CURRICULUM VITAE - Pioneer Selection

advertisement

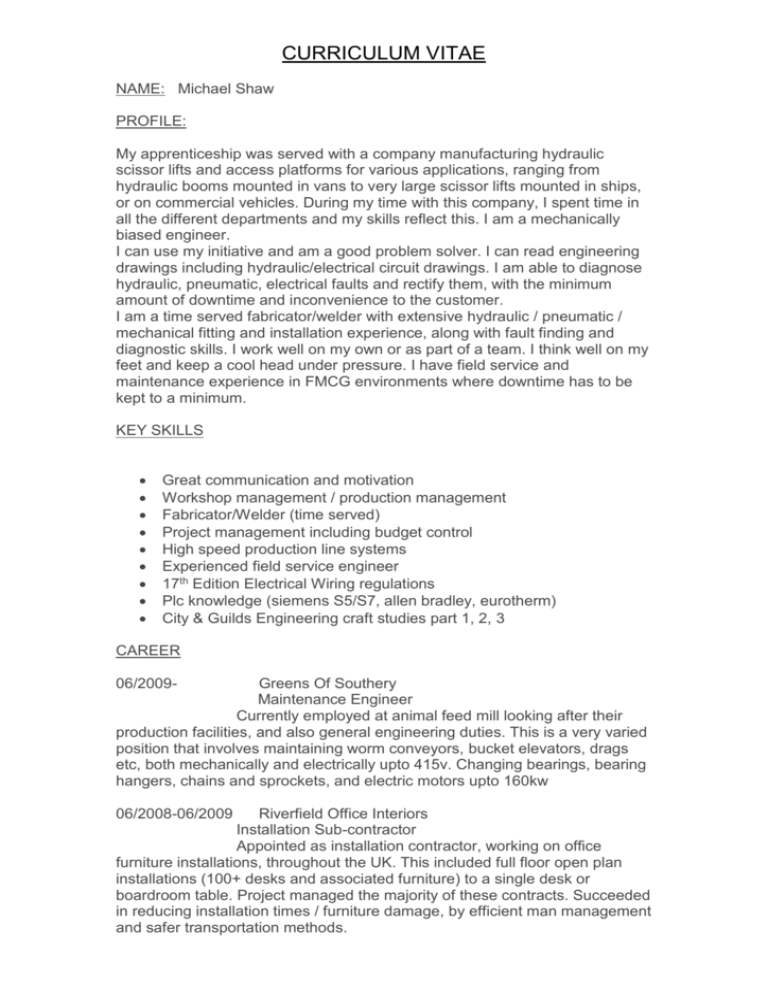

CURRICULUM VITAE NAME: Michael Shaw PROFILE: My apprenticeship was served with a company manufacturing hydraulic scissor lifts and access platforms for various applications, ranging from hydraulic booms mounted in vans to very large scissor lifts mounted in ships, or on commercial vehicles. During my time with this company, I spent time in all the different departments and my skills reflect this. I am a mechanically biased engineer. I can use my initiative and am a good problem solver. I can read engineering drawings including hydraulic/electrical circuit drawings. I am able to diagnose hydraulic, pneumatic, electrical faults and rectify them, with the minimum amount of downtime and inconvenience to the customer. I am a time served fabricator/welder with extensive hydraulic / pneumatic / mechanical fitting and installation experience, along with fault finding and diagnostic skills. I work well on my own or as part of a team. I think well on my feet and keep a cool head under pressure. I have field service and maintenance experience in FMCG environments where downtime has to be kept to a minimum. KEY SKILLS Great communication and motivation Workshop management / production management Fabricator/Welder (time served) Project management including budget control High speed production line systems Experienced field service engineer 17th Edition Electrical Wiring regulations Plc knowledge (siemens S5/S7, allen bradley, eurotherm) City & Guilds Engineering craft studies part 1, 2, 3 CAREER 06/2009- Greens Of Southery Maintenance Engineer Currently employed at animal feed mill looking after their production facilities, and also general engineering duties. This is a very varied position that involves maintaining worm conveyors, bucket elevators, drags etc, both mechanically and electrically upto 415v. Changing bearings, bearing hangers, chains and sprockets, and electric motors upto 160kw 06/2008-06/2009 Riverfield Office Interiors Installation Sub-contractor Appointed as installation contractor, working on office furniture installations, throughout the UK. This included full floor open plan installations (100+ desks and associated furniture) to a single desk or boardroom table. Project managed the majority of these contracts. Succeeded in reducing installation times / furniture damage, by efficient man management and safer transportation methods. 2007-2008 Standen Engineering Ltd Fabricator / Welder Duties included general welding / fabrication on mild steel and stainless steel sub-assemblies, for agricultural machines. Other duties included mechanical fitting, assembling the machines on production line. 2004-2007 Silverstreak Express Freelance Courier Started my own courier business offering same day UK and European delivery service. Managed all bookings and consistently delivered on or before time deadline with great customer service. 2002-2004 Central Hydraulics Hydraulic / Mechanical fitter Employed initially as a fabricator / welder, but became more involved with reactive breakdowns on specialist commercial vehicles based airside at London’s three main airports. This involved tight deadlines, if vehicles were servicing aircraft when the breakdown took place, as thousands of pounds were lost if the aircraft did not take off at its allocated time. I thrived on this pressure and was able to relate to the customer and their concerns, whilst giving the breakdown my full attention. I was then appointed workshop foreman, although I still spent a large part of my time assisting with breakdowns. The company also had a contract with Grundon Recycling, looking after their waste compactors and paper balers. All of these vehicles/machines were PLC controlled and I undertook a lot of Plc fault finding and problem rectification, along with hydraulics, pneumatics and diesel / hgv fitting. 2000-2002 Faberdex Installations Ltd Production Manager Appointed initially as production manager, looking after approximately 30 production staff manufacturing window, door and roof systems. After 10 months I was appointed Special Projects manager where I was involved with any “one off” projects from the manufacture to final installation. These projects included large sliding glass wall systems and large stainless steel sliding roofs. I managed each job from the ordering of parts and budget control to the hand over to the customer on or before the agreed time. 1996-2000 Ram Power Ltd Field Service Engineer My duties included attending various sites providing PPM and reactive breakdown cover. The work involved hydraulic lifting equipment and associated systems mainly in FMCG environments, such as food production, car production and breweries. All of these are fast paced and environments where downtime has to be kept to a minimum. This was a true multi-skilled role with hydraulics, pneumatics, plc’s and electrical systems, all requiring fault finding and remediation. 1995-1996 Industrial Door Systems Ltd Industrial door fitter Duties included the installation / repair of roller shutter doors, sectional doors, fast action doors, also reactive and PPM breakdown cover. This involved mechanical fitting, hydraulic, electrical fault finding and diagnostics. 1995-1995 Ram Power Ltd Fitter Duties included hydraulic ram and component assembly and also power unit and hydraulic system assembly. Also involved with the welding of the hydraulic cylinders. Laid off due to a lost contract after 5 months, but asked to go back the following year. 1990-1995 Security Air Express 7.5t Lorry driver Delivery of goods across UK and Europe 1989-1990 Gibraltar Maintenance Fitter Duties involved the welding and fabrication of steel fencing, gates and security grilles in the naval shipyards. 1981-1989 Power Lifts Ltd Fabricator / Welder Taken on as an apprentice for a 5 year course and my duties included welding, hydraulics, fitting etc within the factory and also out on site throughout the UK and mainland Europe QUALIFICATIONS 1976-1981 9 CSE’s grade 2 – 5 1981-1985 City & Guilds Engineering craft studies part 1, 2, 3 1998 BSEN: 287 Part 1: 1992 Flat Rotated Mig Pipe Welding 1999 Rexroth: Hydraulic components, system faultfinding. 2009 I.E.E. 17th EDITION wiring regulations PERSONAL Telephone: Home tel/fax: 01353-777174 Mobile: 07948-314372 E-Mail: jackie_mick@hotmail.co.uk Driving Licence: UK Full (clean, passed September 1982) Counter balance fork-lift (2009)