1. Summary - EESC European Economic and Social Committee

advertisement

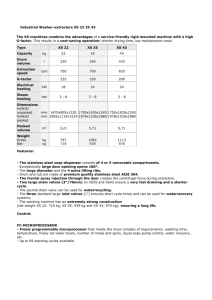

SELON LES DERNIERES DONNEES FOURNIES PAR E.T.S.A. (European Textile Services Association) LE 3 JUIN 2010 LES ANALYSES D'IMPACT ENVIRONNAMENTAL DU SECTEUR INDUSTRIEL EUROPEEN DES SERVICES TEXTILES FIGURENT COMME SUIT: Summary of the Study: Simplified Life Cycle Assessment Home washing and industrial washing of blue workwear - comparison and benchmarking 1. Summary Workwear is washed mainly in private households (approximately 95%); only a small proportion of workwear is washed in industrial laundries (approximately 5%). Washing of workwear soiled by oil, metals etc. can be done in a more environmentally efficient manner in industrial laundries. This report compares the impact on the environment of industrial washing of typical workwear (blue workwear) with home washing. The objectives of the study were to analyse the industrial washing system for internal learning and benchmarking, and to compare industrial with home washing for marketing reasons and to inform policy-makers and regulators. The report was prepared on behalf of the European Textile Services Association (E.T.S.A.), whose members account for 20-30% of industrially washed blue workwear in Europe. The study was carried out as a simplified comparative Life Cycle Assessment (LCA) in accordance with ISO 14040. Simplified means that only the most important parameters were inventoried and assessed: direct input of detergents in the washing process, consumption of primary energy resources and water, as well as the atmospheric emissions of CO 2 and NOx. Due to the comparative nature of the LCA, some parts of the life cycle have not been addressed beyond some simple checking of potential impacts e.g. municipal wastewater treatment. Also, the results of the washing and the quality of the washed workwear is assumed to be equal in the compared systems. In accordance with ISO 14040 the LCA was checked by an independent Critical Review Panel. The functional unit was defined as the washing and finishing of one kilogram of normally soiled blue workwear. The average household system is described in a basic scenario, which represents an average household washing process in Germany. This reference country was chosen to allow the study to refer to a published LCA on the washing of clothing in households. The soiled blue workwear is washed at 60°C with a supercompact heavy duty detergent (112g) in a household washing machine. The wash load is 1.0 kg in one batch as the 2 pieces of workwear are expected to be washed alone. Consumption values correspond to the average in German households (63 l water and 1.61 kWhel at 60°C). In 50% of the households the workwear is dried in a tumble drier (1.26 kWhel per kg workwear). The following aspects were analysed: production of the detergent and packaging, production and consumption of water and energy for washing and drying. Not included is the private transport of the workwear, municipal wastewater treatment and ironing. Under these conditions the washing of 1.0 kg of blue workwear in an average household consumes 37 MJ of primary energy and 63 l of water and emits 1.6 kg CO2 and 3.5 g NOX. The result is influenced by the load or filling rate of the washing machine and the consumption values of the machines. Uncertainties remain, however, concerning the real appliances used by households and the real washing behaviour of households (filling, temperature selection, type of drying). This uncertainty was addressed by varying the parameters applied in six alternative scenarios: washing at 90°C; loading with 2.5 kg workwear; loading with 4.5 kg; washing and drying in new economical machines; electricity supply for washing and drying process from the European UCPTE grid; electricity supply from the Scandinavian Nordel grid. Recourse to alternative scenarios leads to a broad range of results. For example, with a washing temperature of 90°C the energy consumption rises to 46 MJ per kg of washed workwear. With a load of 4.5 kg of workwear, the energy consumption and the water consumption drop to 11 MJ and 14 litres per kg of workwear washed. Nevertheless the conditions which are varied in the alternative scenarios are not realistic or practicable and thus will not be realised in the majority of households washing blue workwear. The average industrial washing system is also described in a basic scenario, which represents the average of 16 European industrial laundries of E.T.S.A. members, mainly German and Scandinavian (average weighted by the weight of the washed workwear). The inventorized washing process comprises transport of the workwear from and to the customers, water softening, washing with a laundry detergent (17.4 grams detergent and 3,6 grams salt) in tunnel washers or wash extractors, finishing and wastewater pre-treatment (neutralisation) until discharge to the public sewer as well as production of the detergent and production of thermal energy (at the laundry itself) and electricity. The source of electricity in the basic scenario is the German grid (to facilitate comparability with households). As opposed to household laundry detergents, both transportation and finishing are included. The packaging (reusable containers) of industrial laundry detergents is not included. An approximate calculation indicated that the packaging of industrial detergents accounts for less than 1% of total energy of the overall inventory. The data for the washing process in industrial laundries was collected from the 16 laundries via questionnaire. All other calculations are based on general data. Under these conditions the washing of 1.0 kg blue workwear in an average industrial E.T.S.A. laundry results in consumption of 18 MJ of primary energy and 18 litres of water, and emissions of 1.1 kg CO2 and 2.2 g NOX. The result is dominated by the energy consumption for washing and finishing and in the case of NOx by transportation. The electricity grid is varied in two alternative scenarios, the European UCPTE grid and the Scandinavian Nordel grid. Using the Nordel grid results in a slight decrease in primary energy consumption (minus 10%) and emissions of CO2 (minus 15%) per kg workwear washed. More remarkable is the wide range of results within the industrial laundries: a multiplication factor of 3(!) in energy use and a multiplication factor of 1.5 in water use. Considerable differences are also found in the individual process stages (transport, washing, detergent use etc.). Reasons for the considerable divergences are: different soilage, differences in washing equipment and process control, differences in on-site energy generation and in the transportation of the workwear. A direct comparison between average household washing and average industrial washing of blue workwear (basic scenarios) shows that industrial washing has distinct environmental advantages. Compared to home washing, industrial washing uses 52% less primary energy, 73% less water and 85% less detergents, and emits 33% less CO2 and 36% less NOx. Various alternative scenarios and best and worst cases were also compared in order to show the main influencing parameters and optimisation options. 2. Recommendations from the LCA study practitioner to the study commissioner The comparison of the basic scenarios for household and industrial laundries shows significant environmental benefits from industrial laundering. Therefore soiled workwear should be washed in an industrial laundry and not at home. Secondly it can be concluded that significant improvements may be possible. Industrial laundries should exploit the opportunities for environmental improvement in primary energy consumption and correspondingly in energy-related emissions, but also in water consumption. Also, for given soilage and customer demand, model plants (tunnel washer, wash extractor) and model washing processes (detergents, washing temperatures, washing times) should be WS-05-06 analysed in a follow-up study in co-operation with manufacturers of industrial washing systems and manufacturers of detergents. Life Cycle Assessment Study – Brochure Launch “Continuous Cotton Roll Towels: Top Environmental Performance” Textiles win hands down. Enclosed you will find a copy of the June 2006 E.T.S.A. commissioned study by the Öko-Institut on the Life Cycle Analysis of Hand-Drying Systems: Cotton versus Paper Towels – one example of the competitive positive benefits of the textile rental service industry. A vision of the textile service industry is to combine maximum quality with unbeatable environmental performance and sustainable progress through incorporating life-cycle thinking in decision making, which this study aptly demonstrates. The study followed stringent ISO 14040 requirements and explored the entire life cycle of hand-drying systems from forestry and cotton farming, through towel production and use, up to recycling or final disposal. For example, cotton towels: Outperform the paper alternatives in six out of seven environmental aspects (even compared to 50% recycled paper). Use up to 63% less energy compared with paper towels. Generate up to 79% less waste compared with paper towels. Only have ½ the global warming potential to that of paper towels. Can be washed and reused about 100 times. Contribute only 10% of the wastewater pollution attributed to paper towels. Use limited packaging materials. To give an overall comparison, luxury paper towels have 2.5 times the Total Environment Burden of cotton towels. The brochure is designed as a tool for use in promoting and explaining the benefits of rental textiles, with particular focus on hand hygiene and washroom services. For more details of the analysis, the full study from the Öko-Institut, including the critical review (as per ISO standards) and a supplement on the Total Environmental Burden are available from the Members’ Area of the E.T.S.A. website, accessible from www.etsaeurope.org , or contact the E.T.S.A. Secretariat for further information.