Peas in Tilapia Feed Formulations

advertisement

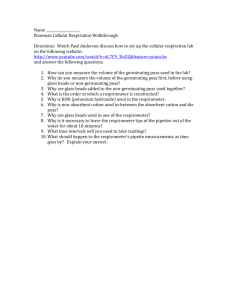

Peas in Tilapia Feed Formulations By Howard Hill, AgriSource Co. Ltd. Timothy Welsh, USA Dry Pea and Lentil Council The use of feed peas, Pisum sativum, as a substitute for other vegetable sources of protein and energy has been well researched and proven (Welsh, 2002; Welsh and Creswell, 2003). Peas have long been known as an alternative crude protein source, as well as a source of energy and starch, in other animal feeds (Tables 1 and 2). Small-scale trials using feed pea as a protein substitute have indicated that, based on prices of soybean meal and fishmeal, peas can be used as an economic substitute. Further trial work has identified peas as an effective pellet binder (Hill & Welsh, 2006) and showed that the addition of peas to an aqua formulation had a binding effect which improved the fines and water stability of feed pellets. Plant breeding of peas is carried out using traditional methods, which further enhances the value of feed peas as a non-GMO ingredient. Table 1: Proximate composition of feed peas Nutrient in % as is Range Moisture Crude Protein Crude Fat Crude Fiber Ash Gross energy (kcal/kg) (Source: Allan 1997) 10.0 - 11.0 22.0 - 25.0 1.0 - 1.5 4.0 - 7.0 3.0 - 3.5 4000-4200 Table 2: Carbohydrates in feed peas Carbohydrate type Starch Cellulose Sugar Oligosaccharides Crude fiber Acid Detergent Fiber Neutral Detergent Fiber % 34.8 –54.1 2.4 - 7.9 1.0 - 5.7 3.7 4.9 - 6.3 6.0 - 8.7 10.0 - 12.0 The USA Dry Pea and Lentil Council contracted research with a large feed miller in the Philippines in order to conduct replicated tilapia, Oreochromis niloticus, feeding trials utilizing pea inclusion at all growth stages from starter to final harvest. The trial was done using cages on Sampaloc Lake, San Pablo City. The objectives of the trials were: 1). To compare Average Daily Gain (ADG) and feed efficiency, measured by Feed Consumption (FC) and Feed Conversion Ratio (FCR) 2). To measure fish dimensions (length and width) in order to establish a possible correlation between feed and size Nile tilapia figerlings were obtained from the Sandigan Cooperative, Samplac Lake, San Paulo. The fingerlings were put into 6 cages measuring 10 x 10 x 7 meters each, with the preparation and setup following standard practice. The 6 cages allowed for 3 replications of two treatments. Each of the 6 cages received 5,000 fingerlings. Before the experiment, the fingerlings received a standard fry mash for 24 days. By the start of the experiment, the fish were 45 days old and weighed 14 grams. Up to this point, all fingerlings were kept in the same conditions and received the same standard fry mash; therefore, similar weight gain and losses can be assumed. The trial had 3 phases: Starter, Juvenile and Adult. Feeding with the starter formulation containing 12% pea lasted 35 days. Feeding of the juvenile formulation containing 20% pea lasted 22 days, while an adult formulation containing 25% pea was fed for 36 days. (Table 3) Table 3: Trial Feeds and Treatments with Pea Content Feeding Days 35 Formulation Starter 22 Juvenile 36 Adult Treatment T1 T2 T1 T2 T1 T2 Component 12% Peas No Peas 20% Peas No peas 25% Peas No Peas The formulations were designed to provide similar nutrients, based on combinations of different raw materials. Composition and prices of the major raw materials are shown in Table 4. Peas mainly replaced soybean meal and materials that contain energy, such as high fat rice bran or tapioca. Ingredient prices are rounded figures in $US, and based on market survey information for prevailing prices in the Philippines during March 2005 (USDPLC). Table 4: Feed Composition, Nutrient Analysis, and Cost Starter Ingredients* Cost $US/ mt Peas 225 Corn, yellow 165 Pollard/Midds 150 Rice Bran HF 170 Tapioca Pellets 135 Corn GM 60%CP 485 SBM 47% CP 310 Other materials Total Cost ($US/mt) Analysis Moisture Crude Protein Crude Fat Crude Fiber Ash Juvenile Adult T1 T2 T1 T2 T1 T2 12 % Peas No Peas 20% Peas No Peas 25% Peas No Peas % Cost % 12 10 27 17 Cost 10 17 3 5 11 19 6 43 26 29 133 105 316 6 47 26 29 146 106 317 % Cost 20 6 6 15 45 10 9 26 36 17 112 62 264 % Cost 10 6 15 7 17 9 26 10 44 18 136 69 267 % Cost 25 56 % Cost 20 20 30 34 25 20 11 38 34 15 24 11 76 42 238 34 10 104 43 234 % % % % % % 11.0 35.1 5.2 3.7 6.8 11.2 35.0 6.4 3.7 7.2 10.8 28.8 6.2 4.8 6.7 11.3 28.6 6.4 4.4 7.3 10.0 13.0 25.2 25.0 5.9 6.2 5.5 5.5 8.2 8.7 * Formulas used are solely for demonstration purposes and based on analysis of the specific materials used in the trial and are not applicable to raw materials with different composition. Other materials were similar in their inclusion and added to obtain similar nutrient composition in all treatments. Results – Dimension – Size of fish Sampling within this “live” type situation provides some difficulties, with accurate measurements only able to be obtained at the start and at harvest. Only small sample sizes were taken in the intermediate phases between starter and juvenile, and juvenile and adult. Fish length and width measurements can be seen in Table 5. There was no significant difference between the treatments. Table 5: Length and Width Measurements of Fish T1 – with Peas Length / Width cm T2 - without Peas Length / Width cm L 7.0 - 9.0 n = 15 AVG = 7.6 W 3.0 - 4.5 n = 15 AVG = 3.5 L 7.0 - 9.0 n = 15 AVG = 7.6 W 3.0 - 4.5 n = 15 AVG = 3.5 14 days from start of culture L 10.0 - 12.0 n = 10 AVG = 10.8 W 4.0 - 5.0 n = 10 AVG = 4.5 L 10.0 - 12.0 n = 10 AVG = 10.5 W 4.0 - 5.0 n = 10 AVG = 4.6 93 days from start of culture (harvest) L 17.5 - 20.0 n = 14 AVG = 19.1 W 7.5 - 9.5 n = 14 AVG = 8.8 L 17.0 - 21.5 n = 16 AVG = 19.1 W 7.5 - 9.5 n = 16 AVG = 8.5 Gain during trial ΔL = 11.5, ΔW = 5.3 ΔL = 11.5, ΔW = 5.0 Stage Start of culture (14 g) L = Length, W = Width Results – Weights T1 pea-fed tilapia had a slightly higher initial weight (2.5% or 1.4 kg; see Table 6) compared to the non-pea group. This difference remained constant till harvest, when T1 final weight was 18.3 kg higher, showing an additional 16.6 kg weight gain. The Average Daily Gain (ADG) was 7.4 kg for pea-fed tilapia and 7.2 kg for non-pea group. These results were achieved with the same level of total feed consumption of 15.1 kg/day. The feed conversion ratio (FCR) for T1 with pea was slightly (numerically +2.5%) better than T2 with no pea inclusion. Table 6: Estimated Bio Mass Change & Final Growth Performance Bio-Mass Treatment Feeding days Init. Wt. kg Final Wt. kg Weight Gain kg ADG kg Total FC kg ADFC kg/day FCR T1 Replicate 1 T1 Replicate 2 T1 Replicate 3 93 93 93 48.2 61.5 61.5 835.0 711.0 696.0 786.8 649.5 634.5 8.5 7.0 6.8 1368.9 1426.2 1426.2 14.7 15.3 15.3 1.74 2.20 2.25 93 57.1 747.3 690.3 7.4 1407.1 15.1 2.04 T2 Replicate 1 T2 Replicate 2 T2 Replicate 3 93 93 93 44.0 61.5 61.5 660.5 805.5 721.0 616.5 744.0 659.5 6.6 8.0 7.1 1368.4 1426.2 1426.2 14.7 15.3 15.3 2.22 1.92 2.16 T2 - Without Peas 93 55.7 729.0 673.3 7.2 1406.9 15.1 2.09 T1 – With Peas Average Average The evaluation of the results has been limited to a comparison of numerical averages because the small number of observations (3 replicates) limits statistical comparisons. The total feed cost of the various formulations can be seen in Table 7. Some advantages can be seen in the pea formulations for starter and juvenile, which equate to some reductions in the overall cost of feed through these stages. At the adult stage the pea formulation has a higher cost, which equates to an additional cost. Over the entire feeding program, the additional cost for using pea within the formulation equates to $US1.94, or 0.5% more expensive than the non-pea formulation. In this trial however, the extra 16.6 kg harvested covered the extra cost. Table 7: Cost of Feed Starter T1 T2 12% Peas Juvenile T1 T2 20% Peas Adult T1 25% Peas T2 Total T1 With Peas T2 Cost ($US/mt) kg Used 316 257.3 317 257.2 264 293 267 293 238 856.7 234 856.7 1407.0 1406.9 Cost ($US/mt) 81.29 81.48 77.33 78.14 203.80 200.87 362.43 360.49 Conclusions It can be concluded that the inclusion of peas into the formulations gave similar results as formulations based entirely on soybean meal as the major protein source. Depending on the cost of peas, they can be a viable alternative to soybean meal, especially in times where soybean meal is expensive. Increasingly, trial results are showing that feed pea can act as a plant protein substitute in fish feeds without affecting growth performance. References Allan, G.L., 1997. Potential for pulses in aquaculture systems. Proceedings of International Food Legume Research Conference III, Sept. 22–26, 1997, Adelaide, Australia. 13 pp. Welsh, Timothy; Feed Pea Offers Attractive Opportunities As An Aqua Feed Ingredient, Aqua Feed International, October-December 2002, pp 22-24 Welsh, Timothy and Creswell, David; Cheaper Plant protein Source for Shrimp, Tilapia and Milkfish, Asian Aquaculture Magazine, September/October 2003, pp 23-25.