submerged fermentation of lignocellulosic wastes under moderate

advertisement

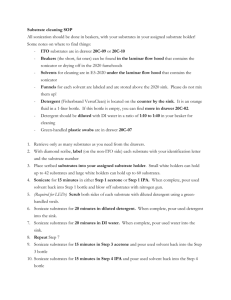

Mushroom Biology and Mushroom Products. Sánchez et al. (eds). 2002 UAEM. ISBN 968-878-105-3 SUBMERGED FERMENTATION OF LIGNOCELLULOSIC WASTES UNDER MODERATE TEMPERATURE CONDITIONS FOR OYSTER MUSHROOM GROWING SUBSTRATES 1 J. Pardo Núñez1 and C. García Mendoza2 Centro de Investigación, Experimentación y Servicios del Champiñón (CIES), Quintanar del Rey, Cuenca (Spain).<jpardo.cies@dipucuenca.es> 2 Centro de Investigaciones Biológicas (CIB), CSIC, Madrid, Spain. <cgm@cib.csic.es> ABSTRACT Several waste materials derived from agriculture and agroindustrial products (cereal straw, vine shoots and grapevine stems, dried olive mill waste, kenaf, cotton and flax wastes) have been utilized as substrates for oyster mushroom cultivation. Ten pairs (1:1 w/w) of these materials were immersed in water causing an spontaneous semi-anaerobic weak lactic acid fermentation produced by the material and environmental microorganisms. The study of this microflora showed the presence of several species of Bacillus, Microccocus, Streptomyces, Geotrichum and Mucor. When the fermentation terminated the substrates were drained, pressed, spawned and put into polyethylene bags. The strain used was Pleurotus ostreatus H9. All the conventional stages of the growth cycle were carried out in environmentally controlled growing rooms. The total period of cultivation ranged between 53-64 days. Seven of the ten substrates showed three production flushes whereas the other three substrates exhibited only two flushes. The yield (biological efficiency) of the studied substrates varied from 106.2 to 50.8 %. INTRODUCTION In commercial oyster mushroom (Pleurotus spp) production the preparation of the growing substrate is considered to be the most critical point in the process. Much research and experience throughout the world, particularly during the last two or three decades, has resulted in many methods of treatment for substrates, such as soaking in water, thermal sterilization and semisterilization, dipping in hot water, steam pasteurisation, aerobic thermophilic fermentation, chemical sterilization, submerged anaerobic or semi-anaerobic mesophilic fermentation, etc. (Stamets 1993, Muez 1994, Oei 1996, Jandaik 1997). Taking into account differences in safety risks and depending on the producers’ abilities, some of these methods are more suitable than others. For this study, submerged semi-anaerobic mesophilic fermentation was used. Principles of this method are mentioned in Lelley (1985), Lelley and Jansen (1993) and Stamets (1993). The procedure is based on utilization of the natural resident microflora from the bulk substrate, and the essence of this technology is to immerse the bulk material in water for four to ten days in order to induce a weak lactic acid fermentation. The aim of this procedure is to remove various easily soluble nutrients by means of the activity of natural microflora. This microflora can then be consumed further on by the mushroom mycelium and the metabolites generated in the process can kill internal competitors and protect the substrate from other external competitors. 271 MATERIALS AND METHODS Selected substrates Several residual lignocellulosic materials derived from agriculture and agroindustrial products were selected: cereal straw, vine shoots, grapevine stems, dried olive mill waste, kenaf, cotton and flax wastes. Each material was characterized physio-chemically following the global technique of Weende (Quarmby and Allen 1989). Various combinations of two materials were assigned, in which one or both of the components were physically bulky (straw, cotton waste, kenaf and flax waste), and the other was fine-structured or milled material (vine shoot and grapevine sawdust and dried olive mill waste). The selected ten pairs of materials combined in a 1: 1 proportion by weight were: barley straw plus cotton waste, kenaf plus vine shoot sawdust, kenaf plus dried olive mill waste, cotton waste plus dried olive mill waste, barley straw plus vine shoot sawdust, kenaf plus flax waste, kenaf plus grapevine stems, barley straw plus olive dried waste, barley straw plus kenaf and barley straw plus grapevine stems. Fermentation process Each mixture of two materials was submerged in water at 25-26C in a proportion of 1:20-25 (material/water), maintaining the external temperature at 25C. Sucrose at different concentrations and times was added as a fermentation stimulator (1% of the substrate weight distributed two times: 2/3 at the beginning of the experiment and 1/3 at the fourth day of fermentation). The different processes were maintained for six to seven days and supernatant samples were taken for their microbiological evaluation at 24, 72 and 144-168 h, measuring pH and temperature daily. The process was finished when the pH values became stable or a slight increase was observed. Microflora isolation and identification Bacteria and actinomycetes were isolated on actidione-augmented nutrient agar plates. Yeasts and moulds were isolated on aureomycin and terramycin-augmented Czapek agar plates. For identification of the microflora the following keys and publications were consulted: Holt et al. 1994 and Barnett and Hunter 1972. Mushroom cultivation At the end of the fermentation processes the culture broth was discarded, the materials were drained, pressed to a moisture content between 72.8-81.6 % (in a manual press), spawned, and then put into polyethylene bags. The strain used was P. ostreatus H9 (Jacq. ex Fr.) Kumm. (3% fresh weight substrate), and all the conventional stages of the growth cycle were carried out in environmentally controlled growing rooms (incubation: 26C; fruiting: 15-17C; 85-90% relative humidity). Three bags were filled with each substrate and the fresh weight for all the bags were standardised at 4 Kg. The total period of cultivation ranged from 53 to 64 days. RESULTS The odors generated during the fermentation processes soon disappeared from the substrates when the mycelial colonization began to take place. Table 1 shows the composition of the selected initial materials. Changes in the pHs of the substrates during the fermentation are shown in Table 2. At the end of the processes, pH values did not vary widely (5.8-6.0) and were close to the optimum value for the oyster fungus development (5.8-6.0). Microflora identified in the distinct substrates 272 were: several species of bacteria (Bacillus and Microccocus), actinomycetes (Streptomyces) and molds (Geotrichum and Mucor), with practically only minor quantitative differences between them (Table 3). Later, all the substrates were fully colonized by the mycelium and no incidence of pests and diseases was observed. Similar results are recorded by Lelley and Jansen (1993) and Stamets (1993). The total period of mushroom cultivation lasted from 53 to 64 days. Seven of the ten studied substrates showed three production flushes whereas the other three substrates exhibited only two flushes (kenaf plus grapevine stems, barley straw plus kenaf, and barley straw plus grapevine stems). After development of P. ostreatus H9 on the substrates, the best biological efficiency was 106.2% (barley straw plus cotton waste) ; the lowest biological efficiency was 50.8% (barley straw plus grapevine stems) (Table 4). DISCUSSION Wood degrading mushrooms such as P. ostreatus are usually cultivated on sawdust or straw, but new alternative substrates are emerging. The production of mushrooms using waste materials is a boon for the restoration of the damaged ecosystem of planet earth. All the substrates used in this study are derived from agriculture and agroindustrial products, in an attempt to adapt oyster mushroom cultivation to recycling these wastes. Pleurotus spp are edible fungi that colonize relatively microorganism-free substrates or substrates with low microorganism populations. Substrates used for cultivating oyster mushrooms support diverse communities of bacteria and fungi, depending on the type of fermentation techniques employed. The addition of easily utilized carbohydrates as fermentation starters increases the presence of molds, which are a detriment to further Pleurotus growth (with the exception of Mucor which exhibits the weakest effect). Bacteria, on the other hand, rapidly multiply and quickly consume the readily utilizable carbohydrates. This creates unfavourable conditions for the molds and also produces antibiotics and polysaccharides which inhibit the growth of competitive microorganisms. However, actinomycetes are partly stimulative because they are good synthesizers of certain vitamins that stimulate the growth of mushroom mycelia. This method does not result in consistent high yields compared to other more expensive heat treatment techniques. However, if we take the figure 50 % as a minimum for acceptable biological efficiency (Patra and Pani 1995), the biological efficiency of all the substrates tested can be considered acceptable. Our results confirm that this method, depending mainly on cleanliness and the aerobic state of the substrates during colonization (Stamets 1993), can be a suitable, simple and cheap alternative for oyster mushroom production in small and medium-sized operations. It is also an appropriate technology for developing countries. REFERENCES Barnett, H. L. and B. B. Hunter. 1972. Illustrated genera of imperfect fungi. Burgess. Minneapolis. Holt, J. G., N. R. Krieg, P. H. A. Sneath, J. T. Staley, and S. T. Williams. 1994. Bergey's Manual of Determinative Bacteriology. Williams and Wilkins. Baltimore. Jandaik, C. L. 1997. History and development of Pleurotus cultivation in the world and future prospects. In: Proceed. Indian Mushroom Conf. Mushroom Society of India, Solan India. 181-192. Lelley, J. 1985. Pilze aus dem eigenem Garten. BLV Verlagsgellschaft. München. Lelley, J., A. Janssen. 1993. Productivity improvement of oyster mushroom substrate with a controlled release nutrient. Mush. News 41: 6-13. Muez, M. A. 1994. Bases para el cultivo de Pleurotus. In: I Jornadas Técnicas del Champiñón y otros hongos comestibles. Patronato de Promoción Económica. Diputación Provincial de Cuenca. 129-141. Oei, P.1996. Mushroom cultivation. Tool Publications. Leiden. Patra, A. K. and B. K. Pani. 1995. Evaluation of banana leaf as a new alternative substrate to paddy straw for oyster mushroom cultivation. J. Phytol. Res. 8: 145-148. 273 Quarmby, C. and S. E. Allen. 1989. Organic constituents. In: S. E. Allen (ed). Chemical Analysis of Ecological Materials. Blackwell Scientific Publication. 160-200. Stamets, P. 1993. Growing Gourmet and Medicinal Mushroom. Ten Speed Press. 274 Table1. Composition of the all raw materials utilized as substrates. Moisture Total Crude Crude N-free Fat Ash content (%) nitrogen protein fiber extract 14.0 0.48 3.00 50.07 0.79 2.69 43.45 Raw materials Barley straw Organic matter 97.31 117.6 C/N Cotton waste 9.0 1.29 8.06 52.80 1.47 13.10 24.67 86.90 39.1 Kenaf 9.4 0.75 4.69 44.06 0.50 5.74 45.01 94.26 72.90 Dried olive mill waste 8.3 1.73 10.81 31.47 4.20 14.08 39.44 85.92 28.8 Vine shoot sawdust 11.5 0.80 5.00 52.65 3.07 4.82 34.46 95.18 69.0 Flax waste Grapevine stem sawdust 13.0 0.65 4.06 64.01 0.77 4.25 26.90 95.75 85.4 12.4 1.16 7.25 45.33 1.01 9.64 36.67 90.36 45.8 All the values except moisture content and C/N are expressed as % of the total dry matter Days Table 2. Evolution of pH along the fermentation process of the mixed materials. Mixtures K+OMD CW+OMD BS+CW K+VSS BS+VSS K+FW K+GSS BS+OMDW W W BS+K BS+GSS 0 Mixtures immersed (*) 1 - - - - - - - - - - 5.97 5.77 6.07 5.98 6.02 5.88 5.72 6.19 5.96 6.09 2 5.84 6.03 5.21 5.48 6.17 6.11 6.03 5.32 6.00 5.97 3 4 (*) 5 6.15 6.18 5.42 5.65 5.85 5.57 6.23 5.43 5.66 6.27 6.15 5.55 5.85 6.06 5.56 5.44 6.46 5.66 5.66 6.32 5.87 5.17 5.78 5.98 5.50 5.37 6.12 5.73 5.46 6.18 6 5.77 5.18 5.68 5.82 5.56 5.40 5.90 5.92 5.51 5.87 7 5.89 - 5.55 - 5.58 5.42 5.56 - 5.58 5.85 (*) Sucrose addition BS = barley straw; CW = cotton waste; K = kenaf; VSS = vine shoot sawdust; OMDV = dried olive mill waste; FW = flax waste; GSS = grapevine stem sawdust 275 Table 3. Percentage of microorganisms isolated from different Pleurotus spp growing substrates. Substrates Bacillus spp Microccocus spp Stretomyces Geotrichum Mucor spp spp spp spp Barley straw + Cotton 50 22 0 13 15 waste Kenaf + Vine shoot 53 19 0 12 16 sawdust Kenaf + Olive mill dried 46 16 11 12 15 waste Cotton waste + Olive mill 51 20 0 13 16 dried waste Barley straw + Vine shoot 58 23 0 19 0 sawdust Kenaf + Flax waste 49 22 0 14 15 Kenaf + Grapevine stem 59 22 0 0 19 Barley straw + Olive mill dried waste Barley straw + Kenaf 44 18 16 10 12 52 23 0 14 11 Barley straw + Grapevine stem 56 16 10 0 18 276 Table 4. Evaluation of different substrates for Biological Efficiency of Pleurotus ostreatus H9. Fresh weight of Moisture Total yield per Dry substrate per Time taken for Substrates (1:1 w/w) substrate per bag content bag bag (g) 1th flush (days) (g) (%) (g)(*) Barley straw 4000 81.0 760 29 807 ab Cotton waste Kenaf 4000 78.7 852 23 848 a Vine shoot sawdust Kenaf Dried olive mill 4000 77.0 920 27 779 ab waste Cotton waste Dried olive mill 4000 72.8 1088 29 880 a waste Barley straw 4000 75.7 972 28 701 bc Vine shoot sawdust Kenaf 4000 75.8 888 27 585 cd Flax waste Kenaf Grapevine stem 4000 78.6 856 31 544 d sawdust Barley straw Dried olive mill 4000 76.3 948 28 584 cd waste Barley straw 4000 81.6 736 35 398 e Kenaf Barley straw 4000 76.4 944 32 480 de Grapevine stem (*) Values followed by different letters are significantly different ( p 0,05, Tukey´s test) Yield values are the average of three replications. B.E. = g of fresh mushroom 100 / g of substrate dry matter 277 Biological Efficiency (B.E.) (%) 106.2 99.5 84.7 80.9 72.1 65.9 63.6 61.6 54.1 50.8