CHAPTER 9 1-16-06

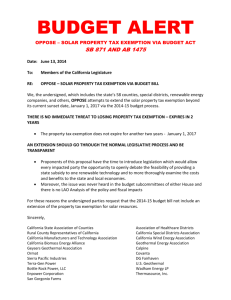

advertisement

DOE/RL-2001-36, Rev. 1, January 2006 HANFORD SITEWIDE TRANSPORTATION SAFETY DOCUMENT CHAPTER 9.0 – NONROUTINE TRANSFERS CONTENTS 9.1 EXEMPTION REQUESTS AND EMERGENCY SHIPMENT PROCEDURES .................. 1 9.1.1 Exemption Requests.......................................................................................................... 1 9.1.2 Emergency Shipments ...................................................................................................... 2 9.2 REFERENCES ........................................................................................................................ 3 9-iii HANFORD SITE TSD 9.1 EXEMPTION REQUESTS CHAPTER 9.0 NONROUTINE TRANSFERS This chapter describes the processes and procedures for dealing with nonroutine transfers. Nonroutine transfer are sub-divided inbto two categories; 1. Exemption Requests, and 2. Emergency Transfers. Conditions and circumstances for exemption requests or emergency transfers are defined, as well as applicable procedures and the approval process. 9.1 EXEMPTION REQUESTS AND EMERGENCY SHIPMENT PROCEDURES This chapter identifies how nonroutine and emergency shipments (transfers) are handled under the onsite hazardous materials T&P safety program. Nonroutine onsite shipments (transfers) and emergency transfers are unusual and unpredictable events that may occur onsite. A nonroutine shipment or transfer may be necessary to facilitate the movement of a piece of equipment that cannot be easily cleaned or dismantled. For example, a test loop contaminated with sodium. Offsite, a request for an exemption would be submitted to DOT by way of DOE. Onsite, DOE must grant the exemption to the onsite requirement. In an emergency, to mitigate a spill or release event, and/or provide immediate protection to workers, the public, or to the environment as a result of an accident or incident, immediate action may be required. For example, a cargo tank could be transported onsite and a road obstruction or collision causes damage to the containment boundary allowing a small spill to begin. The Incident Commander for emergency responders and site management may decide to trans-load the liquid contents to another cargo tank to mitigate the event, minimize the clean up needed, and facilitate recovery operations. Emergency procedures will define such events and protocols to be used in making such a decision. 9.1.1 Exemption Requests Nonroutine onsite shipments (transfers) are handled by submitting a One Time Request for Shipment (OTRS) to the cognizant Hanford DOE Field Offic Manager. OTRSs are exemption requests and are risk based following the risk methodology in this TSD. As an exemption, they are not subject to the USQT program. Any changes to an OTRS will be submitted to the cognizant Hanford DOE Field Office Manager for approval. Compliance of shipments to an OTRS is accomplished through the use of an evaluation form. The OTRS will be issued for a one-time shipment or for a transportation campaign covering a period of time not to exceed five years. Each OTRS is assigned a unique number and that number will not change throughout the life of that particular OTRS. Appendix E provides additional detail on the format and content of an OTRS. DOE/RL-2001-36, Rev. 1 9-1 January 2006 HANFORD SITE TSD 9.1 EXEMPTION REQUESTS 9.1.2 Emergency Shipments The need for an emergency shipment will be determined in accordance with DOE/RL-94-02, Hanford Emergency Management Plan (HEMP). The Emergency Duty Officer shall have the responsibility for event classification and activation of the Hanford Emergency Response Organization as appropriate. Shipments (transfers) are handled in accordance with the site emergency preparedness plan. Additional information about the HEMP is presented in Chapter 12, Incident Reporting and Emergency Response. DOE/RL-2001-36, Rev. 1 9-2 January 2006 HANFORD SITE TSD 9.2 REFERENCES 9.2 REFERENCES 49 CFR 107, “Hazardous Materials Program Procedures,” Code of Federal Regulations, as amended. DOE/RL-94-02, Hanford Emergency Management Plan, U.S. Department of Energy, Richland Operations Office, Richland, Washington. DOE/RL-2001-36, Rev. 1 9-3 January 2006