Optimization of process parameters for Rasogolla cooking at

advertisement

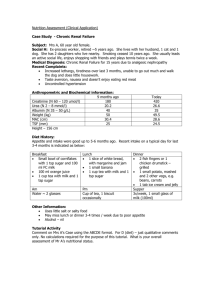

Optimization of process parameters for Preparation of Rasogolla-an Indian Dairy product at atmospheric pressure B. Mohanta1, Dr. S. L. Shrivastava2 Abstract Rasogolla is a typical Indian dairy food. Base material used for the preparation of rasogolla is a heat acid coagulated product of milk, called as ‘chhana’. It is obtained from milk by heating, cooling and acidifying the milk by a suitable acid (citric acid, lactic acid). Acidified milk is incubated for sometime before separating the whey from the coagulum. For the preparation of rasogolla, chhana is kneaded to homogenous and smooth dough. Kneaded chhana is made into balls of desired weight and diameter. These balls are cooked in boiling sugar syrup for 15-20 minutes. Rasogollas, after the cooking are stored in sugar syrup at room temperature. A study was conducted to obtain the optimized conditions of independent parameters for getting good quality rasogolla. Fourteen independent parameters which have influence on the rasogolla quality were selected. The dependent parameters choosen were diameter of rasogolla, weight of rasogolla, volume of sugar syrup expressed, L value of the color of rasogolla, hardness of rasogolla, elasticity of rasogolla and porosity of rasogolla. For good quality of rasogolla, it is desired that the value of all dependent parameters should be maximized except the hardness. Neural network modeling was applied for finding the relation between the independent and dependent parameters and optimization of the independent parameters was done by using genetic algorithm. It was found that for preparing good quality of rasogolla, the independent parameters are to be maintained at the following values: Fat content of milk = 3.45 %, temperature to which milk is heated = 95.05 ºC, rate of heating the milk = 12.59 ºC per min, temperature to which milk is heated = 92.2 ºC temperature to which milk is cooled Rate of cooling the milk = 5.24 ºC per min, Concentration of citric acid solution = 0.014 g per g solution, Ratio of milk to acid solution = 5.2, Residence time of milk acid mixture = 4.31 min, Average temperature of milk during coagulation = 76.7 ºC, , Moisture content of chhana balls after kneading = 0.44 kg per kg chhana, Concentration of sugar solution used for cooking = 41ºBrix , Cooking time of chhana balls = 16.5 min, Concentration of sugar solution used for soaking rasogolla = 35ºBrix, Soaking time of rasogolla = 14.37 h. Key Words Rasogolla, sugar syrup, hardness, elasticity, cooking time Introduction India is the largest producer of milk contributing about 15 percent of the world’s milk production. About 46 percent of the milk produced in the country is consumed as liquid milk and 50 to 55 percent of it is converted into a variety of milk products. Indian milk sweets have played significant role in economic, social, religious and nutritional well being of the country’s population. It has been reported that traditional milk products had a share of Rs 400 billions in 2001 (Patil 2005). Rasogolla is widely popular through out the country, its popularity in eastern part of India is the highest. It is estimated that the raw material cost of rasogolla is about 33 percent of its sale price (Chandan et al. 2002). Fresh cow milk is preferred for rasogolla preparation. As cow milk chhana is soft and has smooth texture, it is suitable for rasogolla preparation. Rasogolla production is largely confined to cottage and small-scale industry. Rasogollas are handled manually during the course of their preparation, packaging and storage. Production of rasogolla is increasing at the rate of about 67% per year (Anon 1994). For meeting the increased demand of rasogolla, maintenance of quality standards is necessary. It must be produced in a continuous manner using machines. Very little work has been done on the mechanization of rasogolla production. Unit operations carried out for the preparation of rasogolla are shown in Fig 1. These include: heating, cooling, acidification, settling, dewheying, kneading, ball making, cooking and soaking. For preparation of rasogolla, milk is heated to its boiling temperature and cooled to 70 ºC. Some suitable coagulating agent like citric acid or lactic acid solution is added and mixed with gentle stirring. The mixture is kept for sometime for settling and coagulation of milk solids. After the coagulation, whey is drained out; the coagulum is called as chhana. After getting chhana the first unit operation for the rasogolla preparation is kneading the chhana to a smooth mass. Generally kneading is done manually. The process is tedious and unhygienic. After kneading of the chhana, balls are prepared. About 8-10 g of kneaded chhana mass is taken, rolled between palms and ball is made. Care is taken not to have cracks on the surface of ball. The balls are put in vigorously boiling sugar syrup for about 15-20 minutes for cooking. During cooking large amount of heat energy is supplied to it. A considerable amount of water evaporates during atmospheric cooking. In order to maintain the sugar syrup concentration, the sweetmeat makers add water to the boiling sugar syrup. After the cooking is complete the balls are taken out of the boiling sugar syrup and soaked in another sugar syrup having sugar concentration lower than that used for cooking. This process stabilizes the texture of rasogolla. During this period, equilibration of sugar syrup concentration present between inside and outside the rasogolla takes place. Fig. 1 Unit operations in rasogolla preparation Several factors affect the quality of chhana and rasogolla. For preparation of suitable quality chhana for rasogolla making cow milk should have 4% fat (Rao 1971, De 1980). Higher rates of heating and cooling the milk enhanced the recovery of milk solids in chhana. It has been observed that higher cooling rate was having more influence than higher heating rate (Choudhury et al. 1998, Patel 2008). Good quality rasogolla could be prepared with 1-2% citric acid solution (De and Ray 1954, Iyer 1978). Rao 1971 found that 3.5 g citric acid per kg of cow milk was required for producing best quality of chhana for rasogolla making. The ratio of milk to acid solution should be 5:1 for the preparation of chhana. Longer residence time of milk-acid mixture before chhana separation was found to be better than shorter residence time for higher yield, and higher recovery of milk solids. Longer residence time of milk - acid mixture before straining produced comparatively soft and smooth texture chhana, which was suitable for rasogolla preparation. Many investigators had used 70 ºC (Soni et al. 1980, Jonkman and Das 1993) and other used 80 ºC as coagulation temperature (De and Ray 1954, Bhattacharya and Des Raj 1980, Kumar and Shrinivasan 1982). As coagulation temperature decreased, moisture retention in chhana increased leading to soft body and smooth texture (De and Ray 1954, Soni et al. 1980). It was reported that 55-58% moisture in chhana was optimum for good quality rasogolla having round shape, soft body, and maximum spongy texture for atmospheric cooking (Bhattacharya and Des Raj 1980). About 30-50% concentration of sugar solution is used for cooking the chhana balls for preparation of rasogolla (Goel 1970, Kundu and De 1972, Bhatttacharya and Des Raj 1980, De 1980). Generally, chhana balls require 20-30 min time for cooking in atmospheric condition (Goel 1970, Kundu and De 1972, De 1980, Bhattacharya and Des Raj 1980, Chandan 1992, Ten Hove and Das 1995). Many people have used 40% concentration of sugar solution for soaking rasogolla. Appropriate soaking time is required as during this period, rasogolla texture gets stabilized (Kundu and De 1972, Singh and Ray 1977). The present study was carried out to identify the parameters affecting the quality of rasogolla and to optimize them for obtaining good quality rasogolla. We have identified 12 independent parameters which affect the quality parameters of rasogolla and 7 parameters depicting the rasogolla quality. Range of variation of the independent parameters was found out from literature survey and the preliminary experiments carried out by the authors. The seven quality parameters identified for rasogolla are: (i) Diameter of rasogolla, (ii) Weight of rasogolla, (iii) Volume of sugar syrup expressed, (iv) L value of the color of rasogolla, (v) Hardness of rasogolla, (vi) Elasticity of rasogolla and (vii) Porosity of rasogolla. For good quality of rasogolla, parameters (i), (ii), (iii), (iv), (vi) and (vii) should be as high as possible and the parameter (v) should be as low as possible. The independent and dependent parameters are mentioned in Table 1. The table also shows the range of variation of the independent parameters within which the experiments were carried out. Table 1. Independent variables affecting the quality parameters of rasogolla Independent variables affecting rasogolla Quality Desirable quality parameters of quality rasogolla Fat content of milk, X1 (3 and 3.5%) Diameter rasogolla Temperature to which milk is heated, X2 ( 90-100 Weight ºC) rasogolla, of As large as possible of As high as possible Rate of heating the milk, X3 (8.1 - 15.82 ºC per Volume of sugar As high min) syrup expressed possible as Temperature to which milk is cooled, X4 (70 - 95 L value of the As high ºC) color of rasogolla possible as Rate of cooling the milk, X5 (0 - 5.83 ºC per min) as Hardness rasogolla of As possible Concentration of citric acid solution used for milk Elasticity coagulation, X6 (0.007 - 0.018 g per g solution) rasogolla of As Ratio of milk to acid solution, X7 (3.33 - 6.67) of As Porosity rasogolla. Coagulation temperature of milk, X8 (68.7 - 89.1 ºC ) Residence time of milk-acid mixture, X9 (3 - 8 low high as possible high possible as min) Moisture content of chhana balls, X10 ( 0.38 0.46 kg per kg chhana) Concentration of sugar solution used for cooking, X11 (35 - 50ºBrix ) Cooking time of chhana balls, X12 (15 - 24 min) Concentration of sugar solution used for soaking rasogolla, X13 (30 - 40ºBrix) Soaking time of rasogolla, X14 (4 -17 h) Neural network is a very powerful tool by which the independent and dependent parameters can be related. A layer of neurons act as input and another as output. Number of neurons in input layer is made equal to the number of independent variables and the number in the output layer, the number of dependent variables. Between the input and output layers one or more hidden layer neuron is inserted. Genetic algorithm solves the optimization of the independent parameters. Erenturk and Erenturk (2006) have applied ANN and GA to study the drying characteristics of carrots. Torrecilla et al. (2005) used neural network in optimization of high pressure food processes. Kashaninejad et al. (2009) used neural network for modeling of wheat soaking. Materials and Methods Red cow brand of 2 types chilled market milk was purchased from local market having 3 and 3.5% fat content with 8.5 and 8 percent solid –not –fat respectively. Average weight of the milk used for the experiment was 500g. Milk was heated to its boiling point. It was then allowed to cool to a lower temperature ranged between 80-95 ºC. Average heating rate and cooling rate were measured. Citric acid having concentration ranged between 0.007-0.018 gram per gram solution was used. The milk-acid solution was agitated gently by using a spoon and was allowed to stay for 3-8 min. Residence time of the mixture was noted. During the mixing of acid to milk the temperature change of coagulation was noted. Chhana was separated from the whey by using a muslin cloth. The chhana was kept on the cloth and slight pressure was applied to drain out more whey. The moisture content of chhana was varied by applying different amount of pressure on the chhana mass for removal of whey from it. The Chhana was then kneaded by using a spoon to a smooth mass. Moisture content of chhana after kneading was determined by using an infrared moisture meter and it varied between 0.38 0.46 kg per kg chhana. About 10±0.5 g of kneaded chhana was taken between the palms and rolled for 1 min to make balls. Care was taken for making the ball surface free from cracks. For the cooking of chhana balls, sugar syrup of different sugar concentrations (35-50º Brix) was prepared. The syrup was heated and when it started boiling, the balls were put into it. The chhana balls were cooked for a time ranged 15 - 24 min. After every 5 min about 30 ml water was added to take care of the evaporation loss of water from the syrup. After the cooking, rasogolla balls were kept in sugar syrup having concentrations 30-40ºBrix. There were twelve independent parameters which were studied to see the effect on the seven dependent parameters. Diameter of rasogolla was measured using vernier caliper. Weight of rasogolla was measured after the soaking of rasogolla in sugar syrup. Initial weight of rasogolla was measured. It was then placed on a plate. On the rasogolla, 5 kg weight was put. After 5 min, the weight was taken out of rasogolla. Final weight of pressed rasogolla was taken. Volume of sugar syrup expressed was measured. Color of rasogolla was measured by using a colorimeter (Konica Minolta, Japan) and it was expressed in terms of Hunterlab L, a and b values. L value indicates whiteness. More the value of L, more is the whiteness. The negative and positive values of a indicate the intensity of red and green color, respectively. Similarly, negative and positive values of b indicate the intensity of yellow and blue color respectively. Hardness of rasogolla was measured by using a texture analyzer (Stevens-LFRA, USA). 1200 g bi-directional load cell was used at 0.5 mm/s cross-head speed of the texture analyzer. Rasogolla samples in the shape of a cube having dimensions 1 cm × 1 cm × 1cm was cut from the centre and compressed to 80% of its original height. After the release of the force, height of the rasogolla was measured after 2 min. Value of elasticity of rasogolla was determined as: Elasticity = height after compression/ original height. Following are the dependent parameters and the range of experimental values that were obtained. 1. Diameter of rasogolla, Y1 (3.5 - 3.7 cm) 2. Weight of rasogolla, Y2 (17 - 21 g) 3. Volume of sugar syrup expressed from rasogolla, Y3 (5.85 - 10.67 cm 3 ) 4. L value of the color of rasogolla, Y4 (68.52 - 79.79) 5. Hardness of rasogolla, Y5 (39.67 - 78.33 g) 6. Elasticity of rasogolla, Y6 (0.81 - 1) The experimental values of independent and dependent variables are given in Table 2 and Table 3 respectively. Table 2. Experimental values of independent parameters from X1-X14 Expt no 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 X1 X2 X3 X4 X5 X6 X7 X8 3.0 3.0 3.5 3.5 3.5 3.5 3.0 3.5 3.5 3.0 3.5 3.5 3.0 3.5 3.0 3.5 3.0 3.0 3.5 3.5 95 95 90 100 100 90 100 90 95 90 95 92 95 90 95 90 100 92 95 90 8.10 10.32 13.38 12.42 13.32 14.63 15.82 13.29 10.05 12.50 10.28 9.81 9.05 8.03 9.46 14.63 15.82 11.05 12.03 13.38 95 90 80 83 83 80 75 90 80 90 80 92 85 75 95 80 75 90 85 80 0.00 1.68 3.54 1.80 1.80 3.43 5.83 0.00 2.00 0.00 1.92 0.00 1.53 1.83 0.00 3.43 5.83 1.56 1.73 3.54 0.015 0.015 0.012 0.018 0.016 0.012 0.013 0.007 0.018 0.012 0.015 0.013 0.013 0.015 0.012 0.012 0.013 0.012 0.013 0.012 5.11 5.14 5.00 6.67 5.00 5.00 5.00 3.33 5.00 5.00 3.33 5.00 5.00 6.67 5.00 5.00 5.00 5.00 6.67 5.00 71.4 75.4 68.7 69.3 69.7 70.6 71.9 89.1 85.5 75.6 73.6 78.9 69.5 82.6 85.4 70.6 71.9 78.9 82.6 68.7 X9 X10 X11 X12 X13 X14 5 5 8 3 4 3 3 3 4 5 3 4 5 3 3 3 3 5 3 8 0.46 0.40 0.38 0.39 0.43 0.42 0.43 0.42 0.45 0.40 0.47 0.43 0.45 0.47 0.51 0.42 0.43 0.45 0.47 0.38 50 50 50 35 35 45 35 48 35 40 35 40 45 35 45 45 35 45 35 50 20 15 25 19 22 24 19 16 15 18 16 18 20 17 20 24 19 20 17 25 30 30 30 35 35 40 35 30 40 40 35 30 40 40 30 40 35 40 40 30 4 17 4 4 4 4 17 4 4 4 5 4 4 5 4 4 17 17 5 4 X1: Fat content of milk (%), X2: Temperature to which milk is heated (oC), X3: Rate of heating the milk (oC per min), X4: Temperature to which milk is cooled (oC), X5: Rate of cooling the milk (oC per min), X6: Concentration of citric acid solution used for milk coagulation (g per g solution), X7: Ratio of milk to acid solution, X8: Average temperature of milk during coagulation (oC), X9: Residence time of milk acid mixture (min), X10: Moisture content of chhana balls after kneading (kg per kg), X11: Concentration of sugar solution used for cooking (oBrix ), X12: Cooking time of chhana balls (min), X13: Concentration of sugar solution used for soaking rasogolla (oBrix), X14: Soaking time of rasogolla (h) Table 3. Experimental values of dependent parameters from Y1 – Y6 Expt no. 1 2 3 4 5 6 7 Y1 Y2 Y3 Y4 Y5 Y6 3.5 3.5 3.6 3.6 3.6 3.6 3.7 17 21 20 20 18 18 19 5.847 10.668 9.736 9.797 7.838 7.805 7.772 68.52 76.22 66.87 71.95 72.07 79.79 73.97 71.33 67.67 73.00 56.00 50.33 78.33 54.00 0.93 1.00 0.90 0.88 0.81 0.96 0.90 8 9 10 11 12 13 14 15 3.5 3.6 3.5 3.5 3.6 3.5 3.5 3.6 21 20 19 18 20 19 18 19 7.738 8.536 7.853 7.415 9.286 8.960 7.843 7.394 78.10 72.59 74.31 72.35 71.57 75.13 69.37 74.06 39.67 40.10 43.00 45.40 51.85 40.74 53.82 41.76 0.85 0.87 0.92 0.90 0.95 0.88 0.99 0.96 Y1: Diameter of rasogolla (cm), Y2: Weight of rasogolla (g), Y3: Volume of sugar syrup expressed from rasogolla ( cm 3 ), Y4: L value of the color of rasogolla, Y5: Hardness of rasogolla (g), Y6: Elasticity of rasogolla Neural network modeling of independent and dependent parameters Neural network (NN) modeling was applied for finding the relation between the independent and dependent parameters. Fifteen experimental data sets were used for developing the NN model. The network consisted of fourteen input neurons corresponding to fourteen independent variables and seven output neurons for the seven dependent variables. In the developed Neural network, input layer is a matrix of size (20×14), where, 20 is the total number of experiments conducted and 14 is the number of input layer neurons. One hidden layer having 25 numbers of neurons was inserted between input and output layer of neurons. For a given set of data, error matrix for output layer and hidden layer were calculated using the initial weights of the neurons. Results and Discussion Designed neural network was trained for 5000 number of computational cycles with a learning rate coefficient of 0.6. Mean relative deviation percent between the estimated and measured values of dependent parameter was found to be 0.01. The optimum values obtained for independent parameters at maximum fitness value are given in Table 4. Table 4. Optimum values for independent parameters Sl. no 1 2 3 4 5 6 Independent parameters Optimum value Fat content of milk (%) 3.45 Temperature to which milk is heated (ºC) 95.05 Rate of heating the milk (ºC per min) 12.59 Temperature to which milk is cooled (ºC) 92.2 Rate of cooling the milk (ºC per min) 5.24 Concentration of citric acid solution used for milk 0.014 coagulation (g per g solution) Ratio of milk to acid solution 5.2 Average temperature of milk during coagulation (ºC) 76.7 Residence time of milk acid mixture (min) 4.31 Moisture content of chhana balls after kneading (kg per 0.44 kg) Concentration of sugar solution used for cooking (°Brix) 41 Cooking time of chhana balls (min) 16.5 Concentration of sugar solution used for soaking rasogolla 35 (°Brix) Soaking time of rasogolla (h) 14.37 7 8 9 10 11 12 13 14 The values of the dependent parameters obtained at the optimum combinations (Table 4) of independent parameters are given in Table 5. Table 5. Values of dependent parameters at optimum conditions of independent parameters. Sl. no Dependent parameters Value 1 Diameter of rasogolla (cm) 3.69 2 Weight of rasogolla (g) 20.99 3 Volume of sugar syrup expressed from rasogolla ( cm 3 ) 10.66 4 L value of Color of rasogolla 79.53 5 Hardness of rasogolla (g) 42.33 6 Elasticity of rasogolla 0.99 Conclusions Based on the quality parameters of rasogolla such as diameter of rasogolla, weight of rasogolla, volume of sugar syrup expressed from rasogolla, L value of colour of rasogolla, hardness of rasogolla, elasticity of rasogolla and porosity of rasogolla it can be concluded that good quality rasogolla can be prepared under atmospheric pressure with following optimum conditions of independent parameters: Temperature to which milk is heated 95.05 ºC, Rate of heating the milk should be 12.59 ºC per min, Temperature to which milk is cooled 92.2ºC, Rate of cooling the milk 5.24 ºC per min, Concentration of citric acid solution used for milk coagulation 0.014 g per g solution, Ratio of milk to acid solution 5.2, Residence time of milk - acid mixture 4.31 min, Moisture content of chhana balls after kneading 0.44 kg per kg chhana, Concentration of sugar solution used for cooking 41ºBrix, Cooking time of chhana balls 16.5 min, Concentration of sugar solution used for soaking 35ºBrix and Soaking time of rasogolla should be 14.37 h. Choudhury et al. (1998) and Patel (2008) reported that the rate of cooling of milk should be higher than the rate of heating of milk for getting higher recovery of milk solids in chhana. But in the present study, optimum value of cooling rate was lower than the rate of heating. Bhattacharya and Des Raj (1980) reported that 55-58% moisture in chhana was optimum for good quality rasogolla having soft body, and high spongy texture. The optimum value of moisture content of chhana in the present study was lower than these values; so the hardness of rasogolla was little higher than the hardness of market rasogolla. The optimized soaking time (i.e., 14.37 h) is very high, as this amount of time must be spent between the cooking and consumption of rasogolla. It is therefore necessary that more experiments are required to be carried out with higher rate if milk cooling before its acidification and higher moisture content of chhana. It might be possible that optimum soaking time would be lower than the present value. References Anon (1994). Processed foods market records 16 pc growth. Indian Food Packer, 48, p 66-67. Bhattacharya, D. C. and Des Raj (1980). Studies on production of rasogolla. Part - I. Traditional method. Indian journal of dairy science, 33(2), p 237-243. Chandan, R. C. (1992). Cheese made by direct acidification. Indian dairyman, 44(3), p 133-141. Chandan, R. C., Mathur, B. N., Banerjee, A. K. and Aneja, R. P. (2002). Indian milk products (Chhana and Fermented products). Souvenior of XXXI dairy industry conference, 7-9 February 2002, Mumbai, p 58-85. Choudhury, R. L., Van Den Berg, M., Singh, M. D. and Das, H. (1998). Effect of heat treatment on recovery of solids in chhana produced from cow and buffalo milks. Journal of Food Science and Technology, 35(1), p 30-34. De, S. (1980). Outlines of Dairy Technology. Oxford University press, Delhi. De, S. and Ray, S. C. (1954). Studies on indigenous method of chhana making. Indian Journal of Dairy Science, 7, p 113-116. Erenturk, S. and Erenturk K. (2007).Comparision of genetic algorithm and neural network approaches for the drying process of carrot. Journal of Food Engineering, 78 (3), p 905912. Goel, V. K. (1970). Studies on the manufacture and packaging of rasogolla. M.Sc. Thesis, Punjab Agricultural University, Ludhiana. Iyer, M. (1978). Physico chemical studies on chhana from cow’s and buffalo’s milk. M.Sc. Dissertation, Kurukshetra University, Kuruskhetra. Jonkman, M. and Das, H. (1993). Optimization of process parameters for production of chhana from low fat cow milk. Journal of Food Science and Technology, 3(6), p 417-421. Kashaninejad M., Dehghani A. A., Kashiri M. (2009) modeling of wheat soaking using two artificial neural networks (MLP and RBF). Journal of Food Engineering, 91, p 602-607. Kumar, G., and Shrinivasan, M. R. (1982). A comparative study on the chemical quality of three types of chhana samples. Indian Journal of Animal Science, 52, p 741. Kundu, S. S. and De, S. (1972). Chhana production from buffalo milk. Indian Journal of Dairy Science, 25, p 159-163. Patel B. S. (2008). Evaluation of a self discharging centrifuge for production of paneer. Unpublished M. Tech. Thesis. IIT Kharagpur. Patil, G. R. (2005). Innovative processes for indigenous dairy products. Indian Dairyman 57(12), p 82-87. Rao, B. V. R. (1971). Effect of different concentrations of citric acid coagulant and fat levels of milk from crossbred cows on yield of chhana, fat losses in whey, moisture retained in chhana and quality chhana, M.Sc. Thesis, Allahabad University, Allahabad. Singh, G. P. and Ray, T. K. (1977). Effect of milk coagulants on quality of chhana and chhana whey. Journal of Food Science and Technology, 14, p 205. Soni, K., Bandhyopadhyaya, A. K. and Ganguli, N. C. (1980). Manufacture of rasogulla from buffalo milk. Indian Journal of Dairy Science, 33(3), p 357 -365. Ten Hove K. and Das H. (1995). Evaluation of yield, texture and cooking time of rasogolla. Journal of Food Science and Technology, 32 (2), p 109-114. Torricella, J. S., Otero, L. and Sanz, P. D. (2005). Artificial neural networks: a promising tool to design and optimize high pressure-food processes. Journal of Food Engineering, 69, p 299-306. About Authors B. Mohanta1 (Corresponding Author) Research Scholar, Agricultural & Food Engineering Department, Indian Institute of Technology Kharagpur Kharagpur- 721302, West Bengal Email: bijayalaxmimohanta@gmail.com Ph no:09338079566 Dr. S. L. Shrivastava2 Professor, Agricultural & Food Engineering Department, Indian Institute of Technology Kharagpur, Kharagpur- 721302, West Bengal Email: slshrivastava@gmail.com Ph no: 09434031341