Section 5 a extraction and uses of metals

advertisement

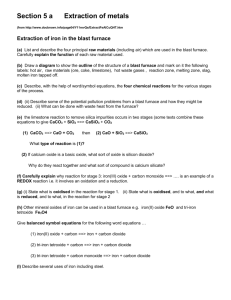

Section 5a: extraction and uses of metals Extraction of metals 5.1 explain how the methods of extraction of the metals in this section are related to their positions in the reactivity series The ease of obtaining a pure metal from its ore depends on the reactivity of the metal. Ore = a mixture of rock which contains a compound with the metal in it. The less reactive metals are easily removed from their ores as it only takes heating to do this. Reactive metals are difficult to obtain as their oxides or salts are difficult to decompose so a lot of energy is needed which is why they can only be reduced by using electrolysis. The unreactive metals do not need extraction as they are found pure in nature although copper is electrolysed further as it needs to be very pure to be used as a conductor of electricity. reactivity series potassium sodium calcium magnesium aluminium zinc iron lead copper silver gold method of extraction reduction using electrolysis reduction by heating with carbon decomposition by heating alone (followed by electrolysis) found pure Extraction of aluminium 5.2 describe and explain the extraction of aluminium from purified aluminium oxide by electrolysis, including i the use of molten cryolite as a solvent and to decrease the required operating temperature ii the need to replace the positive electrodes iii the cost of the electricity as a major factor 5.3 write ionic half-equations for the reactions at the electrodes in aluminium extraction. Ore = bauxite; bauxite is a type of rock which has mainly aluminium oxide but also has some impurities like iron oxide and silica; starting chemical: aluminium oxide conditions: electrolytic cell with graphite electrodes; negative electrode in sides of the cell. aluminium oxide is molten by electrical heating; the large current which is used to electrolyse the aluminium oxide releases heat energy to keep the aluminium oxide molten. to help this process, cryolite is added to lower the operating temperature and the melting point of the mixture. The molten cryolite also acts as a solvent i.e. the aluminium oxide is dissolved in it. very large amounts of current which is why most aluminium smelters are near power stations and why this is an expensive process; after some time the positive graphite electrodes need to be replaced as they react with oxygen producing carbon dioxide. Section 5 a extraction of metals 1|Page Electrolytic cell used to electrolyse aluminium oxide: Label all the parts and add the equations of all the reactions occurring in the electrolytic cell Products: anode Oxygen and carbon dioxide (formed when the oxygen reacts with the graphite rods; a reaction made easy by the large amount of heat energy; carbon electrodes get eroded away and need to be replaced every so often) 2O2- (l) O2 (g) + 4e- cathode Molten aluminium Al3+(l) + 3e- Al (s) 4Al3+(l) + 12e- 4Al (s) 6O2- (l) 3O2 (g) + 12e- overall equation : 4Al3+(l) + 6O2- (l) 4Al (s) + 3O2 (g) or 2Al2O3 4Al (s) + 3O2 (g) Extraction of iron 5.4 describe and explain the main reactions involved in the extraction of iron from iron ore (haematite), using coke, limestone and air in a blast furnace Iron extraction is carried out in a blast furnace using the following raw materials: raw material coke haematite limestone hot air what it is used for? As fuel and to provide the carbon to make the reducing agent carbon monoxide Contains the iron oxide To remove impurities Provides the heat and oxygen to make the reducing agent Section 5 a extraction of metals 2|Page On the diagram of the blast furnace below label all chemical. The table summarises the five reactions which go on in the blast furnace. Reactions Equation Carbon burning to make carbon dioxide; this is important because it provides the heat for the reduction. C (s) + O2 (g) Carbon dioxide reacting with carbon (at the top of the furnace there is little oxygen) to form carbon monoxide C (s) + CO2 (g) Carbon monoxide reduces the iron oxide (this is the main reaction) Fe2O3 (s) + 3CO (g) Calcium carbonate decomposing CaCO3 (s) CaO(s) + CO2 (g) (waste gas) Calcium oxide reacting with silicon dioxide to form slag CaO (s) + SiO2 (s) Section 5 a extraction of metals CO2 (g) 2CO (g) 2Fe (s) + 3CO2 (g) CaSiO3 (s) 3|Page Uses of iron 5.5 explain the uses of aluminium and iron, in terms of their properties The pig iron obtained from the blast furnace is still impure as there is about 5% carbon, silicon, phosphorus and sulfur in it which makes it rather hard and brittle and not very useful. Its properties are modified by first lowering the amount of carbon, silicon, phosphorus and sulfur in it and then alloying it with other elements. When that happens the product is called steel. There are hundreds of alloys of steel, each one with its own properties (some only differ in the carbon content). Conversion to steel (=alloy); the properties of iron are changed by the controlled addition of other elements like carbon, nickel, chromium, tungsten, etc. Type of steel Typical composition Properties Mild steel 99.5% iron, 0.5 % carbon Easily worked, strong as it has lost most brittleness Hard steel 99 % iron, 1 % carbon Tough and brittle Stainless steel 74% iron, 18% chromium, 8% nickel Tough, does not corrode Tungsten steel 95% iron, 5 % tungsten Tough, hard, even at high temperatures. Uses Car bodies and machinery Chemical plant and cutlery Uses of aluminium Aluminium is used for the following: in the manufacture of aircraft, car bodies, step ladders, … because of its strength and low density; in food containers because of its resistance to corrosion (because of its protective aluminium oxide layer) it does not react with the food or drink; also aluminium window frames rely on this property. in overhead cables because of its low density and good electrical conductivity. aluminium is also very malleable Section 5 a extraction of metals 4|Page