Isothermal Titration Calorimetry

advertisement

Using the MicroCal VP-ITC … some brief notes.

Version 1.06, Last modified Sep 06, 2010, by Richard (rl.kingston@auckland.ac.nz)

And with thanks to Jacqui Matthews for assistance.

Isothermal Titration Calorimetry (ITC) is a basic quantitative technique for studying

molecular interactions, in which the tiny amount of heat released or absorbed during

binding is accurately measured. From this raw data, a very complete description of

binding can be achieved. There’s been some good book chapters and reviews written

about ITC (see e.g. {Indyk, 1998, p09394},{Freire, 1990, p06334},{Ladbury, 1998,

p05149},{Harding, 2001, p05148},{Pierce, 1999, p05074},{Leavitt, 2002, p00838},

{Perozzo, 2004, p06447},{Velazquez-Campoy, 2004, p05064},{Velázquez Campoy,

2005, p05058;Buurma, 2007, p06531},{Freyer, 2008, p07431}). These cover both the

theoretical and practical aspects of the technique, and you should read some of them

for proper understanding.

ITC can also be used to study the kinetics of enzyme-catalyzed reactions (see e.g.

{Freyer, 2008, p07431},{Todd, 2001, p06994}). However these notes consider only

the study of binding processes.

The absolute basics of the experimental method

Generally, for studying hetero-complex formation, you fill the sample cell with a

solution of one of your molecules. You then stepwise inject a much more concentrated

solution of the binding partner into the cell. As the binding reaction progresses, heat is

generated or consumed, and this is measured.

The VP-ITC, like all commercial microcalorimeters, is a differential instrument. Inside the VP-ITC

there are two identical cells … sample and reference. The reference cell plays no part in the titration

and, since we work with aqueous solutions, is filled with water. The ITC signal actually results from

the power required to maintain thermal equilibrium between the reference and sample cells.

The raw data is a series of heat “pulses” associated with each injection. Integrating

these peaks generates a titration curve, where the ordinate axis is the heat generated

per mol of injectant. This data can be fitted to a mathematical model of the binding

process … most often a simple 1:1 binding scheme as discussed below.

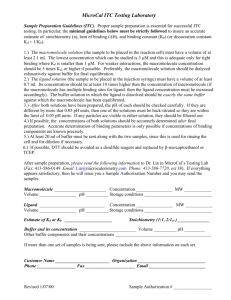

Here’s some good quality ITC data, and a fitted model to give you the general idea …

Binding of the nucleocapsid-binding domain from the measles virus P protein (P457-507)

to a peptide from the measles virus N protein (N477-505).

(A) Raw ITC binding data for 23 automatic injections of P457-507 (each injection 12 µL, protein

concentration 1.44 mM, 240s interval between injections), into a cell containing N477-505 (initial protein

concentration 0.12 mM). Proteins were suspended in 10 mM Na2HPO4/NaH2PO4 buffer (pH 7.0); 100

mM NaCl, 0.01%(wt/vol) Sodium azide. Sample cell temperature was 20 °C. Baseline mixing heats

were determined from duplicate injections of P457-507 into buffer. These were subtracted from the

binding heat data before model fitting.

(B) The integrated titration curve obtained from the raw data in (A), following baseline subtraction. The

solid squares represent the experimental data while the solid line corresponds to the multiple

independent binding site model that was fit to the data. Binding parameters were determined to be

n=0.93, KD = 13 µM, ΔH= -1.1 x104 cal/mol, ΔS = -14 cal/K.mol.

Models of binding

Hetero-dimerization

Typically we characterize the interaction between two different binding partners. The

simplest scheme involves a 1:1 association. This can be written as follows

A + B ? AB

The equilibrium dissociation (KD) and association (KA) constants governing this

reaction are …

KD =

5A ?5B ?

5AB ?

5AB ?

1

KA = K =

5A ?5B ?

D

The change in Gibbs free energy associated with binding is related to the equilibrium

association constant KA …

DG =- RT ln KA = DH - TDS

Where R is the gas constant, and T is the temperature in Kelvin.

ITC can provide us with estimates for KA (or equivalently KD) as well as for ΔH and

ΔS, the enthalpic and entropic contributions to the free energy of binding.

Most ITC data are analyzed in terms of this simple binding scheme. And for now, this

is what these notes mostly discuss

More complicated hetero-complex formation

Obviously many more complicated binding schemes exist, and for some of these, the

equations have been worked which enable fitting to ITC data. Worth noting are the

following

1. One set of binding sites, all identical and independent. Binary complex formation

is usually treated using this general model (since this represents a special case where

there is just one binding site). Using the more general model you determine, in

addition to KD, ΔH, and ΔS, the stoichiometry (n), which should be 1 for a binary

complex.

2. Two sets of binding sites, the members of each set identical and independent.

3. Sequential binding models.

4. Cooperative binding models for ternary complexes{Velazquez-Campoy, 2006,

p00503}.

5. Binding to one-dimensional lattice-like macromolecules e.g. nucleic acids or

carbohydrates (McGhee-von Hippel model){Velazquez-Campoy, 2006, p05057}.

The range of binding processes that can be studied using ITC continues to expand.

Protein self-association

In certain circumstances ITC can also be used to study protein self-association (homocomplex formation). In this case the binding partners are identical, and the

experimental procedure is different. The protein is put into the syringe and then

injected into the sample cell containing only buffer. With the correct concentration

regime, dilution will cause the complex to dissociate, and heat will be generated.

Let’s consider the simplest case … homo-dimerization. The basic reaction scheme is

A + A ? A2

The equilibrium dissociation (KD) and association (KA) constants governing this

reaction are …

KD =

5A ?2

6A2 @

6A @

1

KA = K = 2 2

5A ?

D

Assuming this simple binding scheme, a model for the heat generated during the

experiment is worked out in the appendix.

Coupling of binding to protonation/deprotonation

Many protein-protein and protein-ligand interactions show strong pH dependence,

indicating that binding is coupled to proton uptake and release. Any change in the

observed binding enthalpy (ΔH) or binding affinity (KA) with pH, is indicative of

proton linkage.

Proton-linked equilibria are more complicated to study by ITC, because the protons

absorbed or released will be given to, or taken from, the buffer, and that generates

heat! A full investigation of binding then requires that you take buffer-related

contributions into account.

To establish if your binding process is proton linked, the obvious path is to do repeat

titrations at a different pH’s (i.e. at different proton concentrations), being careful to

keep the other solution variables the same (e.g. ionic strength). Less obviously you can

perform replicate titrations at the same pH, using buffers with different (and known)

ionization enthalpies. In either case if the observed binding parameters shift beyond

the experimental uncertainty, there’s a degree of proton linkage in your binding

reaction.

These two experimental approaches (varying the pH, and/or varying the buffer)

provide the means to investigate proton linkage. The data can be analyzed in terms of

the linkage theory of Wyman{wyman, 1990, p06529}. In general, binding could be

linked to a single protonation event, which is pretty simple to model, or to multiple

protonation events, which is a bit of a nightmare. There are lots of elegant papers that

show you how to proceed{Kresheck, 1995, p06433},{Gómez, 1995, p06357},{Baker,

1996, p06391},{Baker, 1997, p06445},{Xie, 1997, p06438},{Parker, 1999, p06440},

{Velazquez-Campoy, 2000, p06441},{Bruylants, 2007, p04780}. There is also a

comprehensive recent review of the enthalpies associated with ionization of buffers

{Goldberg, 2002, p06449}, very useful when you are planning these sorts of

experiments.

Planning an ITC experiment

Hetero-dimerization.

Too strong, too weak, just right.

There are some limitations in the range of binding affinities that can be studied by

ITC. Generally with KA in the range 104 -108 M-1 (KD = 10-4 – 10-8 M) things are

fairly straightforward. With weaker or stronger binding than this, you will experience

some difficulty. The titration curves will either be too flat, or too “step-like” too allow

routine fitting of the model. However, if a competing moderate affinity ligand is

available, then it’s possible to design competition experiments (“displacement

titration”) to allow binding to be fully characterized in these extreme cases. Consult

the literature for details. Otherwise you need to make some assumptions, and fix some

model parameters to allow estimation of the others. More on this later.

Concentration and volume requirements

Generally the solubility of the molecules will dictate which is to be put into the cell

(low concentration sample) and which is to be put into the syringe (high concentration

sample). To fill the sample cell, without risking introduction of bubbles, you’ll need

2ml of the low concentration sample. To fill the syringe you’ll need 400 µL of the

high concentration sample. But actually you need at the minimum 2 x 400 = 800 µL

of the high concentration sample, because there’s a critical control you must run (see

below). This assumes that nothing goes wrong, and you don’t need to replicate.

Everything works first time in science.

So the short story … ITC requires a truckload of material. But you do get it all back

undamaged afterwards!

For an uncharacterized binding reaction you can’t know how much heat will be

generated, so you must guess the concentrations required. Generally the low

concentration sample should be somewhere between 5-100 µM. Once the titration is

complete, you should have a 2-3 fold molar excess of the injectant in the cell (more

for very weak interactions). For the VP-ITC this requires that the molecule in the

syringe is 10 -15 x more concentrated than the molecule in the cell.

Sample preparation

The main requirements are that the molecules are pure, and are in the same buffer.

For relatively big molecules this can be achieved through exhaustive dialysis. The

safest strategy is to prepare a very large batch of buffer (5L) that will allow dialysis of

both samples, with multiple buffer changes. This is not the place to take short cuts.

Always keep some uncontaminated buffer aside to allow washing of the ITC cell, and

to perform any dilutions that might be needed. Small ligands, which cannot be

effectively retained by a dialysis membrane, will have to be directly dissolved in buffer.

In that case you may want to check the pH and conductivity of the resulting solution.

We don’t currently have a microprobe pH and conductivity meter, but we are working

on it.

Some suggest you should avoid volatile buffers such as formic and acetic acid, as these

may cause problems (samples have to be degassed prior to data collection).

You must know the concentrations of your reactants accurately. The best way to do

this for proteins is by UV-spectroscopy at 280 nm, calculating the extinction

coefficients from the amino acid composition.

Running the ITC

These notes are just to remind you what to do. New users must receive training from

Graham Bailey (gbai015@ec.auckland.ac.nz).

Setting up

* Turn on the monitor and the computer

* Turn on the ITC (switch at back left)

* Click on the VPViewer icon on the desktop (this starts the ITC controller)

* In the Thermostat/Calibration Tab, enter your ITC run temperature and hit “Set

Jacket Temperature” (it takes some time to equilibrate the cells, particularly if the run

is some way from room temperature)

Degassing samples

Before loading the samples, they need to be degassed, to reduce the possibility of

bubble formation. This is particularly critical for low temperature work.

* Place the sample in the opaque plastic tubes. Add clean magnetic stir bars.

* Turn on the ThermoVac.

* Set the temperature to the ITC run temperature … or if you’re running below

room temperature set the temperature to 3 °C < ITC run temperature.

* Place the samples in the ThermoVac, and seat the vacuum chamber over top.

* Connect tubing between the vacuum chamber and the left plug at the rear of the

ThermoVac (“Vacuum”)

* Set the stir speed to Low.

* Make sure the valve on top of the vacuum chamber is open,

* Turn on the vacuum pump by flicking the switch to the timer position (this runs the

pump continuously for 8 minutes).

* Slowly evacuate the chamber by closing the valve, while pressing gently on the

chamber. The pump will change pitch. Watch the samples as you do this. If they begin

to spit, or bubble over, you’ve gone too far!

Fill the sample cell

Using the long Hamilton syringe …

* Withdraw the water from the sample cell.

* Rinse the cell with water.

* Rinse the cell 4 times with buffer.

* Remove as much buffer from the syringe as you can.

* Draw the degassed, low concentration sample into the syringe.

* Lower the syringe into the cell until it touches the bottom, and raise 1-2 mm.

* Push the sample into the cell in three short bursts. Hopefully this will dislodge any

air bubbles trapped at the top of the cell.

* Using the syringe, withdraw excess solution from the filling tunnel, until the liquid

sits just above the entrance port.

* Clean the syringe thoroughly with distilled water.

Filling the injector

With the injector seated in its holder, on the side of the ITC …

* Transfer the high concentration sample into a glass tube.

* Using the control software, close the Fill port

* Temporarily remove the injector.

* Place the glass tube securely in the holder.

* Carefully replace the injector. The bottom of the stir paddle should be near the

bottom of the glass tube.

* Attach the syringe with flexible tubing to the Fill port of the injector.

* Using the control software, open the Fill port.

* Using the syringe, draw sample into the injector. You may end up with a small air

bubble trapped at the top, just below the Teflon plug. This is okay … you’ll probably

introduce more air if you attempt to dislodge it. Very large or multiple air bubbles are

bad news.

* Using the control software, close the Fill Port

* Using the control software, Hit Purge/Refill twice (to appease the ITC fairies)

* Now remove the injector from its holder and carefully wipe any excess solution from

the stir paddle with a Kimwipe.

*Eject a tiny amount of solution. Using the control software, change the distance to

0.01 (of an inch) and click “Dn” (Down). A drop of liquid should appear at the

injector outlet. Blot this drop away on a Kimwipe.

* Lower the injector carefully into the cell. The fit is tight. Make sure it’s properly

seated.

Now set the run parameters and you’re off.

In the absence of prior information try for 24 injections of 12 uL each, spaced around

5-7 minutes (300 - 420s) apart. If the signal is weak, estimating the baseline

accurately becomes more important, so leave at least 400s between injections. Also

adjust the delay time to ~150s, so you get a decent baseline preceding the first

injection. In this case you’ll probably want to integrate the raw data with our local

analysis software, which will work better than the Origin default.

It’s been standard practice to initiate each run with a small “throwaway injection”,

because the heat observed in the first injection is systematically smaller than expected.

Joel Tellingheusen’s lab have shown that this “first injection anomaly” arises from

backlash in the plunger mechanism following the Purge/Refill steps{Mizoue, 2004,

p05043}. If you make sure to push the plunger down a short distance (as detailed

above), the throwaway injection should not be necessary.

Leave the stirring speed at 300 rpm

Reference power of 20 µCal/sec (may need to adjust for highly exothermic or

endothermic reactions … see pg 47 of the manual)

Cleaning up

It is critical that the instrument be left spotless. I would repeat that for emphasis but

this would be boring.

Cleaning the Cell

1. Set up the vacuum pump for cleaning the cell. Instructions are on Page 51 of

the VP-ITC Manual, if you’re nervous.

2. Flush 10-20 mls of cold water through the cell.

3. Heat 250 mls of water in a microwave until it’s hot (but not boiling). Add 1.25

mls of LA2 detergent, and flush the cell with ~240mls of the hot detergent

solution (Leave a little behind for cleaning the injector)

4. Flush the cell with 500 mls of cold water. Leave the cell filled with water.

Cleaning the Injector

1. Using the control software, open the Fill port.

2. Set up the vaccum pump and connect it to the Fill port using the drying

adapter

3. Place the stir paddle of the injector in a beaker of cold water

4. Draw 5 -10 mls of water through the injector

5. Then consecutively, using the same procedure, draw through 5-10 mls of the

detergent solution, 5-10 mls water, and 5-10 mls of methanol.

6. Finally pull air through the injector for five minutes.

Controls

Heat-of-dilution experiments are necessary controls. Let’s say we have component A

in the syringe and component B in the sample cell. Properly we need to run the

following controls

1. Component A is injected into Buffer.

2. Buffer is injected into Component B.

3. Buffer is injected into Buffer.

These heats should be used to correct the binding data in the following way

Heat from binding of A to B = Heat from titration of A and B - (1) - (2) + (3)

In practice contributions from (2) and (3) are usually small and self-cancelling, so are

usually neglected. But contributions from (1) can be considerable and this

control must be performed, and used to correct the raw data before model fitting.

Analyzing the data

The data analysis can be done using the Origin Software package, which allows

integration of the raw data and fitting of some common models. There is a fairly

decent manual. More on this later …

Common problems and things to avoid

Baseline drifts often indicate slow reactions (usually not binding reactions). Slow

oxidation of DTT is a good example (If you must include a reducing agent, you might

consider the less reactive TCEP.HCl instead).

Poor buffer matching between the solutions in the syringe and in the sample cell will

give rise to large heats of mixing and dilution. These can easily obscure binding heats

for the reaction of interest (see notes on sample preparation above). Particularly

troublesome is a change in solution pH, since heats associated with protonation and

deprotonation can be large.

Booking and paying for use of the instrument.

There is a booking sheet posted near the instrument. Use this to indicate the dates you

intend to use it.

The University of Auckland seeks full cost recovery on all pieces of scientific

equipment over $100000. Some of us think this is a bad idea. No matter. The

outcome is an $80 per day charge for using the VP-ITC. This money goes to the SBS

to offset the depreciation payments the university requires for the instrument. There is

a spreadsheet on the desktop of the computer running the ITC. Please enter your

usage and a university account number. The minimum billing time is a day. You may

use the full 24 hours if it pleases you.

Support at Microcal and Beckman-Coulter

1.Application support

Verna Frasca: vfrasca@microcal.com

Dr William Peters: wpeters@microcal.com

2.Service Queries

service@microcal.com

3.Sales

cshorten@beckman.com

Appendix: Models used for fitting data

A1. One set of binding sites, all identical and independent.

The derivation is discussed in detail in several places ({Freire, 1990, p06334}{Indyk,

1998, p09394},{Velazquez-Campoy, 2004, p05064}). See also the appendix of

MicroCal’s Data Analysis guide. Component A is in the calorimeter cell; Component

B is in the syringe.

If there were just a single binding site then the basic reaction scheme could be written

A + B ? AB

With the equilibrium dissociation (KD) and association (KA) constants governing the

reaction …

KA =

5AB ?

5A ?5B ?

5A ?5B ?

1

KD = K =

5AB ?

A

(1)

(2)

In the case of A having n equivalent and independent binding sites for B we need to

describe the system in terms of the fractional occupation of the binding sites Θ , or

the binding function v (the molar ratio of the amount of ligand bound to the total

amount of acceptor). See chapter 15 of Biophysical Chemistry, by Cantor &

Schimmel, for the development of this idea. We will make use of Θ. By definition v =

nΘ

In this case it can be shown that.

kD =

]1 - H g5B ?

H

(3)

Where kD is the microscopic dissociation constant that characterizes all of the sites.

The total concentrations of A and B (which we know from experiment) are related to

the concentration of free B as follows.

6BT @ = 5B ? + nH [AT ]

(4)

Now if we combine (3) and (4) to eliminate [B] we get

n 6AT @H 2 - (kD + 6BT @ + n 6AT @) H + 6BT @ = 0

(5)

This is a quadratic in Θ, with the relevant solutions given by

(kD + 6BT @ + n 6AT @) - (kD + 6BT @ + n 6AT @) 2 - 4n 6AT @6BT @ (6)

2n 6AT @

The experiment consists of performing a series of injections of B into A. We need to

develop a model describing the heat generated by injection i.

First … we need to know the total concentrations of A & B in the cell after injection

number i. When injecting a certain volume, v, into the cell, the same volume is lost. If

we employ the simplest model of this process … that the solution is ejected before any

mixing can take place then.

6BT @C,i = vi 5B ?s + b 1 - vi l6BT @C,i-1

(7)

6AT @C,i = b 1 - vi l6AT @C,i-1

(8)

VO

VO

VO

Where

[AT] C,i = Total concentration of A in the cell after injection i.

[B] S = Concentration of B in the syringe.

[BT] C,i = Total concentration of B in the cell after injection i.

vi = Volume of the i’th injection.

Vo = Active volume of the calorimeter cell.

Now the heat generated on each injection results from the change in the occupancy of

the binding sites, and the heats resulting from dilution of the individual components.

v

qi = VO ;DHA (nH C,i 6AT @C,i - nH C,i-1 6AT @C,i-1 b 1 - Vi l) + QA + QB E

O

(9)

Where

Qa & Qb = The heats of dilution associated with component A and component B.

ΔHA = The molar enthalpy of binding to a single site.

The corrective factor (1- vi/Vo) arises because of the ligand/acceptor complex that is

ejected from the active volume of the calorimeter cell upon injection of more ligand.

We can measure Qa and Qb by performing suitable experiments (Injecting A and B

into buffer,or vice versa). Usually these will be subtracted from the measured heats qi ,

before model fitting. We can calculate [AT]C,i and [BT]C,i using expressions (7) and (8).

Θ can be calculated using expression (6). Therefore non linear least squares fitting of

the experimental qi using expression (9) can be used to determine n, kd and ΔHA.

A2. Two sets of binding sites, the members of each set identical and

independent.

To be completed

A3. Homo-dimerization

For this experiment we have a molecule in reversible monomer-dimer equilibrium in

the syringe, which we inject into the cell. The accompanying dilution causes

dissociation of the dimer, and this generates or consumes heat.

The basic monomer-dimer reaction scheme can be written

A + A ? A2

The equilibrium dissociation (KD) and association (KA) constants governing this

reaction are …

KD =

5A ?2

(1)

6A2 @

6A @

1

KA = K = 2 2

5A ?

D

(2)

First, let’s be clear on what’s happening in both the syringe and cell. There will

generally be both monomer and dimer present, as dictated by the equilibrium

constant. What we generally know is the total concentration of A … [AT]

6AT @ = 5A ? + 2 6A2 @

(3)

Or equivalently

5A ? = 6AT @ - 2 6A2 @

(4)

6A2 @ = 1 ^6AT @ - 5A ?h

2

(5)

Now, using (4) or (5), we can eliminate either [A] or [A2] from expression (1). For

example if we substitute (4) into (1) and rearrange we get

4 6A2 @2 - ^ 4 6AT @ + KDh6A2 @ + 6AT @2 = 0

(6)

This is a quadratic in [A2], and the solutions are given by

6A2 @ =

(7)

^ 4 6AT @ + KDh ! ^ 4 6AT @ + KDh2 - 16 6AT @2

^ 4 6AT @ + KDh ! 8 6AT @KD + KD2

=

8

8

Expression (7) gives the dimer concentration [A2] in terms of KD and the total protein

concentration [AT]. Also recall from high school math, that although there are two

apparent solutions to the quadratic equation, only one will be real and have physical

meaning.

If we substitute (5) into (1) and rearrange we get the corresponding expression for the

monomer concentration [A].

2

5A ? = -KD ! 8 64AT @KD + KD

(8)

Okay – that’s the warm up. Now we need to think about what happens when we

perform a series of injections. For a start – we need to know the total concentration of

A in the cell, after injection number i.

This question is a little more complicated than it appears, because the VP-ITC is a

perfusion instrument. For every volume that’s injected into the cell a corresponding

volume is ejected. It is assumed that the ejected material is never again involved in

mixing or in the production of heat. We are going to employ the simplest model of

this process, which is that the solution exiting the cell is expelled before any mixing

with the injected solution. In this case the total concentration of A in the cell,

following injection i, is given by …

6AT @C,i = b vi l6AT @S + b 1 - vi l6AT @C,i-1

VO

(9)

VO

Where

[AT] C,i = Total concentration of A in the cell after injection i.

[AT] S = Total concentration of A in the syringe.

vi = Volume of the i’th injection.

Vo = Active volume of the calorimeter cell.

From total concentrations of A in the cell we can calculate the concentrations of

monomer and dimer using (7) and (8).

Now we are in a position to consider the heat generated on each injection i. This is

proportional to the change in the concentration of monomer in the active volume of

the cell, following the injection, due to dimer dissociation. This too, is a little tricky to

consider, so we’ll draw a diagram. Once again we’re employing the simplest model of

the injection, assuming no mixing of the introduced and ejected material

Now by inspection

v

v

Dmonomer = 5A ?C,i - b 1 - Vi l5A ?C,i-1 - b Vi l5A ?S

O

O

(10)

Where

[A]C,i = Concentration of monomers in the cell after injection i.

[A]S = Concentration of monomers in the syringe

vi = Volume of the i’th injection.

Vo = Active volume of the calorimeter cell.

The heat generated on each injection (i) is then

qi = VO DHD Dmonomer + the heat of dilution

(11)

v

v

qi = VO ' DHD c5A ?C,i - b 1 - Vi l5A ?C,i-1 - b Vi l5A ?S m + ^6AT @C,i - 6AT @C,i-1 h qdilute 1

O

O

Where ΔHd is the enthalpy of dimer dissociation (per mol of monomer). The last

term is just the heat of dilution. In contrast to the study of hetero-complex formation,

this quantity is difficult to measure experimentally by running suitable control

experiments, so we have to include it explicitly in the model. It is assumed that the

heat of dilution is a linear function of the change in protein concentration(mol/L).

This is an approximation, but a reasonably decent one.

Now we have everything we need to characterize binding. First for our injection series,

we can determine the total concentration of A in the cell, [AT]C,i using expression (9).

The concentrations of monomer in cell and syringe ([A]C,i and [A]S) can be calculated

from the total concentrations ([AT]C,i and [AT]S) using expression (8). Hence from nonlinear fitting of qi as a function of [AT]C,i, we can get Kd and ΔHd.

References

![[125I] -Bungarotoxin binding](http://s3.studylib.net/store/data/007379302_1-aca3a2e71ea9aad55df47cb10fad313f-300x300.png)