the fluid mechanics course, CHE 204, Transport Phenomena I

advertisement

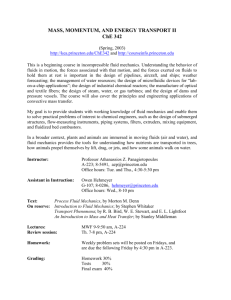

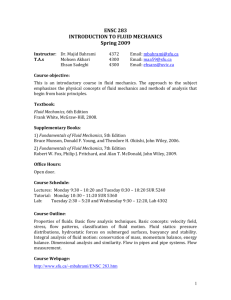

CHE 204 Lecture No. 1 1.1. Introduction: Welcome to the fluid mechanics course, CHE 204, Transport Phenomena I. This is the first lecture from the module number 1; Introduction to Fluid Mechanics. Here we will be talking about the fundamental of fluid mechanics; general concepts in fluid mechanics, macro and micro problems; we will define stress, velocity gradient and continuum. So, what is fluid mechanics? Fluid mechanics is a branch of applied physics that is concerned with the motion of the fluid and the forces associated with that motion. It is the behavior of the fluid at rest and in motion. Also, fluid mechanics is the science of deformation in flow so mechanics is the study of forces and motion. Thus fluid mechanics is the study of forces and motion in fluids. Fluid mechanics plays a role in most engineering discipline and certain underlying principles are common to all area of application. Emphasis differs within each area however certain topics of fluid mechanics takes precedence over others in each discipline. Knowledge of fluid mechanics is essential for a chemical engineer as well as for a petroleum engineer because majority of the processing operations are conducted either partly or totally in liquid phase. Examples of such operations are bound in biochemical, chemical, energy, fermentation, materials, mining, petroleum, petrochemicals, polymers and waste processing industries. Fluid mechanics is based largely on the following four conservation laws: 1) 2) 3) 4) Law of conservation of mass The first law of thermodynamics (the principle of conservation of energy) The second law of thermodynamics Newton’s law of motion which may be summarized as F = ma Each of these four laws is a generalization of experimental data. No one of them can be deduced from others or from any other principles. None can be proved mathematically whether they stand on their ability to predict correctly the result of any experiment ever run to test them. Sometimes in fluid mechanics we may start with these four laws and the measured physical properties of the materials under consideration and proceed directly to solve mathematically for the desired forces, velocity and so on. This is generally possible only in the case of very simple flows. The observed behavior of great many fluid flows is too complex to be solved directly from these four principles so we have to perform experimental tests. Though, the use of technique called dimensional analysis often allows us to use the result of one experiment to predict the result of a much different experiment. Thus careful experimental work is very important in fluid mechanics. 1.2. Branches of Fluid Mechanics: Some of the applications or branches of fluid mechanics are given as follows: 1) Hydraulics: the study of flow of water in rivers, pipes, canals, pumps, turbines etc. 2) Aerodynamics: the study of flow of air around airplanes, rockets, projectiles, structures. 3) Meteorology: the study of flow of atmosphere. 4) Particle dynamics: the flow of fluids around particles, the interaction of particles in fluids (i.e. dust setting, slurries, pneumatic transport, fluidized beds, air pollutant particles). 5) Hydrology: the study of flow of water and water born pollutants in the ground. 6) Reservoir mechanics: the flow of oil, gas and water in petroleum reservoirs. 7) Multiphase flow: the study of coffee percolator, oil wells, carburetors, fuel injectors, combustion chambers, sprays. Now, coming back to the same question; what is a fluid? We can all think of some things which obviously are fluids. For example, air, water, gasoline, lubricating oil and milk. We can also think of some things which obviously are not fluid. For example, steel, diamonds, rubber band and paper. These we called solids. But there is some very interesting intermediate type of matter. For example jelly, peanut butter, cold cream, mayonnaise, tooth paste, bread dough and auto mobile grease. So, coming back again to the same question; what is a fluid? A fluid is a substance that will deform continuously when it is subjected to a shear force. The rate at which fluid deforms continuously depends on the magnitude of the applied force and viscosity which is a property of a fluid. Broadly speaking, when a fluid is subjected to a tangential or shear force is much similar type of force when a water skier skims over the surface of lake or butter is spread on a slice of bread. The rate at which the fluid deforms continuously depends not only on the magnitude of the applied force but also on the property of the fluid called viscosity or the resistance to deformation in flow. Solids will also deform when a shear force is applied but a position of equilibrium is soon reached in which elastic forces induced by the deformation of the solid exactly counter balance the applied shear force and further deformation ceases. In order to understand fluids more clearly, we have to consider first the idea of shear stress. A simple apparatus for shearing a fluid is shown in Fig 1.1. The fluid is contained between two concentric cylinders; the outer cylinder is stationary, and the inner one (of radius R) is rotated steadily with an angular velocity ω. This shearing motion of a fluid can continue indefinitely, provided that a source of energy – supplied by a means of torque here – is available for rotating the inner cylinder. The diagram also shows the resulting velocity profile; note that the velocity in the direction of rotation varies from the peripheral velocity Rω of the inner cylinder down to zero at the outer stationary cylinder, these representing typical no-slip conditions at both locations. However if the intervening space is filled with a solid – even one with obvious elasticity, such as rubber – only a limited rotation will be possible before a position of equilibrium is reached, unless, of course, the torque is so high that slip occurs between the rubber and the cylinder. There are various classes of fluids. Those that behave according to nice and obvious simple laws, such as water, oil, and air are generally called Newtonian fluids. These fluids exhibit constant viscosity but, under typical processing conditions, virtually no elasticity. Fortunately, a very large number of fluids of interest to the chemical engineer exhibit Newtonian behavior. A fluid whose viscosity is not constant (but depends, for example, on the intensity to which it is being sheared), or which exhibits significant elasticity, is termed non-Newtonian. For example, several polymeric materials subject to deformation can “remember” their recent molecular configurations, and in attempting to recover their recent states, they will exhibit elasticity in addition to viscosity. Other fluids, such as drilling mud or toothpaste, behave essentially as solids and will not flow when subject to small shear forces, but will flow readily under the influence of high shear forces. Fluids can also be broadly classified into two main categories – liquids and gases. Liquids are characterized by relatively high densities and viscosities, with molecules close together; their volumes tend to remain constant, roughly independent of pressure, temperature, or the size of the vessels containing them. Gases, on the other hand, have relatively low densities and viscosities, with molecules far apart; generally, they will rapidly tend to fill the container in which they are placed. However, these two states – liquid and gaseous – represent but the two extreme ends of a continuous spectrum of possibilities. 1.3. Macro-Problems: Problems of processing interests can be roughly categorized as macro- and micro- problems. (The categorization should not be taken too seriously, but it is helpful for all preliminary discussion). This division reflects two rather different needs in the application of results from a fluid mechanics analysis. Macro- problems are those in which the end result is some overall characteristic of motion itself, often the energy requirement, with no interest in the detailed structure of the flow field. The following examples illustrate typical macro problems: 1.3.1. Pipeline Flow: A fluid with known physical properties is to be pumped form point A to point B. Flow rate and pipe sizes are specified. Determine the power required to pump the fluid, and hence the pumping cost. An interesting corollary problem is to determine the optimal pipe size in order to minimize the sum of operating and investment cost. (Larger pipe costs more per unit length but requires less pumping energy). 1.3.2. Packed Reactor: Many chemical reactions are carried out in packed reactors, as shown schematically in Fig 1.2. Gas or liquids flows through a solid packing; the solid may catalyze the reaction, it may take part directly in the reaction (as in a coal gasification reactor), or it may simply be an inert packing which is present for other reasons, such as improving the heat removal. The pressure drop from one end of the reactor to the other is required as an important design parameter. The pressure drop not only affects the power requirements, but is also enters directly into reaction kinetics and equilibrium parameters and hence into reactor product conversions and distributions. Fig. 1.2 1.4. Micro Problems: Micro problems are those in which the detailed structure of the flow field is of importance. This information is often required for the subsequent analysis of other physical processes; in this regard, fluid mechanics provides an essential foundation for the study of heat transfer and mass transfer. The formulation and solution of micro- problems is often different from, and often more complex than the solution of macro- problems. Some typical micro-problems are discussed in the following paragraphs. 1.4.1. Heat Transfer Coefficient: A liquid flowing in a pipe is to be cooled by removing heat through the wall. The detailed flow pattern near the wall is required in order to calculate the heat transfer coefficient (the ratio of heat removal per unit surface area to temperature difference from the inside to the out side of the pipe). The reason that the flow pattern is required can be seen by reference to the Fig 1.3a and b. If the flow pattern shown schematically in Fig 1.3a prevails, fluid which starts at a given distance from the wall never gets any closer to the wall; whereas for the case shown in Fig. 1.3b , fluid moves from pipe core to the wall and back again. The latter is an effective means of heat transfer, because hot fluid is convected to the colder wall, cooled, and returned to contact the hotter fluid again. In contrast, when the flow lines are straight and no circulation occurs, heat can be removed from the center of the pipe only by conduction to the wall. Conduction is a molecular process and is a much slower way of removing heat than the convective recirculation. 1.4.2. Particle-Fluid Mass Transfer: Particle-fluid mass transfer is similar is similar to the wall heat transfer coefficient problem and is relevant to packed reactors like that in Fig. 1.2 when the solid is a catalyst. For illustrative purposes it is more convenient to consider an isolated spherical particle, as shown in Fig. 1.4. The flow pattern shown in Fig. 1-4a and b can occur, as can other patterns, depending on overall flow conditions. Clearly, the rate at which reactants move from the bulk fluid to the catalytic surface depends on the nature of the flow patterns; if the chemical reaction is rapid, the rate at which the catalytic process occurs is controlled by the rate at which reactants move to the surface, and hence by the fluid mechanics around the particle. 1.5. Stresses, Pressure, Velocity, and the Basic Laws: Stresses. The concept of a force should be readily apparent. In fluid mechanics, a force per unit area, called a stress, is usually found to be a more convenient and versatile quantity than the force itself. Further, when considering a specific surface, there are two types of stresses that are particularly important. 1. The first type of stress, shown in Fig 1.5a, acts perpendicularly to the surface and is therefore called a normal stress; it will be tensile or compressive, depending on whether it tends to stretch or to compress the fluid on which it acts. The normal stress equals F / A, where F is the normal force and A is the area of the surface on which it acts. The dotted outlines show the volume changes caused by deformation. In fluid mechanics, pressure is usually the most important type of compressive stress, and will shortly be discussed in more detail. 2. The second type of stress, shown in Fig 1.5b, acts tangentially to the surface; it is called a shear stress τ, and equals F / A, where F is the tangential force and A is the area on which it acts. Knowledge of the shear stress is very important when studying the flow of viscous Newtonian fluids. For a given rate of deformation, measured by the time derivative dγ / dt of the small angle of deformation γ, the shear stress τ is directly proportional to the viscosity of the fluid. Fig. 1.5(a) Fig. 1.5(b) Pressure. In virtually all hydrostatic problems – those involving fluids at rest – the fluid molecules are in a state of compression. For example, for the swimming pool whose cross section is depicted in Fig 1.6, this compression at a representative point P is caused by the downwards gravitational weight of the water above point P. Fig. 1.6 A small spherical balloon pulled down from the surface and tethered at the bottom by a weight will still retain its spherical shape, but will be diminished in size, as in Fig 1.6a. It is apparent that there must be forces acting normally inwards on the surface of the balloon, and that these must essentially be uniform for the shape to remain spherical, as in Fig 1.6b. This normal compressive force, per unit area of the surface, is a stress known as the pressure, p. This compressive state is almost always present, but is typically rendered more obvious by considering the pressure acting normally on a plane – real or hypothetical – located in the fluid. The value of the pressure at a point is independent of the orientation of such a plane, as can be deduced with reference to a differentially small wedge – shaped element of the fluid, shown in Fig. 1.7. Fig. 1.7 There are three pressures, pA, pB, and pC, that act on the three rectangular faces of areas A, B, and C. Since the wedge is not moving, equate the two forces acting on it in the horizontal or x direction, noting that pA must be resolved through an angle (π / 2 - θ) by multiplying it by cos(π / 2 - θ) = sin θ: Observe that the vertical force pBB acting on the bottom surface is omitted, because it has no component in the x direction. Also omitted from consideration – and, for clarity, from the diagram – are the horizontal pressure forces acting on the two triangular faces of the wedge in the y direction, since again these forces have no effect in the x direction. From geometrical considerations, areas A and C are related by: These last two equations yield: verifying that the pressure is independent of the orientation of the surface being considered. A force balance in the z direction leads to a similar result, pA = pB. For moving fluids, the normal stresses include both a pressure and extra stresses caused by the motion of the fluid. The amount by which a certain pressure exceeds that of the atmosphere is termed the gauge pressure, the reason being that many common pressure gauges are really differential instruments, reading the different between a required pressure and that of the surrounding atmosphere. Absolute pressure equals the gauge pressure plus the atmospheric pressure. Velocity. Many problems in fluid mechanics deal with the velocity of the fluid at a point, equal to the rate of change of the position of a fluid particle with time, thus having both a magnitude and a direction. In some situations, particularly those treated from the macroscopic viewpoint, it sometimes suffices to ignore variations of the velocity with position. In other cases – particularly those treated from the microscopic viewpoint, and later – it is invariably essential to consider variations of velocity with position. Fig. 1.8 Velocity is not only important in its own right, but leads immediately to three fluxes or flow rates. Specifically, if u denotes a uniform velocity (not varying with position): 1. If the fluid passes through a plane of area A normal to the direction of the velocity, as shown in Fig. 1.8, the corresponding volumetric flow rate of fluid through the plane is Q = uA. 2. The corresponding mass flow rate is m = ρQ = ρuA, where ρ is the fluid density. 3. When velocity is multiplied by mass it gives momentum, a quantity of prime importance in fluid mechanics. The corresponding momentum flow rate passing through the area A is = mu = ρu2A. Basic laws. In principle, the laws of fluid mechanics can be stated rather simply, and – in the absence of relativistic effects – amount to conservation of mass, energy, and momentum. When applying these laws, the procedure is first to identify a system, its boundary, and its surroundings; and second, to identify how the system interacts with its surroundings. Refer to Fig. 1.9 and let the quantity X represent either mass, energy, or momentum. Also recognize that X may be added from the surroundings and transported into the system by an amount Xin across the boundary, and may likewise be removed or transported out of the system to the surroundings by and amount Xout. Fig. 1.9 The general conservation law gives the increase ΔXsystem in the X-content of the system as: Although this basic law may appear intuitively obvious, it applies only to a very restricted selection of properties X. For example, it is not generally true if X is another extensive property such as volume, and is quite meaningless if X is an intensive property such as pressure or temperature. In certain case, where Xi is the mass of a definite chemical species i, we may also have an amount of creation or destruction due to chemical reaction, in which case the general law becomes: The conservation law is of such fundamental importance that in various guises it will find numerous applications throughout all of this text. To solve a physical problem, the following information concerning the fluid is also usually needed: 1. The physical properties of the fluid involved. 2. For situations involving fluid flow, a constitutive equation for the fluid, which relates the various stresses to the flow pattern.