Naval Architecture Design Ratios: A Primer for Small Craft

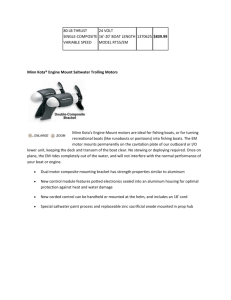

advertisement