Some recommendations for the operation of solar-dryers

advertisement

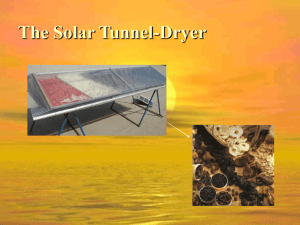

Some recommendations for the operation of solar-dryers Walter E.L. Spiess c/o Karlsruhe Institut für Technologie (KIT) Institut für Bio- und LebensmitteltechnikKaiserstr. 12 D-76131 Karlsruhe Germany Donald G. Mercer Department of Food Science, University of Guelph Kemptville Campus, 830 Prescott Street, Kemptville Ontario K0G 1J0 1. General considerations Before the decision for a dryer is formed the climatic, technical and economic environment in which the dryer will be operated has to be analyzed. Not all dryers fit for all produce. Fruits are in general dried for export, in such cases driers which can handle up to 100 kg daily and more are required in order to develop a sustainable business situation. Dried vegetables are mainly suited for local markets; in such cases smaller dryers with a daily drying capacity up to 10 kg are sufficient. It has also to be considered that fresh fruits and vegetable finished for drying (cutting, slicing etc.) are subject to fast deterioration in hot climates, they should therefore be dried during a drying cycle to a water content which allows avoiding spoilage during any interruption of the drying process. Some important questions are: Which produce will mainly be dried; Are the climatic conditions during the harvesting period favorable for drying (sunshine duration around 6 to 8 hours) In case fruits e.g. mango, pineapple, banana are dried for export are the dryer capacity and the produce sources of a size to allow for a substantial and steady market supply, furthermore · Is the operating team able to cope with minor technical problems and can the team observe International quality standards e.g. CODEX STANDARD FOR DRIED APRICOTS CODEX STAN 130-1981 Page 1 of 5. · Are there packaging facilities for packaging and storage facilities (dark and possibly cool/not humid) for an intermediate storage of dried products available? 2. The drying equipment and the drying operation The dryer should be operated in optimal technical conditions, it should always be positioned in full sunlight, air inlets and outlets should be free of any obstructions. Air inlets should be protected from dust and any fumes. Trays on which the product is positioned for drying and the whole interior of the dryer should always be clean and free from any residues. In order to assure optimal hygienic conditions measures have to be taken to keep especially insects and rodents out of the dryer. Special care has to given to the transparent cover it should be clean, free of dirt and dust and tightly stretched over the dryer frame also when the dryer is not in operation. Further points to consider are: It is not advisable to operate dryers when the environmental relative humidity very high since the relative humidity of the air used for drying has a pronounced effect on the water removal capacity of the air. The linear velocity of the air within the drying chamber is an important consideration for sweeping away the saturated stagnant boundary layer around the material being dried. Without sufficient air movement, drying will be slow which may allow time for spoilage to occur. The temperature of the drying air should optimally be in the range of 50°C to 55°C for most fruits and vegetables. For drying herbs, 45°C is a reasonable maximum. Temperatures that are too high (above 60°C) may cause case hardening which will reduce the effectiveness of the dryer and lead to future problems with the dried material. The dryer trays and other food contact surfaces should be made of materials appropriate for this purpose e.g. wood or stainless steel. When loading the fresh product on the trays it is recommended not to exceed a thickness of about 0.5 to 0.6 cm since it allows for good removal of the water and diffusion to the surface while giving a good thickness of finished product. In case of products with a waxy cuticle e.g. berries it is in addition helpful to slice the products or disrupt the outer surface otherwise. The product should be monitored frequently during the drying process. It should be turned at regular intervals and racks may need to be rotated and their positions changed to enhance drying uniformity. The direction of airflow should be across the surfaces of the material being dried rather than from a bottom up direction through the dryer. If this cannot be avoided, then a solar-powered fan inside the dryer may create horizontal flow patterns (which will also address the stagnant boundary layer problems). In cases where the material cannot be dried in a single day, appropriate measures must be taken to handle the partially dried food for overnight storage. This may be done by sealing off the inlets and outlets to the dryer to prevent the ingress of humid air during the cooler night-time hours or removing the material and storing it in another area overnight. Such measures may be especially required when drying products with high moisture contents (such as tomatoes with ca. 95% wet basis moisture). Those products offer additional challenges not offered by products like apples or mangoes (ca. 84% to 85% wet basis moistures). The drying times of products with high moisture content will be much longer than the ones of products with moderate water content. Relevant is also that materials with high moisture content have a lower yield (kg of dried product per 100 kg of fresh product) compared with products of moderate moisture content; 100 kg of tomatoes at 95% moisture will give about 6 kg of finished dried product whereas 100 kg of fresh apples at 84% moisture will deliver over 17 kg of dried product at 10% moisture. 3. Fruits/vegetable suited for drying Fruits Apples, Apricots, Banana, Dates, Figs, Lemon, Mango, Oranges, Papaya, Peaches, Pears, Pineapple, Plumes, and many other. Vegetable Broccoli, Cabbage, Carrots, Celery, Chives, Corn, Garlic, Green Beans, Edible Fungi and Mushrooms, Jalapeno, Leeks, Okra, Onions, Peas, Peppers, Potatoes, Shallots, Spinach, Sweet Potatoes, Tomatoes, Zucchini, and many other. Green vegetable and potatoes should be blanched before drying. Peppers and other vegetable used as condiments are not suited for drying. 4. Drying end point. The produces have to be dried to different water contents in order to avoid deterioration. A good indication for a stable product is once the structure is between a leathery and brittle; products with a sugar content should be close to leathery where as vegetable should be close to brittle. 5. Final Remark In case the solar dryer is part of a commercial drying operation it should be considered to safeguard the operation by including a “classical” dryer in the train of dryers. Under optimal conditions the “classical” dryer could be energized by biogas generated from biodegradable waste. IUFoST Food Security Task Force/ WELS/DGM/2012-03-02