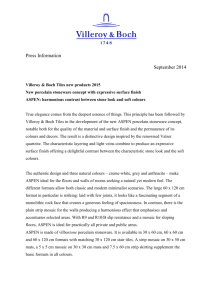

Durastone tile variation

advertisement

DURASTONE DOUBLE LOADING PORCELAIN TILES The full body Durastone Range of Porcelain tiles are manufactured through a Double Loading process; this process allows the introduction of different mixture into the bottom layer of the tiles without jeopardizing the quality and pattern of the exposed finished top layer. This is where the required characteristics of the exposed top surface of the tile are not required. The two layers of porcelain clay are pressed together and then fired at high temperature fusing the two layers together as one. The pressed and fired porcelain clays will not separate from each other. The Double-Loading (or double-charging) process is similar to the single powder process except that a second loading of very fine coloured powder clay of approximately 3mm thick is introduced under high pressure on the pre-pressed base powder thus creating the required exposed aesthetic face of the tiles. This fine powder layer is a random combination of different colours clay which once pressed, form the distinctive linear movement on the surface of the tiles. The mixture of the different colours clays and randomness of the linearity of its distribution aesthetically classify these tiles under the group V2 - Slight Variation; clearly distinguishable differences in texture and/or pattern within similar colours. Floor trimming accessory, such as edged-tiles, coving and skirting are all manufactured separately to any standard tile run and due to the multitude of style, texture and patterns; some colour and shading variation must be tolerated, these should be reviewed prior any installation to determine the acceptable colour variations. EVERSTONE PTY Ltd. EVERSTONE GROUP TEL: 61-2-9795 2000 FAX: 61-2-9644 3353 EMAIL: info@everstone.com.au Web: www.everstone.com.au 20 Princess Road East. AUBURN NSW 2144 SYDNEY, AUSTRALIA