Oral History Panel on the Development and Promotion of the Intel

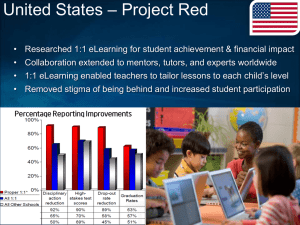

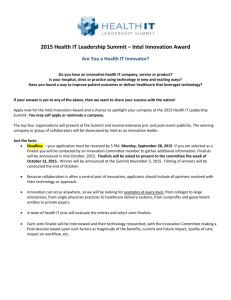

advertisement