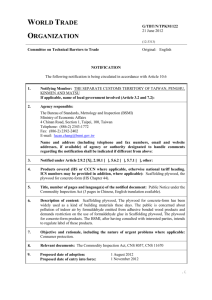

26095 Test properties of boatbuilding timber

26095 version 1

Page 1 of 3

Test properties of boatbuilding timber

Level 5

Credits 10

Purpose People credited with this unit standard are able to select boatbuilding timber for testing and conduct tests of boatbuilding timber.

Subfield Boating Industries

Domain

Status

Status date

Date version published

Boatbuilding

Registered

21 May 2010

21 May 2010

Planned review date

Entry information

31 December 2014

Open.

Accreditation Evaluation of documentation and visit by NZQA and industry.

Standard setting body (SSB) Boating Industry Training Organisation

Accreditation and Moderation Action Plan (AMAP) reference 0136

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do

.

Special notes

1 Reference standards that may be used for test method determination.

ISO 8905:1988 Sawn timber – Test methods – Determination of ultimate strength in shearing parallel to grain.

Determines the maximum load causing the test piece made of coniferous and broadleaved sawn timber to break by shearing as a result of compressive stresses, and calculates the stress at this load. Reference is made to ISO 3130.

ISO 8906:1988 Sawn timber – Test methods – Determination of resistance to local transverse compression.

This method is based on the load proportional limit and the load at a defined defo rmation which are given in the ‘load/deflection’ curve. Stresses at these loads are calculated. Testing of small defect-free test pieces of wood is not covered.

New Zealand Qualifications Authority 2020

26095 version 1

Page 2 of 3

ISO 12580:2007 Timber structures – Glued laminated timber – Methods of test for glue-line delamination .

Specifies five delamination methods for factory quality assurance of the glue line of glued laminated timber.

ISO 8375:2009 Timber structures – Glued laminated timber – Test methods for determination of physical and mechanical properties.

Specifies test methods for determining the following characteristic values of glued laminated timber: modulus of elasticity in bending, shear modulus, bending strength, modulus of elasticity in tension parallel to the grain, tension strength parallel to the grain, modulus of elasticity in compression parallel to the grain, compression strength parallel to the grain, modulus of elasticity in tension perpendicular to the grain, tension strength perpendicular to the grain, modulus of elasticity in compression perpendicular to the grain, compression strength perpendicular to the grain and shear strength.

In addition, the determination of dimensions, moisture content, and density are specified. The methods apply to rectangular shapes of glued laminated timber.

AS/NZS 4357.0:2005 Structural laminated veneer lumber – Specifications

AS/NZS 4357.1:2005 Structural laminated veneer lumber

– Method of test for measurement of dimensions and shape

AS/NZS 4357.2:2006 Structural laminated veneer lumber – Determination of structural properties – Test methods

AS/NZS 4357.3:2006 Structural laminated veneer lumber

– Determination of structural properties – Evaluation methods

AS/NZS 2098.0:2006 Methods of test for veneer and plywood – General introduction and list of methods

AS/NZS 2098.1:2006 Methods of test for veneer and plywood – Moisture content of veneer and plywood

AS/NZS 2098.11:2005 Methods of test for veneer and plywood

– Determination of formaldehyde emissions for plywood

AS/NZS 2098.2:2006 Methods of test for veneer and plywood – Bond quality of plywood (chisel test)

AS/NZS 2098.3:2006 Methods of test for veneer and plywood

– Bond quality and strength of scarf joints in plywood

AS/NZS 2098.4:2006 Methods of test for veneer and plywood – Measurement of dimensions and shape for sheets of veneer and plywood

AS/NZS 2098.5:2006 Methods of test for veneer and plywood – Resistance of gluelines in plywood to attack by micro-organisms

AS/NZS 2098.6:2006 Methods of test for veneer and plywood

– Depth of peeler checks in veneer and plywood

AS/NZS 2098.7:2006 Methods of test for veneer and plywood – Density of veneer and plywood

AS/NZS 2098.8:2006 Methods of test for veneer and plywood

– Water absorption and thickness swelling of unpainted plywood

2 The testing part of this unit standard is intended to be done in a suitable facility such as an appropriately resourced university or technical institute.

New Zealand Qualifications Authority 2020

26095 version 1

Page 3 of 3

3 Competence must be demonstrated for

– a minimum of three different species or laminated configurations of timber

– using a minimum of two different quantitative assessment tests from the reference standards noted in special note 1.

Elements and performance criteria

Element 1

Select boatbuilding timber for testing.

Performance criteria

1.1 Boatbuilding timber is selected for testing in accordance with selected reference standards.

Element 2

Conduct tests of boatbuilding timber.

Performance criteria

2.1 Tests are carried out in accordance with selected reference standards.

2.2 Test results are recorded in accordance with selected reference standards.

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact the Boating Industry Training Organisation training@bia.org.nz

if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020