Ask many a seasoned truck or bus engineer the simple question

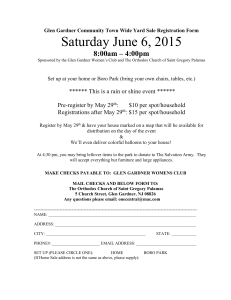

advertisement

Ask many a seasoned truck or bus engineer the simple question ‘who made the best large diesel engine?’ and more than likely the answer without delay would be Gardner. Most of you out there in readerland will claim not to have had any experience with such engines, some may not even know who they, but I’ll bet you ten bob that at some point in your life, you will have been either propelled or scared half to death thanks to a Gardner. The world regarded company of L Gardner & Son of Patricroft in Manchester for many years, were the world export leaders in diesel engines for commercial use all around the globe. Throughout the 50s 60s & 70s, most of the British made trucks and buses relied on Gardner power, and they were certainly engines of legend. In the latter part of the company history, Brothers Hugh & John Gardner designed some of the longest lasting and fuel efficient commercial diesels of the 20th century, and just like Land Rover, a huge proportion of their output is still in daily use, if not for the original purpose it was designed for. Their swansong engine with no shadow of doubt, was the 10.5 litre 6LX design which first saw the light of day in 1958 being based on the previous 8.4 litre 6LW design but featuring many improvements to aid longevity and efficiency. What made Gardner quite unique in the world of engine building was the fact that most of the components involved, even parts of the fuel pumps, were all cast or fabricated in house to standards of utmost quality. Initially offered with a rating of 150bhp in automotive tune, the 6LX went on to become the most popular engine of its type being fitted into generators, mobile cranes, boats, mining machinery, commercial vehicles & buses. Gardner used separate cast iron cylinder heads in a similar vain to the likes of AEC or Leyland, but the cylinder block also in iron, was fitted to a cast alloy crankcase. Another unique feature that contributed to the lasting nature of the engine was the crankshaft main bearings that were not only located and secured vertically in the normal way, but also horizontally braced. This gave the bottom end of the engine phenomenal strength and rigidity with warranty claims for terminal failure being virtually unheard of. Our very own Leyland & AEC also had respected engine ranges with the 680 and AV690 respectively and as the 1960s progressed, squeezed more power from them. The Leyland 680 engine in power plus tune developed 200bhp but not without problems of cylinder head gasket issues. Gardner responded with the 6LXB vertical or 6HLXB in horizontal form putting out 180bhp amazingly with hardly any noticeable difference in fuel consumption. So talented was Hugh Gardner that thermal efficiency of this variant was a shade over 40% - a figure unmatched before, and maximum torque was developed at a staggeringly low 975 – 1100rpm. Even maximum power was achieved at only 1850rpm where nearly all other rivals figures were gained at 2000 or 2100rpm. A large capacity engine working well within its design capabilities were key to a long trouble free life. Leyland bus for example, were very reluctant to specify Gardner power units, but following some catastrophic disasters, notably with their fixed head 500 series and the impressive yet mortally under developed AEC / Leyland 800 V8 had to offer 6LXB in later model National buses. Bristol who was also in the BL group sold thousands of RE & VRT buses with Gardner as the standard engine. In a bid to offer even more output, Gardner further improved output following the addition of the 6LXC rated at 195bhp towards the latter part of the 1970s. This same period however, saw Gardner loose its independence following a sell out to the Hawker Siddley group. To say that the Gardner family were stuck in their ways and tradition would be an understatement. Hugh Gardner, despite seeing foreign and UK competition engines offering ever more power ratings refused to offer turbocharged power units to his designs. The bus market remained fairly buoyant, but truck chassis from UK manufacturers started looking elsewhere for engines with the likes of Rolls Royce and Cummins simply picking off traditional Gardner customers one by one. The 6LXC developed under 200bhp whereby a Cummins N series offered 250 and beyond with far superior torque. Subsequent designs in the Hawker Siddley era offered comparable levels of output but sadly lacked the development required to match the competition. Gardner then introduced a turbocharged version known as the 6LXCT rated at 230bhp but the days of Gardner ruling the roads were numbered – the competition simply just got better. The 6LX series remained in production even after Hawker Siddley sold Gardner onto the Perkins group, right through the 80s and even into the early 90s, the 6LX remained the number one choice for British bus buyers. Sadly, Leyland bus entered a preferential purchase agreement with Cummins as did Dennis and the forthcoming Euro1 emission criteria tolled the knell for the Gardner 6LX series engine. Engine production of 6LX ceased in 1992 after a run of almost 100.000 units. Gardner powered buses and trucks are pretty rare these days, but should you wish to enjoy the sound and smell of a plodding Gardner 6LX engine, peer round the back of your typical fairground ride where the generators reside – that’s where you’ll find them!