vibration and seismic controls for hvac piping and equipment

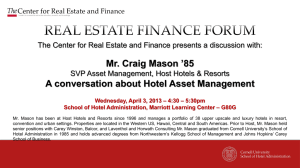

advertisement

Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. This Product MasterSpec Section is licensed by ARCOM to Mason Industries, Inc ("Licensee"). This Product MasterSpec Section modifies the original MasterSpec text, and does not include the full content of the original MasterSpec Section. Revisions made to the original MasterSpec text are made solely by the Licensee and are not endorsed by, or representative of the opinions of, ARCOM or The American Institute of Architects (AIA). Neither AIA nor ARCOM are liable in any way for such revisions or for the use of this Product MasterSpec Section by any end user. A qualified design professional should review and edit the document to suit project requirements. For more information, contact Mason Industries, Inc, 350 Rabro Drive, Hauppauge, NY 11788; phone: (631) 348-0282; fax: (631) 348-0279; Website: www.mason-ind.com; e-mail: info@mason-ind.com. For information about MasterSpec contact ARCOM at (800) 424-5080 or visit www.arcomnet.com. For information about MasterSpec contact ARCOM at (800) 424-5080 or visit www.MasterSpec.com. Copyright 2011 by The American Institute of Architects (AIA) Exclusively published and distributed by Architectural Computer Services, Inc. (ARCOM) for the AIA SECTION 230548 - VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING AND EQUIPMENT This Section uses the term "Architect." Change this term to match that used to identify the design professional as defined in the General and Supplementary Conditions. Verify that Section titles referenced in this Section are correct for this Project's Specifications; Section titles may have changed. PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. This Section includes the following: Adjust list below to suit Project. 1. 2. 3. 4. Isolation pads. Isolation mounts. Restrained elastomeric isolation mounts. [Freestanding] [Restrained] [Freestanding and restrained] spring isolators. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 1 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 1.3 Housed spring mounts. Elastomeric hangers. Spring hangers. Spring hangers with vertical-limit stops. Pipe riser resilient supports. Resilient pipe guides. [Freestanding] [Restrained] [Freestanding and restrained] air-mounting system. Restrained vibration isolation roof-curb rails. Seismic snubbers. Restraining braces and cables. [Steel] [Inertia] [Steel and inertia], vibration isolation equipment bases. Flexible piping connectors and hoses for equipment connections. DEFINITIONS Retain abbreviations that remain after this Section has been edited. A. IBC: International Building Code. B. ICC-ES: ICC-Evaluation Service. C. OSHPD: Office of Statewide Health Planning and Development for the State of California. 1.4 PERFORMANCE REQUIREMENTS Retain first paragraph and subparagraphs below for outdoor equipment. A. Wind-Restraint Loading: Obtain values for items in subparagraphs below from Project structural engineer or from SEI/ASCE 7. 1. 2. 3. B. Basic Wind Speed: <Insert value>. Building Classification Category: [I] [II] [III] [IV]. Minimum 10 lb/sq. ft. (48.8 kg/sq. m) multiplied by the maximum area of the HVAC component projected on a vertical plane that is normal to the wind direction, and 45 degrees either side of normal. Seismic-Restraint Loading: Obtain values for items in subparagraphs and associated subparagraphs below from Project structural engineer or from SEI/ASCE 7. If the code at Project site is other than the IBC or NFPA 5000, revise parameters to comply with applicable code. Specify design spectral response acceleration at short periods (0.2 second) and at 1 second based on site class in subparagraph below. Typical values range from 2 to 200 percent. Design spectral response acceleration is required for seismic force calculations to size seismic restraints. For each seismic restraint, include component importance factor, component response modification factor, and component amplification factor in the HVAC Vibration-Control and Seismic-Restraint Device Schedule. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 2 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 1. Site Class as Defined in the IBC: [A] [B] [C] [D] [E] [F]. In subparagraph below, retain Seismic Use Group or Building Category for Project structure from three classifications defined in the IBC. 2. Assigned Seismic Use Group or Building Category as Defined in the IBC: [I] [II] [III]. Retain first three subparagraphs below if these values are not included in the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. Factors below often vary among supported equipment. However, it is possible to specify maximum values for these factors for various classes of equipment or for all equipment instead of scheduling each piece of equipment. a. b. c. 3. 4. 1.5 Component Importance Factor: [1.0] [1.5] <Insert value>. Component Response Modification Factor: [1.5] [2.5] [3.5] [5.0] <Insert value>. Component Amplification Factor: [1.0] [2.5] <Insert value>. Design Spectral Response Acceleration at Short Periods (0.2 Second): <Insert percent>. Design Spectral Response Acceleration at 1-Second Period: <Insert percent>. ACTION SUBMITTALS A. Product Data: For the following: 1. 2. Include rated load, rated deflection, and overload capacity for each vibration isolation device. Illustrate and indicate style, material, strength, fastening provision, and finish for each type and size of seismic-restraint component used. See Evaluations for a discussion on seismic-restraint capacities and rating services. a. b. 3. Tabulate types and sizes of seismic restraints, complete with report numbers and rated strength in tension and shear as evaluated by [an evaluation service member of ICC-ES] [OSHPD] [an agency acceptable to authorities having jurisdiction]. Annotate to indicate application of each product submitted and compliance with requirements. Interlocking Snubbers: Include ratings for horizontal, vertical, and combined loads. Paragraph below is defined in Section 013300 "Submittal Procedures" as a "Delegated-Design Submittal." Retain if Work of this Section is required to withstand specific design loads and design responsibilities have been delegated to Contractor or if structural data are required as another way to verify compliance with performance requirements. Professional engineer qualifications are specified in Section 014000 "Quality Requirements." B. Delegated-Design Submittal: For vibration isolation and seismic-restraint details indicated to comply with performance requirements and design criteria, including analysis data signed and sealed by the qualified professional engineer employed by the supplier for a minimum of 5 years who is responsible for their preparation. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 3 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 1. Design Calculations: Calculate static and dynamic loading due to equipment weight and operation, seismic[ and wind] forces required to select vibration isolators, seismic[ and wind] restraints, and for designing vibration isolation bases. a. 2. 3. Coordinate design calculations with wind load calculations required for equipment mounted outdoors. Comply with requirements in other Sections for equipment mounted outdoors. Riser Supports: Include riser diagrams and calculations showing anticipated expansion and contraction at each support point, initial and final loads on building structure, spring deflection changes, and seismic loads. Include certification that riser system has been examined for excessive stress and that none will exist. Vibration Isolation Base Details: Detail overall dimensions, including anchorages and attachments to structure and to supported equipment. Include auxiliary motor slides and rails, base weights, and equipment static loads. Retain subparagraph and associated subparagraphs below only if seismic design requirements apply but calculations have not been made and details or charts on Drawings do not describe seismic restraints in detail. Retaining subparagraph will require Contractor to submit seismic-restraint Delegated-Design Drawings prepared by a professional engineer. Revise to suit local requirements. Retain option in subparagraph and first associated subparagraph below if Project includes equipment mounted outdoors. 4. Seismic[- and Wind]-Restraint Details: a. b. Design Analysis: To support selection and arrangement of seismic[ and wind] restraints. Include calculations of combined tensile and shear loads. Details: Indicate fabrication and arrangement. Detail attachments of restraints to the restrained items and to the structure. Show attachment locations, methods, and spacings. Identify components, list their strengths, and indicate directions and values of forces transmitted to the structure during seismic events. Indicate association with vibration isolation devices. Retain first subparagraph below if Project includes equipment mounted outdoors. c. Coordinate seismic-restraint and vibration isolation details with wind-restraint details required for equipment mounted outdoors. Comply with requirements in other Sections for equipment mounted outdoors. d. Preapproval and Evaluation Documentation: By [an evaluation service member of ICC-ES] [OSHPD] [an agency acceptable to authorities having jurisdiction], showing maximum ratings of restraint items and the basis for approval (tests or calculations). Commerical trade organizations are not an acceptable evaluation service. 1.6 INFORMATIONAL SUBMITTALS Retain paragraph below if seismic bracing of piping, ducts, equipment, and other HVAC system components will be installed in congested areas. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 4 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. A. Coordination Drawings: Show coordination of seismic bracing for HVAC piping and equipment with other systems and equipment in the vicinity, including other supports and seismic restraints. Coordinate paragraph below with qualification requirements in Section 014000 "Quality Requirements" and as supplemented in "Quality Assurance" Article. B. Qualification Data: For [professional engineer] [and] [testing agency]. Retain paragraph below if procedures for welder certification are retained in "Quality Assurance" Article. C. Welding certificates or certification that all welding meets Mason Industries' welding standards. Retain option in paragraph below if authorities having jurisdiction require independent testing. D. Air-Mounting System Performance Certification: Include natural frequency, load, and damping data. Retain paragraph below if Contractor is responsible for field quality-control testing. E. 1.7 Field quality-control test reports. CLOSEOUT SUBMITTALS Retain paragraph below for air-mounting systems. A. 1.8 Operation and Maintenance Data: maintenance manuals. For air-mounting systems to include in operation and QUALITY ASSURANCE If an independent testing agency is required, see Section 014000 "Quality Requirements" for general testing and inspecting agency qualification requirements. If additional control is needed, use first paragraph below to specify 29 CFR 1910.7. 29 CFR 1910.7 defines a nationally recognized testing laboratory as it applies to testing and inspecting for safety, and lists, labels, or accepts equipment and materials that meet certain OSHA criteria. Retain first paragraph below if Contractor selects testing agency. A. Testing Agency Qualifications: An independent agency, with the experience and capability to conduct the testing indicated, that is a nationally recognized testing laboratory (NRTL) as defined by OSHA in 29 CFR 1910.7, and that is acceptable to authorities having jurisdiction. B. Comply with seismic-restraint requirements in the IBC unless requirements in this Section are more stringent. Delete first paragraph below if no welding. Retain "Welding certificates" Paragraph in "Informational Submittals" Article if retaining below. AWS states that welding qualifications remain in effect indefinitely unless welding personnel have not welded for more than six months or there is a specific reason to question their ability. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 5 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. C. Welding: Qualify procedures and personnel according to AWS D1.1/D1.1M, "Structural Welding Code - Steel," or certify that all factory fabricated items meet Mason Industries' welding standards. D. Seismic-restraint devices shall have horizontal and vertical load testing and analysis and shall bear anchorage preapproval OPA number from OSHPD, preapproval by ICC-ES, or preapproval by another agency acceptable to authorities having jurisdiction, showing maximum seismic-restraint ratings. Ratings based on testing are preferred to ratings based on calculations. If preapproved ratings are not available, submittals based on testing witnessed by a qualified independent professional engineer are preferred. Calculations (including combining shear and tensile loads) to support seismic-restraint selection and anchorage must be signed and sealed by a qualified professional engineer. PART 2 - PRODUCTS See Editing Instruction No. 1 in the Evaluations for cautions about naming manufacturers and products. Retain one of three paragraphs and list of manufacturers below. See Section 016000 "Product Requirements." 2.1 VIBRATION ISOLATORS Copy paragraph and subparagraph below for each type of pad configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. A. Pads <Insert drawing designation>: 3/4-inch (19-mm) thick with a load distribution plate of sufficient stiffness for uniform loading over pad area, molded with a nonslip pattern, and factory cut to sizes that match requirements of supported equipment. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason Super WM Pads or a comparable product by one of the following: a. b. 2. 3. Kinetics Noise Control. Vibration Eliminator Co., Inc. Resilient Material: Oil- and water-resistant neoprene. Anchor-Bolt Grommets: Neoprene, Mason Type HG Copy paragraph and subparagraphs below for each type of mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. B. Neoprene Mounts <Insert drawing designation>: Double-deflection type, with a molded, oilresistant neoprene isolator elements with an encapsulated steel washer with factory tapped hole for bolting to equipment and with encapsulated baseplate with factory drilled holes for bolting to structure. Color-code or otherwise identify to indicate capacity range. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 6 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason ND mountings or comparable product by one of the following: a. b. 2. Kinetics. Vibration Eliminator. Materials: Oil resistant molded neoprene. Copy paragraph and subparagraphs below for each type of restrained mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. C. Restrained Neoprene Mounts <Insert drawing designation>: All-directional mountings with seismic restraint. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason BR mountings or comparable product by one of the following: a. b. 2. 3. Kinetics. Vibration Eliminator. Materials: Cast-ductile-iron or welded steel housing containing two separate and opposing, oil-resistant neoprene elements that prevent central threaded element and attachment hardware from contacting the housing during normal operation. Neoprene: Shock-absorbing materials compounded according to the standard for bridgebearing neoprene as defined by AASHTO. Copy paragraph and subparagraphs below for each type of spring isolator configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. D. Spring Isolators <Insert drawing designation>: Freestanding, laterally stable, open-spring isolators. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SLF or comparable product by one of the following: a. b. 2. Kinetics. Vibration Eliminator. Outside Spring Diameter: Not less than 80 percent of the compressed height of the spring at rated load. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 7 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 3. 4. 5. 6. 7. Minimum Additional Travel: 50 percent of the required deflection at rated load. Lateral Stiffness: More than 80 percent of rated vertical stiffness. Overload Capacity: Support 200 percent of rated load, fully compressed, without deformation or failure. Baseplates: Factory bonded to 1/4-inch (6-mm) thick, rubber isolator pad attached to baseplate underside. Baseplates shall limit floor load to 500 psig (3447 kPa). Neoprene cup with molded steel washer is an acceptable alternate. Top Cup and Adjustment Bolt: Threaded top plate with adjustment bolt and cap screw to fasten and level equipment. Copy paragraph and subparagraphs below for each type of restrained spring isolator configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. E. Restrained Spring Isolators <Insert drawing designation>: Freestanding, steel, open-spring isolators with seismic or limit-stop restraint. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SLR or SLRS or comparable product by one of the following: a. b. 2. 3. 4. 5. 6. 7. 8. Kinetics. Vibration Eliminator. Housing: Steel with resilient vertical-limit stops to prevent spring extension due to weight being removed; a factory-drilled baseplate with adjustable equipment mounting and leveling bolt that acts as blocking during installation. Restraint: Seismic or limit stop as with all-directional molded neoprene bushings and 1/4" airgap. Outside Spring Diameter: Not less than 80 percent of the compressed height of the spring at rated load. Minimum Additional Travel: 50 percent of the required deflection at rated load. Lateral Stiffness: More than 80 percent of rated vertical stiffness. Overload Capacity: Support 200 percent of rated load, fully compressed, without deformation or failure. Spring element complete with adjustment bolt and baseplate with neoprene pad or cup. Copy paragraph and subparagraphs below for each type of housed spring mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. F. Housed Spring Mounts <Insert drawing designation>: Housed spring isolator with integral seismic snubbers. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SSLFH or comparable product by one of the following: VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 8 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. a. b. 2. 3. 4. Kinetics. Vibration Eliminator. Housing: Ductile-iron or steel housing to provide all-directional seismic restraint. Base: Factory drilled for bolting to structure. Snubbers: Vertically adjustable to allow a maximum of 1/4-inch (6-mm) travel up or down before contacting a resilient collar. Copy paragraph and subparagraphs below for each type of elastomeric hanger configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. G. Elastomeric Hangers <Insert drawing designation>: Hangers shall consist of rigid steel frames containing a steel washer reinforced neoprene element on the bottom. The neoprene element shall have a neoprene bushing projecting through the steel box. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason HD hangers or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. Copy paragraph and subparagraphs below for each type of spring hanger configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. H. Spring Hangers <Insert drawing designation>: Combination coil-spring and elastomericinsert hanger with spring and insert in compression. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason 30N or comparable product by one of the following: a. b. 2. 3. 4. 5. 6. Kinetics. Vibration Eliminator. Frame: Steel, fabricated for connection to threaded hanger rods and to allow for a maximum of 30 degrees of angular hanger-rod misalignment without binding or reducing isolation efficiency. Outside Spring Diameter: Not less than 80 percent of the compressed height of the spring at rated load. Minimum Additional Travel: 50 percent of the required deflection at rated load. Lateral Stiffness: More than 80 percent of rated vertical stiffness. Overload Capacity: Support 200 percent of rated load, fully compressed, without deformation or failure. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 9 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 7. Elastomeric Element: Molded, oil-resistant rubber or neoprene. Steel-washer-reinforced cup to support spring and bushing projecting through bottom of frame. Copy paragraph and subparagraphs below for each type of spring hanger with vertical-limit stop configuration required for Project. Use drawing designation and coordinate with the HVAC VibrationControl and Seismic-Restraint Device Schedule on Drawings. I. Spring Hangers with Vertical-Limit Stop <Insert drawing designation>: Combination coilspring and elastomeric-insert hanger with spring and insert in compression and with a verticallimit stop. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason RW30N or PC30NS or comparable product by one of the following: a. b. 2. 3. 4. 5. 6. 7. 8. Kinetics. Vibration Eliminator. Frame: Steel, fabricated for connection to threaded hanger rods and to allow for a maximum of 30 degrees of angular hanger-rod misalignment without binding or reducing isolation efficiency. Outside Spring Diameter: Not less than 80 percent of the compressed height of the spring at rated load. Minimum Additional Travel: 50 percent of the required deflection at rated load. Lateral Stiffness: More than 80 percent of rated vertical stiffness. Overload Capacity: Support 200 percent of rated load, fully compressed, without deformation or failure. Elastomeric Element: Molded, oil-resistant rubber or neoprene. Adjustable Vertical Stop: One piece molded steel washer with neoprene washer "upstops" on upper connection and lower threaded rod. Copy paragraph and subparagraphs below for each type of pipe riser resilient support configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. J. Pipe Riser Resilient Support <Insert drawing designation>: All-directional, acoustical pipe anchor consisting of 2 steel tubes separated by a minimum of 1/2-inch (13-mm) thick neoprene. Include steel and neoprene vertical-limit stops arranged to prevent vertical travel in both directions. Design support for a maximum load on the isolation material of 500 psig (3.45 MPa) and for equal resistance in all directions. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason ADA or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 10 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. Copy paragraph and subparagraphs below for each type of pipe riser resilient support configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. K. Resilient Pipe Guides: Telescopic arrangement of 2 steel tubes or post and sleeve arrangement separated by a minimum of 1/2-inch (13-mm) thick neoprene. Where clearances are not readily visible, a factory-set guide height with a shear pin to allow vertical motion due to pipe expansion and contraction shall be fitted. Shear pin shall be removable and reinsertable to allow for selection of pipe movement. Guides shall be capable of motion to meet location requirements. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason VSG telescopic guides or comparable product by one of the following: a. b. 2.2 Kinetics. Vibration Eliminator. AIR-MOUNTING SYSTEMS Copy paragraph and subparagraphs below for each type of air mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. A. Air Mounts <Insert drawing designation>: Freestanding, multiple, compressed-air bellows. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason MT or comparable product by one of the following: a. b. 2. 3. 4. 5. 6. Kinetics. Vibration Eliminator. Assembly: Upper and lower steel sections connected by a flexible, nylon-reinforced neoprene bellows. Maximum Natural Frequency: 3 Hz. Operating Pressure Range: 25 to 100 psig (172 to 690 kPa). Burst Pressure: At least three times manufacturer's published maximum operating pressure. Leveling Valves: Minimum of 3 required to maintain leveling within plus or minus 1/8inch (3-mm). Copy paragraph and subparagraphs below for each type of restrained air mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 11 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. B. Restrained Air Mounts <Insert drawing designation>: Housed compressed-air bellows. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SLR-MT or comparable product by one of the following: a. b. 2. 3. 4. 5. 6. 7. 8. 2.3 Kinetics. Vibration Eliminator. Housing: Steel with resilient vertical limit stops and factory drilled baseplate that acts as blocking during installation. Restraint: Seismic limit stop with all-directional molded neoprene bushings and 1/4-inch (6-mm) airgap. Assembly: Upper and lower steel sections connected by a flexible, nylon-reinforced neoprene bellows and spring. Maximum Natural Frequency: 3 Hz. Operating Pressure Range: 25 to 100 psig (172 to 690 kPa). Burst Pressure: At least three times manufacturer's published maximum operating pressure. Leveling Valves: Minimum of 3 required to maintain leveling within plus or minus 1/8inch (3-mm). RESTRAINED VIBRATION ISOLATION ROOF-CURB RAILS Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. Retain option and delete insert note if manufacturer's name and model number are indicated on Drawings. A. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason RSC Roof-Curb Rails or a comparable product by one of the following: 1. 2. Kinetics. Vibration Eliminator. Retain option in first two paragraphs below if required by authorities having jurisdiction. B. General Requirements for Restrained Vibration Isolation Roof-Curb Rails: Factory-assembled, fully enclosed, insulated, air- and watertight curb rail designed to resiliently support equipment and to withstand seismic[ and wind] forces. C. Lower Support Assembly: Formed sheet-metal section containing adjustable and removable steel springs that support upper frame. Upper frame shall provide continuous support for equipment and shall be captive to resiliently resist seismic[ and wind] forces. Lower support assembly shall have a means for attaching to building structure and a wood nailer for attaching roof materials, and shall be designed to accept a minimum of 2-inches (50-mm) of rigid, glassfiber insulation on outside of assembly. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 12 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. D. Spring Isolators: Adjustable, restrained spring isolators shall be mounted on 1/4-inch (6-mm) thick, elastomeric vibration isolation pads and shall have access ports, for level adjustment, with removable waterproof covers at all isolator locations. Spring adjustment shall be made with a rigid lift platform located under the springs to minimize spring side sway. Isolators shall be located so they are accessible for adjustment at any time during the life of the installation without interfering with the integrity of the roof. 1. Restrained Spring Isolators: Freestanding, steel, open-spring isolators with seismic[ or wind] restraint. a. b. c. d. e. Housing: Steel with resilient vertical-limit stops and adjustable equipment mounting and leveling bolt. Outside Spring Diameter: Not less than 80 percent of the compressed height of the spring at rated load. Minimum Additional Travel: 50 percent of the required deflection at rated load. Lateral Stiffness: More than 80 percent of rated vertical stiffness. Overload Capacity: Support 200 percent of rated load, fully compressed, without deformation or failure. E. Snubber Bushings: All-directional, molded elastomeric snubber bushings at least 1/4-inch (6mm) thick. F. Water Seal: Galvanized sheet metal with EPDM seals at corners, attached to upper support frame, extending down past wood nailer of lower support assembly, and counter-flashed over roof materials. 2.4 VIBRATION ISOLATION EQUIPMENT BASES Copy paragraph and subparagraphs below for each type of restrained air mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. A. Steel Base <Insert drawing designation>: Factory-fabricated, welded, structural-steel bases and rails. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason WFSL/MSL or comparable product by one of the following: a. b. 2. Kinetics. Vibration Eliminator. Design Requirements: Welded steel frames with not less than 1-inch (25-mm) clearance above the floor. Include equipment attachment holes and auxiliary motor slide bases or rails. Retain first subparagraph below if steel bases are required for pumps. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 13 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. a. 3. 4. Include supports for suction and discharge elbows for pumps. Structural Steel: Steel shapes, plates, and bars complying with ASTM A 36/A 36M. Bases shall have shape to accommodate supported equipment. Support Brackets: Factory-welded height saving steel brackets on frame for outrigger isolation mountings. Copy paragraph and subparagraphs below for each type of restrained air mount configuration required for Project. Use drawing designation and coordinate with the HVAC Vibration-Control and SeismicRestraint Device Schedule on Drawings. B. Inertia Base <Insert drawing designation>: Factory-fabricated, formed-steel member, bolted bases ready for placement of cast-in-place concrete. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason BMK or comparable product by one of the following: a. b. 2. Kinetics. Vibration Eliminator. Design Requirements: Integral height saving brackets to limit mounting height with not less than 1-inch (25-mm) clearance above the floor. Include anchor bolt sleeves for equipment anchor bolts and auxiliary motor slide bases or rails. Base shall have a minimum depth of 1/12 the longest dimension of the base but not less than 6-inch (152mm). Minimum concrete reinforcing shall be 1/2-inch (12-mm) bars at 6-inch (152-mm) on center both ways. Retain first subparagraph below if inertia bases are required for pumps. a. 3. 4. 5. 6. 2.5 Include supports for suction and discharge elbows for pumps. Steel: Steel shapes, plates, and bars complying with ASTM A 36/A 36M. Bases shall be designed to accommodate supported equipment. Support Brackets: Factory-welded steel brackets bolted on frame for outrigger isolation mountings. Fabrication: Fabricate steel templates to hold equipment anchor-bolt sleeves and anchors in place during placement of concrete. Finish: Bolted base members and brackets shall be powder coated. SEISMIC-RESTRAINT DEVICES Coordinate specifications for seismic-restraint components in this Article with structural engineer and with Drawings. See Evaluations for a discussion on seismic-restraint capacities and rating services. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 14 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. A. General Requirements for Restraint Components: Restraints shall have an Anchorage Preapproval "OPA" Number from OSHPD in the State of California verifying the maximum certified horizontal and vertical load ratings. 1. B. Structural Safety Factor: Allowable strength in tension, shear, and pullout force of components shall be at least two times the maximum seismic forces to which they will be subjected. Snubbers: Interlocking steel members restrained by a one-piece molded neoprene bushing of bridge bearing neoprene. Bushing shall be replaceable and a minimum of 1/4-inch (6-mm) thick. An air gap of 1/4-inch (6-mm) shall be incorporated in the snubber design in all directions. Snubber end caps shall be removable to allow inspection of internal clearances. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason Z1225 or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. Retain the following paragraph when low amplification and limited acceleration is required on sensitive equipment or when reduced anchorage loads are required. C. Snubbers: Interlocking steel members restrained by molded neoprene bushings of bridge bearing neoprene. Bushings shall be replaceable and a minimum of 3/4-inch (18-mm) thick. An air gap of 1/4-inch (6-mm) shall be incorporated in the snubber design in all directions. Snubbers shall be manufactured with factory set clearances. The capacity of the snubber at 3/8inch (9-mm) deflection shall be used in selecting the snubber for seismic load. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason Z1011 or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. D. Channel Support System: Shop- or field-fabricated support assembly made of slotted steel channels with accessories for attachment to braced component at one end and to building structure at the other end and other matching components and with corrosion-resistant coating; and rated in tension, compression, and torsion forces. E. Restraint Cables: Pre-stretched galvanized 7x19 steel cables with brackets that swivel to the final installation angle and with a minimum of two clamping bolts for cable engagement for capacities more than 500 lbs (227 kg). Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 15 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SCB/SCBH or comparable product by one of the following: a. b. F. Kinetics. Vibration Eliminator. Solid Braces: Steel struts or steel angle with brackets that swivel to the final installation angle. Steel braces shall be designed to resist both tension and compression loads with a minimum safety factor of 2. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SSB/SSBS or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. Retain paragraph and subparagraphs below for strengthening resistance of hanger rods against seismic forces that may cause buckling of rods; delete if detailed on Drawings. Use with either channel- or cabletype bracing assemblies when required to counter seismic forces. Detail fabrication and indicate locations on Drawings. G. Hanger Rod Stiffener: Steel strut or angle rod braces ductile-iron clamped with a minimum of two clamps to the threaded hanger rods at the seismic sway brace locations. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason UC-C or SRC or comparable product by one of the following: a. b. H. Kinetics. Vibration Eliminator. Bushings for Floor-Mounted Equipment Anchor Bolts: Neoprene and cotton duck fabric washers and bushings designed for rigid equipment mountings, and matched to type and size of anchor bolts and studs. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries Type HW and HL or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 16 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. I. Bushing Assemblies for Wall-Mounted Equipment Anchorage: Assemblies of neoprene elements and steel sleeves designed for rigid equipment mountings, and matched to type and size of attachment devices used. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries Type PB or comparable product by one of the following: a. b. J. Kinetics. Vibration Eliminator. Resilient Isolation Washers and Bushings: neoprene, with a flat washer face. One-piece, molded, oil- and water-resistant Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason HG or comparable product by one of the following: a. b. Kinetics. Vibration Eliminator. Expansion-type anchor bolts are not permitted by SEI/ASCE 7 for nonisolated equipment in excess of 10 hp (7.46 kW). K. Mechanical Anchor Bolts: Stud-wedge or screw type in zinc-coated steel for interior applications and stainless steel for exterior applications. Select anchor bolts with strength required for anchor and as tested according to ASTM E 488. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SAS, SAST or comparable product by one of the following: a. b. L. Hilti. Powers. Adhesive Anchor Bolts: Drilled-in and capsule anchor system containing polyvinyl or urethane methacrylate-based resin and accelerator, or injected polymer or hybrid mortar adhesive. Provide anchor bolts and hardware with zinc-coated steel for interior applications and stainless steel for exterior applications. Select anchor bolts with strength required for anchor and as tested according to ASTM E 488. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 17 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Mason Industries; Mason SRA or comparable product by one of the following: a. b. 2.6 Hilti. Powers. FLEXIBLE PIPE CONNECTORS AND HOSES A. Flexible Connectors: Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide products by Mason Industries, Safeflex SFDEJ, SFEJ, SFDCR or SFU or comparable product by one of the following: a. b. 2. Description: Flexible spherical expansion joints shall employ peroxide cured EPDM in the covers, liners and Kevlar tire cord frictioning. a. b. c. B. Kinetics. Vibration Eliminator. Solid steel rings shall be used within the raised face rubber flanged ends to prevent pullout. Flexible cable bead wire is not acceptable. Sizes NPS 2 (DN 50) and larger shall have two spheres reinforced with a ductile iron external ring between spheres. Flanges shall be split ductile iron or steel with hooked or similar interlocks. Sizes NPS 16 to 24 (DN 400 to 600) may be single sphere. Sizes NPS 3/4 to 2 (DN 19 to 50) may have threaded two piece bolted flange assemblies, one sphere and cable retention. Connectors shall be rated at 250 psig (1723 kPa) up to 170 deg F (77 deg C) with a uniform drop in allowable pressure to 215 psig (1481 kPa) at 250 deg F (121 deg C) in sizes NPS 14 (DN 350) and smaller. For sizes NPS 16 through 24 (DN 400 through 600) the single sphere minimum ratings are 180 psig (1240 kPa) at 170 deg F (77 deg C) and 150 psig (1870 kPa) at 250 deg F (121 deg C). Higher rated connectors may be used to accommodate service conditions. All expansion joints must be factory tested to 150 percent of rated pressure for 12 minutes before shipment. Safety factors to burst and flange pullout shall be a minimum of 3/1. Concentric reducers to the above ratings may be substituted for equal ended expansion joints. Expansion joints shall be installed in piping gaps equal to the length of the expansion joints under pressure. Mason CR control rods need only be used in unanchored piping locations where the manufacturer determines the installation exceeds the pressure requirement without control rods. If control rods are used, they must have 1/4-inch (6-mm) thick Neoprene washer bushings large enough in diameter to take the thrust at 1000 psig (6890 kPa) maximum on the washer area. Submittals shall include two test reports by independent consultants showing minimum reductions of 20 dB in vibration accelerations and 10 dB in sound pressure levels at typical blade passage frequencies on this or a similar product by the same manufacturer. Flexible, Stainless-Steel Hose: VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 18 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide products by Mason Industries, BSS or comparable product by one of the following: a. b. 2. Description: Flexible braided stainless steel hose with stainless steel bodies and carbon steel fittings. Submittals shall include original test data showing force/displacement, fittings, material, live lengths, number of corrugations per foot and a minimum safety factor of 4 at pressure ratings. Flanged hoses shall have one fixed and one floating raised face carbon steel plate flange. Hoses shall be installed on the equipment side of the shut off valves horizontal and parallel to the equipment shafts wherever possible Hoses shall be available with end connections, minimum lengths, minimum live lengths and minimum number of corrugations (convolutions) per foot as tabulated below: 3. 4. 5. 6. C. Adsco. Hyspan. Flexible, Braided-Bronze Hose: Retain "Basis-of-Design Product" Subparagraph and list of manufacturers below to identify a specific product or a comparable product from manufacturers listed. 1. Basis-of-Design Product: Subject to compliance with requirements, provide products by Mason Industries, CPSB or comparable product by one of the following: a. b. 2. Description: Flexible braided bronze hose shall have copper sweat ends and stainless steel bodies for gas service and bronze bodies for water service. Submittals shall include original test data showing force/displacement, fittings, material, live lengths, number of corrugations per foot and a minimum safety factor of 4 at pressure ratings. Flanged hoses shall have one fixed and one floating raised face carbon steel plate flange. Hoses shall be installed on the equipment side of the shut off valves horizontal and parallel to the equipment shafts wherever possible Hoses shall be available with end connections, minimum lengths, minimum live lengths and minimum number of corrugations (convolutions) per foot as tabulated below: 3. 4. 5. 6. Pipe Size NPS (DN) Flanged Length Face to Face in (mm) 1/2 (15) Adsco. Hyspan. - Flanged Live Length Threaded End to End in (mm) in (mm) - 24 (610) Threade d Live Length in (mm) 19-3/4 (502) Grooved End to End Grooved Live Length in (mm) in (mm) - - Copper Sweat Bronze End to End Copper Sweat Bronze Live Length in (mm) in (mm) 18 (457) 14-1/4 (362) VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND Min Convolutions Per 1 foot (305mm) 92 230548 - 19 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. 3/4 (19) 1 (25) 1-1/4 (32) 1-1/2 (40) 2 (50) 2-1/2 (65) 3 (80) 4 (100) 5 (125) 6 (150) 8 (200) 10 (250) 12 (300) 14 (350) 16 (400) 2.7 - - - - - - 24 (610) 24 (610) 24 (610) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914) 21-7/8 (556) 21-1/8 (537) 21-1/8 (537) 33-1/8 (841) 33-1/8 (841) 32-7/8 (835) 32-7/8 (835) 32-5/8 (829) 32-5/8 (829) 32-5/8 (829) 32-5/8 (829) 32-5/8 (829) 24 (610) 24 (610) 24 (610) 24 (610) 24 (610) 24 (610) 36 (914) 36 (914) 19-3/4 (502) 19-3/4 (502) 18-3/4 (476) 18-3/4 (476) 18 (457) 17 (432) 29 (737) 29 (737) - - - - - - - - - - - 18 (457) 18 (457) 18 (457) 18 (457) 18 (457) 18 (457) 18 (457) 24 (610) 13-3/4 (349) 13-3/8 (340) 13-1/4 (337) 13 (330) 12-1/2 (318) 10-3/4 (273) 10-1/2 (267) 15-1/2 (394) - - 29 - - 25 - - 23 - - 21 - - 20 - - - 18 - - - 16 - - - - - - - - 24 (610) 24 (610) 36 (914) 36 (914) 36 (914) 36 (914) 36 (914 36 (914) 36 (914 18 (457) 18 (457) 30 (762) 28 (711) 28 (711) 28 (711) 28 (711) 26 (660) 26 (660) - - - - 80 72 67 63 58 48 46 32 FACTORY FINISHES Specify field-painting requirements in painting Sections. Verify compatibility of factory finishes with field-applied coats. A. Finish: Manufacturer's standard prime-coat finish ready for field painting. Edit paragraph and subparagraphs below to include custom colors. requirements with sample submittal requirements. B. Coordinate custom-color Finish: Manufacturer's standard paint applied to factory-assembled equipment before shipping. 1. 2. 3. 4. Powder coating on springs and housings. All hardware shall be zinc electroplated. Baked enamel or powder coat for metal components on isolators for interior use. Color-code or otherwise mark vibration isolation and seismic[- and wind]-control devices to indicate capacity range. Include the following for installations exposed to extreme weather or caustic environments only. This may require special fabricated isolators and restraints and should be used only when absolutely necessary. Additional notes and special details should be added to plans to clarify the extent of this requirement. 5. Hot-dip galvanized metal components for exterior use. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 20 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine areas and equipment to receive vibration isolation and seismic[- and wind]-control devices for compliance with requirements for installation tolerances and other conditions affecting performance. B. Examine roughing-in of reinforcement and cast-in-place anchors to verify actual locations before installation. C. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 APPLICATIONS A. Multiple Pipe Supports: Secure pipes to trapeze member with clamps approved for application by [an evaluation service member of ICC-ES] [OSHPD] [an agency acceptable to authorities having jurisdiction]. Indicate on Drawings, by details, schedules, or a combination of both, the locations where hanger rods for individual pipes and hanger rods for trapeze hangers require hanger rod stiffeners. B. Hanger Rod Stiffeners: Install hanger rod stiffeners where indicated or scheduled on Drawings to receive them and where required to prevent buckling of hanger rods due to seismic forces. C. Strength of Support and Seismic-Restraint Assemblies: Where not indicated, select sizes of components so strength will be adequate to carry present and future static and seismic loads within specified loading limits. 3.3 VIBRATION-CONTROL AND SEISMIC-RESTRAINT DEVICE INSTALLATION A. Comply with requirements in Section 077200 "Roof Accessories" for installation of roof curbs, equipment supports, and roof penetrations. B. Equipment Restraints: Indicate type and quantity of snubbers described in first subparagraph below on Drawings or in the HVAC Vibration-Control and Seismic-Restraint Device Schedule on Drawings. 1. 2. 3. Install seismic snubbers on HVAC equipment mounted on vibration isolators. Locate snubbers as close as possible to vibration isolators and bolt to equipment base and supporting structure. Install resilient bolt isolation washers on equipment anchor bolts where clearance between anchor and adjacent surface exceeds 0.125 inch (3.2 mm). Install seismic-restraint devices using methods approved by [an evaluation service member of ICC-ES] [OSHPD] [an agency acceptable to authorities having jurisdiction] providing required submittals for component. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 21 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. C. Piping Restraints: 1. Comply with requirements in MSS SP-127. In first subparagraph below, options for 40 and 80 feet (12 and 24 m) are recommended by MSS SP-127. Consider reducing these dimensions based on the configuration of piping. 2. Space lateral supports a maximum of [40 feet (12 m)] <Insert dimension> o.c., and longitudinal supports a maximum of [80 feet (24 m)] <Insert dimension> o.c. 3. Brace a change of direction longer than 12 feet (3.7 m). D. Install cables so they do not bend across edges of adjacent equipment or building structure. E. Install seismic-restraint devices using methods approved by [an evaluation service member of ICC-ES] [OSHPD] [an agency acceptable to authorities having jurisdiction] providing required submittals for component. F. Install bushing assemblies for mounting bolts for vibration isolated wall-mounted equipment, arranged to provide resilient media where equipment or equipment-mounting channels are attached to wall. G. Attachment to Structure: If specific attachment is not indicated, anchor bracing to structure at flanges of beams, at upper truss chords of bar joists, or at concrete members. H. Drilled-in Anchors: 1. 2. 3. 4. 5. 6. 7. I. Install anchors according to requirements in the ICC-ER report. Identify position of reinforcing steel and other embedded items prior to drilling holes for anchors. Do not damage existing reinforcing or embedded items during coring or drilling. Notify the structural engineer if reinforcing steel or other embedded items are encountered during drilling. Locate and avoid prestressed tendons, electrical and telecommunications conduit, and gas lines. Do not drill holes in concrete or masonry until concrete, mortar, or grout has achieved full design strength. Wedge Anchors: Protect threads from damage during anchor installation. Heavy-duty sleeve anchors shall be installed with sleeve fully engaged in the structural element to which anchor is to be fastened. Adhesive Anchors: Clean holes to remove loose material and drilling dust prior to installation of adhesive. Place adhesive in holes proceeding from the bottom of the hole and progressing toward the surface in such a manner as to avoid introduction of air pockets in the adhesive. Set anchors to manufacturer's recommended torque, using a torque wrench. Install zinc-coated steel anchors for interior and stainless-steel anchors for exterior applications. Piping Isolation Installation: 1. Horizontal Piping: The first three pipe supports from vibration isolated equipment shall be vibration isolated. a. b. Suspend overhead piping from spring hangers. Support floor-supported piping on spring isolators. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 22 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. c. 2. Riser Isolation: Suspended risers with spring hangers or supported with spring mounts, anchored with piping anchors, and guided with sliding guides. a. b. 3.4 The static deflection of the pipe hangers and support isolators shall be equal to the static deflection for the isolators supporting or suspending connected equipment. Suspend horizontal pipe runs and branches with spring hangers for the first three supports from the risers. Steel springs shall be selected to provide a minimum of 3/4-inch (19-mm) static deflection except in those expansion locations where additional deflection is required to limit load changes to plus 25 percent of the initial load ACCOMMODATION OF DIFFERENTIAL SEISMIC MOTION Coordinate this Article with Drawings. A. Install flexible pipe connectors at all equipment connections to allow seismic motion of piping relative to the equipment. Equipment to include air terminals, fan-coil units and duct mounted coils. Flexible connectors as noted in section 2.7 must be selected to allow seismic movement without exceeding acceptable nozzle loads on equipment connections. Acceptable nozzle loads provided by equipment manufacturer. B. Install flexible pipe connectors and hoses on the equipment side of the shut off valves. C. Install flexible connections in piping where they cross seismic joints, where adjacent sections or branches are supported by different structural elements, and where the connections terminate with connection to equipment that is anchored to a different structural element from the one supporting the connections as they approach equipment. Comply with requirements in Section 232116 Hydronic Piping Specialties" for piping flexible connections. 3.5 FIELD QUALITY CONTROL Retain one of first two paragraphs below to identify who shall perform tests and inspections. If retaining second option in first paragraph, or if retaining second paragraph, retain "Field quality-control test reports" Paragraph in "Informational Submittals" Article. A. Testing Agency: [Owner will engage] [Engage] a qualified testing agency to perform tests and inspections. Retain paragraph below to require Contractor to perform tests and inspections. B. Perform tests and inspections. Retain first paragraph and subparagraphs below to describe tests and inspections to be performed. C. Tests and Inspections: 1. Measure isolator restraint clearance. 2. Measure isolator deflection. 3. Verify snubber clearances. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 23 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. Retain first three subparagraphs below if air-mounting systems are included in Project. 4. Air-Mounting System Leak Test: After installation, charge system and test for leaks. Repair leaks and retest until no leaks exist. 5. Air-Mounting System Operational Test: Test the compressed-air leveling system. 6. Test and adjust air-mounting system controls and safeties. 7. If a device fails test, modify all installations of same type and retest until satisfactory results are achieved. D. Remove and replace malfunctioning units and retest as specified above. E. Prepare test and inspection reports. 3.6 ADJUSTING A. Adjust isolators after piping system is at operating weight. B. Adjust limit stops on restrained spring isolators to mount equipment at normal operating height. After equipment installation is complete, adjust limit stops so they are out of contact during normal operation. Retain first paragraph below for air-mounting systems. C. Adjust air-spring leveling mechanism. D. Adjust active height of spring isolators. E. Adjust restraints to permit free movement of equipment within normal mode of operation. 3.7 DEMONSTRATION Retain this Article for air-mounting systems. A. 3.8 Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain air-mounting systems. Refer to Section 017900 "Demonstration and Training." HVAC VIBRATION-CONTROL AND SEISMIC-RESTRAINT DEVICE SCHEDULE A. Retain isolation and seismic restraint schedule below or delete and include on Drawings. The actual selection of isolation type and required deflection can be made using ASHRAE recommendations or the Mason selection table. Mason Industries always recommends the use of a professional acoustical consultant. END OF SECTION 230548 The table below represents columns to be added to equipment schedules on Drawings in order to designate vibration isolation product types and static deflection requirements for various equipment types. VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT AND 230548 - 24 Copyright 2011 AIA MasterSpec Full Length 06/11 PRODUCT MASTERSPEC LICENSED BY ARCOM TO MASON INDUSTRIES, INC. VIBRATION ISOLATION AND SEISMIC RESTRAINT SCHEDULE EQUIPMENT Pumps Chillers Cooling Towers Rooftop Air Conditioning Units(Up to 20 Ton) Rooftop Air Conditioning Units(Over 20 Ton) Exhaust Fans SPECIFICATION SLAB ON GRADE STATIC DEFLECTION Inertia Base Spring Isolators Snubbers Flexible Connectors Restrained Spring Isolators Flexible Connectors Steel Bases Restrained Spring Isolators Flexible connectors Roof-Curb Rails Roof-Curb Rails Steel Bases Restrained Spring Isolators .75 2.5" .75 1.5 .75 2.5 Not Applicable Not Applicable Not Applicable VIBRATION AND SEISMIC CONTROLS FOR HVAC PIPING EQUIPMENT ABOVE GRADE STATIC DEFLECTION AND 1.0" 3.0" 1.0" 230548 - 25