst Fon: +49(0)2131/660393, Fax: +49(0)2131/660394, E-Mail: info@ingrid-bork.de it was not until 2010 that the necessary financial resources (almost seven million euro) for a comprehensive refurbishment of the villa were provided. A working group of three architecture firms were commissioned to restore the object to its original state. Also the tradition-rich, Czech tile brand Rako, who already manufactured the original tiles of the house, was involved in the two year rehabilitation measures. The subsidiary of the Austrian Lasselsberger Group accepted the challenge and manufactured replicas for the in the house omnipresent Rako tiles, for baths and kitchen, for the dining room and boiler room. 850 square meters of white wall and floor tiles reproduced A total of about 600 square meters of white wall tiles and 250 square meters of white floor tiles with the format of 15 x 15 cm were reproduced by Rako for this measure. Only in the strongroom for fur coats was no need for renovation: The original ceramic wall coverings have been completely preserved. Already then: Calibrated tiles „Based on the provided original patterns that have been taken from the walls and floors of the villa, the difference between production technology back then and today's possibilities of modern production facilities was immediately visible.“ according to Ing. František Oujiří, Head of the Development and Technology Division at Rako and involved in the development of the tile replication: „The originals were initially produced in a double burning procedure from a kaolinite sherd called raw material mixture. Its white colour is considered typical and constituted the great value of the back then Czechoslowakian earthenware.“ The second characteristic and worldwide appreciated feature was the high level of dimensional accuarcy of the back then produced tiles. „For that we had our own patented calibrating machines in our plant in Horní Bříza, that were developed and produced by us.“ Tiling with narrow joints was thus possible already over 80 years ago – just like it is viewed as the ultimate of modern tiling today. P r e s s c o n t a c t Informationsbüro Ingrid Bork, Schwalmstr. 27, D 41564 Kaarst Fon: +49(0)2131/660393, Fax: +49(0)2131/660394, E-Mail: info@ingrid-bork.de Activated again: The old calibrating machine The solution for the manufacture of new „old“ tiles eventually lay in the combination of early and modern production processes. Used were raw material mixtures and glazes, that could be manufactured with one burning process. The architects and restorers put particular emphasis on the rounded tile edges for margins and edges – nowadays no longer common but typical of this period – to be adopted true to original. A requirement that could be met through the development of a specific mould. Merely this part of the replicas was made using the double burning technique. At last, the calibration of the reproduced ceramics symbolically took place in Horní Bříza, the same plant where the first calibrating machines were located, forgotten and now rediscovered and back in use. A special layout plan for each tiled wall Also the laying of the reconstructed tiles with the format 15 x 15 cm turned out to be a challenging task. From old photographs became apparent how accurate the former joint cuts were. That is why the original surface image as well as the inclusion of furnishing elements should play an essential part during the renewal. For example, it was not usual in the 1930s to cut circular cutouts into the tiles to enable a supply line to the washbasin. Rather had the joint lines to be planned ahead in a way so that the pipeline could be worked into the joints and the 9 mm thick tiles would enable the opening only by laterally breaking off. Thus for every bathroom and for every single wall there had to be a specially made layout plan. Throughout the whole renovation measures it were the details that made the difference: By taking a closer look at the tub installation, the use of shelf space or the connections on the door frames it becomes clear with how much accuracy and in some cases even personal ingenuity people have worked here. Up to the production of a self-mixed jointing material ranged the sensitive restoration of the ceramic surfaces. „It was chosen from several colour shades and perfectly rounds off the final impression.“ according to the satisfied conclusion by Petr Miklíček, ceramic restorer with a licence from the Czech ministry of education and cultural affairs and responsible for the tiling at the „Villa Tugendhat“. RAKO housing ceramic, manufacturer: LASSELSBERGER s.r.o., Adelova 2549/1, 320 00 Pilsen, Czech Republic www.rako.eu P r e s s c o n t a c t Informationsbüro Ingrid Bork, Schwalmstr. 27, D 41564 Kaarst Fon: +49(0)2131/660393, Fax: +49(0)2131/660394, E-Mail: info@ingrid-bork.de