It is well known that the metal hydroxides are amphoteric

advertisement

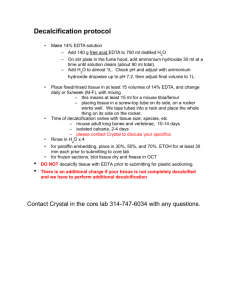

Supplementary Material for: Chelant soil washing technology for metal contaminated soil (Environmental Technology) David Voglar1 and Domen Lestan1,2* 1 Agronomy Department, Biotechnical Faculty, University of Ljubljana, Jamnikarjeva 101, 1000 Ljubljana; Slovenia 2 Envit Ltd., Vojkova 63, 1000 Ljubljana; Slovenia * E-mail address: domen.lestan@bf.uni-lj.si (10 pages, 5 Figures) Chemical background of the EDTA and process water recycling Fig. SM1 Fig. SM2 Fig. SM3 Fig. SM4 1 Page 2 4 6 6 7 Chemical background of the EDTA and process water recycling The recycling method relies on a combination of substitution/precipitation reactions in an imposed pH gradient for EDTA recovery, and on electrochemical polishing of process waters for total water recycle in a closed loop. By using Ca(OH)2 and H2SO4 as the base/acid pair, the accumulation of added reagents in the process water after multiple soil remediation batches/recycles is prevented by precipitation and removal of poorly-soluble CaSO4 during the process. Alkaline metal precipitation: At low pH [1] Fe interferes with acidic EDTA precipitation from the used washing solution [2.3] and must be removed. Alkaline conditions make the formation of Fe-EDTA complexes less favorable [1], leading to Fe hydrolysis and Fe(OH)3 precipitation [2]. Alkalization with Ca(OH)2 efficiently removed not only Fe but also Pb, Zn and Cd [3], since Ca replaces PTMs in the EDTA complex due to a higher stability constant of Ca-EDTA at high pH [1]. However, the hydroxides of most PTMs are amphoteric. They are increasingly soluble at both low and high pHs, and the optimum pH for precipitation depends on the metal: Pb (pH 9.5), Zn (pH 9.2) and Cd (pH 11.2) [4]. Since the pH must be raised to 12 and above before the stability constant for Ca-EDTA exceeds that of Pb-EDTA [5], part of the PTMs remains in the solution after alkaline precipitation. Using NaOH did not remove any of the Pb, Zn or Cd from the solution [2] due to the low affinity of Na to form complexes with EDTA. Ca(OH)2 has fewer free electrons than NaOH, making it less likely to change its structure when exposed to water and is therefore less water-soluble (0.173 g L-1 at 20oC) and normally decreases with pH. However, Ca replacement of Fe and PTMs in the EDTA complex at high pH pushes the chemical equilibriums towards Ca(OH)2 dissolution. Released metals (Me) proteolitically react with waters, releasing H+, which additionally enhances Ca(OH)2 dissolution: Me2+ + 2H2O → Me(OH)2 +2H+ (1) The product of alkaline precipitation is process water with an active Ca-EDTA form of chelant. Fe and PTMs substituted from the chelant precipitate as hydroxides. Acidic precipitation of EDTA: As mentioned above, removal of Fe in the alkaline phase prior to acidification significantly improves the yield of recovered EDTA [2,3], since the stability of Fe-EDTA complexes is relatively high in acidic conditions between pH 2-4 and higher than the stability of EDTA complexes with other metals [1]. Protonated EDTA (H4EDTA) is poorly soluble in acidic media below pH 3 [6] and, after acid (H2SO4) addition, precipitates from the solution. PbEDTA complexes are increasingly less stable in more acidic conditions [1], leading to sharp PbSO4 precipitation at pH < 1.8 [2.31]. To avoid contamination of recycled EDTA with precipitated Pb, the process water was not acidified below pH 2. In addition to EDTA, excess Ca in the process water is removed as poorly-soluble CaSO4 (solubility 2.98 g L-1 at 20 °C, [7]). This prevented the accumulation of added reagents through consecutive soil remediation/EDTA recycling batches Electrochemical cleansing of process waters: Naumczyk et al. [8] demonstrated that several anode materials, such as graphite and noble metal anodes, successfully mediate the oxidation of organic compounds. According to the 2 generally accepted mechanism of EAOP, water is first discharged (at potentials above 1.23V vs standard hydrogen electrode, standard conditions) at anode active sites (M), producing adsorbed hydroxyl radicals, M(•OH)ads, which are involved in the mineralization of an organic compound (R) in aqueous solutions: Raq + (n/2)M(•OH)ads → (n/2)M + mineralization products + (n/2)H+ + (n/2)e− (2) where n is the number of electrons involved in the oxidation reaction of organics [9]. Reaction (2) is in competition with the anodic discharge of these radicals to form dioxygen: M(•OH)ads → M + (1/2)O2 + H+ + e− (3) The activity of these electrogenerated hydroxyl radicals is therefore strongly linked to their interaction with the anode surface; the weaker the interaction, the lower the electrochemical activity towards oxygen evolution (higher O2 overpotential). In relation to the EDTA degradation pathway in the electrolytic cell, EDTA is electro-oxidized through sequential removal of the acetate groups, until small size hydrocarbon products are formed [10]. References [1] C. Kim, Y Lee, and S.K. Ong, Factors effecting EDTA extraction of lead from leadcontaminated soils, Chemosphere 51 (2003), pp. 845-853. [2] M. Pociecha, and D. Lestan, Novel EDTA and process water recycling method after soil washing of multi-metal contaminated soil, J. Hazard. Mater. 201-202 (2012), pp. 273-279. [3] M. Pociecha, and D. Lestan, Soil washing of metal contaminated soil with EDTA and process water recycling, J. Hazard. Mater. 235-236 (2012), pp. 384-387. [4] G.C. Cushnie, Pollution Prevention and Control Technologies for Plating Operation, 2nd ed., National Center for Manufacturing Sciences: Ann Arbor, MI, USA, 2009. [5] G.A. Brown, and H.A. Elliot, Influence of electrolytes on EDTA extraction of Pb from contaminated soil, Water, Air and Soil Pollut. 62 (1991), pp. 157-165. [6] L. Di Palma, P. Ferrantelli, C. Merli, and F. Biancifiori, Recovery of EDTA and metal precipitation from soil washing solutions, J. Hazard. Mater. 103 (2003), pp. 153-168. [7] P. Theodoratos, N. Papassiopi, T. Georgoudis, and A. Kontopoulos, Selective removal of read from calcareous polluted soils using the Ca-EDTA salt, Water, Air and Soil Pollut. 122 (2000), pp. 351-368. [8] J. Naumczyk, L. Szpyrkowicz, M. De Faveri, and F. Zilio Grandi, Electrochemical treatment of tannery wastewater containing high strength pollutants, Trans. I ChemE B. 74 (1996), pp. 58-59. [9] C. Comninellis, A. Kapalka, S. Malato, S.A. Parsons, I. Poulios, and D. Mantzavinos, Advanced oxidation processes for water treatment, J. Chem. Technol. Biotechnol. 83 (2008), pp. 769-776. [10] Y. Yamaguchi, Y. Yamanaka, M. Miyamoto, A. Fujishima, and K. Honda, Hybrid electrochemical treatment for persistent metal complexes at conductive diamond electrodes and clarification of its reaction rute, J. Electrochem. Soc. 153 (2003), pp. 1123-1132. 3 4 Fig. SM1. Pilot-scale soil washing plant. Step 1: soil washing. Step 2: separation and rinsing of the process oversize material. Step 3: phase separation and soil rinsing. Step 4: treatment of remediated soil. Step 5: alkaline substitution and metal precipitation. Step 6: acid precipitation and EDTA recovery. Step 7: electrolytic degradation of EDTA remaining in the process solution. Step 8: preparation of the recycled washing solution. 5 Fig. SM2. Coloration of process waters from different steps of novel soil remediation technology (step 1: soil washing solution; step 5: solution after alkaline substitution and metal precipitation; step 6: solution after acid precipitation and EDTA recovery; step 7: solution after electrolytic cleansing). Fig. SM3. Solid wastes stabilized with bitumen (0.9 kg of bitumen per 1 kg of solid waste). 6 Fig. SM4. Experimental plots with original and remediated soils and vegetables produced. 7