Epoxy Resin Best Practices Troubleshooting

advertisement

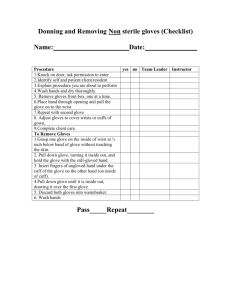

Epoxy Resin Best Practices - Troubleshooting Guide Consider each of the following potential problems for laminating and reduce incidence of any failure Temperature too hot or too cold Variable rise in temperature Variable decrease in temperature Humidity Too high or Too low Mix Ratio Incorrect by 5% Additives used beyond recommendations Mix process variables Mixing Too little-unmixed Mixing Too much-introduce air bubbles Mixing Too long –too hot Mixing Not thoroughly in corners of cup Stir stick packaging particles contaminants Surface prep Contaminations Fingerprint oils Residual tape contaminants Tape adhesive compatibility to resin Tape adhesive age changes chemistry Glove and Resin incompatible chemistry Glove chemical residue contaminant Glove cleaner residue contaminant Glove cleaner and resin compatibility Glove porosity and hand contaminant wash through Laminating tool contaminants Cleaners and degreasers residual particulate matter Cleaners and degreasers compatibility issue with epoxy Acetone Airborne contaminants-Paint overspray Airborne contaminants-Foam dust Airborne contaminants-Styrene monomer gasses Airborne contaminants-Personal hygiene aromatic chemicals Airborne contaminants-Mold spores Airborne contaminants-Fiberglass fiber Fiberglass fabric finish compatibility