Corrosion of Aluminum in aqueous solutions containing aspartic

1

Corrosion of Aluminum in aqueous solutions containing aspartic , glutamic acid with / without Sodium chloride

L. Al Juhaiman*, A. Al Mayouf, and A. Suhaybany

Chemistry Department, Science College, King Saud University, Riyadh, Saudi Arabia

The corrosion behavior of Aluminum alloy 6063 (Al 6063) in aerated aqueous solutions containing food additives namely aspartic (Asp) and glutamic (Glu) acids with/without chloride ions was studied. Several techniques were used chemical methods (weight loss, atomic absorption) and potentiodynamic polarization measurements. Surface morphology and surface analysis were investigated by SEM and EDX techniques.

Good consistency between the data obtained from weight loss and atomic absorption was observed. In polarization measurements, the effect of pH, temperature, and immersion time was studied. Polarization measurements showed that the combination of chloride ions and amino acids has a synergistic effect on Al dissolution in the acidic medium while no pronounced effect was noticed in both neutral and alkaline media. Increasing temperature leads to an increase in corrosion current density with different extents depending on the existence of chloride ions.

Increasing immersion time increases corrosion current density for Al

6063 in amino acid solutions and the adverse effect was observed in sodium chloride solutions with/without amino acids, showing the complexity of the adsorption mechanism of both chloride and amino acids.

1-Introduction

The importance of Aluminum (Al) as a toxic environmental factor has led to extensive research [1-4]. In the eighties Al was regarded to be a neurotoxin agent due to its accumulation in brain, bones and liver and its later association with some diseases like dialysis encephalopathy, bone disorders and other diseases [1-7]. The corrosion behavior of Al alloys has been widely studied in the literature in acidic [8-10], neutral [11-17] and alkaline medium [18-20]. It is well known that Al exhibits a passive behavior in aqueous solutions due to the thin compact oxide film on its surface. Al oxide solubility increases in acidic and alkaline medium which explain the importance of studying the role of pH as shown by

Lampease et al [14]. The aim of this paper is to study the corrosion behavior of Al in some aqueous solutions containing food additives,

2 namely sodium chloride and aspartic and glutamic amino acids w/without sodium chloride. Aluminum alloy 6063 (Al 6063) was chosen for this study because there is no evidence in the literature that it was used under similar conditions, moreover it contains some magnesium and iron which is added to aluminum cookware.

2-Experimental methods

Chemical and electrochemical measurements were used to study the corrosion of Al 6063 in aerated aqueous solutions. Chemical measurements include weight loss (WL) and atomic absorption (AA). Al was obtained from Alubco Company, Saudi Arabia. Its composition is listed in table (1). Al 6063 was used as circular disks with a surface area of 5.03 cm 2 ± 0.10. These disks were hanged in the solutions for 10-60 days. All solutions were prepared from AR grade of Merck Company and distilled water was used for preparing solutions. The concentration of the studied solutions NaCl, Asp and Glu were 0.10M, 0.02M and 0.05M respectively. Before each experiment the Al specimens were polished with 600 and 1200 emery paper, washed with distilled water, ultrasonically cleaned in acetone for 1 minute then weighed and kept dry for surface study. The remaining solutions from WL were analyzed by

AA technique using an instrument from Shimadzu (A.A. 6701F) to determine the amount of dissolved Al. The surface morphology and surface analysis of Al 6063 disks were studied using Scanning Electron

Microscope (SEM) from (Joel-JSM-T330A) connected with Energy

Dispersion X-Ray (EDX). The effect of immersion time on WL was studied at the same temperature (25ºC ±1) and constant pH.

Electrochemical measurements were done using a

Potentiostat/galvanostat (ACM # 395) connected to a computer. For potentiodynamic polarization measurements the effect of pH, temperature and immersion time was studied. The pH of solutions was adjusted using

NaOH pellets and concentrated HCl. All experiments were carried out using a three electrode cell with saturated calomel as the reference electrode and platinum as the counter electrode. The Al working electrode (alloy 6063) was in the form of a rod embedded in Teflon with an exposed area of 0.783 cm 2 . The electrode was prepared directly before electrochemical measurements then immersed in solutions to perform open circuit potential for one hour before polarization measurements. All experiments were done in aerated solutions and maintained at 25°C±1 except otherwise stated.

3

3 Results and discussion

3-1 Chemical Measurements

Corrosion rate (CR) from WL was calculated using the following equation:

Corrosion rate = ∆ w

A * t

Where ∆ w is the weight loss of Al 6063 (g); A is the surface area (cm 2 ) and t is the immersion time (days)

The corrosion rate of Al 6063 was measured at 25ºC and constant pH.

CR from WL and AA measurements in presence of chloride ions and amino acid solutions and a mixture of both are listed in table (2).

In general, it was found that the corrosion rate of Al 6063 in the studied solutions can be given in the following order:

NaCl << amino acids < amino acids +NaCl

It is well known that Al exhibits a passive behavior in aqueous solutions due to the thin compact oxide film on its surface. Solution pH normally influences the corrosion behavior of Al and its alloys by changing the solubility of the oxide film which exists naturally on the metal surface.

Accordingly, the difference in corrosion rate observed for Al 6063 in the studied solutions is attributed to the change in the stability of the oxide film.

In neutral NaCl solutions (pH 6.5) this protective film has low solubility hence the lowest corrosion rate was observed in such solutions although chloride ion is known to be a corrosive ion. However, in amino acid solutions (pH 3.1-3.3), the solubility of the oxide layer is enhanced which leads to higher corrosion rates for Al. Another factor, which enhances corrosion rate in acid solutions, is the acceleration of cathodic reaction due to the high concentration of H + ions as suggested by Ambat et al [21].

It is clear from table (2) that the corrosion rate of amino acids with chloride is about 1.5-3.6 times greater than that of amino acids. This is caused by addition of more anions which form different complexes with

Al 3+ [6] and agrees with Tomcsani et al [22] that chloride ions act as partners in the electrochemical reaction.

The analysis of dissolved Al +3 ions in solutions from WL experiments by AA are shown in table (2). It is clear that good consistency was observed between the data from WL and AA. Using AA for analysis after WL is an uncommon method in the literature although some researchers have found similar correlation in 1977 for stainless steel

[20]. This is a promising method of analysis because it can be used to analyze dissolved metals in ppb range and in shorter time intervals.

4

3-2 Surface Analysis

Scanning Al 6063 surface is shown in Fig (1-5) for the studied solutions. For NaCl there were only a few pits because the pH was neutral. Local corrosion was clear for amino acids with /without chloride ions. For Asp acid there were some remaining Al

2

O

3

but not for Glu where semicircular pits of 4 µm diameter were observed. This result shows that Glu acid has more ability to dissolve the Al oxide layer which is in agreements with the corrosion rate results from WL. For amino acids with chloride the surface morphology was different, in addition to increasing number of bigger pits, the surface was full of cracks with variable depth.

Elemental analysis using EDX for Al 6063 surface after immersion in test solutions for 30 days from WL measurements is shown in table (3).

It is clear that the composition of Al 6063 from the company is different from the EDX elemental analysis. Inspection of table (3) shows the remarkable decrease in Mg and Fe after immersion in acid solutions with/without NaCl. The transfer of Mg and Fe from the alloy to the solution depends on there distribution in the microstructure of the surface and explains the low concentration of Mg and Fe after immersion in test solutions. This result is in agreements with Brillas et al [23] that the local corrosion of Al alloys increased with increasing amounts of magnesium.

It may be attributed to deposition of the phase Mg

5

Al

8 which makes an anodic phase in the aluminium matrix making it an optimum region of dissolution [24, 25]. The role of Fe resembles that of Mg and agrees with the findings mentioned by Seri [13] that the aluminium oxide around

FeAl

3

is weak and prone to local corrosion.

3-3 Electrochemical measurements

Polarization measurements for Al 6063 were studied at different pH, temperature and immersion time for solutions of NaCl and amino acids with /without NaCl.

3-3-1 Effect of pH

To study the effect of pH, the concentration was kept constant as stated earlier and the temperature was kept at (25±1ºC). Tafel plots are shown in Fig (6-8) for NaCl, Glu and Glu+NaCl respectively as a representation of amino acids. The electrochemical parameters for Al

5

6063 in the studied solutions are shown in table (4). The results obtained from these plots and table (4) can be summarized as follows:-

1.

Corrosion potential, E corr decreased with increasing pH which is in agreements with open circuit potential results of these acids [26].

2.

For NaCl corrosion current density (I corr

) increased with decreasing pH, reaching its lowest value in neutral medium with a slight increase in I corr

in alkaline medium as shown in Fig (11 a). Our findings are in agreement with McCaferty [27] who found that the amount of adsorbed Cl ions increased with decreasing pH. Our results are also in good agreement with Kolice et al [15] who found a correlation between the amount of adsorbed chloride and pH.

Our results agree also with another recent study by Kolice et al

[28] where they have shown using XPS studies that the amount of

Cl ions taken up by the passive film on Al surface varied with pH and the minimum concentration of surface chloride occurred at a pH near pH9.5 in agreement with the isoelectric point determined by McCaferty [29]. The exact mechanism by which Cl - ions penetrate into the interior of oxide films is not known with certainty however, it is widely accepted that the incorporation of

Cl ions into the Al oxide film is a partial step before initiation of pits[27]. The low I corr

in alkaline medium may be explained by the findings of Foley in 1986 [30] that the presence of chloride ions in alkaline medium increase the resistance of the oxide layer due to incorporation of chloride ion in the defected sites forming compounds like AlCl

3

,Al(OH)

2

Cl , Al(OH)Cl

2

. The removal of surface defects by incorporation of chloride ions was experimentally verified by Lee & Pyun using Auger Analysis [31].

A previous model by McCaferty [27] was extended to consider that penetration of Cl ions can occur by film dissolution or by migration through oxygen vacancies [32].

3.

Corrosion current density, (I corr

) for Al 6063 in amino acid solutions decreased with increasing pH reaching its minimum at pH 6.5 then started to increase reaching its maximum at pH 9.5 as shown in Fig (11 b). Limiting Current appeared in alkaline and neutral medium which may be attributed to reduction of oxygen and/or water.

4.

The addition of NaCl to amino acids increased greatly the values of

I cor

for Al 6063 in the acidic medium only (63.5, 37.53 fold for Asp

+NaCl and Glu+NaCl respectively at pH 3.1) but it didn't affect the neutral and alkaline medium as shown in Fig (11 c). As explained earlier the isoelectric point of Al of 9.5 makes the Al surface positive below pH 9.5 and allows for penetration of Cl - ions whereas when the pH is ≥ 9.5 the Al surface would be negative

6 which will prevent the penetration of Cl - ions. Cathodic Tafel's slops (B c

) of amino acids with sodium chloride in neutral medium were almost the same as that of amino acids but it increased greatly in acidic medium. However the addition of chloride ions to amino acids decreased anodic Tafel's slops (B a

) in the acidic medium.

This means that the presence of chloride ions increased the cathodic reactions and decreased the anodic reactions.

3-3-2 Effect of Temperature

To study the effect of temperature on the electrochemical behavior of Al 6063 in NaCl, amino acids with/without NaCl, the concentration and pH were kept constant and the temperature was changed from (10-

60ºC). Tafel plots are shown in Figs (10-11) for NaCl, Glu and

Glu+NaCl respectively and the electrochemical parameters for Al 6063 in the studied solutions are listed in table (5). Apparent activation energy values, E a

for Al 6063 in the studied solutions were calculated from

Arrhenius equation by plotting ln I corr

versus 1/T and the results are listed in table (6). The variation of I corr values with temperature for Al 6063 in the studied solutions is shown in Figure (12a, b). It is clear from tables (5,

6) that:

1.

In general increasing temperature shifts E corr

values to the negative direction which indicates thinning the Al oxide film and correlates with increasing I corr values.

2.

I corr

values for amino acids increased slightly with increasing temperature as shown in Fig (12 a) , may be because the dominant reduction reaction is reduction of oxygen. The small corrosion rate of Al in these amino acids in the studied temperature range agrees with Al Mayouf's findings in using these amino acids as corrosion inhibitors in acidic medium [33].

3.

For amino acids with sodium chloride I corr values increased 3-

4 times with increasing temperature as shown in Fig (12b)which reflects the role of chloride ions in stimulating dissolution of the

Al oxide layer in acidic medium.

4.

It is noticed that E a

values increase in the following order :

NaCl > amino acids > amino acids + NaCl

This is in agreement with the trend observed earlier for I corr in these solutions.

7

3-3-3 Effect of Immersion Time

The effect of immersion time on Tafel plots was studied at pH4.5 after 60 hours and compared to that after one hour; the results are listed in table (7). It is surprising that I corr

values for NaCl and amino acids + NaCl decrease with increasing immersion time, opposite to the trend noticed with amino acids only. This explains the complexity of adsorption of amino acid anions in presence of chloride ions and that some adsorption reactions on Al may need longer times as some researcher prove [15, 34].

The presence of chloride ions may change the mode of adsorption of amino acid anions by increasing the oxide layer resistance [35]. Our results agree with the findings of Lee & Pyun [36] that the removal of surface defects by pre immersion in neutral NaCl solution may be accomplished by formation of defect repairing oxide films compounds like Al (OH)

2

Cl and Al(OH)Cl

2

. This was experimentally verified by

Augar Analysis where they found that the ''number of available pit initiation sites was noticeably reduced by pre immersion in 1 M NaCl solution, which is due to occurrence of metastable pitting'' [36].

Although the previous results about the role of chloride ions in forming defect repairing oxide films were in the neutral and alkaline media, our results show that they may play the same role in acidic medium at long immersion times.

Conclusion

1.

It is obvious from this study that use of atomic absorption is a promising method for analyzing weight loss measurements as it allows analysis in ppb range and shorter time intervals.

2.

The depletion of Mg and Fe from the Al 6063 in amino acids w/without NaCl reflects the formation of anodic phases in Al matrix.

3.

The addition of chloride ions to amino acids increased the CR of Al 6063 especially at low pH.

4.

The addition of chloride ions to amino acids reduced the corrosion rate of Al 6063 at long immersion times which indicate formation of defect repairing oxide films compounds.

5.

The dietary sources of Al are food and water. The increase in corrosion rate of Al in presence of these acids with chloride ions needs more elaborate studies to determine the dissolution of Al from cooking utensil and compare them with the daily allowed amount from WHO.

8

Acknowledgment

The authors wish to thank King Abdulaziz City for Science and

Technology for their valuable financial support of this study.

9

Table (1) Composition of Al alloy

Al

6063

Zn Ti Cr Si

97.50-

98.35

0.10 0.10 0.1

0

0.20 -

0.60

Fe

0.35

Mg

0.45-

0.90

Mn

0.10

Cu

0.10 other

0.15

Table (2) Corrosion rate for Al 6063 in studied solutions obtained from

WL and AA measurements

CR(g/cm

2

.days) CR(g/cm

2

.days) solution pH WL AA solution WL AA

NaCl 6.5 7.50E-06 6.80E-06 NaCl 7.50E-06 6.80E-06

Asp 3.1 2.20E-05 2.06E-05 Asp+ NaCl 8.09E-05 8.29E-05

Glu 3.3 6.32E-05 7.03 E-05 Glu+ NaCl 9.16E-05 10.93E-05

Table (3) Elemental analysis for Al6063 surface before and after exposure to the studied solutions using EDXR

Solution pH Al Si Fe Mg Mn

---- ---- 97.13 1.4 0.21 0.94 0.38

3.1 98.11 1.60 0.08 0.06 0.30 Asp

Glu

Asp +NaCl

Glu +NaCl

3.3

3.1

3.3

98.57 1.32

98.21 1.89

97.76 1.71

0.06

0.12

0.14

0.10 0.34

---- 0.33

---- 0.39

10

Table (4) Electrochemical parameters for Al 6063 in the studied

solutions at 25, and different pH values

Sol. pH E corr

, mV

B a

, mV/dec.

-B c

, mV/dec.

I corr

,

μA /cm 2

NaCl 2.5

4.5

-782

-674

91

18

77

229

5.98

1.32

Asp

6.5

9.5

3.0

4.5

6.5

9.5

-697

-813

-460

-502

-821

-1264

Glu 3.3

4.5

6.5

9.5

Asp + NaCl 3.0

4.5

6.5

9.5

Glu + NaCl 3.3

4.6

-423

-561

-695

-1274

-753

-731

-826

-1355

-720

-666

6. 6 -655

9. 5 -1258

272

78

67

272

292

77

105

77

75

373

100

77

84

104

92

68

67

84

28

72

106

25

20

83

85

101

134

28

82

123

22

76

85

83

70

175

0.40

0.66

0.44

0.18

0.17

10.03

0.40

0.24

0.21

22.8

27.5

20.0

0.18

10.84

15.01

4.64

0.16

22.11

11

Asp +

NaCl

Glu+

NaCl

Asp

Glu

Table (5) Electrochemical parameters for Al 6063 in the Studied solution at different temperatures

Sol. pH T ,°C E corr

, mV

B a

, mV/dec.

-B c

, mV/dec.

I corr

,

μA /cm 2

NaCl 6.5 10 -694 19 104 0.32

6.5 25 -697

6.5 45 -699

6.5 60 -700

3.1 10 -427

3.1 25 -460

3.1 45 -490

3.1 60 -482

3.3 10 -479

3.3 25 -423

3.3 45 -513

3.3 60 -529

3.1 10 -701

22

17

21

58

85

90

92

56

83

88

60

28

84

256

236

54

92

61

97

46

77

75

75

415

0.40

1.23

5.88

0.16

0.44

0.47

1.92

0.22

0.40

0.71

1.22

19.85

3.1 25 -753

3.1 45 -722

3.1 60 -727

3.3 10 -720

3.3 25 -680

28

26

28

22

23

373

385

277

222

468

27.5

39.5

55.70

10.38

15.34

3.3 45 -731

3.3 60 -728

31

25

254

297

36.4

40.97

Table (6) Apparent Activation Energy values ( E a

) for Al 6063 in the

Studied solutions at different temperatures

Solution pH E a , kJ /mol

NaCl 6.5 44.63

Asp

Glu

Asp +NaCl

Glu +NaCl

3.1

3.3

3.1

3.3

33.49

26.11

15.80

23.250

12

Table (7) Electrochemical parameters for Al 6063 in the studied solutions at pH4.5 and different immersion times

Solution Immers ion time ,hr

NaCl 1

E corr

, mV

-674

B a

, mV/dec.

18

-B c

, mV/dec.

229

I corr

,

μA /cm 2

1.32

Asp

Glu

Asp +

NaCl

Glu +

NaCl

60

1

60

1

60

1

60

1

60

-729

-502

-475

-561

-506

-731

-827

-666

-700

46

83

86

85

84

28

93

20

22

94

68

90

105

107

272

70

292

68

0.18

0.18

0.72

0.24

2.50

20.0

3.45

4.64

3.43

13

Fig (1) SEM for Al 6063 surface in NaCl solution after 30 days immersion , 25

ºC

0.10M

Fig (2) SEM for Al 6063 surface in Asp solution after 30 days immersion, 25

ºC

,0.020M,

14

Fig (3) SEM for Al 6063 surface in Asp +NaCl solution after 30 days immersion,

25ºC ( Asp=0.020M,NaCl=0.10 M),

Fig (4) SEM for Al 6063 in Glu solution after 30 days immersion , 25 ºC ,0.050M

15

Fig (5) SEM of Al in Glu +NaCl solution after 30 days immersion ,25

ºC

(Glu=0.050M, NaCl=0.10 M) ,

Fig (6) Tafel plots for Al 6063 in NaCl solution at different pH, 25

ºC

, 0.10M

16

Fig (7) Tafel plots of Al 6063 in Glu acid at different pH, 25

ºC

,0.050M

Fig (8) Tafel plots for Al 6063 in Glu+NaCl at different pH, 25

ºC

(Glu=0.050M

,NaCl=0.10M) ,

17

,

Fig (9) Tafel plots for Al 6063 in Glu solution at different temperatures, pH3.1,

0.020M (1=10

ºC

,2=25

ºC

,3=45

ºC

,4=60

ºC

)

Fig (10) Tafel plots for Al 6063 in Glu+NaCl solution at different temperatures , pH3.1, 0.020M (1=10

ºC

,2=25

ºC

,3=45

ºC

,4=60

ºC

)

18

10

8

6

4

2

0

NaCl

(a)

25

20

15

10

5

0

2 3 4 5 6 7 8 9 10

(b)

Asp

Glu

30

20

10

50

40

2 3 4 5 6 7 8 9 10

Asp+NaCl

Glu+NaCl

(c)

0

2 3 4 5 6 7 8 9 10 pH

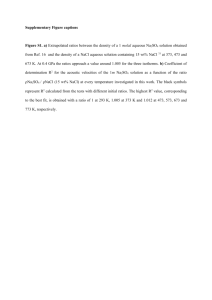

Fig. (11): Variation of I corr.

with pH values of Al 6063 for the tested solutions

19

6

5

4

3

2

1

0

NaCl

Asp

Glu

(a)

75

60

45

30

15

0

0 10 20 30 40 50 60 70

Asp+NaCl

Glu+NaCl

(b)

0 10 20 30 40 50 60 70

Temperature ( o

C)

Fig. (12): Variation of I corr.

values for Al 6063 in the studied solutions

with temperature

20

References

[1] H.J. Gitelman, “ Aluminum and Health ”, a critical review, Marcel

Dekker, Inc. (1989)

[2]A.Lion , Food Chem. Toxico ., 21 ,(No.1), 103(1983)

[3]K.Winship, Adverse Drugs React. Toxicol. Rev ., 11 , (No.2), 123(1992)

[4] A.Bard “ Encyclopedia of the Elements

” VI (1976)

[5]D.V.Brown, “ Metallurgy Basics

”, Van Nostrand Reinhold Company

Inc. (1983)

[6] A.Martel , R.Motekaitis and R.Smith, Polyhedron , 9 ,(No.2/3) , 171

(1990)

[7] P.Slanina andY.Falkeborn , Fd.Chem.Toxic

., 22 , (No.5) , 39 (1984)

[8]A.A.Al-Suhybani, Corr. Preven. &Control , 6 , 71 (1989)

[9]B.Mǜller, Corr. Sc. ,

46 ,159(2004)

[10] S. S. Abd. El Rehim,H.H.Hassan and M.A.Amin , Corr. Sc.

, 46 ,

(No.6) , 1011 (2004)

[11] A.Al- Mayouf and A.A.Al-Suhybani, J. King Saud Univ ., 9 ,(No.1),

49 (1997)

[12]M.Abdulhay and A.A.Al-Suhybani , International J. of Chemistry , 4 ,

(No.3), 97 (1993)

[13] O.Seri , Corr. Sc.

, 36 , (No.10), 1789 (1994)

[14] N.Lampease , and P. Koutsokos , Corr. Sc.

, 36, No.6 , 1011 (1994)

[15] A.Kolice , J.C.Polkinghorne and A.Wieckoski , Electrochem. Acta ,

43 ,(No.18) ,2605 (1998)

[16]V.Guillaumin and G.Mankoski , Corr. Sc.

, 41 ,421(1999)

[17]V.Guillaumin and G.Mankoski , Corr. Sc.

, 42 ,105 (2000)

[18]A.A.Al-Suhaybani , Mat.Wiss.Werkstofftech

, 22 , 301 (1991)

[19]K.Wong & R.Alkire , J. Electrochem. Soc.

, 137 , No.10, 3010 (1990)

[20]M.BÖRÖCZ-SZABó , Acta Alimentaria , 6 , (No.4), 341 (1977)

[21] R. Ambat and E. S. Swarakadasa, J. Appl. Electrochem., 24 ,

911(1994).

[22]L.Tomcsanyi , K.Varga,I.Bartik ,G.Horani and E.Maleczki ,

Electrochimca Acta , 34 , (No.6) , 855 (1989)

[23]E. Brillas, P. L. Cabot, F. Centellas, J. A. Carrido, E. Parez and R

M. Rodfiques. Electrochim. Acta , 43 ,799(1998)

[24]Metals Handbook, 9 th edition, , Am. Soc. for Metals, Metals Park,

Ohio,13, 583 (1987)

21

[25]G.M.Scamans,N.Jholroyd,And C.D.Tuck, Corr. Sc.

, 27 ,329 (1987)

[26]A. Al Mayouf, L. Al Juhaiman and A. Suhaybany, J. Saudi Chem.

Soc., 365,2000

[27]E. McCafferty, Corr. Sc.

, 37 ,481(1995)

[28]A.Kolice,A.S.BEsing,P.Baradlai,R.Haasch,A.Weickowski

,

J.Electrochem. Soc.

, 148 , 251 (2001)

[29] E.McCafferty,J.P.Wightman, J.Colloid Interface Sci., 194 ,344(1997)

[30]Foley, Corr.

, 42 , 277(1986)

[31] W.Lee , S. Pyun, Elecrochim.Acta., 45 ,1901(2003)

[32]E. McCafferty ,Corr. Sc., 45 ,1421(2003)

[33] A.A.Al-Mayouf, Corr. Preven. &Control , 6 , 68 (1996)

[34]Lars-Ölof Ohman &Staffan Sjöberg J.Chec,Soc, Dalton Trans ,

2513(1983)

[35]S.Pyun, Corr. Sc.

, 4 , 653(1999)

[36]S.Pyun,W.Lee, Corr. Sc.

, 43 , 353(2001)