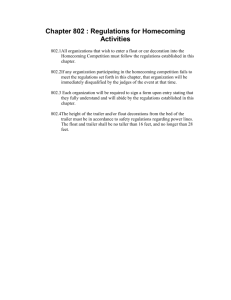

Towing Documentation - College of Engineering

advertisement

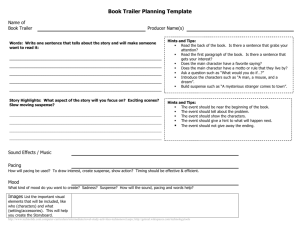

Pre Trip Preparation and Inspection – Trailer BEFORE LOADING TRAILER 1. Be sure that DOT inspection is current. Long Trailer – Inspection Tag on front of trailer Short Trailer – Inspection Tag on passenger side near side door Tires and spare – must be air pressure gage checked prior to any trip off campus Trailer Tires Inflate to MAX COLD Pressure – Information on Side Wall Check tread wear – wear strip (min. 1/16” tread and no wear strip showing) General conditions of tire Previous user may have damaged examples 2/13/2016 1 2. Trailer check list and condition report must be completed Total miles – based on Tow vehicle odometer Which student group Dates of use Trailer inspection before and after each use (see Form B) 3. Wheel bearing must be checked/lubed every 12000 miles/ 12 months. Lug nuts checked before each trip Do not use “bearing buddy” (can blow out bearing seals). 4. Replace any broken light bulbs and/or color lens on lights AFTER LOADING TRAILER 5. Attach trailer weight equalizer bars to truck and adjust so that truck fender height is 41.75”. 2/13/2016 2 6. Attach sway control bar to truck and trailer and adjust tension. 2/13/2016 3 7. Test emergency brake away battery and attach emergency brake away switch cable from trailer to truck’s frame 2/13/2016 4 8. Attach chains from trailer to truck’s hitch (cross chains before attaching i.e., left side of hitch to right side of trailer). 9. Attach brake electrical line and light cable from trailer to truck, threaded through bicycle type hitch lock (to prevent dragging if disengaged), snap cap down into place and wrap with electrical tape). 10. Verify that all retaining pins/locks are in place 2 weight equalizer bar pins 2 sway control bar pins locking hitch pin in place bicycle lock securing trailer hitch When hitch is removed, replace with oily rag to prevent dirt and rust 2/13/2016 5 Secure Cargo Do not use bungee cords – they stretch and sometimes do not hold during panic stops 1. Inspect all tie down straps and replace if: Frayed edges of 1/16 inch or more Cuts in straps Gas or oil soaked Ratchet slips or binds 2. * Once object is secured, be sure that Tie Downs, when in use, are in a “lock” position 3. Cargo must be secured with tie downs Pull forward Pull back Pull down 4. No loose items should be in the trailer or the truck when in transport (including spare) 5. Do not load heavy to the back of trailer (balance load) Handling problems 10-20% of total trailer weight should rest on the tow vehicle hitch 6. Tall objects, i.e. Tool Box must be secured at top and bottom Lock caster wheels if possible 2/13/2016 6 Tow Vehicle Inspection and Use 1. Fuel vehicle prior to connecting trailer 2. Check all fluid levels – coolant, oil, transmission, windshield wiper 3. Check air pressure on all 7 tires (you can’t tell by looking, tires can be under inflated by 25 psi and not look like they are low on air.) 4. Record on “Vehicle Conditions Record” any vehicle damage, i.e.: dents scratches marks on tire or wheels glass damage front and rear bumper marks 5. Check service record for oil and lube dates and or mileage – be sure enough miles remain to get the unit back to MSU 6. Never leave the vehicle idling when unattended 7. Vehicle to be locked at all times 8. Never leave the keys in ignition when parked or standing 9. Spare key should be assigned to team member when truck travels to distant events. 10. Backing Don’t back up unless you ABSOLUTELY MUST Get spotting help – Position one spotter on each side of the trailer - work together Plan ahead – know how you will get back out when entering gas station, restaurant, etc Avoid blind side backing without having spotting help Before backing, reduce sway control bar tension to minimum or off. NEVER back over obstructions (curbs, drops, etc.) – this can damage tires and cause blow-outs 11. All passengers must wear seatbelts 2/13/2016 7 Tow-Vehicle & Trailer Inspection When on Trip 1. Before starting vehicle make sure there are not fresh vehicle fluids under vehicle Check fluids under the hood (oil, transmission, windshield) 2. Start vehicle check gages Place vehicle in “Park” Apply emergency brake Turn on headlamp switch Turn on 4-way flasher unit (same circuit as brakes and turn signals) 3. Get out of vehicle and do “walk around” Check all lights on truck and trailer Visual check of tires Record any fresh damage Be sure all windows are clear 4. Have fellow team members help to check Turn signals Brake lights 5. Check Hitch Tighten sway control bar adjustment (Use ONLY while on road, loosen when parking, backing, etc.) Be sure all 5 pins are in place to secure hitch parts, i.e. ball insert, weight equalizing bars, sway control bar Check electrical plug – make sure it is secure Check safety chains Check break away cable 6. Before moving the truck and trailer Be sure there are no objects in front or rear of your tires Clear headlights and tail lights Clear all due, snow, fog from outside windows Adjust mirrors so that you can see the trailer tires- no blind spots when adjusted properly Check Hitch EVERY time you return to the truck and trailer (pins get taken) 7. Parking Chock wheels when parked Park straight when changing drivers so that the next driver can adjust mirrors Use 4x4 wood base for tongue jack 8. Passing Remember – truck has 30% decreased acceleration when towing Pass on divided highways only – no passing on two lane roads 9. Width of truck and trailer – 8.5” - Lane width 9’-12’ 10. Upon Driving Note normal operating transmission and engine gage temperatures – for use as baseline temps Test handling, lane change, etc., immediately after starting trip while traveling at 55mph highway speed. After a short time on the road Check load for load shift, loose tie downs, etc. Re-secure load as needed. check bearing heat on trailer Immediately after exiting vehicle when parking or stopping, touch tires and wheels to see if they are too hot. 2/13/2016 8 Stopping Distance w/o Trailer Brakes Truck & Trailer @ 30mph. d s2 s f x wt wa wa d 302 4000 3000 x 30 x.71 3000 d 900 7000 x 21.3 3000 d=42.25 x 2.33 d=98.4 Truck only @ 30mph. s2 d 30 f d 900 21.3 d=42.25 2/13/2016 9 Stopping distance for truck & trailer without trailer brakes traveling @ 70 mph 702 6000 4500 d x 30.7 4500 d 4900 10500 x 21 4500 d= 233.3 x 2.33 d = 543.6 ft. Stopping distance for truck & trailer with trailer brakes @ 70 mph s2 d 30 f 702 d 30.70 d 4900 21 d = 233 ft. If friction is reduced by 66% fa = .3, truck speed after breaking for 233ft. S at a Point in a skid S = 70 mph fa = .3 d= 233 ft. S = 52.8 mph 2/13/2016 10 Towing Tips DRIVING A TOW VEHICLE Good habits for normal driving need extra emphasis when towing a trailer. The additional weight of the trailer affects acceleration and braking. Extra time should be allowed for passing, stopping and changing lanes. Signal well in advance of a maneuver to let other drivers know your intentions. Severe bumps and badly undulating roads can damage your towing vehicle, hitch and trailer, and should be negotiated at a slow, steady speed. If any part of your towing system "bottoms out" or if you suspect damage may have occurred in any other way, pull over and make a thorough inspection. Correct any problems before resuming travel. CHECK YOUR EQUIPMENT Before towing, check the condition of all your towing equipment and keep all components in top condition. TRAILER LOADING Proper trailer loading is very important. Heavy items should be placed close to the floor near the trailer axle centerline. The load should be balanced side to side and firmly secured in the trailer to prevent shifting. Tongue weight should be 10-15% of the gross trailer weight for most trailers. To low a tongue weight often produces tendency to sway. TIRE INFLATION - Tires should be inflated to their maximum recommended pressure. PASSENGERS IN TRAILERS Trailers should not be occupied while being towed. Most states enforce this regulation. TRAILER LIGHTS, TURN SIGNALS, ELECTRIC BRAKES Always hook up all of the trailer lights, electric brakes and break-away switch connection, whenever trailer is being towed. MAINTENANCE Keep the round ends of the spring bars and the sockets in the head assembly free from dirt and well lubricated. Excessive wear in this area may indicate an overload or inadequate lubrication. Keep the head assembly exterior clean, especially in the area of the spring bar retainer. Do not allow dirt or stones to lodge in this area. Keep lift brackets clean and lubricated to insure ease of operation. AT THE BEGINNING OF EVERY TOWING DAY: Coat the round ends of the spring bars with fibrous grease. . Clean ball and coupler socket and coat ball lightly with grease. Check spring bar chains and U-bolts for wear and security. Replace before they become worn. Check to see that all hitch bolts are properly tightened and that the locking pins in the lift brackets are securely in place. Also, check that the hitch pin is in place and secure. Check to see that all electrical hook-ups are in working order and that the safety chains are securely connected. CHECK ALL TRAILER TO TOWING VEHICLE CONNECTIONS FOR SECURITY AND OPERATION NOTE: Surge brakes usually require a small amount of fore and aft movement for their actuating mechanism 2/13/2016 11 to function. To avoid restricting movement, it may be necessary to increase the number of chain links between the lift brackets and spring bars, by tilting the head down. Tighten the two 3/4" bolts to 260 ft. lbs. torque once head angle is set. Those surge brake actuators not designed for use with a weight distributing hitch, may bind and not operate freely. Check your surge brake operating instructions for any specific requirements regarding their use with weight distributing hitches. WARNINGS Loaded ball height should never be greater than the uncoupled ball height. Front wheel overload and loss of rear wheel traction can result and can lead to unstable handling. It can reduce braking ability and create a tendency to "jackknife when turning or braking at the same time. If the loaded ball height is greater than the uncoupled height, reduce take up on the spring bar chains and remeasure and adjust until the proper height is obtained. CAUTION: If the lift chain is angled fore or aft at the top within the lift bracket, it may catch on the bracket when turning. This could damage the lift bracket or pry it open. St. Paul Pioneer Press 05-17-2005 3 Mankato college students killed in crash CHIKAMING TOWNSHIP, Mich. - Three Minnesota State University, Mankato students died today and five other people riding in the same van were injured when the vehicle crossed the Interstate 94 median and was hit by two oncoming semitrailer trucks At least one of the injured was in critical condition, said Michael Cooper, media relations director at the southern Minnesota University “We really are devastated by it." Cooper said. "We're in shock, and obviously our hearts go out to the families." The group, which included seven students and one faculty member, was on its way to Detroit to compete in a national Society of Automotive Engineers student competition. Chikaming Township police said the van was towing a trailer and traveling east near Sawyer when it crossed the median and was struck by the two semis, which were heading west. Cooper said he was told a gust of wind blew the van into the oncoming traffic, but police still were investigating. Cooper said the group was towing a Formula Series car that the students built for the competition in Detroit, an annual event that includes about 140 colleges and universities from across the country. The names of the victims were not immediately released. Cooper said most of the students were seniors. Another group of nine people from the university was following the van that crashed. That group was not involved in the accident, Cooper said. Police said several other motorists were also injured in the crash. 2/13/2016 12 Form B Trailer Checklist DAILY LOG Log must be completed prior to towing Trailer NOTE: Maximum Speed when towing is 60 MPH. Date: ____________ Driver ____________________ Department/Group: ___________________________ To: _____________ City: ___________________ Reason for trip______________________________ Trailer SAFETY CHECK: (check if OK) Check ONE Long Trailer or Tail Lights Short trailer Brake Lights Tire Pressure (gage is in glove box – record pressures) Record Actual PSI Right Front - __________ Turn Signal Lights Right Rear - __________ Side marker lights Left Front - ___________ Emergency Flasher Left Rear - ____________ Body and paint (describe problems in comments) Spare – ___________ Current Insurance and Registration forms (including copy of trailer registration) Brakes Torque lugs, nuts and bolts* Fluid Leak (prior to moving vehicle look beneath truck and describe problems in comments below) Service date on inspection sticker is current Overall cleanliness (inside and out) Dirty Clean Comments: _______________________________________________________________________________________ _______________________________________________________________________________________ Begin Mileage ___________________________Miles since last wheel bearing service ______________ Next Wheel bearing Service due in ___________miles * Torque to 90-120#. Check first trip after 10, 25 and 50 miles. 2/13/2016 13 DAILY LOG and Vehicle Condition Record - 2004 Chevy Silverado LS 3500 Log must be completed prior to driving truck NOTE: Maximum Speed when towing is 60 MPH. Date: _______________ Driver _______________________________________ Department/Group: ___________________________________ To: _____________________________________ City: ________________________ Reason for trip_______________________________ VEHICLE SAFETY CHECK: (check if OK) Headlights Tail Lights Brakes Engine Oil Jack Safety Triangles Brake Lights Fuel level (should be full!) Service date on sticker is current Turn Signal Lights (including mirror signals) Wiper Fluid Current Insurance and Registration forms (including copy of trailer registration) Side marker lights Fluid Leak (prior to moving vehicle - look beneath truck and describe problems in comments below) Emergency Flasher Windows, mirrors, body and paint (describe problems in comments) Right Front - 80 PSI Left Front - 80 PSI Right Outside Rear – 65 PSI Right Inside Rear – 65 PSI Left Outside Rear – 65 PSI Left Inside Rear – 65 PSI Spare – 80 PSI Horn Wipers operational Tire Pressure (gage is in glove box – record pressures) Record Actual PSI __________ ___________ ___________ ___________ ____________ ___________ ___________ First Aid kit sealed opened Overall cleanliness (inside and out) Dirty Clean Comments: ___________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ Begin Mileage ________________________________ Next Service due at 30,174 miles Miles to next service ___________________________ 2/13/2016 14