SWP M6 - Faculty of Medicine

advertisement

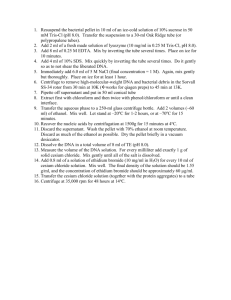

OHS026 Safe Work Procedure Faculty/Division School/ Divisional Unit Medicine POWCS/ORC Document number POWCS.ORC.SWPM6 Initial Issue date 16/06/2006 Current version 1 Current Version Issue date Next review date 01/12/2010 18/03/2008 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Isolation of plasmid DNA (replaces M5.2, M6.2 and M24.1) Description: Associated risk assessment title and location: POWCS.ORC.RA M6 Describe the activity or process This SWP describes the protocols for isolating plasmid DNA from bacterial cell cultures. These procedures are performed in the PC-2 facility following the OGTR guidelines. PC-2 induction must be carried out before these methods are undertaken. When producing DNA for restriction enzyme screening, a mini-prep is used. Once the identity and the quality of the plasmid have been confirmed, larger amounts of DNA for experimental use are generated using either a midi- or a maxi-prep (depending upon your requirements). These protocols involve the use of hazardous substances. The attached Risk Assessment and all relevant MSDSs must be accessed and read before the work is commenced. In addition, this document references SWP M4: “Broths and buffers for molecular biology” and SWP M10: “Preparation of competent bacteria and transformation by heat shock”; be aware that the hazards associated with the procedures described in those documents will not be detailed here. Furthermore, all persons carrying out these protocols must also be familiar with SWP P4 and P5, which describe the correct procedures to be followed when disposing of PC-2 waste. NB: - in this document, preparation of DNA both “by hand” and using commercial kits will be described. Using a kit is quicker, and involves less exposure to hazardous substances, but preparing DNA by hand gives a much better yield (in terms of both quantity and quality) and is less expensive. These methods are described in the singular, however you should never make just one preparation! Even numbers make centrifuging simpler. A1. Mini-prep DNA 1. Working in a biohazard hood, transfer 5 mL LB into a 50 mL centrifuge tube, then add the required concentration of antibiotic. (NB: - the antibiotic that you add and its concentration will be determined by the nature of your plasmid) 2. Inoculate the LB with a single colony from an agar plate or 10 µL of thawed glycerol stock. Incubate overnight (15-17 hr, no longer) at 37oC in the shaking incubator at 180 rpm. All cultures must be labeled with the full plasmid name and the type of bacteria (e.g. p922KAICAT in XL1 Blue E. coli), as well as your name and the date 3. Cool the culture on ice; also pre-cool the bench-top centrifuge to 4oC 4. Working in a biohazard hood, fill a labeled 1.5 mL tube near to the top with culture 5. Centrifuge at 12000 g for 10 sec at 4 oC 6. Decant the supernatant into an appropriate container for decontamination by bleaching (see SWP P5) ______________________________________________________________________________________________________________________ Page 1 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. Repeat steps 4, 5 and 6; the rest of the culture can be stored at 4oC for up to 1 week Still in the hood, add 100 µL Solution 1 containing 5 mg/mL lysozyme. Resuspend the pellet and incubate on ice for 5 min. While the mixture is incubating, prepare fresh Solution 2. Working on the bench, add 200 µL Solution 2, mix, and incubate on ice for 10 min Add 150 µL Solution 3, then centrifuge at 12000 g for 10 min at 4oC Transfer the supernatant into a new 1.5 mL tube (~400 µL) Add 200 µL phenol and 200 µL chloroform. Vortex thoroughly and centrifuge at 12000 g for 3 min at 4 oC Remove the supernatant to a new 1.5 mL tube and add 2 volumes of absolute ethanol Mix and centrifuge at 20817 g for 10 min at 4 oC Remove the supernatant, taking care not to disturb the pellet, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible Resuspend the pellet in 100 µL TE buffer Add 1 µL 10 mg/mL RNaseA and incubate at 37oC for 15 min Add 40 µL Solution 3 and 260 µL ddH2O. Mix well. Add 400 µL phenol, vortex thoroughly, and centrifuge at 12000 g for 3 min at 4 oC Carefully remove the top layer to a new 1.5 mL tube and add 200 µL phenol and 200 µL chloroform. Vortex thoroughly to mix, and centrifuge at 12000 g for 3 min at 4oC Carefully remove the top layer to a new 1.5 mL tube and add 400 µL chloroform. Vortex thoroughly to mix, and centrifuge at 12000 g for 3 min at 4oC Carefully remove top layer to a new 1.5 mL tube and add 1/10th the existing volume of 3 M sodium acetate. Mix well. Add twice the new total volume of absolute ethanol. Centrifuge at 12000 g for 20 min at 4oC Remove the ethanol, taking care not to disturb the pellet, and gently wash the pellet with 500 µL 70% v/v ethanol. Centrifuge at 12000 g for 2 min at 4oC Carefully remove the ethanol wash, taking care not to disturb the pellet, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible. Resuspend the DNA pellet in 20 µL TE buffer, warming gently if necessary to help dissolve the pellet. This DNA can now be used for sequencing or restriction enzyme digests or stored at -20oC A2. Mini-prep DNA using the QIAGEN alkaline lysis methodology 1. Working in a biohazard hood, transfer 2 mL LB into a 14 mL round-bottom tube and add the required concentration of antibiotic. (NB: - the antibiotic that you add and its concentration will be determined by the nature of your plasmid) 2. Inoculate the LB with a single colony from an agar plate or 1-10 µL of thawed glycerol stock. Incubate overnight (15-17 hr, no longer) at 37oC in the shaking incubator at 180 rpm. All cultures must be labeled with the full plasmid name and the type of bacteria (e.g. pShuttle.CMV.PNP in E. coli DH10B-alpha), as well as your name and the date 3. Working in a biohazard hood, transfer 1.5 mL of culture into a labeled 1.5 mL tube; the rest of the culture can be stored at 4oC for up to 1 week 4. Centrifuge at 12200 g for 5 min at room temperature 5. Remove the supernatant, leaving the bacterial pellet as dry as possible. (NB: - it is important to remove all traces of medium from the bacterial pellet, otherwise the plasmid DNA may be resistant to cleavage by restriction enzymes) 6. Add 200 L of chilled P1 buffer and resuspend the bacterial pellet by pipetting it up and down 7. Add 200 L of P2 buffer and invert a few times. Incubate at room temperature for 4 min, no longer than 5 min; timing is crucial. The bacterial lysate will become viscous as large complexes containing bacterial proteins, broken cell walls, and denatured chromosomal DNA are precipitated from solution when sodium ions are replaced by potassium ions. 8. Add 200 L of chilled P3 buffer, mix by inversion and incubate on ice for 15 min 9. Centrifuge the lysate at 15000 g for 20 min at 4C 10. Transfer the supernatant into a new labeled 1.5 mL tube and discard the pellet 11. Add 1 mL of absolute ethanol to the tube and mix by inversion. Allow the mixture to stand for 2 min at room temperature 12. Centrifuge at 15000 g for 15 min at room temperature 13. Slowly and carefully remove the supernatant; do not disturb the pellet 14. Add 600 L of chilled 70% v/v ethanol, then centrifuge at 15000 g at room temperature for 5 min 15. Carefully remove the ethanol wash, taking care not to disturb the pellet, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible ______________________________________________________________________________________________________________________ Page 2 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process 16. Air dry the pellet in a 57C oven (a hybidisation chamber can be used for this purpose), checking for the presence of any ethanol every minute (1-2 minutes of drying is usually sufficient). Do not overdry the pellet as dehydrated DNA is difficult to dissolve, and it may denature 17. Dissolve the pellet in 30-50 L of sterile ddH2O; it should contain 2-3 (up to 5) g of DNA 18. Store at -20C until ready for use B1. Midi-prep DNA 1. Working in a biohazard hood, transfer 100 mL LB into a 250 mL conical flask, then add the required concentration of antibiotic. (NB: - the antibiotic that you add and its concentration will be determined by the nature of your plasmid) 2. Inoculate the LB with 100 L glycerol stock or 100 L of a pre-screened small-scale culture. Incubate overnight (15-17 hr, no longer) at 37oC in the shaking incubator at 180 rpm. All cultures must be labeled with the full plasmid name and the type of bacteria (e.g. p922KAICAT in XL1 Blue E. coli), as well as your name and the date 3. Cool the culture on ice; also pre-cool the centrifuge to 4oC and label the appropriate number of 250 mL centrifuge pots 4. Working in a biohazard hood, 100 mL culture are transferred into 250 mL centrifuge pots; it is necessary to prepare even numbers, so that they will balance 5. Centrifuge at 3000 g for 15 min at 4oC; in the hood, decant the supernatant into the empty conical flask and bleach (see SWP P5) 6. In the hood, add 4 mL Solution 1 containing 5 mg/mL lysozyme. Resuspend the pellet and incubate on ice for 10 min. While the mixture is incubating, prepare fresh Solution 2. 7. Working on the bench, add 6 mL Solution 2, mix, and incubate on ice for 10 min 8. Add 8 mL Solution 3, mix, and incubate on ice for 10 min; centrifuge at 3000 g for 15 min at 4oC 9. Pack a small funnel with glass wool and decant the supernatant through it into a 50 mL tube; discard the glass wool as cytotoxic waste 10. Add 17 mL isopropanol, mix, and place at -80oC for 15 min; centrifuge at 3000 g for 15 min at 4oC 11. Discard the supernatant and resuspend the pellet in 2 mL TE buffer; add 2.5 mL 4.4 M lithium chloride, mix, and incubate on ice for a minimum of 1 hr; centrifuge at 3000 g for 15 min at 4oC 12. Transfer the supernatant to a new 50 mL tube and add 10 mL absolute ethanol; centrifuge at 3000 g for 15 min at 4oC 13. Remove the ethanol, taking care not to disturb the pellet, and gently rinse the pellet with 70% v/v ethanol; if the pellet dislodges, centrifuge at 3000 g for 15 min at 4oC; otherwise, slowly and carefully remove the ethanol wash, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible 14. Resuspend the pellet in 400 L TE buffer, transfer to a new 1.5 mL tube, add 10 L 10 mg/mL RNase A and incubate at 37oC for 15 min 15. Add 20 L 10% SDS, heat at 70oC in a water bath for 10 min, then cool on ice 16. Add 430 L phenol and vortex thoroughly to mix; centrifuge at 12000 g for 3 min at 4 oC 17. Remove the top layer to a new 1.5 mL tube and repeat the phenol extraction; centrifuge at 12000 g for 3 min at 4oC 18. Remove the top layer to new 1.5 mL tube and add 200 L phenol and 200 L chloroform. Vortex thoroughly, then centrifuge at 12000 g for 3 min at 4oC 19. Remove the top layer to a new 1.5 mL tube and add 400 L chloroform. Vortex thoroughly, then centrifuge at 12000 g for 3 min at 4oC 20. Remove the top layer to a new 1.5 mL tube and add 1/10th the existing volume of 3 M sodium acetate. Mix well. 21. Add twice the new total volume of absolute ethanol; centrifuge at 12000 g for 3 min at 4oC 22. Carefully remove the ethanol and gently wash the pellet with 500 L 70% v/v ethanol; centrifuge at 12000 g for 2 min at 4oC 23. Slowly and carefully remove the ethanol wash, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible 24. Resuspend the DNA pellet in 200 L TE buffer. If necessary, warm gently to help dissolve the pellet. The DNA can now be used for sequencing or restriction enzyme digests, or stored at -20oC ______________________________________________________________________________________________________________________ Page 3 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process B2. Midi-prep and Maxi-Prep DNA using the QIAGEN Plasmid Kits (NB: - the QIAGEN Midi- and Maxi-Prep methods follow essentially the same methodology, except for differences of scale. In the following protocol, the Midi-Prep procedure will be given in the text, while the Maxi-Prep procedure will be given in square brackets and bolded – e.g. [Maxi-Prep] ) 1. Midi- and Maxi-preps are carried out using bacteria (colonies on plates or cultures stored at 4 oC) that have already been screened by restriction enzyme digest. A culture can be expanded prior to commencing the full methodology, by inoculating a single colony or 1 mL culture into 5 mL Terrific broth (TB) plus the appropriate antibiotic in a 50 mL tube, and incubating at 37oC and 180 rpm for 6-8 hr. Alternatively, 1 mL of a pre-existing culture may be used without pre-expansion. For a Maxi-prep, it is preferable always to expand first. 2. In a biohazard hood, inoculate 1 mL culture into 50-70 mL [120-150 mL] TB (plus antibiotic) in a 500 mL [1000 mL] conical flask and incubate overnight (15-17 hr, no longer) at 37oC and 180 rpm. All cultures must be labeled with the full plasmid name and the type of bacteria (e.g. p922KAICAT in XL1 Blue E. coli) , as well as your name and the date 3. Working in the hood, prepare a glycerol stock of cultured bacteria by mixing 812.5 L of bacteria from the flask with 887.5 L of 80% glycerol; store at -20C (NB: - this glycerol stock is merely a “back-up” in case of later problems; for preparation of stocks for long-term-storage, see SWP M10) 4. Harvest the remainder of the bacterial cells by transferring the culture into 250 mL pots and centrifuging at 3000 g for 1 hr at 4C 5. Decant the supernatant and bleach (see SWP P5). Invert the open centrifuge bottle to allow all the supernatant to drain away onto absorbent paper; dispose of this as GMO waste (see SWP P4). The pellet should be as dry as possible; residual medium can interfere with restriction enzyme cleavage of the DNA 6. Thoroughly resuspend the pellet in 6 mL [12 mL] buffer P1 containing 100 g/mL RNase A; there should be no clumps 7. Add 6 mL [12 mL] buffer P2, mix by inverting the bottle vigorously 4-6 times, then incubate at room temperature for 5 min; the bacterial lysate will become viscous as large complexes containing bacterial proteins, broken cell walls, and denatured chromosomal DNA are precipitated from solution when sodium ions are replaced by potassium ions 8. Add 6 mL [12 mL] chilled buffer P3, mix by inverting the bottle vigorously 4-6 times, then incubate on ice for 15 min [20 min] and centrifuge at 3100 g for 45 min at 4oC 9. While the lysate is spinning, put together a filtration system by lining a plastic funnel with medical gauze, and sitting it in a 50 mL tube; carefully pour the supernatant through the gauze, collecting as much as possible, and discarding the debris in the gauze 10. Equilibrate a QIAGEN-tip 100 [QIAGEN-tip 500] by placing it over a conical flask and running 4 mL [10 mL] buffer QBT through it and allowing it to drain completely 11. Pour the collected supernatant through the column; wash through by pouring 2 x 15 mL [2 x 30 mL] buffer QC through the column 12. Elute the bound DNA into a fresh 50 mL tube by pouring 5 mL [15 mL] buffer QF through the column (NB: - Buffer QN may also be used for this purpose) 13. Add 3.5 mL [10.5 mL] – i.e. 0.7 volumes – room temperature isopropanol; mix, and incubate at room temperature for a minimum of 2 min 14. Have ready an appropriate number of 1.5 mL tubes; divide the mixture into them (1.5 mL per tube) and centrifuge at 15000 g for 30-60 min at 4oC; carefully pour off all the supernatants 15. Using a 1000 µL filter tip, add 800 µL 70% v/v ethanol to the first tube; gently pipette up and down to ensure that the pellet is resuspended, then transfer the contents (including the pellet) to the second tube; repeat this process for all tubes, until all of the pellets/washings are merged in the final tube; put this tube aside ______________________________________________________________________________________________________________________ Page 4 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process 16. Using a fresh 1000 µL filter tip, re-wash the other tubes; add 1 mL 70% v/v ethanol to the first tube; pipette up and down, and transfer the solution to the second tube; repeat for all of the remaining tubes 17. Centrifuge the pellet-containing tube and the washings-tube (making sure they balance) at 15000 g for 30-60 min at 4oC 18. Remove the supernatant, taking care not to disturb the pellet, then use a Thirsty-Stix, cotton bud or tissue to remove as much residual ethanol as possible 19. Complete the drying of the pellet by placing it at 50-55oC in the hybridisation oven for 40-60 sec; do not overdry!! Check for residual ethanol, and examine the pellet; when dry, it will become clear around the edges 20. If the DNA is to be used immediately, resuspend it in molecular biology-grade H2O; for longer term storage, use TE buffer The resuspension volume is according to the size of the pellet, 150-200 µL for a Midi-Prep, 300-400 µL for a Maxi-Prep; less for the pellet in the “washings” tube; it may be necessary to pipette the pellet up and down to encourage resuspension, or to incubate it at 37oC 21. Merge the main DNA solution with that from the “washings” tube 22. Determine the concentration of the DNA using the Nanodrop spectrophotometer 23. Store at -20oC List all resources required including plant, chemicals, personal protective clothing and equipment, etc L-broth (LB) (see SWP M4) Solutions 1, 2 and 3 (see SWP M4) TE buffer (see SWP M4) Appropriate selection agent for your plasmid Agar plate(s) with colonies or a glycerol stock Lysozyme (Sigma, cat. # L-7651; stored at -20oC) (NB: - this is an irritant) Phenol, saturated, pH 6.6 (MP Biomedicals, cat. # 802519; stored at 4 oC) (NB: - this is a hazardous and toxic substance) Chloroform (BDH, cat. # 10077.6B) (NB: - this is a hazardous substance) Absolute ethanol (Lomb, cat. # JJOOABS20) (NB: - this is a hazardous and flammable substance) 70% v/v ethanol (NB: - this is a hazardous and flammable substance) RNase A (Sigma, cat. # R-6513; stored at -20oC; 10 mg/mL stock) (NB: - this is an irritant) 3 M sodium acetate (prepared from powder and sterilised) Glass wool (NB: - this is a hazardous substance) 4.4 M lithium chloride (NB: - this is a hazardous substance) Isopropanol (NB: - this is a hazardous and flammable substance) 10% sodium dodecyl sulphate (SDS) (NB: - this is a hazardous substance) QIAGEN Plasmid Midi-Kit (cat. # 12143 or 12145) QIAGEN Plasmid Maxi-Kit (cat. # 12163 or 12165) Buffers P1, P2 and P3 (see SWP M4) Buffer QBT (see SWP M4) Buffer QC (see SWP M4) Buffer QF (see SWP M4) Buffer QN (see SWP M4) Terrific broth (TB) (see SWP M4) 80% glycerol Medical gauze ______________________________________________________________________________________________________________________ Page 5 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required There are several hazardous, flammable and toxic substances used in the various sections. PPE- latex gloves, long-sleeve laboratory gowns and covered shoes, MUST be worn at all times when carrying out any of these procedures. Aliquots of flammable liquids such as chloroform, absolute ethanol should be used and aliquots made in the fume hood when possible. Extra CAUTION should be taken when handling glass wool is a respiratory hazard When dealing with GMO, PC2 regulations has to be consulted List emergency shutdown instructions List clean up and waste disposal requirements Ethanol, Chlorofom and Phenol waste has to be collected separately and collected as chemical waste List legislation, standards and codes of practice used in the development of the SWP MSDS for all the listed chemicals. Supervisory approval, training, and review Supervisor: Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: SWP review date: Responsibility for SWP review: ______________________________________________________________________________________________________________________ Page 6 of 6 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007