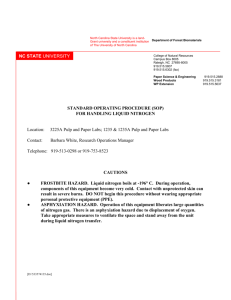

Use of Liquid Nitrogen

advertisement

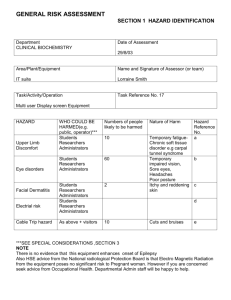

GENERAL RISK ASSESSMENT SECTION 1 HAZARD IDENTIFICATION Department IMS-MRL (Clinical Biochemistry) Date of Assessment 24/02/03; Updated 26/10/04; Updated 04/03/2011 Area/Plant/Equipment Name and Signature of Assessor (or team) Liquid nitrogen use Malgorzata Martin (CNH)/ Chris Ford Jonathan Fort (on 4th March 2011) Task/Activity/Operation - Snap freezing samples in liquid nitrogen - Cell storage in liquid nitrogen - Defrosting samples stored in liquid nitrogen - Transport of liquid nitrogen to CBS Task Reference No. 6 HAZARD WHO COULD BE HARMED(e.g. **public, operator) Numbers of people likely to be harmed Nature of Harm Hazard Reference No. Very low temperature related Operator, Any person in proximity 1 6a Evaporation of nitrogen from the tanks (asphyxiation) The explosion potential of the tank/cylinder as a pressure vessel Explosion of cryovails taken from cryovessels Operator, Any person in proximity Especially when transported in lift Operator, Any person in proximity 1 Cold burns, frostbites, severe blistering, hypothermia Depletion of oxygen content, asphyxiation 1 Trauma injuries, frostbites, burns, severe blistering 6c Operator, Any person in proximity 1 6d Manual handling of heavy tanks/containers Employees receiving, despatching or moving large tanks/containers 1 Trauma injuries, frostbites, burns, severe blistering, contact with foreign materials stored in cryovails (possible infection) Musculo-skeletal or trauma injuries ** see section 3 –Special Considerations 6b 6e SECTION 2 – RISK EVALUATION Note: Section 2 &3 must be completed for each hazard identified in Section 1 Hazard from section 1 Reference No. Very low temperature related 6a Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm PROBABILITY 1 2 3 X SEVERITY OF HARM 1 2 3 = RISK LEVEL 10 20 30 X Most Likely Severity (will increase if large numbers will be hurt) 4 5 6 7 8 9 10 4 5 6 7 8 9 10 40 50 60 70 80 90 100 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description Use of Ventilation of purpose area produced tanks/cylin For delivery ders/conta (use of lift) A iners warning sign has been applied Are they Adequate Measures Required By who & When Procedural controls (inc. training and supervision) Training and supervision of new users. Training to include: care, selection and use of protective equipment, hazards associated with use and emergency procedures Personal protective equipment Other Lab coat; -Pour liquid nitrogen warm, dry carefully and slowly;gloves; -Only use containers protective designed for liquid face screen nitrogen use and or goggles; transport (should adequate have lid and handles) footwear -Use forceps to (avoidance withdraw objects of open toed immersed in the shoes) liquid nitrogen - Avoid contact of liquid nitrogen with skin, in particular wet skin Yes Yes Yes Yes Yes - - - - - - - - - - SECTION 2 – RISK EVALUATION Note: Section 2 &3 must be completed for each hazard identified in Section 1 Hazard from section 1 Reference No. Evaporation of nitrogen from the tanks 6b (asphyxiation) Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm PROBABILITY 1 2 3 X SEVERITY OF HARM 1 2 3 = RISK LEVEL 10 20 30 X Most Likely Severity (will increase if large numbers will be hurt) 4 5 6 7 8 9 10 4 5 6 7 8 9 10 40 50 60 70 80 90 100 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description Use of -Storage in purpose well ventilated produced but weather tanks/cylinders protected area - Yearly control of tanks Procedural controls (inc. training and supervision) Training and supervision of new users. Personal protective equipment Other Are they Adequate Additional Measures Required Yes Yes Yes Lab coat; warm, dry gloves; protective face screen or goggles; adequate footwear (avoidance of open toed shoes) Yes - - - - - - By who & When - - - - - SECTION 2 – RISK EVALUATION Note: Section 2 &3 must be completed for each hazard identified in Section 1 Hazard from section 1 Reference No. The explosion potential of the tank/cylinder as a 6c pressure vessel Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X Most Likely Severity (will increase if large numbers will be hurt) PROBABILITY 1 2 3 X SEVERITY OF HARM 1 2 3 = RISK LEVEL 10 20 30 4 5 6 7 8 9 10 4 5 6 7 8 9 10 40 50 60 70 80 90 100 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description - tanks/ - Separation cylinders fitted from with valve cylinders protection containing guards and toxics, appropriate flammables pressure oxidants and reducing corrosives by regulator distance or structural fire-resisting partitions - Yearly control of tanks Are they Yes Yes Adequate Additional Measures Required By who & When - - Procedural controls (inc. training and supervision) Personal protective equipment Other Training and supervision of new users. Pressure systems tested annually by qualified BOC engineer as part of the maintenance contract for the equipment. Lab coat; warm, dry gloves; protective face screen or goggles; adequate footwear - Yes Yes - - - - - - - SECTION 2 – RISK EVALUATION Note: Section 2 &3 must be completed for each hazard identified in Section 1 Hazard from section 1 Explosion of cryovials taken from cryovessels Reference No. 6d Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X PROBABILITY 1 2 X 3 Most Likely Severity (will increase if large numbers will be hurt) 4 5 6 7 8 9 10 SEVERITY OF HARM 1 2 3 4 5 6 7 8 9 10 = RISK LEVEL 10 20 40 50 60 70 80 90 100 30 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description - use of appropriate cryovials Procedural controls (inc. training and supervision) Training and supervision of new users. Personal protective equipment Other Lab coat; warm, dry gloves; protective face screen or goggles; adequate footwear Are they Adequate Additional Measures Required Yes - Yes Yes Physical containment of cryovails during transport e.g. use of polystarine box for transport Yes - - - - - By who & When - - - - - SECTION 2 – RISK EVALUATION Note: Section 2 &3 must be completed for each hazard identified in Section 1 Hazard from section 1 Reference No. Manual handling of heavy tanks/containers 6e Make an assessment without taking into account current control measures (subjective) RISK = Probability of Harm X Most Likely Severity (will increase if large numbers will be hurt) PROBABILITY 1 2 3 X SEVERITY OF HARM 1 2 3 = RISK LEVEL 10 20 30 4 5 6 7 8 9 10 4 5 6 7 8 9 10 40 50 60 70 80 90 100 CURRENT CONTROL MEASURES Type Control at Engineering source controls (intrinsic) (guards, local exhaust ventIllation etc. Description Cylinders/tanks Yearly control equipped with of tanks wheels by (inspection) manufacturers Procedural controls (inc. training and supervision) Personal Other protective equipment Training before use. - Are they Adequate Additional Measures Required Yes Yes Yes Yes -Use of adequate mechanical aids e.g. wheeled trolley when required -Use of the smallest container consistent with the activity or process - - - - - - By who & When - - - - - Use of good manual handling practices. Self assessment of physical capability SECTION3 SPECIAL CONSIDERATIONS 1. After carrying out the assessment and assuming adequate training, is this task one that can be carried out by a lone worker? This decision is one made by a group leader, please state their name and answer. Group leader name: Sue Ozanne Answer: Yes 2. Are there any special considerations for other groups of workers e.g. Pregnant and new mothers, young people, cleaners etc. that you have not considered in your main Assessment? If so, please make a comment below. SECTION 4- REVIEW Circumstances for Review Incident on Friday 4th March 2011 when the liquid nitrogen vessel fell on to it’s side during transporting from the basement to Level 5 IMS-MRL. Default Date review: 04/03/2011