high productive filtered direct current cathodic vacuum

NANOTECHNOLOGY (RESEARCH AND TECHNOLOGY)

DEVELOPMENT OF NOVEL NANOSTRUCTURAL

Cu-W

COMPOSITES

Description

The creation of novel, high dense, long body cylindrical

Cu-20%W composites consisting from nanostructural W phase is carried out using hot shock wave consolidation technology with intensity of compression up to 10GPa.

The temperature of consolidation was equal to 800˚C.

The new approach to use the hot shock wave consolidation technology for nanoscale powders makes it possible to fabricate high dense, long body bulk nanostructural compositions. The novelty of this new approach hinges on the application of hot shock-wave consolidation technology and compression of nanoscale W – Cu powders in a cylindrical geometry in hot conditions up to recrystallization temperature of W (1200˚C).

Figure 1

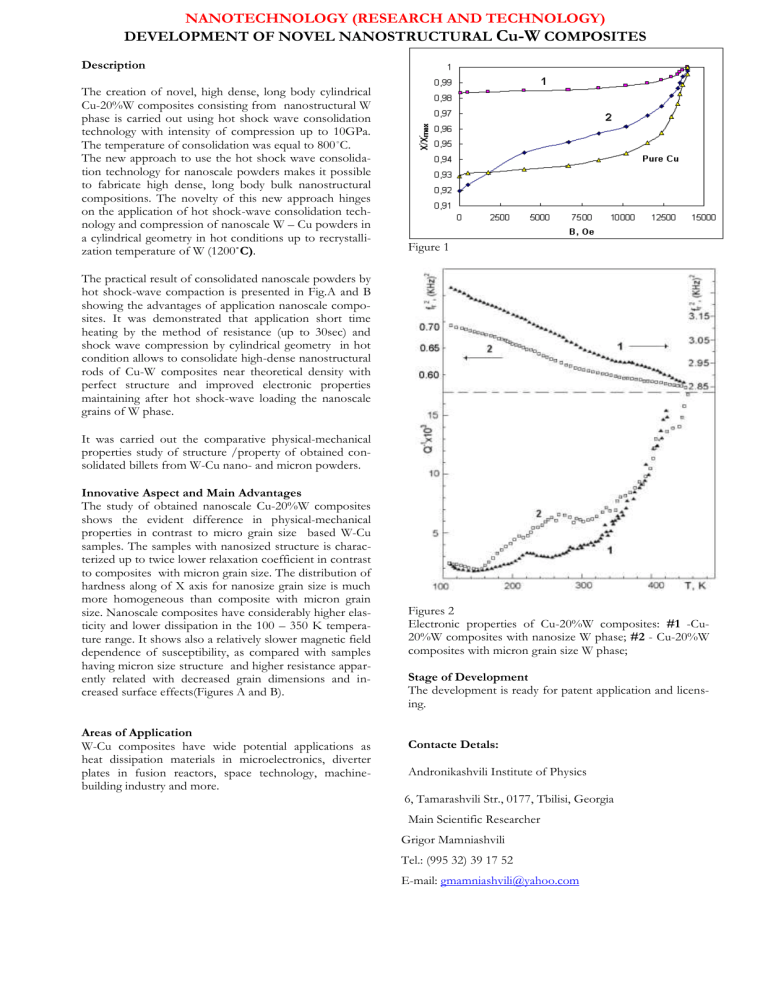

The practical result of consolidated nanoscale powders by hot shock-wave compaction is presented in Fig.A and B showing the advantages of application nanoscale composites. It was demonstrated that application short time heating by the method of resistance (up to 30sec) and shock wave compression by cylindrical geometry in hot condition allows to consolidate high-dense nanostructural rods of Cu-W composites near theoretical density with perfect structure and improved electronic properties maintaining after hot shock-wave loading the nanoscale grains of W phase.

It was carried out the comparative physical-mechanical properties study of structure /property of obtained consolidated billets from W-Cu nano- and micron powders.

Innovative Aspect and Main Advantages

The study of obtained nanoscale Cu-20%W composites shows the evident difference in physical-mechanical properties in contrast to micro grain size based W-Cu samples. The samples with nanosized structure is characterized up to twice lower relaxation coefficient in contrast to composites with micron grain size. The distribution of hardness along of X axis for nanosize grain size is much more homogeneous than composite with micron grain size. Nanoscale composites have considerably higher elasticity and lower dissipation in the 100 – 350 K temperature range. It shows also a relatively slower magnetic field dependence of susceptibility, as compared with samples having micron size structure and higher resistance apparently related with decreased grain dimensions and increased surface effects(Figures A and B).

Areas of Application

W-Cu composites have wide potential applications as heat dissipation materials in microelectronics, diverter plates in fusion reactors, space technology, machinebuilding industry and more.

Figures 2

Electronic properties of Cu-20%W composites: #1 -Cu-

20%W composites with nanosize W phase; #2 - Cu-20%W composites with micron grain size W phase;

Stage of Development

The development is ready for patent application and licensing.

Contacte Detals:

Andronikashvili Institute of Physics

6, Tamarashvili Str., 0177, Tbilisi, Georgia

Main Scientific Researcher

Grigor Mamniashvili

Tel.: (995 32) 39 17 52

E-mail: gmamniashvili@yahoo.com