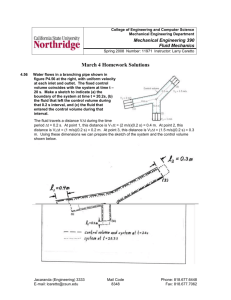

ICS FLUID FLOW

advertisement

ICS FLUID FLOW Important Conversions and Equalities: 1 Newton force (N) causes 1 kg mass to accelerate at 1 m/s2 1 dyne force (dyn) causes 1 g mass to accelerate at 1 cm/s2 1 pound force (lbf) causes 1 slug mass to accelerate at 1 ft/s2 1 pound force (lbf) causes 1 lb mass to accelerate at 32.2 ft/s2 1 poundal force (pdl) causes 1 lb mass to accelerate at 1 ft/s2 1 pdl = 1N = 1 lbf = 1 lbmft/s2 1 kgm/s2 1 slugft/s2 1 lbm = 1 kg 1 slug = 0.454 kg 14.594 kg = = 7.233 pdl 32.2 pdl = = 2.204623 lbm 32.174 lbm g = 9.81 N/kg or m/s2 g = 981 dyn/g or cm/s2 g = 32.2 lbf/slug or ft/s2 g = 1.0 lbf/lbm g = 32.2 pdl/lbm or ft/s2 105 dyn 32.2 lbmft/s2 = = = 4.448 N g = 32.2 lbf/slug = 1 lbf/lbm= 32.2 pdl/lbm = 9.81 N/kg = 981 dyn/g = 1037 pdl/slug The following conversions apply at 3.98 C where water is densest. H2O = 1 g kg 1 slug 1 m3 slug 1.9403 3 = 1000 3 3 3 3 cm m 14.594 kg 3.2808 ft ft 981 dyn 1 g 981 dyn 3 cm g cm3 DH2O = g = or 32.2 lbm lbm 62.43 3 ft 1slug 1000 kg 9 .807 N m3 kg 9807 N m3 . slug 32 .2 lbf 62 .43 lbf 2009 pdl 19403 62.43 lbm 32 .2 pdl or 3 3 3 slug lbm ft ft ft ft 3 DH2O = 1m 1 IMP gal 1 US gal 1 IMP gal H2O 1 US gal H2O = = = = = 3.28083 ft 4.5461 L = 1.201 US gal 3.7854 L = 0.8327 IMP gal 4.5461 L (1 kg/L) (2.2046 lb/kg) = 10.02 lb/IMP gal 3.7854 L (1 kg/L) (2.2046 lb/kg) = 8.345 lb/US gal H2O = 62.43 lbm/ft3 (1 IMP gal/10.0 lbm) H2O = 62.43 lbm/ft3 (1 US gal/8.345 lbm) Power = Also, work time = Fd t N Power = p Q e.g. 2 m e.g. 6.24 IMP gal/ft3 7.48 US gal/ft3 Nm J = = W s s 3 m N m s s lbf or 2 ft or lbf ft s ft 3 lbf ft s s 1 horse power (HP) = 745.7 watts (W) = 550 ftlbfs-1 = 33000 ftlbfmin-1 FLUID FLOW Page 1 of 51 EQUATIONS FOR FLUID FLOW When an incompressible fluid flows through a pipe at a steady flow rate, the quantity of flow past all points in the pipe is constant. A = d2/4 d Q V (A d) Av t t The front of this section of fluid moves a distance ‘d’ in time ‘t’, so its velocity, v = d/t. Volumetric flow rate (Q) is the volume of fluid passing a certain point per unit time. Volumetric flow rate has units of V/t, e.g., m3/h, L/min, mL/s, ft3/s, gal/h, etc. Be careful not to confuse V for volume with v for velocity. It is often easier to calculate cross sectional area as d2/4 rather than r2. Problem 1: The nozzle of a garden hose has an I.D. of 0.500 in. If water flows through the hose at 10.0 US gal/min, find the speed at which it leaves the nozzle in ft/s. Ans: 16.3 ft/s wall thickness I.D. = internal diameter O.D. = outside diameter OD – 2(thickness) = ID I.D. O.D. FLUID FLOW Page 2 of 51 THE CONTINUITY EQUATION or STEADY STATE FLOW EQUATION Consider a steady flow rate of a liquid flowing through a pipe of varying cross-sectional area, from point 2 to point 1. The flow rate must remain constant even though the velocity may vary. 2. 1. Q1, A1, v1 Q 1 = Q2 Q1 = A 1 1 Since Q1 = Q2 , d1 2 or Q2, A2, v2 A1 < A 2 v1 > v2 and Q2 = A 2 2 thus: Q = A1 1 = A2 2 2 d v2 A d1 4 1 1 2 2 v1 A2 d2 d2 d2 4 2 r 1 r2 2 Note that velocity is inversely proportional to cross-sectional area and thus also to the square of the radius and diameter of the pipe, i.e., the larger the pipe, the lower the velocity for a given flow rate. The equation of continuity holds for incompressible fluids (liquids) in any direction of flow, i.e., up, down, back, forth, etc. Problem 2: Water in a pipe 12.0 cm in diameter flows with a velocity of 8.00 m/s. Calculate the velocity at a point in the pipe where its diameter is constricted to 3.00 cm. Ans: 128 m/s. FLUID FLOW Page 3 of 51 BERNOULLI’S EQUATION When a liquid flowing through a pipe enters a region where the pipe diameter is reduced, its speed increases (because the flow rate is constant). A change in speed involves acceleration, which means a net force must be acting upon the liquid. This force can only arise from a difference in pressure between the different parts of the pipe. Obviously the pressure in the section of pipe where the diameter is larger must be greater since the liquid increases in speed as it enters the constriction. By similar reasoning, the pressure must be lower in the constriction where the speed is greater. Q1, A1, v1 p1 Q2, A2, v2 p2 v1 > v2 p1 < p2 Ignoring friction, change in elevation, heat transfer, chemical reaction, etc. the total mechanical energy of a liquid remains constant. As a pipe constricts, v (KE) increases at the expense of pressure, i.e., as velocity increases, pressure must decrease. Thus we expect a relationship between the pressure in a moving liquid and its speed. This was derived by Daniel Bernoulli (1700-1782), a Swiss mathematician and physicist and it is thus called Bernoulli’s equation. p1 + gz1 + ½12 = p2 + gz2 + ½22 where p1, z1, & 1 are pressure, height above a reference level, and speed of a liquid of mass density at point 1 in a body of liquid and p2, z2, & 2 are values of these quantities at point 2. According to Bernoulli’s equation, the quantity (p + gz + ½v2) is a constant at all points in an incompressible liquid with negligible viscosity that undergoes laminar flow, i.e., no losses due to friction are considered. If viscosity (internal friction) is not negligible, then the quantity (p + gz + ½v2) decreases in the direction of flow. FLUID FLOW Page 4 of 51 DERIVATION OF BERNOULLI’S EQUATION W = Fd = weight height (of lifting) = mgh = gravitational PE Recall: KE = ½m2 Pressure energy (PV work) = PV i.e., (F/A)(V) = Fd 3 units; Pam = (N/m2)(m3) = Nm = J For a closed system E1 = E2 Considering mechanical energy (ignoring heat and chemical energy) then: pressure E + GPE + KE = constant 1. PV + mgz + ½m2 = constant (Units = Nm or lbfft) Convert V term to mass using = m/V V = m/ we obtain: m mv2 p mgz cons tan t 2 “h” is height of a particle not height of a column of fluid above it so it was changed to “z” to avoid confusion; reserve “h” for height of a fluid column, i.e., pressure. Dividing all terms by ‘m’ since it is common, yields a second form of Bernoulli’s eqn. p v2 gz cons tan t 2. units are height2/time2 (e.g., m2/s2 or ft2/s2) 2 In equation 1, mass terms can be converted to V terms using m = V yielding: PV + (V)gz + ½V2 = constant Canceling the common V term yields a third form of Bernoulli’s eqn. 3. p + gz + ½2 = constant By dividing eqn 2. by g 4. or p v2 z cons tan t g 2g units are pressure (N/m2 or lbf/ft2 or dyn/cm2) dividing eqn 3. by g we obtain a fourth equation. units are height (e.g., m. or ft.) By substituting p = gh into eqn. 4. we obtain 5. hz v2 cons tan t 2g gh v2 z cons tan t . Canceling yields: g 2g units are height (m, ft, etc.) Remember, ‘h’ is pressure expressed as height of a column of the working fluid above a point (units are ft, m, etc.). ‘z’ is the relative elevation of a point or particle also expressed in m or ft. Do not confuse these! Since weight density, D = g we can substitute = D/g in eqn. 3 to obtain: D D v2 p gz cons tan t and canceling ‘g’ in the second term yields: g g 2 FLUID FLOW Page 5 of 51 p Dz 6. Dv 2 cons tan t 2g units are pressure (N/m2 or lbf/ft2) Equation 5. is often the simplest form to use. If we now consider this equation in an open system we must also include terms for energy input from pumps (pump head, hp) and energy loss due to friction (friction head, hf) and equation 5. becomes: 7. hp + h1 + z1 + 12/2g = h2 + z2 + 22/2g + hf where: hp = pressure head added by pump h1 = pressure head at point 1 h2 = pressure head at point 2 z1 = elevation of point 1 z2 = elevation of point 2 1 = velocity at 1 2 = velocity at 2 hf = head loss due to friction. All terms are in height of the working fluid. Equations 3, 5 and 7 are most commonly used. FLUID FLOW Page 6 of 51 SPECIAL CASES OF BERNOULLI’S EQUATION In many cases the pressure, height, or speed of a liquid is constant and simplified forms of Bernoulli’s equation result. 1. Liquid at Rest: When a column of liquid is stationary, equation 3. becomes: p1 + gz1 = p2 + gz2 p = (p2 - p1) = g(z1 – z2) This is simply the pressure-depth equation (p = gh) Extra problem: The gage pressure of water standing in a vertical pipe is 0.20 atm at a certain depth. Calculate the gage pressure in the water at a point 2.0 m higher. (ans. = 2.6” H2O) 2. When p1 = p2: When an open tank is draining, both ends are at atmospheric press. gz1 + ½12 = gz2 + ½22 patm If the orifice is small compared to the cross section of the tank, the liquid level (draining under gravity) will fall slowly enough that the liquid speed at the top of the tank (1) is negligible (assume 1 = 0), then: gz1 = gz2 + ½22 Solving for we get: ½22 = g(z1 - z2) = gz v 2gz (Toricelli’s Theorem) Note that the speed with which a liquid is discharged under gravity is the same as the speed of a body falling from rest from height, h, and is independent of the density of the object. Recall intro physics, the KE of an object at any point all comes from PE. ½m2 = mgh v 2gh The flow rate at which liquid discharges through an orifice can be calculated as follows: Since Q = A, Q = A 2gh (Flow from an orifice) Problem 3: Calculate the flow rate at which water will leak through a hole 1.0 cm2 in area at the bottom of a water tank which is filled to a height of 3.0 m. Ans: 0.77 L/s FLUID FLOW Page 7 of 51 3. Constant Height: p1 + ½12 = p2 + ½22 Pressure and speed are inversely related. As increases (through a constriction), p decreases. This relationship is responsible for such phenomena as lift on an airplane wing, movement of sailboats at angles to the wind, venturi action in carburetors, Bunsen burners, and paint sprayers, aspirators (nebulizers) in perfume bottles and AA spectrophotometers. h = p h Extra Problem: Calculate the difference in height (in cm) of H2O in the pressure taps shown above when the velocity of H2O is 10.0 cm/s in a pipe with diameter of 2.00 cm, which then constricts to a diameter of 1.00 cm. (ans = 0.765 cm) Problem 4: The pressure is 25 ft. of water and flow velocity is 100 ft/s in a 2.00 in. I.D. pipe. The pipe widens to 28 in. I.D. and rises 5.0 ft. from its original level. Calculate the pressure (in psi) in the elevated and enlarged section of pipe. Ans: 76 psi. Problem 5: Water flows in a pipe in the direction of ‘a’ to ‘b’ at a rate of 8.50 m3/min. The diameter at ‘a’ is 30.4 cm. and the diameter at ‘b’ is 15.2 cm. The pressure at ‘a’ is 1.03 105 N/m2. Calculate the pressure (in Pa) at ‘b’ if the center at ‘b’ is 60.4 cm lower than the center at ‘a’. Ans: 8.03 104Pa FLUID FLOW Page 8 of 51 LIQUID HEADS IN FLUID FLOW 1. Vertical depth in ft. or m. of any point below the surface of a liquid is called pressure head or hydrostatic head, i.e., it is a pressure usually expressed in ft. or m. of the liquid. Recall p = Dh h = p/D Extra Problem: Using fresh water as the fluid, calculate the depth of water that would exert a force of 1.00 atm. Use the equation above and use p and D in British and SI units. (ans. h = 33.9 ft and h = 10.3 m) 2. A drop in pressure in moving water due to friction is called friction head. It is directly proportional to the total area of the rubbing surface as well as the roughness of the surface and the velocity of the fluid. Abrupt changes in cross-sectional area or direction of flow also causes increased friction head. 3. Pressure in a pipe or channel due to the velocity of liquid particles is called velocity head. From Toricelli’s Theorem, v 2gh hv = 2/2g This indicates that a pressure due to velocity is equivalent to the hydrostatic head, which would produce such a velocity (at least theoretically, in absence of friction). In real systems, friction head causes velocity head to be less than pressure head. In other words, a static fluid under pressure would move with a velocity calculated by Toricelli’s theorem if a hole (or valve) were opened in the side of a pipe or vessel. Neglecting friction, all static pressure energy would be converted to velocity. Problem 6.: Water discharges under gravity from a tank with a very large surface area through a 6 in. I.D. pipe. The depth of water above the opening is 12.0 in. As water leaves the pipe it travels a horizontal distance of 3.45 ft. through the air, before reaching a pond which is 3.68 ft. below. a) Calculate the actual horizontal velocity of water as it leaves the pipe. Ans: 7.22 ft/s b) Calculate the theoretical velocity of water in the pipe. Ans: 8.02 ft/s c) Calculate the coefficient of velocity (Cv), (actual v/theor. v) Ans: 0.90 d) Calculate the actual flow rate of water Ans: 1.42 ft3/s e) Calculate the hydrostatic head (hh), velocity head (hv), and friction head (hf). Friction head is simple the head (pressure) lost to friction, i.e., (hf = hh – hv) Ans: hh = 1 ft. H2O, hv = 0.81 ft H2O, hf = 0.19 ft. H2O Note: For all Bernoulli equations use ‘h’ and ‘z’ as actual heights (actual dist.). Do not factor in density to calculate an equivalent height of water but understand that the answer will be in height of solution (not water). Then apply density to convert to usual pressure units. FLUID FLOW Page 9 of 51 Problem 7: A pump draws a solution (s.g. = 1.84) from a storage tank through a 3.00 in. I.D. pipe. The velocity in the suction line is 3.00 ft/s. The pump discharges through a 2.00 in. I.D. pipe into an overhead tank. The end of the discharge is 50.0 ft. above the level of solution in the feed tank. Friction losses are 10.0 ft. of solution. a) What pressure must the pump develop in psi? Ans: 48.3 psi. b) What is the HP of the pump assuming it is 65% efficient? Ans: 2.86 H.P. FLUID FLOW Page 10 of 51 H 10' E F G 50' A 10' B P D C Pressure head in feet (’) at designated points in the process diagram A B C D E F G H I hp 0’ 0’ 0’ 100’ 0’ 0’ 0’ 0’ 0’ hh 0’ 10’ 1’ 1’ 47’ 30’ 10’ 0’ 0’ Z 10’ 0’ 0’ 0’ 50’ 50’ 50’ 60’ 50’ v2/2g 0’ 0’ 8’ 8’ 8’ 20’ 10’ 0’ 35’ hf 0’ 0’ 1’ 1’ 5’ 10’ 40’ 50’ 25’ Total 10’ 10’ 10’ 110’ 110’ 110’ 110’ 110’ 110’ hh = hydrostatic head (gauge pressure or pressure due weight of liquid above a point or pressure applied by a pump). hp = pump head (pressure due to a pump) Z = elevation 2 v /2g = velocity head (pressure of moving fluid) hf = head loss due to friction Point 1 ( hh + Z + v2/2g ) = Point 2 ( hh + Z + v2/2g ) The 1st Law of Thermodynamics tells us that energy may change forms but is conserved. The basic form of Bernoulli’s equation above shows this (in terms of pressure), but only applies in this form to ideal systems where no pressure energy is lost due to friction and no pressure energy is added by pumps. Terms for both head loss due to friction and increase in head due to a pump (pump head) are thus included. ( hh + Z + v2/2g ) + hp = ( hh + Z + v2/2g ) + hf Note that hf is really hf , i.e., the increase in head loss due to friction between 2 points. FLUID FLOW Page 11 of 51 VISCOSITY Viscosity is internal friction or resistance to flow. Absolute or dynamic viscosity () is ... SI units : shear stress F/A F dx = velocity gradient dV / dx A dV (kg m s -2 )(m) (m 2 )(m s -1 ) kg Pa s m s cgs units : (g cm s -2 ) (cm 2 )(cm s 1 ) g poise (P) cm s 10 poise (P) = 1 Pa s 1 poiseuille (Pl) = 1000 centipoise (cP) 1 cP = 6.72 10 -4 pdl s lbm 6.72 10 -4 ft s ft 2 = 2.089 10 -5 slug lbf s = 2.089 10 -5 ft s ft 2 Kinematic Viscosity () is absolute viscosity adjusted for density of the fluid. cgs units : SI units : 1 poise g cm 3 cm 2 stokes (St) s g/cm 3 cm s g 3 2 kg m m s m s kg m 2 10 4 cm 2 10 4 stokes 10 6 centistokes (cSt ) s s lbf s ft 3 lbf s ft 3 ft ft 2 lbm ft 3 ft 2 British units : or 2 2 2 s slug s ft ft lbf s ft s lbm 1.076 10-5 ft2/s = 1 centistokes One advantage of kinematic viscosity is that it eliminates confusion of the British units for absolute viscosity in lbm vs. lbf. Viscosity has been covered in detail in physical chemistry so we will only review some units of viscosity and their conversion factors here. Viscosity is needed to calculate Reynolds number in the next section. FLUID FLOW Page 12 of 51 FLOW OF LIQUIDS When a liquid flows through a passage such as a pipeline, it will encounter resistance due to friction and viscosity. If the average velocity of the fluid is very low, the fluid will flow in parallel lines along the sides of the pipe. In such a case the flow is said to be laminar, viscous, or streamline. If the velocity is increased beyond a certain critical value when eddy currents start to form, the laminar flow pattern is changed and the flow becomes turbulent. The critical value of the velocity occurs when the Reynolds number (Re) is equal to about 2000. In practice it is found that: 1. If the Re value is less than 2,000, the flow is laminar, viscous, or streamline. 2. If the Re value is between 2,000 and 4,000, the flow is critical, i.e., in a transition phase, changing from laminar, to turbulent or vice versa. 3. If the Re value is greater than 4,000, the flow is turbulent. TURBULENT FLOW LAMINAR FLOW Velocity Velocity r 0 r distance from center of pipe r 0 r distance from center of pipe COLOUR-BAND METHOD FOR DETERMINING CRITICAL VELOCITY The critical value may be found by allowing water to flow through a glass tube and injecting a thin stream of colored liquid (e.g., KMnO4 solution) into the center of the stream. As long as the velocity is below the critical value, the colour band will remain in a straight line pattern along the center of the stream. As soon as the velocity exceeds the critical value, the colored band will be broken up because of turbulence and will mix with the water. FLUID FLOW Page 13 of 51 REYNOLDS NUMBER The wide variety of pipes and other conduits that must be considered, along with an equally wide variety of fluid properties, makes it difficult to describe flow conditions in a generalized manner. However, the ratio of internal forces to viscous forces for a flowing fluid has been found to be a characteristic of the flow conditions. This ratio, known as the Reynolds number, is defined by the following equation. Re d v or d D g d = diameter (e.g. cm, m, or ft.) = absolute viscosity -1 -1 v = average or bulk velocity (e.g., cms , ms or fts-1 ) g = grav. accel. -3 -3 -3 -3 = mass density (gcm , kgm , slug/ft or lbm/ft ) D = weight density (e.g. N/m3, etc.) Re is dimensionless and 2000 for laminar flows but > 4000 for turbulent flows. 2000 is called the lower critical velocity and 4000 is called the upper critical velocity. 2000 < Re > 4000 is a zone of transition between laminar and turbulent flow. (cm)(cm s -1 )(g cm -3 ) cgs : dimensionl ess ( g cm 1 s 1 ) (ft)(ft s -1 )(lbm ft -3 ) British : (lbm ft 1 s 1 ) d Since: = Re cgs: ( cm)( cm s 1 ) ( cm 2 s 1 ) SI: or (m)(m s -1 )(kg m -3 ) SI : = dimensionl ess (kg m 1 s 1 ) (ft)(ft s -1 )(slug ft -3 ) dimensionl ess ( slug s ft 2 ) ( m)( m s 1 ) ( m 2 s 1 ) British: ( ft )( ft s 1 ) ( ft 2 s 1 ) all dimensionless Extra Problem: Oil (sg = 0.765, = 1.70 centipoise) is pumped through a 4 inch Schedule 40 steel pipe at a flow rate of 150 Imperial gallons/minute. Calculate the Reynolds number (to 3 sig figs) for the fluid under these conditions and state whether the flow is turbulent, laminar or transitional. (ans. Re = 63,500). FLUID FLOW Page 14 of 51 FLUID FLOW MEASUREMENT Flow has been called the controlling variable in fluid process industries, since by controlling flow, all other process conditions are controlled. Flow measurement is necessary for determining production rates and for accounting purposes. Although it is one of the most frequently measured variables, it is the most difficult to measure accurately. A flowmeter is an instrument capable of measuring flow rates in circular pipes. Weirs are flow measuring devices used in open channels such as ditches and open drains where the fluid has a free surface. There are many different kinds of flowmeters. We will consider 5 classes of them. 1. Head meters measure volumetric flow indirectly by means of a detecting element (primary element, e.g., orifice) that produces a pressure-differential effect, which is observable on a measuring device (secondary element, e.g., manometer). Head meters include: orifice plates, venturi tubes, and Pitot tubes. 2. Variable area flowmeters adjust their orifice size (area) as flow rates change, e.g. rotameters. 3. In positive displacement meters the fluid passes in successive quantities or displacements, filling and emptying in a cyclic manner, containers of known capacity. The flow is read by counting revolutions. The rotary vane meter is one example among many. Metering pumps that deliver known volumes of liquid include: piston, diaphragm, gear and peristaltic. 4. Velocity-principle volumetric flowmeters respond to the velocity of the flowing fluid. There are many meters that operate on this principle. One particularly useful for corrosives is the magnetic (‘mag’) flow meter, discussed later. 5. Mass flow meters respond directly to the true mass flow rate rather than volumetric flow rate. In general the density of the fluid coupled with its velocity creates a measurable momentum (m v) as it impacts various detecting elements. One example is the gyroscopic type in which the process fluid is channeled through a spiraling path within the meter. The centripetal forces are proportional to the flow rate. FLUID FLOW Page 15 of 51 FLUID FRICTION Fluids in motion are subjected to certain resistances, which are assumed to be caused by friction, i.e., viscosity, which is resistance to sliding between two adjacent layers of the fluid. This is the result of molecular attraction between particles of the fluid. It is generally found that for steady viscous or streamline motion of a liquid, i.e., for velocities less than the critical value, the frictional resistance is: 1. Proportional to the velocity 2. Proportional to the area of surface in contact 3. Independent of the pressure 4. Greatly affected by temperature changes 5. Independent of the nature of the surface in contact Point 5 infers that, when a liquid is flowing past a surface with a velocity of less than the critical velocity, a film of stationary liquid is formed over the surface. The resistance to flow in the rest of the pipe is caused by viscosity only. When the flow is increased beyond the critical velocity, i.e., when turbulent flow occurs, frictional resistance is: 1. Proportional to the square of the velocity 2. Proportional to the mass density () 3. Independent of pressure value 4. Independent of temperature effects which are negligible 5. Directly proportional to the area of surface in contact 6. Dependent on the surface in contact Point 6 infers that the internal surface of the pipe is an important factor, i.e., the smoother the surface the lower is the frictional resistance. FLUID FLOW Page 16 of 51 HEAD LOSS PER UNIT LENGTH OF PIPE Osborne Reynolds conducted experiments to measure the drop in pressure (head loss) as a fluid travels through a pipe. The term “head loss per unit length of pipe” (i) is given by: h head loss between two points of pipe i L L distance between these points His results showed that i increases with fluid velocity according to: i = kn , where is the average velocity, k is some constant, and n = 1 for Re < 2,000 (which yields a direct, linear relationship for laminar flow) but n 2 for Re > 4,000 (yielding a direct, exponential relationship between velocity and head loss for turbulent flow). overflow water supply B A v1 D C v2 F E v3 Explain the relative magnitudes of v1, v2 and v3. Explain the relative fluid heights in the tubes (pressure taps) above A, B, C, D, E and F FLUID FLOW Page 17 of 51 DISCHARGE THROUGH ORIFICES AND NOZZLES A flowing fluid that passes through an orifice or constriction of any kind will contract in area as in the case of water from a tap or faucet. The contraction is caused by the inward motion of the fluid around the opening as it rushes inwards to funnel through the opening. The point of minimum cross-sectional area, called the vena contracta, is also the point of highest velocity of the flowing fluid. vena contracta The extent of contraction is called the coefficient of contraction (Cc) which is: area of jet at vena contracta Cc area of orifice There is a certain amount of frictional resistance at the sides or edge of the orifice. The resistance is lowest for sharp-edged orifices. In such cases the Cc approximates 0.65. A related term is the coefficient of velocity (Cv). Cv actual velocity at vena contracta theoretical velocity 2gh The difference between the theoretical velocity (as given by Toricelli's theorem) and the actual measured velocity is caused by friction at the orifice edge and is very small for sharp-edged orifices. A typical value for C is approximately 0.97, depending upon the head, shape, and size of the orifice. A third coefficient is of considerable importance in fluid flow measurement; the coefficient of discharge (Cd): Cd actual discharge Q theoretical discharge A 2 g h Again, owing to resistance, the actual discharge (flow rate) is usually less than theoretical. FLUID FLOW Page 18 of 51 FLOW RATE of fluids in pipes is often calculated by installing a venturi tube or orifice plate and measuring the pressure drop (p) that occurs. With open manometers mounted above the pipe (Figure 1.), the manometer fluid will be the same as the fluid flowing through the pipe. Since the manometers in this system are open to atmosphere, air lies above the manometer fluids, hence p can be calculated directly from the difference in height (h) of manometer fluid levels, i.e., p = fluidgh. Figure 1. air air h = ? cm. h = ? cm. ORIFICE PLATE VENTURI d2 d2 d1 d1 A more practical arrangement is to use enclosed Hg manometers as shown in Figure 2. Since Hg is very dense (s.g. = 13.6), the manometer can be much smaller. In this case, air is trapped above the Hg and p is simply Hggh. air air Figure 2. Hg Hg h = ? cm. h = ? cm. ORIFICE PLATE VENTURI d2 d2 d1 d1 A third arrangement (Figure 3.) places Hg manometers below the pipe. In this case the section of manometer tube above the Hg will be filled with the process fluid. This creates a ‘bifluid’ manometer and thus p = [.gh(for Hg) - gh(for process fluid)] or p = (Hg - fluid)gh or simply =gh. ORIFICE PLATE VENTURI d2 d2 d1 process fluid process fluid h = ? cm. Hg FLUID FLOW d1 h = ? cm. Figure 3. Hg Page 19 of 51 A SINGLE EQUATION FOR FLOW RATE IN VENTURIS & ORIFICE PLATES: The equation for calculating fluid flow through a venturi is derived from Bernoulli’s equation: h1 + z1 + 12/2g = h2 + z2 + 22/2g (where 2 is in pipe, 1 is in throat) eqn 1) Since elevation is constant, (Z1 = Z2), this term is cancelled from both sides of the equation and the equation then rearranged to solve for p as p2 – p1 (where p2 > p1). p = (p2 – p1) = ½ (v12 – v22) eqn 2) From A1v1 = A2v2, we know (by rearrangement) that v1 = v2(A2/A1) After substituting for v1 in eqn 2) we obtain p = (p2 –p1) = ½ ( [v2(A2/A1)]2 – v22] After factoring out v22 we obtain: p = (p2 –p1) = ½ v22 [(A2/A1)2 – 1] Rearranging to isolate v22 and then taking the square root we obtain the following for v2: v2 2 2p 2 A2 1 A 1 2p v2 d2 d1 4 1 Units = ft 2 s2 ft m cm , , , etc. s s s difference of mass densities of manometer fluids. mass density of process fluid 2p and since Q = Av, then Q A2 v 2 A2 d2 d1 4 1 Units = ft 3 m 3 , , etc. s s eqn 3) p can be calculated as gh for a single fluid manometer (Fig 1 & 2) or as gh for a bifluid manometer (Fig 3), where is the difference in the mass densities of the two different manometer fluids. See the following two equations 2 g h 2 g h Single fluid: Q A2 d2 d1 4 1 or Bifluid: Q A2 d2 d1 4 1 Since the manometer and process fluid are the same fluid cancels and the equation is further simplified. Q A2 FLUID FLOW 2 g h d2 d1 4 1 Page 20 of 51 Equation 3), although derived for venturis will also work for orifice plates. However, because greater frictional loss is incurred across an orifice plate, a correction factor (called the Coefficient of Discharge), Cd, is included for orifice plates. 2 g h Q C d A2 d2 d1 4 1 Cd is a dimensionless factor that is empirically determined, i.e., determined by actual flow rate measurements. Typical values range from 0.78 to 0.98. The Orifice Plate: The orifice plate is exactly what its name implies; a plate with an orifice in it. There remains a permanent head loss downstream of the orifice; pressure does not fully recover to the pressure ahead of the orifice. The loss can be attributed to the great amount of friction (turbulence) induced as the flow lines change abruptly through the orifice. concentric orifice plate eccentric orifice plate segmental orifice plate Orifice Plate Shapes: 1. Concentric: In this case the hole in the orifice plate is on the same center as the pipe. This is most common. 2. Eccentric: The orifice plate hole is not centered with the pipe center and is usually situated tangential to the pipe bottom. This is used for slurries in which suspended solids would build up around the orifice plate. 3. Segmental: The orifice hole is not circular; but rather a partial circle. FLUID FLOW Page 21 of 51 Orifice Faces: . are usually either sharp edged or round-edged sharp-edged orifice round-edged orifice Pressure taps or manometer connections are most important. In order to obtain valid results, the downstream pressure tap should be located directly over the vena contracta. However, the position of the vena contracta and its diameter are not known exactly since these change depending upon the flow rate. The 3 generally accepted positions recommended by manufacturer’s and ISA are: 1. taps located right at the flanges on either side of the orifice (integral with the flange) 2. taps 1 D (pipe diameter) upstream and ½ to 1 D downstream (approx. vena contracta taps) 3. taps 2.5 D upstream and 8 D downstream (gives total pressure loss; there is no further pressure recovery). Problem 9: Calculate the flow rate of water flowing through a 12.0 in. diameter pipe given that when passing through a 6.00 in. diameter orifice plate a pressure differential of 3.50 ft. is measured with a manometer containing a fluid with s.g. = 1.25. Assume the manometer is below the pipe and assume a Cd of 0.970. Ans: 1.48 ft/s Obtaining Cd: 1. Data and graphs are available from manufacturers, which relate Cd to factors such as orifice to pipe diameter and position of pressure taps. 2. Cd can be measured in the lab or process by taking pressure readings with known flow rates. Test conditions should approximate process conditions. 3. A calibration curve can be prepared in the process, which plots pressure differential versus flow rates again using known flow rates. Cd is thus unnecessary. The orifice meter is convenient and inexpensive. It can usually be fabricated on the work site and sufficient data is readily available in the literature so that calibration is often not necessary. It yields reasonably good accuracy when properly installed and calculations are carried out correctly. The orifice must be installed in a location devoid of turbulence from the piping system and so is usually installed in a long straight section of piping. Accuracy: The square root relationship between pressure differential and flow makes the orifice plate impractical for low flow rates. At higher flow rates, e.g., Q > 5 gal/min, orifice plates give an accuracy of 5%. FLUID FLOW Page 22 of 51 Venturi Tubes This is an accurately machined piece and few shops are equipped to fabricate it. It is normally purchased. This design gives a Cd of 0.97 to 0.98. It gives better accuracy than other pressure differential meters and creates less permanent head loss but is more expensive. Problem 10: Calculate the flow rate through a venturi meter having a pipe diameter of 10.0 cm and throat diameter of 5.0 cm if the difference in the height of water in the manometer is 6.0 cm. p is measured by pressure taps above the pipe. Ans: 2200 cm3/s Problem 11: Using the same pipe and venturi dimensions as in problem 10 (above), calculate the flow rate of water when the difference in height of Hg in a manometer is 0.476 cm. Water is the fluid being measured. The manometers are below the pipe. Ans: 2200 cm3/s Comparison of Head Meters Flow meters, like the orifice plate and venturi meter, that measure pressure drop to determine flow rate are called head meters. Head meters work best at higher flow rates. At lower rates, accuracy suffers dramatically. Orifice plates are inexpensive, easy to install and maintenance free. They are usually accurate to within 3-5%. However, they will wear with time (causing drift in readings), have a variable & unknown Cd so they may require on site calibration and they induce high permanent pressure drops (hf). Venturis, by comparison, are more accurate and stable over time. They also introduce only a small pressure drop. However, they are considerably more expensive than orifice plates. FLUID FLOW Page 23 of 51 Pitot Tubes impact pressure static pressure Pitot tubes, also designated stagnation meters or impact meters, are included in the general class of Head meters because flow rates are deduced from a pressure head created by the impact of a moving fluid. Consider a bent glass tube submerged in a flowing liquid and with its submerged end pointing directly upstream. x is a point just outside the tube entrance y is a point just inside the tube entrance x y Total energy at x = Total energy at y H + v2/2g = H + h h = v2/2g 2g h C 2g h where C is a correction factor called the Pitot tube coefficient. C is 1 when Re > 3,000. The Pitot tube can also be inserted into closed pressurized systems (pipes and vents). In this case the tube will measure static head in addition to velocity head. To eliminate the static head, the Pitot tube is encased with an outer tube, which also contains an opening but at right angles to the flow rather than in line with the flow. The outer port thus only measures static head. The two ports are connected to opposite ends of a manometer (or some other p measuring device) and the differential pressure recorded is only the velocity head (impact pressure). Flow is thus measured by the same square law formula previously discussed. Installation is simple and permanent head loss is negligible. However, measurement is an indication of velocity at one point only, in contrast to other flow elements that measure the average velocity of the entire stream. To obtain an average velocity it is necessary to traverse the conduit both horizontally and vertically with the Pitot and average the results. This factor plus the difficulty in properly positioning the Pitot, the low differential pressure produced, and the tendency to pluggage has resulted in the Pitot tube being used in limited applications, e.g., sampling rather than continuous process measurement. FLUID FLOW Page 24 of 51 With proper positioning and suitable flow rates, accuracy can attain 1%. Pitot tubes are used for measuring gas or liquid flows at up to 2000 psi and 1200 ºF. As previously discussed, flow velocity is not uniform over the entire cross section of a pipe but in fact a profile of velocities exists beginning with very low flows at the pipe wall and maximum velocities at the center. Problem 12: Calculate the Pitot tube coefficient (C) for the following set of data: v (ft/s) 1.86 3.92 4.20 7.80 h (in. H2O) 0.76 1.73 3.50 14.40 Ans: 1.03 Head Meters and Automatic Process Control Although converting pressure differentials to flow can be done with the aid of tables or calculators, for use in automatic process control suitable transducers and microprocessors are required. A number of the pressure measuring devices already discussed in the unit on pressure are used in industry. In many instances, temperature and density sensors (densitometers) are coupled to a computer and volumetric flow can be converted to mass flow, which is generally more desirable. CLASS 1 flow meters are ‘DIFFERENTIAL (HEAD) METERS, just discussed, i.e., orifice plates, venturis and Pitot tubes, for example. FLUID FLOW Page 25 of 51 CLASS 2 flow meters are VARIABLE AREA METERS, the most familiar example being rotameters. Rotameters Rotameters are classed as variable-area meters. They consist of a tapered glass tube in which a suitable "float" is buoyed up to a height that corresponds to the flow rate of the fluid moving up the tube. The flow rate is proportional to the height of the float. The basic eqn for flow through orifice, nozzle, and venturi meter is ... Q A Cd 2g h outlet metal or glass ‘float’ suspended in tapered tube by rising fluid. In the rotameter, the downward force is the weight of the float (often steel, glass, etc.) and ROTAMETER the upward force is a combination of friction and impact from the rising fluid. However the p (or h) is constant at any position of the inlet float, the area in the annular space between the float and the tapered walls changes to keep upward force constant. Rotameters are suitable for low or high flow measurement, limited only by the construction of the meter. Rotameters are used for liquids and gases. The float can be connected to an armature and its position thus can provide variable inductance to an electronic transducer as part of an automated process control loop. Float height is sensitive to density changes (and thus temperature changes). Density compensation is accomplished by using a float whose density is one half that of the fluid. Rotameters are made in a large variety of materials and in sizes from 1/8 in. to 6 in. nominal pipe size. Maximum flow capacities range from 2 cm3/min to 900 gal/min for water and 70 cm3/min to 1000 SCFM for air. Accuracy is normally about 2% of full scale. At 10 % flow, 2 % full scale translates to 20 % of rate, however, by comparison, a head meter would be useless at 5 to 10 % of full scale at the same flow rates. OMEGA ROTAMETER FLUID FLOW Page 26 of 51 CLASS 3. POSITIVE DISPLACEMENT METERS The positive displacement meter for liquid service is made up of a measuring chamber and a scaling section between the inlet and outlet connections. It splits the flow of the liquid into separated measured volumes based on the physical dimensions of the meter and counts them or ‘totalizes’ them. The measuring chamber follows a fixed path and on each revolution of the meter is filled at the inlet and discharges at the outlet. The total quantity of fluid passing through the meter in a given time is the product of the volumes of the chambers and the number of fillings. Flow is measured by counting the number of revolutions. Since the moving components of the meter are in the flowing stream, a pressure drop occurs. Close mechanical clearances are necessary to minimize leakage from one measuring chamber to the next. Thus operation is enhanced by the lubricity of the flowing fluid, and leakage decreases as fluid viscosity increases. Solid particles in the fluid cause rapid wear and loss of accuracy. A strainer is required upstream from each positive displacement meter to prevent foreign particles from entering the meter. Many positive displacement flow meters are used industrially. One type is shown. Rotary Sliding Vane vane rotor Spring-loaded vanes seal increments of liquid between the eccentrically mounted rotor and the housing and transport them from inlet to outlet. The vanes slide in and out of the rotor as it rotates. As the liquid enters the meter, the vanes extend to enclose the measuring chamber. At the outlet, the vanes retract and discharge the volume of liquid. FLUID FLOW Page 27 of 51 Class 4 Volumetric Flow Meters Electromagnetic Meter (Mag Flow Meter) are one of the most important examples of volumetric flow meters. The mag flow meter is based on the principle that electrical currents are induced in a conductor that is moved through a magnetic field. According to Faraday’s Law, the voltage produced is proportional to the intensity of the magnetic field and the velocity of the conductor. The flowmeter consists of straight section of pipe (no pressure drop or clogging from solids), encased with the windings of an electromagnet. A magnetic field produced by these windings induces a current in a secondary circuit, which is completed via two electrodes that make electrical contact through the flowing liquid. In order to serve as a conductor, the fluid requires a minimum conductivity of 50 micromhos/cm (5000 microSiemens/m). All electrical hardware must be well shielded to prevent interference from stray magnetic flux from nearby equipment. Accuracy is as good as 1%. Mag meters are not affected by dirt or varying viscosity but are suitable for liquids only. FLUID FLOW The pipe is straight through (unobstructed) and encases electromagnetic windings OMEGA MAG FLOW METER Page 28 of 51 OPEN CHANNEL FLOWMETERS Most open channel flow measuring devices are sophisticated adaptations of level measurements practiced by the Egyptians on the Nile over 4000 years ago. Measurements are made by the use of a calibrated restriction inserted into the channel, which changes the level of the flowing liquid in or near the restriction. The shape and dimensions of the restricting structure establish a known relationship. Flow rates in an open channel are thus derived from a single measurement of liquid level in the channel. Weirs A weir is an open dam with an opening or notch in the upper edge through which the liquid flows. The weir is low in cost, relatively easy to install, and quite accurate ( 5%) if carefully installed. However, it normally operates with a significant loss in head, and accuracy is very sensitive to the approach velocity of the liquid. Thus it requires an upstream weir box or silting chamber that permits the flowing liquid to attain low velocity before reaching the weir and serves as a chamber to settle out debris. notch weir h The weir must be cleaned regularly to prevent accumulation of solids and sediment in the upstream side that would otherwise adversely affect accuracy. Weirs are classified according to the shape of the notch; common types are trapezoidal (Cipolletti), rectangular, and triangular (V-notch). The V-notch weir is well suited to low flows (0.01 - 10 cfs). The rectangular weir is used in flow ranges of 0.5 - 300 ft3/s. The Cipolletti weir has a slightly wider range and a simpler level/ flow relationship but is slightly less accurate. The top edge of a weir is thin or beveled so that the overflowing liquid does not contact any part of the weir’s downstream face but is projected past it as a sheet of water. The water surface downstream must be far enough below the bottom of the notch so that air moves beneath the sheet of water. The condition is known as free critical flow and is required for dependable measurements. The sharp-crested weir can be damaged by floating objects in the flow or even by the force of large quantities of liquid. It is thus used for clean liquids and relatively small flows. Broad-crested weirs are much more robust, being constructed of concrete, and are normally use for larger sizes of open channels or rivers. Broad-crested weirs, in practice, are usually pre-existing structures such as dams and levees. Discharge coefficients are obtained by calibrating the weir in place or by model studies. FLUID FLOW Page 29 of 51 Flumes A flume is a specially shaped open channel flow section which consists of a converging section to restrict flow, a throat section and/or a change in channel slope that results in increased velocity, and a diverging section that ensures that the downstream level is less the level in the converging section. A float well, connected to the side of the flume contains a graduated float that measures the depth of water moving through the flume. float well throat size W Parshall Flume (top view) A flume can measure a higher flow rate than an equally sized weir but with much smaller head loss than the weir. It is better suited to flows carrying solids or sediment, since its high velocity makes it self-cleaning. Disadvantages include poorer accuracy ( 10 %) and a more costly installation. The flow through the flume can be classified as subcritical, critical, or supercritical by the Froude number, which is a ratio of inertial forces to gravity forces in the flowing liquid. Since inertia is related to throat velocity, the flume increases velocity by increasing channel slope and reducing throat width. Flumes that operate at subcritical velocity require two level measurements, one at the inlet and one at the throat, to determine flow rate. Critical and supercritical velocities permit determination of flow by a single level measurement at the inlet. Thus most flumes are designed to pass flow from subcritical through critical near the point of measurement. A flume is said to be submerged downstream when the downstream level rises sufficiently to reduce the discharge. This results in a reduction in velocity and an increase in flow depth in the throat. The measurement of submerged flow requires level measurements at the inlet and at the throat and greatly complicates the determination of flow rate. Flow rates are usually determined by taking level measurements and reading flow rates from nomographs or tables. FLUID FLOW Page 30 of 51 CARBON STEEL PIPE DATA Nominal Tube Size (in) Schedule Number O.D. 3/8 40 80 1/2 FLUID FLOW Wall Thicknes s (in) Wt./Ft. (lbs) Wt. H2O/ft (lbs) 0.675 0.091 0.126 0.567 0.738 0.083 0.061 40 80 0.840 0.109 0.147 0.850 1.087 0.132 0.101 3/4 40 80 1.050 0.113 0.154 1.130 1.473 0.230 0.186 1 40 80 1.315 0.133 0.179 1.678 2.171 0.374 0.311 1¼ 40 80 1.660 0.140 0.191 2.272 2.996 0.647 0.555 1½ 40 80 1.900 0.145 0.200 2.717 3.631 0.882 0.765 2 40 80 2.375 3.652 5.022 2½ 40 80 2.875 0.154 0.218 0.203 0.276 5.790 7.660 1.452 1.279 2.072 1.834 3 40 80 3.500 0.216 0.300 7.570 10.250 3.200 2.860 3½ 40 80 4.000 0.226 0.318 9.110 12.510 4.280 3.850 4 40 80 4.500 0.237 0.337 10.790 14.980 5.510 4.980 5 40 80 5.563 0.258 0.375 14.620 20.780 8.660 7.870 6 40 80 6.625 0.280 0.432 18.970 28.570 12.510 11.290 8 40 80 8.625 0.322 0.500 28.550 43.390 21.600 19.800 10 40 80 10.750 0.365 0.593 40.480 64.400 34.100 31.100 12 40 80 12.750 0.406 0.687 53.600 88.600 48.500 44.000 (in) Page 31 of 51 Problems for Fluid Flow 1. Water if flowing through a pipe with a 6.00 inch ID at a flow velocity of 20.0 ft/s. The pipe ID reduces to 3.00 in. What is the flow rate in the reduced section? 2. Oil flows through a 1.00 in ID pipe at a rate of 20.0 gpm (Imp.). A valve placed in the pipe has a passage in it of 0.750 in diameter. What are the flow velocities in the pipe and through the valve? 3. Fluid is introduced into a pump through a 1.50 in suction line and discharged through a 1.00 in port. If the discharge flow rate is 40.0 gpm (Imp.), what are the flow velocities in the inlet and outlet port? 4. If the discharge pressure of the pump in question 3 is 1.50 103 psi, calculate the horsepower required to drive the pump. (Assume inlet pressure to be 0). 5. A standpipe 50.0 ft high rests on top of a hill, 135 ft above the level of a pumping station. The pump sits in a pit 10.0 ft. below the floor level. If it delivers 1.00 104 gpm (Imp.) of water to the standpipe, what is the efficiency of the pump if it is driven by an electric motor of 6.00 102 H.P.? 6. The ballast pumps in a submarine submerged at a depth of 1.00 102 m discharge 2.00 104 L/s of sea water. Neglecting losses, determine the horsepower required to drive the pumps. 7. The fuel pumps in a ballistic missile deliver 1500 kg/min of liquid fuel (sg = 1.47) to the rocket engine nozzles at a pressure of 2.0 MPa. What horsepower must be delivered by the pumps? 8. Sea water is being pumped up a vertical pipe at a rate of 1.5 102 Imp gal/min. The cross-sectional area of the pipe at the bottom is 10.0 in2. The pipe narrows to a cross-sectional area of 4.00 in2 at a point 330.0 ft higher. What is the pressure difference between these two points (in atmospheres)? 9. If there was a head loss due to friction of 3.0 ft between the two points in question 8, what would be the pressure difference? 10. In the pump shown below, flow at the outlet is 35.0 Imp. gpm a) What is Q at the inlet? b) If the fluid is water, the pump is 65% efficient and is driven by a 5.00 H.P. motor. What is the pressure difference across the pump? 2.00” ID 1.00” ID P FLUID FLOW Page 32 of 51 11. In the diagram below, water is being pumped up from a reservoir. The elevation at point 1 is 30.0 m, at point 2 and 3 is 33.0 m, and at point 4 is 40.0 m. The velocity at point 3 is 6.0 m/s. An electrical motor delivers 25 H.P. to the pump, which is 75.0 % efficient. If the head loss from 1 to 2 is 0.60 m and the head loss from 3 to 4 is 1.20 m, what is the pressure at point 4 in m H2O? 4. 1.00” ID 3.00” ID 2. 3. P 1. 12. A 45.0 cm ID pipeline carries oil ( = 0.700 g/mL) at an average velocity of 3.60 m/s. If the pipe narrows to 30.0 cm ID, what will be the velocity in the narrow portion? 13. A piping system is constructed of schedule 40 steel pipe. A 3 inch pipe carries water at a velocity of 50 fps and a 2 inch pipe carries water at a velocity of 25 fps. Both the 2 inch and the 3 inch pipes flow into a 6 inch pipe (Schedule 40). What is the velocity in the 6 inch pipe? 14. Crude oil (sg = 0.800) at a rate of 3.00 103 lb/min flows in a channel 3.00 ft wide and 18.0 inches deep. If the flow occupies exactly one half of the depth of the channel, what is the velocity of the crude oil in ft/s? 15. The city water main supplying a large apartment building has a maximum pressure of 51.5 psia. The water taps on the top floor at the building are 150 ft above the water mains. Calculate the maximum pressure available at these taps in psig. 16. If the head loss between sections 1 and 2 is 3.50 ft, calculate the pressure (in psig) in the 3 inch pipe. The velocity in the 6 inch pipe is 10.0 ft/s of water. 3.00” ID 2. 6.00” ID, 28.0 psig 18.0’ 1. FLUID FLOW Page 33 of 51 17. A pump takes water at 50F from a large reservoir and delivers it to the bottom of an open elevated tank. The level in the tank averages 160 ft above the surface of the reservoir. The line is 3 inch standard pipe and head loss is 18.6 ft. If the pump delivers 150 gal/min and has an efficiency of 55%, what horsepower is consumed. 18. At one point A in a pipeline carrying oil (sg = 0.900) the diameter is 6.00 in and the pressure is 25.0 psig. At another point B, 20.0 ft above A, the diameter is 12.0 in and pressure is 18.0 psig. If oil flows in the system at a rate of 1.00 ft3/s, is the oil flowing from A to B or B to A? 19. An aqueous methanol solution ( = 0.83, = 0.96 cP) is to be pumped from a storage tank to a process through a 1¼ inch standard steel pipe. The process end of the line must have a pressure of 8.0 psig and is 22 ft above the surface of the liquid in the storage tank. The flow is rated at 20 gpm (Imp) but may be overloaded by 50%. The head loss due to friction is 300 ft of the methanol solution. Assuming a 60 % pump efficiency, calculate the output required by the electric motor for this service. Report your answer to 3 sig figs. 20. A standard 2 inch steel pipe is conveying an oil of specific gravity of 0.850 at a rate of 90.0 L/min. At a certain point in the line the pressure is 310 kPa. Calculate the Reynolds number and pressure at a point in the line that is 61.0 m of pipe further along in the direction of flow and is 15.0 m lower in elevation. Assume a head loss due to friction of 1.00 m of oil. The oil has a viscosity of 20.0 cP at the temperature of the process. 21. A technologist is investigating a gravity feed that is to supply a vinegar solution to a processing unit as shown in the diagram. The process requires a flow rate of 10.0 gal/min (Imp) and a pressure of 10.0 psig at point B, just before the processing unit. The vinegar has a specific gravity of 1.005 and a viscosity of 1.00 cP. The piping is 3 inch schedule 40 steel pipe. Calculate the velocity and Reynolds number at point B. Assuming the frictional head loss is 0.11 ft. of fluid, determine the minimum height of vinegar required in the storage tank. A ?’ 10.0’ 10.0’ FLUID FLOW B Page 34 of 51 Answers to Problems 1. Q = 3.93 ft3/s 2. 2 = 80.1 ft/s p = 587 ft/min valve = 1044 ft/min 3. in = 8.69 ft/s out = 19.6 ft/s 4. 42.0 HP 5. 98.5% effic. 6. 2.70 104 HP 7. 45.6 HP 8. p = 10.1 atm 9. p = 330 ft sea H2O 10. a) Q = 35.0 Imp gal/min b) 302 ft H2O 11. p = 454 m fresh H2O 12. = 8.1 m/s 13. = 15.3 ft/s 14. = 0.44 ft/s 15. p = -28.2 psig 16. p = 8.6 psig 17. HP = 14.8 18. B A 19. Re = 7.12 104, hp = 17900 lb/ft2, HP = 4.34 20. Re = 1546 (laminar), p = 426 kPa 21. Re = 1.24 104, depth of fluid in tank must be at least 3.1 ft.. FLUID FLOW Page 35 of 51 SOLUTIONS TO “PROBLEMS FOR FLUID FLOW’ (pages 32-34) 1. 1. 2. v1 = 20.0 ft/s d1= 6.00 in. v2= ? d2 = 3.00 in. v2 = v1 (d1/d2)2 = 80.0 ft/s Q = A1v1 = (d12/4)v1 = 3.93 ft3/s (3 sig figs) Q is constant so it is calculated as A1v1 or as A2v2 Convert d1 from inches to feet and include units in calc. 2. Q = (20.0 Imp g/min)(1 min/60s)(1 ft3/6.24 Imp gal) 1. 2. = 0.0534 ft3/s A1 = [(1/12 ft)2/4] = 0.00545 ft2 d1 = 1.00 in d2 = 0.750 in v1 = Q/A1 = (0.534 ft3/s)/[0.00545 ft2] = 9.8 ft/s = 587 ft/min Q = 20 Imp gpm v2 = v1 (d1/d2)2 = (9.8 ft/s)(1 in/0.75 in)2 = 1044 ft/min Q has 3 sig figs. 3. Q = (40.0 Imp g/min)(1 min/60s)(1 ft3/6.24 Imp gal) P 1. 2. = 0.1068 ft3/s A1 = [(1.5/12 ft)2/4] = 0.0123 ft2 d1 = 1.50 in d2 = 1.00 in v1 = Q/A1 = (0.107 ft3/s)/[0.0123 ft2] = 8.70 ft/s Q = 40.0 Imp gpm v2 = v1 (d1/d2)2 = 19.6 ft/s Answers should have 3 sig figs. 4. p = 1.5103 psi. P = pQ = [1500 lb/in2 (144 in2/1 ft2)] (0.1068 ft3/s) = 23070 ftlbs-1 HP = (23070 ftlbs-1)(1 HP/ 550 ftlbs-1) = 41.9 HP This calculation assumes that the pump is 100% efficient (which is never true). To calculate a realistic value, divide the answer by the efficiency, e.g., 0.95, 0.80, etc. Q = (1.00E4 Imp g/min)(1 min/60s)(1 ft3/6.24 Imp gal) = 26.71 ft3/s p = 195 ft H2O (2116 lb/ft2/33.9 ft H2O) = 12,180 lb/ft2 P = pQ = (12,180 lb/ft2) (26.71 ft3/s) = 3.25E4 ftlbs-1 HP = (3.25E4 ftlbs-1)(1 HP/ 550 ftlbs-1) = 591 HP The pump consumes 600 HP, but works at a rate of 591 HP The % efficiency of the pump = (591 HP/600 HP) 100% = 98.5% efficient 5. 50 ft 135 ftPumping Station 10 ft P FLUID FLOW Page 36 of 51 6. The pump must work at a pressure equal to the water pressure at a depth of 100 m Sea water is denser than fresh water (s.g. = 1.027) 100 m sea H2O exerts the same pressure as 102.7 m 100m deep fresh submarine 7. 102.7 m H2O(101325 Pa / 10.33m H2O) = 1.010E6 Pa Q = 2.00E4 L/s (1 m3/103L) = 20 m3/s P = pQ = (1.01E6 N/m2)(20 m3/s) = 2.02E7 watts = 2.02E7 watts (1 HP/ 746 W) = 2.70E4 HP Q = 1500 kg/min (1L/1.47 kg)(1 min/60s)(1m3/103L) = 0.017m3/s p = 2.0 MPa = 2.0E6 Pa or N/m2 P = pQ = (2.0E6 N/m2)(0.0170m3/s) = 34010 Watts (1 HP/746 W) = 45.6 HP 8. 2. A1 = 10.00 in2, A2 = 4.00 in2 Q = 1.5E2 gal/min (1 min/60 s)(1 ft3/6.24 Imp gal) = 0.401 ft3/s 330 A1 = 10 in2 (1ft2/144in2) =0.0694 ft2 3 2 ft v1 = Q/A1 = (0.401 ft /s) (0.0694 ft ) = 5.77 ft/s 1. v2 = v1(A1/A2) = 5.77 ft/s (10in2/4in2) = 14.4 ft/s You cannot simply use the pressure depth equation because the fluid is moving through pipes of changing diameter and this also affects pressure. Use Bernoulli’s equation to calculate the difference in pressure. 2 h1 z1 2 v1 v h2 z 2 2 2g 2g (5.77 ft / s ) 2 (14.4 ft / s ) 2 h 330 ' 2 2 (32.2 ft / s 2 ) 2 (32.2 ft / s 2 ) h1 0'0.52' h2 330 '3.22' h1 0' 1 atm h1 h2 333 .2 0.52 333 ft sea water 10.1 atm 33.0 ft sea water Note the pressure is lower at the higher elevation. The pressure is 333 ft sea water less at an elevation 330 ft higher. The additional 3 feet pressure loss is due to the increased fluid velocity in the smaller pipe. 9. If 3 ft of fluid pressure were lost due to friction of the fluid traveling between 1 and 2, there would be 3 ft less fluid pressure difference between these points. The difference in pressure between point 1 and 2 would then be only 330 ft sea water or 10.0 atm. FLUID FLOW Page 37 of 51 10. a) b) 2.00” ID The inlet and outlet flows must be constant since liquids are relatively non compressible fluids. Q = 35.0 gpm 1.00” ID P P = 5.00 HP(550 ftlbs-1/1 HP) 0.65 efficiency = 1788 ftlbs-1 Q = (35 Imp gal/min) (1 min/60 s)(1 ft3/6.24 Imp gal) = 0.0935 ft3/s p = P/Q = (1788 ftlbs-1) / (0.0935 ft3/s) = 19120 lb/ft2 (33.9 ft. H2O/2116 lb/ft2) = 306 ft H2O A1 = [(2”/12 ft)2/4] = 0.0218 ft2 v1 = Q/A1 = (0.0935 ft3/s) / (0.0218 ft2) = 4.29 ft/s v2 = v1 (d1/d2)2 = 17.1 ft/s 2 h p h1 z1 2 v1 v h2 z 2 2 2g 2g (4.29 ft / s ) 2 (17.1 ft / s ) 2 h 0 ' 2 2 (32.2 ft / s 2 ) 2 (32.2 ft / s 2 ) 306 .1 h1 0'0.29' h2 0'4.56' 306 .1' h1 0' h2 h1 306 .4 4.56 302 ft fresh water The pressure added by the pump is the term ‘hp’ in Bernoulli’s equation. Since no change in elevation is stated we assume the elevation is unchanged so z1 and z2 are both zero and can be left out of the equation if you wish. 11. 3.00” ID 4. 1.00” ID hf = 1.20 m 2. P 3. z = 10 m hf = 0.60 m 1. d2 = 3.00 in d3 = 1.00 in v2 = ? m/s v3 = 6.0 m/s FLUID FLOW v2 = v3 (d3/d2)2 = 0.667 m/s d3 = 1 in = 2.54 cm = 0.0254 m A3 = [(0.0254 m)2/4] = 5.067E-4 m2 Q = A3v3 = (5.067E-4 m2) (6.0 m/s) =0.00304 m3/s P = 25 HP 0.75 effic. = 18.75 HP (746 W/1 HP) = 13990 Watts or Nm/s Page 38 of 51 p = P/Q = (1.4E4 Nms-1)/(0.00304 m3/s) = 4.60E6 N/m2 (10.3 m/101325 Pa) = 468 m H2O=hp 2 2 v v h p h1 z1 1 h4 z 4 4 h f The elevation (z1) and pressure head 2g 2g (h1) at 1 are both zero since the pump is (0.667 m / s ) 2 (6.0m / s ) 2 h 10 m hf 4 2 (9.81m / s 2 ) 2 (9.81m / s 2 ) 468 m 0.023 m h2 10 m 1.83m h f 468 m 0 0 h2 (456 .2m fresh water - h f ) (456.2m - 1.8m) 454m fresh water drawing from the surface of the reservoir. The head losses due to friction, hf, (1.2m + 0.6m H2O) total 1.8m. The pressure at 4 (from Bernoulli’s eqn) is decreased by this amount. 12. The density is irrelevant for the calculation required. Velocity is inversely proportional to the square of the diameter of the pipe. v2 = v1 (d1/d2)2 = 8.1 m/s 13. You must use the pipe tables to determine the correct internal diameters. 1 2 ID = OD – 2(wall thickness) d1 = 3.50” – 2(0.216”) = 3.068” d2 = 2.375” – 2(0.154”) = 2.067” d3 = 6.625” – 2(0.280”) = 6.065” A1 = [(3.068”/12 ft)2/4] = 0.0513 ft2 A2 = [(2.067”/12 ft)2/4] = 0.0233 ft2 A3 = [(6.065”/12 ft)2/4] = 0.201 ft2 Q3 = Q1 + Q2 = A1v1 + A2v2 = (0.0513ft2 50 ft/s) + (0.0233ft2 25 ft/s) = (2.565 ft3/s + 0.5825 ft3/s) = 3.148 ft3/s v3 = Q3/A3 = (3.148 ft3/s) (0.201 ft2) = 15.7 ft/s The flow rate in pipe 3 must be the sum of the flow rates in pipes 1 and 2 3 14. This is a simple calculation of fluid velocity using Q = Av. The carrier is a rectangular-shaped trench rather than a cylindrical pipe. The cross sectional area of flow is 3.00 ft 18”/12 ft ½ (because the trench is half-full). A works out to 2.25 ft2. Convert Q to units of ft3/s and you can calculate velocity in ft/s. Doil = DH2O 0.80 = (62.43 lb/ft3) 0.8 = 49.94 lb/ft3 Qoil = 3000 lb/min (1 ft3/49.94 lb) (1 min/60s) = 1.00 ft3/s voil = Q/A = (1.00 ft3/s) 2.25 ft2 = 0.44 ft/s 15. Calculate the height of water that exerts the same pressure as supplied by the water main. Compare this to the height to the top floor of the building. Don’t forget to work in psi gage not absolute. When a person on the top floor opens the tap, atmospheric pressure will push against the water flowing from the tap. pg = 5.5 psia – 14.7 psi = 36.8 psig 150 ft 36.8 psig (33.9 ft H2O/ 14.7 psi) = 85 ft! This is not enough pressure to reach the top. p = 51.5 psia The maximum height at which water will flow from the tap is 85 ft. FLUID FLOW Page 39 of 51 Tall apartments buildings must supplement city water presssure by adding a pump. In this case the building will need an additional 28 psi. because 150 ft H2O (14.7 psi/33.9 ft) = 65.0 psi 65.0 psi – 36.8 psi = 28.2 psi. FLUID FLOW Page 40 of 51 16. 3.00” ID 2. This is another problem where Bernoulli’s eqn is needed because both elevation and velocity are changing. v2 = v1 (d1/d2)2 = 40.0 ft/s 6.00” ID, 28.0 psig 1. 2 h1 z1 18.0 ’ hf = 3.50 ft 2 v1 v h2 z 2 2 h f 2g 2g (10 ft / s ) 2 (40 ft / s ) 2 h 18 ' 3.5' 2 2 (32.2 ft / s 2 ) 2 (32.2 ft / s 2 ) 64.6'0'1.55' h2 18'24.8'3.5' 64.6'0' 14.7 psi h2 19.85 ft fresh water 8.6 psig 33.9 ft Since you are given p1 = 28 psig, the changes in pressure due elevation and velocity do not change the fact that we are calculating gage pressure. If the pressure at p1 were given as 28.0 psia, then the pressure at p2 would be 8.6 psia. 17. Q = (150 Imp gal/min) (1 min/60 s)(1 ft3/6.24 Imp gal) = 0.401 ft3/s p = 160 ft + 18.6 ft = 178.6 ft ( 2116 lb/ft2/33.9 ft H2O) patm = 11,150 lb/ft2 18.6 ft is head loss due to friction, (hf). P = pQ = (11,150 lb/ft2) (0.401 ft3/s) = 4470 ftlbs-1 = 4470 ftlbs-1 (1 HP/550 ftlbs-1) = 8.13 HP required. P consumed by pump = 8.13 HP/0.55 = 14.8 HP At a temperature of 50°F, the s.g. of water is very close to standard value of 1.0. The limited acccuracy of the data in the question does not warrant factoring in the density. It wouldn’t make P any difference in this problem. FLUID FLOW 160 ft Page 41 of 51 18. A tricky problem. Calculate the total energy of the oil at both A and B. Since it is flowing, there must be some energy loss due to friction (hf). If energy at A B is less than at B, then flow must be from B to A, since energy would be lost when the oil flows from B to A. 20 ft Get it? Oil has s.g. = 0.90, so the height of oil that would exert a pressure equivalent to 33.9 ft of H2O will be A 33.9 ft/0.90 = 37.67 ft oil. It’s best to work in height of process fluid in Bernoulli’s equation and only convert to other units at the end, if necessary. v1 = Q/A1 = (1.0 ft3s)/(0.1964 ft2) = 5.09 ft/s [It is assumed that you can calculate A1] v2 = v1 (d1/d2)2 = 1.27 ft/s p1 = 25 psig(37.67 ft oil/14.7 psig) = 64.1 ft oil p2 = 18 psig(37.67 ft oil/14.7 psig) = 46.1 ft oil 2 h1 z1 2 v1 Energy at A 2g h2 z 2 (5.09 ft / s ) 2 64.5' oil 2 (32.2 ft / s 2 ) 46.1'20' 64.1'0' v2 Energy at B 2g (1.27 ft / s ) 2 66.1' oil 2 (32.2 ft / s 2 ) Note that the Energy (as pressure) at B is greater than at A by 1.6 ft of oil. Since the pressure is greater at B, the flow must be from B to A, i.e., from high pressure to low. 19. The viscosity is irrelvant but the density is important. to process The pump must deliver 8 psig greater than the hydrostatic p = 8.0 psig head (h1) of the methanol in the tank. patm Calculate what height of methanol this 8 psig is 22 ft equivalent to. Methanol has s.g. = 0.83, so the height of methanol that would exert a pressure equivalent to 33.9 ft of H2O will be 33.9 ft/0.83 = 40.8 ft methanol. p2 = 8.0 psig(40.8 ft methanol/14.7 psig) = 22.2 ft methanol. The pump must supply enough power to raise the P methanol 22.0 ft and deliver it at a pressure equivalent to 22.2 ft. The pump must also supply power to increase the velocity of the methanol from rest (0 ft/s) in the tank to some velocity on the output side of the pump. Calculate this velocity and then combine all terms in Bernoulli’s equation. d2 = OD – 2(thickness) = 1.660” -2(0.140”) = 1.38” (Standard 1 ¼ “ pipe means Schedule 40 1 ¼ “ pipe. Use the pipe tables to get ID) A2 = [(1.38”/12 ft)2/4] = 0.01039 ft2. The flow must be multiplied by 1.5 to allow for 50% overload mentioned in the problem Q = (20 1.5 Imp gal/min) (1 min/60 s)(1 ft3/6.24 Imp gal) = 0.0801 ft3/s v2 = Q/A2 = (0.0801 ft3/s)(0.01039 ft2) = 7.71 ft/s You should now be able to solve Bernoulli’s equation FLUID FLOW Page 42 of 51 2 2 v v h p h1 z1 1 h2 z 2 2 h f 2g 2g (7.71 ft / s ) 2 300 ' 2 (32.2 ft / s 2 ) hp 0'0'0' 22.2'22'0.92 300 ' hp 345 ' methanol hp 0'0'0' 22.2'22' h1 is set to 0’ because we know it is 22.2’ of methanol less than h2. z1 is set to 0’ because we know it is 22 ft less than z2 hf is given in the problem as 300’ methanol 345 ft methanol is equivalent to: 345 ft (0.83/1) = 286 ft H2O (2116 lb/ft/33.9 ft H2O) =17880 lb/ft2 P = pQ = (17880 lb/ft2)(0.0801 ft3/s) = 1432 ftlbs-1 (1 HP/550 ftlbs-1) = 2.60 HP Finally, we must factor in the efficiency of the pump. We will need to use a pump that draws 2.60 HP/0.60 = 4.34 HP 20. For ‘standard’ (Schedule 40) 2” steel pipe: p = 310 kPa 1. d = 2.375” – 2(0.154”) = 2.067” ID. (0.0254 in/m) = 0.0525 m 3 3 3 Q = 90 L/min (1 m /10 L)(1 min/60 s) = 0.0015 m /s A = [(0.0525 m)2/4] = 0.00216 m2 v = Q/A = (0.0015 m3/s) (0.00216 m2) = 0.693 m/s 15.0 m We don’t need velocity for Bernoulli’s equation because the pipe does not change size (velcoity is constant), but we will 2. need fluid velocity to calculate Reynolds number. Convert the pressure at 1 from kPa to meters of oil (s.g. = 0.850) 310 kPA (10.3 m H2O/101.325 kPa) = 31.51 m H2O (1/0.850) = 37.1 m oil 2 2 v v h1 z1 1 h2 z 2 2 h f 2g 2g 37.1m 15m 0m h2 0m 0m 1m The mass density of oil = 1000 kg/m3 0.850 h2 51.1 m oil 51.1 m oil (0.850/1) = 43.4 m H2O (101.3 kPa/10.3 mH2O) = 426 kPa The pressure at elevation 1 is 426 kPa greater than at elevation 1. d v (0.0525m) (0.693m/s) (850kg/m 3 ) = 1546 = Laminar flow. 0.020 k g m 1 s 1 Be careful with viscosity units. 20.0 cP given = 0.20 Poise = 0.020 Pas. The units of Pa.s are kgm-1s-1 and are required to cancel all units. Reynolds number is dimensionless. Be sure to include units in your calculations. One mark is assigned to each question for units. Even if you get the correct answer, but leave out units, you will still lose a mark. You will make fewer errors if you include units (and you’ll get more marks from the instructor as well). Re FLUID FLOW Page 43 of 51 21. 3” Sch. 40 steel pipe has an ID of 3.068 in or 0.2557 ft. A = 0.0513 ft2 Q = 10.0 gal/min (1 min/60 s)(1 ft3/6.24 Imp gal) = 0.0267 ft3/s v = Q/A = 0.520 ft/s Pressure at B = 10 psig (33.9 ft H2O/14.7 psig) = 23.1 ft H2O (1/1.005) = 23.0 ft vinegar 2 2 v v h1 z1 1 h2 z 2 2 h f 2g 2g (0.52 ft / s ) 2 .011' 2 (32.2 ft / s 2 ) 0' z1 '0' 23.0 0'0.004 '.011' 0' z1 '0' 23.0 0' z1 23.1 ft vinegar You can see from the diagram that the bottom of the tank is 20 ft above point B, so we only need an additional 3.1 ft of vinegar to attain the 23.1 ft height of vinegar. So the tank need only be filled to a level of 3.1 ft to supply the required pressure at B. Re d v (0.256ft) (0.520ft/s ) (1.950slug /ft 3 ) 12420 turbulent 2.089 10 5 slug ft 1 s 1 The mass density of the vinegar is 1.9404 slug/ft3 (for water) 1.005 = 1.950 slug/ft3 1.00 cP = 2.089E-5 slugft-1s-1 Be careful. You must use a consistent set of units in calculating Re. is mass density so be sure to use either slug/ft3 or lbm/ft3. ’lbm’ is a mass unit called ‘pounds mass’. It is numerically equal to ‘lbf’, (1 lbm = 1 lbf), but they are not the same. ‘lbf’ is a unit of force. If you use lbm units for in calculating Re, then use a = 6.74E-4 lbmft-1s-1, as shown below. Re d v (0.256ft) (0.520ft/s ) (62.17lbm/ ft 3 ) 12420 turbulent 6.72 10 4 lbm ft 1 s 1 You will need to convert the mass density from slug/ft3 to lbm/ft3. Note that 1 slug = 32.17 lbm, so 1.950 slug/ft3 = 61.17 lbm/ft3. FLUID FLOW Page 44 of 51 FLUID FLOW TEST SUMMARY 1. You are responsible for all problems, those in the body of the notes and the problem set at the end of the notes. You will be required to read a pipe table (the ones in the notes) to get data to solve problems, e.g., determine ID for flow calc., or other such info. If you do the Pipes, Fittings and Valves self study, you should be prepared for this. 2. There will be a few short answer questions on the following topics a) the various types of flow meters described in the notes. b) Understand laminar and turbulent flow and critical velocity and the corresponding Reynolds numbers c) Understand factors that affect fluid friction in laminar and turbulent flow. You don’t have to memorize them all, but given certain factors, you should be able to describe their effects on fluid flow and frictional resistance. d) You should have a conceptual understanding of the three coefficients of velocity, contraction and discharge. The formulas are given in the test aids, but what do they mean/how are they applied? e) Sketch the cross section of a venturi and/or orifice plate in a pipe and the pressure changes that occur and read the comparison of only these two meters. Don’t forget the calculations re: these meters. From the labs: Lab #2: Bomb Calorimetry Perform calculations like those required for the lab report. You will not be required to calculate rate corrections for temperature or a corrected temperature rise but you may be required to use a given corrected T in the calculation of the heat equivalent of a calorimeter or the heat of combustion of a sample. You should be able to explain purpose and effect of rate corrections. You may also omit the acid correction calculations since you did not do this but you are responsible for corrections for the combustion of the ignition wire. You are also responsible for calculations involving Cl determination of a sample given data on dilution, aliquots and titration with AgNO3 or measurement via specific ion electrode, including logarithmic regression analysis of data (emf vs. ppm Cl-). Equations will not be provided. You can derive them from the units or purchase them for marks on the test. Lab #10 Heat Transfer Expect a calculation involving the overall heat transfer coefficient. The test is closed book but you will be given test aids (attached). FLUID FLOW Page 45 of 51 TEST AIDS FOR FLUID FLOW TEST pabs = gh + patm or This pressure-depth equation: pabs = Dh + patm p = gh = Dh The standard density for water is 1.00 g/cm3 which occurs at 3.98 ºC D4º = 62.4 lb/ft3 = 9810 N/m3 and 4º = 1.00 g/cm3 = 1000 kg/m3 = 1.94 slug/ft3 Atmospheric Pressure at sea level is: 2 5 2 6 2 2 14.70 lb/in = 2116 lb/ft = 1.01325 10 N/m (Pa) = 1.01325 10 dyn/cm = 101.325 kPa = 1 atm = 760 mmHg. (Torr) = 76 cm Hg = 29.92 inHg = 33.90 ft fresh water (~ 33 ft. sea water) = 1.01325 bar = 1013.25 mb p F A sg = Ds s = Dw w = m v D v Recall units of force: A Newton (N) is a force that will cause a 1 kg mass to accelerate at 1 m/s2. The force of gravity on earth (g) is 9.81 N/kg. Gravity causes a 1 kg mass to accelerate (fall) at a rate of 9.81 m/s2. A pound of force (lbf) will cause a mass of 1 slug to accelerate at 1 ft/s2. The force of gravity on earth (g) is 32.2 lb/slug. Gravity causes a 1 slug mass to accelerate (fall) at a rate of 32.2 ft/s2. Conversions: force-force: mass-mass: mass-force: 1 in. = 2.54 cm FLUID FLOW 1 lb = 4.45 N 1 slug = 14.6 kg 1 kg = 9.81 N 1 N = 105 dynes 1 kg = 2.205 lb 1 slug = 32.2 lb 1 m = 3.2808 ft g/cm3 H2 O 1.00 Hg 13.596 air 0.00129 Page 46 of 51 ICS FLUID FLOW Important Conversions and Equalities: 1 Newton force (N) causes 1 kg mass to accelerate at 1 m/s2 1 dyne force (dyn) causes 1 g mass to accelerate at 1 cm/s2 1 pound force (lbf) causes 1 slug mass to accelerate at 1 ft/s2 1 pound force (lbf) causes 1 lb mass to accelerate at 32.2 ft/s2 1 poundal force (pdl) causes 1 lb mass to accelerate at 1 ft/s2 1 pdl 1N 1 lbf 1 lbmft/s2 1 kgm/s2 1 slugft/s2 = = = 1 lbm = 1 kg 1 slug = = = 7.233 pdl 32.2 pdl = = = = 2.204623 lbm 32.174 lbm g = 9.81 N/kg or m/s2 g = 981 dyn/g or cm/s2 g = 32.2 lbf/slug or ft/s2 g = 1.0 lbf/lbm g = 32.2 pdl/lbm or ft/s2 105 dyn 32.2 lbmft/s2 = 4.448 N 0.454 kg 14.594 kg g = 32.2 lbf/slug = 1 lbf/lbm= 32.2 pdl/lbm = 9.81 N/kg = 981 dyn/g = 1037 pdl/slug The following conversions apply at 3.98 C where water is densest. H2O = 1 g kg 1 slug 1 m3 slug 1.9403 3 = 1000 3 3 3 3 cm m 14.594 kg 3.2808 ft ft 981 dyn 1 g 981 dyn 3 cm g cm3 DH2O = g = or 32.2 lbm lbm 62.43 3 ft 1slug 1000 kg 9 .807 N m3 kg 9807 N m3 . slug 32 .2 lbf 62 .43 lbf 2009 pdl 19403 62.43 lbm 32 .2 pdl or 3 3 3 slug lbm ft ft ft ft 3 DH2O = 1m 1 IMP gal 1 US gal 1 IMP gal H2O = 1 US gal H2O = 3.28083 ft = 4.5461 L = 1.201 US gal = 3.7854 L = 0.8327 IMP gal 4.5461 L (1 kg/L) (2.2046 lb/kg) = 10.02 lb/IMP gal = 3.7854 L (1 kg/L) (2.2046 lb/kg) = 8.345 lb/US gal H2O = 62.43 lbm/ft3 (1 IMP gal/10.0 lbm) 6.24 IMP gal/ft3 H2O = 62.43 lbm/ft3 (1 US gal/8.345 lbm) 7.48 US gal/ft3 Power = Also, work time = Fd t e.g. Nm J = = W s s or lbf ft s 3 lbf ft 3 lbf ft N m N m Power = P Q e.g. 2 or 2 s s m s ft s 1 horse power (HP) = 745.7 watts (W) = 550 ftlbfs-1 = 33000 ftlbfmin-1 FLUID FLOW Page 47 of 51 d1 2 2 2 d1 r1 v2 A1 d1 4 2 d v1 A2 d22 d2 2 r2 4 V ( A v ) t Q A v t t 2 The Continuity Equation: Since Q1 = Q2 , thus: Q = A1 1 = A2 2 Bernoulli’s Equation-the most common forms: p + gz + ½2 = constant v2 hz cons tan t 2g p Dz = units are height (m, ft, etc.) Dv 2 cons tan t 2g hp + h1 + z1 + 12/2g h2 + z2 + 22/2g + hf units are pressure (N/m2 or lbf/ft2 or dyn/cm2) units are pressure (N/m2 or lbf/ft2) hp = pressure head added by pump h1 = pressure head at point 1 h2 = pressure head at point 2 z1 = elevation of point 1 z2 = elevation of point 2 1 = velocity at 1 2 = velocity at 2 hf = head loss due to friction. All terms are in height of the working fluid LIQUID HEADS IN FLUID FLOW 1. Vertical depth in ft. or m. of any point below the surface of a liquid is called pressure head or hydrostatic head, i.e., it is a pressure usually expressed in ft. or m. of the liquid. Recall p = Dh h = p/D 2. A drop in pressure in moving water due to friction is called friction head. It is directly proportional to the total area of the rubbing surface as well as the roughness of the surface and the velocity of the fluid. Abrupt changes in cross-sectional area or direction of flow also causes increased friction head. 3. Pressure in a pipe or channel due to the velocity of liquid particles is called velocity head. From Toricelli’s Theorem, v 2gh hv = 2/2g FLUID FLOW Page 48 of 51 SPECIAL CASES OF BERNOULLI’S EQUATION In many cases the pressure, height, or speed of a liquid is constant and simplified forms of Bernoulli’s equation result. 1. Liquid at Rest: When a column of liquid is stationary, equation 3. becomes: p1 + gz1 = p2 + gz2 p = (p2 - p1) = g(z1 – z2) This is simply the pressure-depth equation (p = gh) 2. When p1 = p2: When an open tank is draining, both ends are at atmospheric press. gz1 + ½12 = gz2 + ½22 If the orifice is small compared to the cross section of the tank, the liquid level (draining under gravity) will fall slowly enough that the liquid speed at the top of the tank (1) is negligible (assume 1 = 0), then: gz1 = gz2 + ½22 ½22 = g(z1 - z2) = gz Solving for we get: v 2gz (Toricelli’s Theorem) Note that the speed with which a liquid is discharged under gravity is the same as the speed of a body falling from rest from height, h, and is independent of the density of the object. Recall intro physics, the KE of an object at any point all comes from PE. ½m2 = mgh v 2gh The flow rate at which liquid discharges through an orifice can be calculated as follows: Since Q = A, Q = A 2gh (Flow from an orifice) 3. Constant Height: p1 + ½12 = p2 + ½22 Reynolds number, is defined by the following equation. Re d v or d D g = absolute viscosity d = diameter (e.g. cm, m, or ft.) -1 -1 v = average or bulk velocity (e.g., cms , ms or fts-1 ) g = grav. accel. -3 -3 = mass density (gcm , kgm , slug/ft-3 or lbm/ft-3 ) D = weight density (e.g. N/m3, etc.) (cm)(cm s -1 )(g cm -3 ) cgs : dimensionl ess ( g cm 1 s 1 ) British : FLUID FLOW (ft)(ft s -1 )(lbm ft -3 ) (lbm ft 1 s 1 ) or (m)(m s -1 )(kg m -3 ) SI : = dimensionl ess (kg m 1 s 1 ) (ft)(ft s -1 )(slug ft -3 ) dimensionl ess ( slug s ft 2 ) Page 49 of 51 The term “head loss per unit length of pipe” (i) is given by: i h L head loss between two points of pipe L distance between these points coefficient of contraction (Cc) which is: Cc area of jet at vena contracta area of orifice coefficient of velocity (Cv). Cv actual velocity at vena contracta theoretical velocity 2gh coefficient of discharge (Cd): Cd actual discharge Q theoretical discharge A 2 g h Bernoulli’s Equation for an Orifice 2 g h Q C d A2 f 4 d2 1 d1 Q = volume flow rate g = grav. accel. h = pressure head Cd = coeff. of discharge A1 = area of orifice A2= area of pipe = difference in mass densities of 2 manometer fluids f = mass density of process fluid (fluid in pipe) Recall from our study of manometers that for a bifluid manometer p is not just gh but rather ()gh. For a single fluid manometer, use p = gh Bernoulli’s Equation for a Venturi The same equation is used for flow calculations in a venturi but without Cd. Venturis have lower pressure drops than orifice plates (minimal frictional losses) resulting in flow calculations that are close to the true values as obtained by actual flow measurements. You must include units in your calculations and you must use a consistent set of units. FLUID FLOW Page 50 of 51 VISCOSITY Viscosity is internal friction or resistance to flow. Absolute or dynamic viscosity () is ... SI units : shear stress F/A F dx = velocity gradient dV / dx A dV (kg m s -2 )(m) kg Pa s 2 -1 m s (m )(m s ) cgs units : (g cm s -2 ) 1 (cm )(cm s ) 2 g poise (P) cm s 10 poise (P) = 1 Pa s 1 poiseuille (Pl) = 1000 centipoise (cP) 1 cP = 6.72 10 -4 pdl s lbm 6.72 10 -4 ft s ft 2 = 2.089 10 -5 slug lbf s = 2.089 10 -5 ft s ft 2 Heat Transfer q m c T t FLUID FLOW q U 0 A0 Tm Tm T2 T1 ln (T2 / T1 ) Page 51 of 51