The student will be able to - College of Micronesia

advertisement

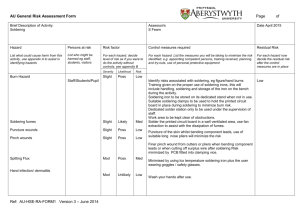

College of Micronesia PO Box 159 Pohnpei FM 96941 Course title: Soldering and Mechanical Termination Techniques Department & number: VEE100 Course Description: The course covers soldering connections and identify and rectify inferior solder joints. Students will select and prepare the correct soldering tools. In addition the student will master printed circuit board component insertion/extraction techniques, basic connector termination techniques and wire wrapping. Prepared by: Lecture/Lab Dr. Nelchor T. Permitez Hours/Week 1.5 Purpose of Course No. Of Weeks x 16 Degree Requirement Degree Elective Advanced Certificate Certificate Remedial Other (Workshop) State: Pohnpei, Pohnpei Campus Total Hours = 24 Total Semester Credits Semester Credits 1.5 1.5__ √ This course also meets PLO #(s) 1-4 of Telecommunication program. Prerequisite Course: VSP 121 Industrial Safety ________________________________________ Signature, Chairperson Curriculum & Assessment Committee __________________ Date Approved ________________________________________ Signature, VPIA, COM-FSM __________________ Date Approved VEE100 SOLDERING AND MECHANICAL TERMINATION TECHNIQUES RECOMMENDED BY CAC: 11/28/11 APPROVED BY VPIA: 12/14/11 A. PROGRAM LEARNING OUTCOMES (PLOs): The student will be able to: 1. Practice safety and occupational health procedures in the workplace. 2. Use electronics tools and test equipment competently. 3. Interpret schematic diagrams and waveforms. 4. Build electronics projects to a given specification. B. STUDENT LEARNING OUTCOMES (SLOs) - GENERAL: The student will be able to: 1. Identify the common tools and materials in soldering/desoldering techniques. 2. Describe the proper soldering/desoldering procedure using printed circuit board (PCB). 3. Differentiate standard solder link and cold solder link. 4. Perform soldering and desoldering of electronic circuits. 5. Demonstrate the correct method of terminating connectors in electronics. 6. Describe the characteristics and procedures in making good wire wrap connections. SLO 1 2 3 4 5 6 PLO 1 I I I I I I PLO 2 DM M M DM M M PLO 3 D D D D D D PLO 4 DM M DM M M DM I = Introduced D = Demonstrated M = Mastered C. STUDENT LEARNING OUTCOMES (SLOs)-SPECIFIC: The student will be able to: General SLO1: Identify the common tools and materials in soldering/desoldering techniques. Student Learning Outcomes Assessment Strategies 1.1 Define soldering/desoldering. 1.2 Enumerate the tools and materials use in Quizzes, written test and soldering/desoldering. practical exam. 1.3 Describe types of solder and flux. 1.4 Describe personal and laboratory safety habits. 1.5 Describe and demonstrate safety rules in the workshop. 1.6 Practice correct safety precaution. General SLO2: Describe the proper soldering/desoldering procedure using printed circuit board (PCB). Student Learning Outcomes Assessment Strategies 2.1 Describe the standard soldering procedure. Quizzes, written test and VEE100 SOLDERING AND MECHANICAL TERMINATION TECHNIQUES RECOMMENDED BY CAC: 11/28/11 APPROVED BY VPIA: 12/14/11 2.2 Describe the standard desoldering procedure. 2.3 Enumerate types of printed circuit board. 2.4 Demonstrate soldering/desoldering technique. practical exam. General SLO3: Differentiate standard solder link and cold solder link. Student Learning Outcomes Assessment Strategies 3.1 Describe standard solder link. Quizzes, written test and practical exam. 3.2 Describe cold solder link. 3.3 Demonstrate the effect of proper solder link. 3.4 Demonstrate the effect of cold solder link. 3.5 Describe different solder link. General SLO4: Perform soldering and desoldering of electronic circuits. Student Learning Outcomes Assessment Strategies 4.1 Desolder and resolder of fixed resistors. Quizzes, written test and practical exam. 4.2 Desolder and resolder of capacitors. 4.3 Desolder and resolder of transistors. 4.4 Desolder and resolder of integrated circuits (IC). 4.5 Desolder and resolder of surface mount devices (SMD). General SLO5: Demonstrate the correct method of terminating connectors in electronics. Student Learning Outcomes Assessment Strategies 5.1 Describe the banana plug connector termination. Quizzes, written test and practical exam. 5.2 Describe the crimp connector termination. 5.3 Describe the British Naval Connector (BNC) termination. 5.4 Demonstrate proper connector terminating procedure. General SLO6: Describe the characteristics and procedures in making good wire wrap connections. Student Learning Outcomes Assessment Strategies 6.1 Enumerate types of wire. Quizzes, written test and practical exam. 6.2 Describe the parameters of wire. 6.3 Illustrate wire wrap connections. 6.4 Demonstrate wire wrapping procedure. 6.5 Differentiate standard and sub standard wire wrap. D. COURSE CONTENTS 1. Tools and materials in soldering and desoldering 2. Soldering procedure 3. Good solder vs. Cold solder 4. Soldering and resoldering 5. Terminating electronic connector 6. Wire wrapping VEE100 SOLDERING AND MECHANICAL TERMINATION TECHNIQUES RECOMMENDED BY CAC: 11/28/11 APPROVED BY VPIA: 12/14/11 E. METHODS OF INSTRUCTION Computer Aided Instruction Practical/Experimentation Lecture/Demonstration F. REQURIED TEXT(S) AND COURSE MATERIALS Schuler, C.A. (1999). Electronics Principles and Applications, 5th Edition. USA: Mc Graw- Hill Corporation (or most recent edition). Toolbox and electronics circuits kits G. REFERENCE MATERIALS Nida Corporation. (2001). Cables and Connectors. Melborne, FL: Nida Corporation publishing (or most recent edition). H. INSTRUCTIONAL COST None I. EVALUATION Student in electronics and telecommunication program must achieve a grade of "C" or better to pass the course. J. CREDIT BY EXAMINATION None VEE100 SOLDERING AND MECHANICAL TERMINATION TECHNIQUES RECOMMENDED BY CAC: 11/28/11 APPROVED BY VPIA: 12/14/11