Section 08161 - Sliding Metal Doors

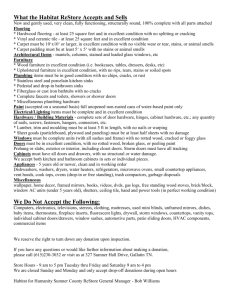

advertisement

PRODUCT SPECIFICATIONS Weiland Sliding Doors & Windows, Inc. manufactures aluminum, aluminum/wood, and wood sliding doors, Beefy bifold doors, bifold doors, swinging doors and windows. Weiland Sliding Doors and Windows, Inc. has evolved from a specialty woodworking business to a manufacturer of high precision European doors and windows. With over two decades of experience behind our designs, the company has positioned itself as the forerunner in European door and window products, modified for U.S. applications. In the early 90’s, an aluminum and aluminum wood door was introduced using European hardware. Our manufacturing plant has been located in the San Diego area since 1985. SLIDING GLAZED DOORS ORGANIZED BY MATERIAL REFERENCES ............................................................................................................................................. 1 SUBMITTALS ............................................................................................................................................... 2 QUALITY ASSURANCE ............................................................................................................................... 2 DELIVERY, STORAGE, AND HANDLING ................................................................................................... 3 PROJECT CONDITIONS.............................................................................................................................. 3 TERMS & CONDITIONS .............................................................................................................................. 3 MANUFACTURER ........................................................................................................................................ 3 MATERIALS .................................................................................................................................................. 3 FABRICATION .............................................................................................................................................. 3 WOOD DOORS and HARDWARE ............................................................................................................... 4 WOOD LIFTSLIDE DOOR SYSTEM ........................................................................................................ 4 WOOD HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM ...................................................................... 5 WOOD BIFOLD DOOR SYSTEM ............................................................................................................. 6 ALUMINUM DOORS ..................................................................................................................................... 7 ALUMINUM LIFTSLIDE DOOR SYSTEM ................................................................................................. 7 ALUMINUM HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM .............................................................. 8 ALUMINUM BIFOLD DOOR SYSTEM ................................................................................................... 10 ALUMINUM WOOD DOORS ...................................................................................................................... 11 ALUMINUM WOOD LIFTSLIDE DOOR SYSTEM .................................................................................. 11 ALUMINUM WOOD HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM ............................................... 13 ALUMINUM WOOD BIFOLD DOOR SYSTEM ....................................................................................... 14 EXECUTION ............................................................................................................................................... 16 EXAMINATION ........................................................................................................................................ 16 PREPARATION ....................................................................................................................................... 16 INSTALLATION ....................................................................................................................................... 16 PROTECTION ......................................................................................................................................... 16 REFERENCES A. AAMA - American Architectural Manufactures Association: Page 1 of 16 2009.04 PRODUCT SPECIFICATIONS a. AAMA 605.2 - High Performance Organic Coatings on Architectural Extrusions and Panels. b. AAMA/WDMA/SCA 101/I.S.2/A440-05 Standard/Specification for Windows, Doors and Unit Skylights. B. ASTM - American Society for Testing and Materials: a. ASTM E 2068 Standard Test Method for Determination of Operating Force of Sliding Windows and Doors. b. ASTM E 283 Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen. c. ASTM E 547 Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Cyclic Static Air Pressure Difference. d. ASTM E 331 Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference. e. ASTM E330 Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference. f. ASTM F 588 Standard Test Methods for Measuring the Forced Entry Resistance of Window Assemblies, Excluding Glazing Impact. g. High Velocity Hurricane Zone, Protocols TAS 201-94, TAS 202-94, and TAS 203-94 for series/model Aluminum Wood Liftslide (AWLS) doors (wood clad aluminum lift and slide doors). SUBMITTALS A. Shop Drawings: Submit under provisions of Section 01300. B. Product Data: Submit manufacturer's catalog data on each product to be used. Include glazing system and two color samples representing specified colors and finishes. C. Shop Drawings: Indicate location, size, and hand of each door; elevation of each kind of door; construction details, including those for stiles, rails, panels, moldings and other pertinent construction; provide configuration of door panels. QUALITY ASSURANCE A. Installer Qualifications: Installer acceptable to door manufacturer for installation of units required for this Project. B. Manufacturer Qualifications: Single manufacturer with a minimum of fifteen (15) years experience shall provide all primary products specified in this section. C. Performance: Doors and windows are assembled in-house and operated for quality control before shipped to jobsite. Page 2 of 16 2009.04 PRODUCT SPECIFICATIONS DELIVERY, STORAGE, AND HANDLING A. Each door shall be marked on packing material with the panel and door unit number used on Shop Drawings. B. Store products in manufacturer's packaging in an upright position off the ground in a clean, dry area until ready for installation. C. Protect wood surfaces by priming or sealing as recommended by manufacturer. PROJECT CONDITIONS A. Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer's absolute limits. B. Field Measurements: Verify fenestration openings by field measurements before fabrication and indicate measurements on Shop Drawings. TERMS & CONDITIONS A. Manufacturer’s Warranty: Manufacturer’s standard warranty, terms & conditions as published on the company website. MANUFACTURER Weiland Sliding Doors & Windows, Inc., 2601 Industry St., Oceanside, CA 92054; Phone: (760)722-8828; Fax: (760)722-8838; Email: customerservice@weilandslidingdoors.com Web: http://www.weilandslidingdoors.com/ MATERIALS 1. Aluminum: Meets requirements of ASTM G34. A. Alloy and Temper: 6063-T5. B. Ultimate Strength: 185 Mpa. 2. Glazing: Comply with requirements of Section 08810 and with AAMA/WDMA 101/I.S.2/NAFS. A. Safety Glass: Provide laminated and tempered products complying with testing requirements in 16 CFR 1201, for Category II materials. B. Insulated glass. C. Low E Insulated glass. 1) Color: Clear. 2) Color: Bronze. 3) Color: Gray. 4) Color: _________. FABRICATION 1. Fabricate panels, jambs and tracks in sizes indicated, re-glazable. 2. Weather Stripping: Provide full-perimeter weather stripping for each operable and or stationary panel, unless otherwise indicated. 3. Factory machine doors for openings and for hardware that is not surface applied. Page 3 of 16 2009.04 PRODUCT SPECIFICATIONS WOOD DOORS and HARDWARE WOOD LIFTSLIDE DOOR SYSTEM 1. Product: Liftslide Doors as manufactured by Weiland Sliding Doors & Windows, Inc. Panel height 10 feet (3048mm), panel width 5 feet (1524mm) and system length 60 feet (18 meters). 2. Operation: When activated, geared hardware system shall lift panels off track. Panels shall glide on wheels set on track. Doors shall be lowered when closed, creating weather seal. 3. System Configuration: Provide the following system configuration. A. Stacked at jamb, center meeting or single sided. B. Pocketed into the wall, center meeting or single sided. C. Meeting at corners with no fixed posts (stacked or pocketed). 4. Size: Refer to Door Schedule on drawings for sizes. All door sizes are custom. Glass warranty limited to 50 sf. 5. Track: Corrosion resistant aluminum extrusion, 6005 aluminum alloy, anodized, for non-marine environment, 5083 aluminum alloy, anodized, for marine environments; extends 3/16 inch (4.8 mm) above finished floor with transverse drain. A. Standard flush track with transverse drain. B. Multi door track: stepped track with transverse drains. C. Drainage track system with transverse drains (for in floor drainage). D. Shallow track with drain (Used when floor channeling needs to be minimized). E. Sloped track with a raised threshold (Used when channeling into floor is not desired – limited to 3 panels or 6 panels if meeting). 6. Head Track: Head track size depends on the number of panels. Please reference drawings. 7. Frame and Sash: A. Wood: Laminated solid wood. Wood Species: 1) Alder (clear or knotty) 2) Mahogany 3) Cherry 4) Douglas Fir 5) Cedar 6) Walnut 7) Other: ____________. B. Panel Frame Thickness: 2-5/8 inches (66.7 mm). C. Top rail and side rail standard size 3-5/8 inch. Bottom rail standard size 7-1/4 inch. Other sizes available. 8. Glass Thickness: 1/2 inch (12.7 mm) Laminated up to 1-1/2 inch (38 mm) Insulated Glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware: Multi point locking system. Provide the following: A. Handle, permanent, finish: 1) Dark bronze 2) White 3) Mill finish. B. Handle, permanent keyed. Cylinder finish: 1) Dark bronze 2) White 3) Mill finish C. Handles, removable, (Allows narrower pockets in wall pockets or allow evenly stacked doors at jamb.) finish: Page 4 of 16 2009.04 PRODUCT SPECIFICATIONS 1) 2) 3) Dark bronze Mill finish White 10. Screens (Optional) A. Screens on jamb-jamb door systems are normally located on the exterior, and optionally can be on the interior side. Screen track for exterior screens is always drainage track. Pocketing door system screens are always located on the interior. Meeting units must have a minimum of two screens. Number of screens possible depends on the system configuration. Screen frame is wood. WOOD HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM 1. Product: Beefy Bifold Door as manufactured by Weiland Sliding Doors & Windows, Inc. Specialized hardware allows panel sizes up to 12 feet (3658 mm) tall. Center pivot hardware accommodates maximum width of 60 inches (1524mm) and system width up to 50 feet (15 meters). 2. Operation: Moving glass wall system, center hung panels, except for man-doors (French doors), panels fold half in and half out of opening, allowing panels to accordion and stack toward the handle. 3. System Configuration: Provide the following system configuration. A. Opening at center B. Opening at jamb C. Corner unit meeting at corners with no fixed posts D. Man-door at doorjamb for entry/exit. Man-door operates without operating bifold doors. 4. Size: Refer to Door Schedule on drawings for sizes. All door sizes are custom. Glass warranty limited to 50 sf. 5. Floor Track: A. Standard stainless steel track with drains 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor. 2) In floor drainage: Provide drainage track system. 3) Material: 304 stainless steel. B. Sloped threshold with standard drain track 1) Height: Bottom track extends 1-1/8 inch (28.5 mm) above exterior floor. 2) Material: 304 stainless steel, wood, aluminum. 6. Head Track: A. Panels shall be center hung from a 5-7/8 inch aluminum (149.2 mm) wide head track. 7. Frame and Sash: A. Wood: Laminated solid wood. Wood species: 1) Alder (clear or knotty). 2) Mahogany. 3) Cherry. 4) Douglas fir. 5) Cedar. 6) Walnut. 7) Other: ____________. B. Panel frame thickness: 2-5/8 inches (66.7 mm). C. Top rail and side rail: 3-5/8 inch (92 mm). For larger panels dimensions will increase. D. Bottom rail: 7-1/4 inches (184 mm). For larger panels dimensions will increase. Page 5 of 16 2009.04 PRODUCT SPECIFICATIONS 8. Glass Thickness: 1/2 inch (12.7 mm) laminated to 1-1/4 inch (31.8 mm) Insulated glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware multi point locking system. Provide the following: A. Keyed cylinders. B. Center pivot hardware. C. Handle finish: 1) Oil rubbed bronze 2) Brushed chrome 3) Solid brass 4) Black D. Shootbolt finish: 1) Oil rubbed bronze 2) Stainless steel 3) Solid brass E. Hinge finish: 1) Mill finish, painted to match Kynar finish 2) White 3) Black WOOD BIFOLD DOOR SYSTEM 1. Product: Bifold doors as manufactured by Weiland Sliding Doors & Windows, Inc. Panel height up to 9 feet (2743 mm), panel width up to 48 inches (1219 mm) and system length up to 48 feet (15 meters). 2. Operation: Moving glass wall system, pivoting at the panel hinge, allowing panels to accordion and stack away from the handle. Panels can be infold (fold to interior) or outfold (fold to exterior). 3. System Configuration: Provide the following system: A. Doors fold to interior (infold). B. Doors fold to exterior (outfold). C. Opening at the center. D. Opening at the jamb. E. Man-door for entry/exit. Man-door (French door) operates without operating the folding door panels. Man-door may be hinged on the jamb or the panel, but man-doors can only be hinged from the panel when the door configuration has an odd number of panels. F. Free swinging panels 4. Size: Refer to door schedule on drawings for sizes (Consult with manufacturer for doors over 9 feet (2743 mm) in height or for large numbers of panels. All door sizes are custom. Standard bifold hardware allows panel sizes up to 9 feet (2743 mm) tall, maximum panel width of 48 inches (1219 mm), and door systems up to 48 feet (15 meters) wide. 5. Bottom Track: A. Standard stainless steel track with drains 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor 2) In floor drainage: Provide drainage track system 3) Material: 304 stainless steel B. Slope threshold with standard stainless steel track with drains (Used when channeling into floor is not desired.) 1) Height: Bottom track extends 2 inches (50.8 mm) above exterior floor 2) Material: 304 stainless steel, wood, aluminum C. U-channel track Page 6 of 16 2009.04 PRODUCT SPECIFICATIONS 1) 2) Height: flush with finished floor For interior applications only, no drains are included. 6. Head Track: A. Panels shall be edge (hinge) hung from a 7 inch (177.8 mm) wide head track with wood trim covering the hinges. 7. Side Jamb: 7 inches (177.8 mm) wide. 8. Frame and Sash: A. Wood: laminated solid wood. Wood species: 1) Alder (clear or knotty) 2) Mahogany 3) Cherry 4) Douglas Fir 5) Cedar 6) Walnut. 7) Other: ____________. B. Panel frame thickness: 1-3/4 inches (44.5 mm). C. Bottom frame 7 inch (177.8 mm) wide. D. Side and top frame 4-5/8 inch (117.5 mm) wide. 9. Glass Thickness: 7/8 inch (22 mm) insulated glass (3/16 inch (4.8 mm) glass both sides of 1/2 inch (12.7 mm) spacer). 10. Hardware: Provide the following: A. Hinges: hinge system shall allow operable doors to be placed within the system to act as man-doors (French doors). B. Hinge Cover options: 1) White 2) Bronze 3) Brushed chrome C. Multi point locking system. D. Handle, keyed with cylinder, finish: 1) Black 2) Oil-rubbed bronze 3) Brushed chrome ALUMINUM DOORS ALUMINUM LIFTSLIDE DOOR SYSTEM 1. Product: Liftslide doors as manufactured by Weiland Sliding Doors & Windows, Inc. Panel height up to 13-1/2 feet (4115 mm), panel width up to 6 feet (1829) and system length up to 60 feet (18 meters). 2. Operation: When activated, geared hardware system shall lift panels off track. Panels shall glide on wheels set on track. Doors shall be lowered when closed, creating weather seal. 3. System Configuration: Provide the following system configuration. A. Stacked at jamb, center meeting or single sided. B. Pocketed, center meeting or single sided. C. Meeting at corners with no posts (stacked or pocketed). D. Curved (or radius) (stacked or pocketed). E. Serpentine Page 7 of 16 2009.04 PRODUCT SPECIFICATIONS 4. Size: Refer to door schedule on drawings for sizes. All door sizes are custom. Glass warranty limited to 50 sf. 5. Track: Corrosion resistant aluminum extrusion, 6005 aluminum alloy, anodized, for non-marine environments, 5083 aluminum alloy, anodized, for marine environments; extends 3/16 inch (4.8 mm) above finished floor with transverse drain. A. Standard flush track with transverse drains. B. Multi door track: Stepped track, with transverse drains. C. Drainage track system (for in floor drainage). D. Shallow track with drain (Used when floor channeling needs to be minimized). E. Sloped track with raised threshold (Used when channeling into floor is not desired). 6. Head Track: A. Head track size depends on the number of panels. 7. Frame and Sash: A. Aluminum: 6063 – T5 aluminum alloy. 1) Panel frame thickness: 3-3/16 inches (80.9 mm). 2) Sash Width: 3-1/2 inches (89 mm). 3) Aluminum finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. a. Color: As selected from manufacturer’s standard colors b. Color: Custom color to match color sample provided. c. Color: Anodized 8. Glass Thickness: 1/2 inch (12.7 mm) Laminated to 1-1/2 inch (38 mm) Insulated Glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware: Multi point locking system. Provide the following: A. Handle, permanent, finish: 1) Dark bronze 2) White 3) Mill finish B. Handle, permanent, keyed with cylinder, finish: 1) Dark bronze 2) White 3) Mill finish C. Handles, removable (Allows narrower pockets in wall pockets or allow evenly stacked doors at jamb.) finish: 1) Dark bronze 2) Mill finish 3) White 10. Screens (Optional). A. Screens on jamb-jamb door systems are normally located on the exterior, and optionally can be on the interior. Screen track for exterior screens is always drainage track. For pocketing door systems, screens are always located on the interior. Meeting units must have a minimum of two screens. Number of screens possible depends on the system configuration. Screen frame is aluminum. ALUMINUM HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM 1. Acceptable Product: Beefy Bifold door as manufactured by Weiland Sliding Doors & Windows, Inc. Specialized hardware allows panel sizes up to 13-1/2 feet (4115 mm) tall. Center pivot Page 8 of 16 2009.04 PRODUCT SPECIFICATIONS hardware accommodates maximum width of 60 inches (1524 mm) and system length up to 50 feet (15 meters). 2. Operation: Moving glass wall system, hinged at in the center of the panels (doors fold half in and half out of opening), allowing panels to accordion and stack toward the handle. 3. System Configuration: Provide the following system configuration. A. Opening at center. B. Opening at jamb. C. Corner unit meeting at corners with no posts. D. Man-door at doorjamb for entry/exit (Man-door operates without operating Bifold doors). 4. Size: Refer to door schedule on drawings for sizes. All door sizes are custom. Glass warranty limited to 50 sf. 5. Floor Track: A. Standard drain track 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor 2) In Floor Drainage: Provide drainage track system 3) Material: 304 stainless steel B. Slope threshold with standard drain track 1) Height: Bottom track extends 1-1/8 inch (25.4 mm) above exterior floor 2) Material: 304 stainless steel, Wood, Aluminum 6. Head Track: A. Panels shall be center hung from a 5-7/8 inch (149.2 mm) wide aluminum head track. 7. Frame and Sash: A. Aluminum: 6063 aluminum alloy. B. Panel Frame Thickness: 3-3/16 inches (80.9 mm). C. Sash Width: 3-1/2 inches (89 mm). D. Aluminum Finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. 1) Color: As selected from manufacturer’s standard colors 2) Color: Custom color to match color sample provided. 3) Color: Anodized 8. Glass Thickness: 1/2 inch (12.7 mm) Laminated to 1-1/2 inch (38 mm) Insulated Glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware: Multi point locking system. Provide the following: A. Keyed cylinders. B. Center pivot hardware and roller assembly. C. Handle finish: 1) Oil rubbed bronze 2) Brushed chrome 3) Solid brass 4) Black D. Shootbolt finish 1) Solid brass 2) Stainless steel 3) Oil rubbed bronze Page 9 of 16 2009.04 PRODUCT SPECIFICATIONS E. Hinge finish: 1) Mill finish, painted to match Kynar finish. 2) White 3) Black ALUMINUM BIFOLD DOOR SYSTEM 1. Acceptable Product: Bifold doors as manufactured by Weiland Sliding Doors & Windows, Inc. 2. Operation: Moving glass wall system, pivoting at the panel hinge, allowing panels to accordion and stack away from the handle. Panels can be infold (fold to interior) or outfold (fold to exterior). 3. System Configuration: Provide the following system: A. Doors fold to interior (infold). B. Doors fold to exterior (outfold). A. Opening at the center. B. Opening at the jamb. C. Man-door for entry/exit. Man-door operates without operating bifold doors. A man-door may be hinged on the jamb or the panel, but man-doors can only be hinged from the panel where the panel configuration has an odd number of panels. 4. Size: Refer to door schedule on drawings for sizes. All door sizes are custom. Standard bifold hardware allows panel sizes up to 118 inches (2997 mm) tall, maximum panel width of 39 inches (991 mm), and door systems up to 48 feet (15 meters) wide. 5. Floor Track: A. Standard drain track 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor 2) In Floor Drainage: Provide drainage track system 3) Material: 304 stainless steel B. Slope threshold with standard drain track 1) Height: Bottom track extends 1-1/8 inch (25.4 mm) above exterior floor 2) Material: 304 stainless steel, wood, aluminum C. U-channel track 1) Height: Flush with finished floor 2) For interior application only (no drains included). 6. Head Track: Panels shall be edge (hinge) hung from a 2-5/8 inch (66.7 mm) wide head track. 7. Side Jamb: 2-3/4 inches (69.9 mm) wide and 1-11/16 (42.9 mm) inches thick. 8. Frame and Sash: A. Aluminum: 6063 aluminum alloy. 1) Panel frame thickness: 1-9/16 inch (39.7 mm). 2) Sash width: 2-1/16 inch (52.4 mm). 3) Aluminum finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. a. Color: As selected from manufacturer’s standard colors b. Color: Custom color to match color sample provided. c. Color: Anodized 9. Glass Thickness: 7/8 inch (22 mm) Insulated Glass (3/16 inch (4.8 mm) glass both sides of 1/2 inch (12.7 mm) spacer). Page 10 of 16 2009.04 PRODUCT SPECIFICATIONS 10. Hardware: Provide the following: A. Hinges: Concealed hinge system shall allow operable doors to be placed within the system to act as man-doors (French doors). B. Multi point locking system. C. Lever pull handle finish: 1) Brass 2) Black 3) White D. Lever pull handle with thumb turn, finish: 1) Brass 2) Black 3) White E. Handle, keyed cylinder, finish: 1) Brass 2) Black 3) White F. Handle finish: 1) Brass 2) Black 3) White ALUMINUM WOOD DOORS ALUMINUM WOOD LIFTSLIDE DOOR SYSTEM 1. Acceptable Product: Liftslide doors as manufactured by Weiland Sliding Doors & Windows, Inc. Panels up to 16’ tall (4877 mm) with steel stiffeners needed over 13-1/2 feet (4115 mm) tall, panels up to 60 inches (1524 mm) wide and system length up to 60 feet (18 meters). 2. Operation: When activated, geared hardware system shall lift panels off track. Panels shall glide on wheels set on track. Doors shall be lowered when closed, creating weather seal. 3. System Configuration: Provide the following system configuration. A. Stacked center meeting or single sided. B. Pocketed center meeting or single sided. C. Meeting at corners with no posts (stacked or pocketed). D. Curved (or radius) (stacked or pocketed). E. Serpentine 4. Size: Refer to door schedule on drawings for sizes. All door sizes are custom. Glass warranty limited to 50 sf. 5. Track: Corrosion resistant aluminum extrusion, 6005 aluminum alloy, anodized, for non-marine environments, 5083 aluminum alloy, anodized, for marine environments; extends 3/16 inch (4.8 mm) above finished floor with transverse drain. A. Standard flush track with transverse drain. B. Multi door track: Stepped track with transverse drains. C. Drainage track system (for in floor drainage). D. Shallow track with drain (Used when floor channeling needs to be minimized). E. Sloped track with raised threshold (Used when channeling into floor is not desired). 6. Head Track: Head track size depends on the number of panels. Page 11 of 16 2009.04 PRODUCT SPECIFICATIONS 7. Frame and Sash: A. Aluminum with wood cladding: 6063 aluminum alloy with wood species indicated. B. Panel frame thickness: 3-3/16 inches (80.9 mm), total thickness (2 11/16 inches (68.2 mm) of aluminum and 1/2 inch (12.7 mm) wood cladding). C. Sash Width: 3-1/2 inches (89 mm). D. Separator Clip: PVC clip separates aluminum and wood. Clip shall provide sliding joint that allows materials to expand and contract independently and serves as a thermal insulator. E. Wood Species: 1) Alder (clear or knotty) 2) Mahogany 3) Cherry 4) Douglas Fir 5) Cedar 6) Walnut 7) Other: ____________. 8) As indicated on Drawings. F. Aluminum Finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. 1) Color: As selected from manufacturer’s standard colors 2) Color: Custom color to match color sample provided. 3) Color: Anodized 8. Glass Thickness: 1/2 inch (12.7 mm) Laminated to 1-1/4 inch (31.8 mm) Insulated glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware: Multi point locking system. Provide the following: A. Handle, permanent finish: 1) Dark bronze 2) White 3) Mill finish B. Handle, permanent, keyed with cylinder, finish: 1) Dark bronze 2) White 3) Mill finish C. Handles, removable: (Allows narrower pockets in wall pockets or allow evenly stacked doors at jamb.) finish: 1) Dark bronze 2) Mill finish 3) White 10. Screens (Optional). A. Screens on jamb-jamb door systems are normally located on the exterior, and optionally can be on the interior. Screen track for exterior screens is always drainage track. For pocketing door systems, screens are always located on the interior. Meeting units must have a minimum of two screens. Number of screens possible depends on the system configuration. Screen frame can be wood or aluminum. Page 12 of 16 2009.04 PRODUCT SPECIFICATIONS ALUMINUM WOOD HEAVY DUTY (BEEFY) BIFOLD DOOR SYSTEM 1. Acceptable Product: Beefy Bifold door as manufactured by Weiland Sliding Doors & Windows, Inc. Specialized hardware allows panel sizes up to 13-1/2 feet (4115 mm) tall. Center pivot hardware accommodates maximum width of 60 inches (1524 mm) and system length up to 50 feet (15 meters). 2. Operation: Moving glass wall system, hinged at in the center of the panels (doors fold half in and half out of opening), allowing panels to accordion and stack toward the handle. 3. System Configuration: Provide the following system configuration. A. Center pivot door system; doors fold half in and half out of opening. B. Stacked. C. Meeting at corners with no posts. D. Man-door at door jamb for entry/exit. Man-door operates without operating bifold doors. 4. Size: Refer to door schedule on drawings for sizes. All door sizes are custom. Specialized hardware allows panel sizes up to 13-1/2 feet (4115 mm) tall. Center pivot hardware accommodates maximum width of 60 inches (1524 mm). Glass warranty limited to 50 sf. 5. Track: Straight track. A. Standard drain track 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor 2) In floor drainage: Provide drainage track system 3) Material: 304 stainless steel B. Slope threshold with standard drainage track 1) Height: Bottom track extends 1-1/8 inch (28.5 mm) above exterior floor 2) Material: 304 stainless steel, Wood, Aluminum 6. Head Track: Panels shall be center hung from a 5-7/8 inch (149.2 mm) wide head track. 7. Frame and Sash: A. Aluminum with wood cladding: 6063 aluminum alloy with wood species indicated. B. Panel frame thickness: 3-3/16 inches (80.9 mm), total thickness (2 11/16 inches (68.2 mm) of aluminum and 1/2 inch (12.7 mm) thick wood cladding). C. Sash width: 3-1/2 inches (89 mm). D. Separator Clip: PVC clip separates aluminum and wood. Clip shall provide sliding joint that allows materials to expand and contract independently and acts as a thermal insulator. E. Wood Species: 1) Alder (clear or knotty) 2) Mahogany 3) Cherry 4) Douglas Fir 5) Cedar 6) Walnut 7) Other: ____________. F. Aluminum Finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. Page 13 of 16 2009.04 PRODUCT SPECIFICATIONS 1) Color: As selected from manufacturer’s standard colors 2) Color: Custom color to match color sample provided. 8. Glass Thickness: 1/2 inch (12.7 mm) laminated to 1-1/2 inch (38 mm) Insulated glass (in the case of 1-1/4 inch IG, the glass is 1/4 inch (6.35 mm) both sides of a 3/4 inch (19 mm) spacer). 9. Hardware: Multi point locking system. Provide the following: A. Keyed cylinders B. Center pivot hardware C. Handle finish: 1) Oil rubbed bronze 2) Brushed chrome 3) Solid brass 4) Black D. Shootbolt finish: 1) Solid brass 2) Stainless steel 3) Oil-rubbed bronze. E. Hinge finish: 1) Mill finish, painted to match Kynar finish 2) White ALUMINUM WOOD BIFOLD DOOR SYSTEM 1. Acceptable Product: Bifold doors as manufactured by Weiland Sliding Doors & Windows, Inc. Panel height up to 118 inches (2997 mm), width up to 39 inches (991 mm)and system length up to 48 feet (15 meters). 2. Operation: Moving glass wall system, pivoting at the panel hinge, allowing panels to accordion and stack away from the handle. Panels can be infold (fold to interior) or outfold (fold to exterior). 3. System Configuration: Provide the following system configuration: A. Doors fold to interior (infold). B. Doors fold to exterior (outfold). C. Opening at the center. D. Opening at the jamb. E. Man-door for entry/exit. Man-door operates without operating bifold doors. Man-door may be hinged on the jamb or the panel, but man-doors can only be hinged from the panel where the panel configuration has an odd number of panels. 4. Size: Refer to Door Schedule on drawings for sizes. All door sizes are custom. Standard Bifold hardware allows panel sizes up to 118 inches (2997 mm) tall, maximum panel width of 39 inches (991 mm), and door systems up to 48 feet (15 meters) wide. 5. Floor Track: A. Standard drain track 1) Height: Bottom track extends 3/8 inch (9.5 mm) above finished floor. 2) In floor drainage: Provide drainage track system. 3) Material: 304 stainless steel. B. Slope threshold with standard drain track 1) Height: Bottom track extends 1-1/8 inch (28.5 mm) above exterior floor. 2) Material: 304 stainless steel, wood, aluminum. C. U-channel track 1) Height: Flush with finished floor. 2) For interior application only (no drains are included). Page 14 of 16 2009.04 PRODUCT SPECIFICATIONS 6. Head Track: Panels shall be edge (hinge) hung from a 3-3/8 inch (85.7 mm) wide head track with wood trim. 7. Side Jamb: 1-13/16 inches (46.0 mm) wide and 2-7/16 inches (61.9 mm) thick. 8. Frame and Sash: A. Aluminum with wood cladding: 6063 aluminum alloy with wood species indicated. 1) Panel Frame Thickness: 2-7/16 inches (61.9 mm), total thickness. 2) Sash Width: 2-9/16 inches (65.1 mm). 3) Separator Clip: PVC clip separates aluminum and wood. Clip shall provide sliding joint that allows materials to expand and contract independently. 4) Wood species: a. Alder (clear or knotty) b. Mahogany c. Cherry d. Douglas Fir e. Cedar f. Walnut g. Other: ____________. 5) Aluminum finish: Kynar 70, meeting the performance criteria of AAMA 605.2 specification and certified by the formulator as containing KYNAR 70 resin as manufactured by Elf Atochem North America, Inc. a. Color: As selected from manufacturer’s standard colors b. Color: Custom color to match color sample provided. c. Color: Anodized 9. Glass Thickness: 7/8 inch (22 mm) Insulated Glass (3/16 inch (4.8 mm) glass both sides of 1/2 inch (12.7 mm) spacer). 10. Hardware: Provide the following: A. Hinges: Concealed hinge system shall allow operable doors to be placed within the system to act as man-doors (French doors). B. Multi point locking system. C. Lever pull handle finish: 1) Brass 2) Black 3) White D. Lever pull handle with thumb turn finish: 1) Brass 2) Black 3) White E. Handle, keyed cylinder, finish: 1) Brass 2) Black 3) White F. Handle finish: 1) Brass 2) Black 3) White Page 15 of 16 2009.04 PRODUCT SPECIFICATIONS EXECUTION EXAMINATION 1. Do not begin installation until substrates have been properly prepared. 2. If substrate preparation is the responsibility of another installer, notify architect of unsatisfactory preparation before proceeding. PREPARATION 1. Clean surfaces thoroughly prior to installation. 2. Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions. INSTALLATION 1. Install in accordance with manufacturer's instructions. PROTECTION a. Protect installed products until completion of project. b. Touch-up, repair or replace damaged products before Substantial Completion. c. Finished Doors: Replace doors that are damaged or do not comply with requirements. Doors may be repaired or refinished if work complies with requirements and shows no evidence of repair or refinishing. Page 16 of 16 2009.04