23314 Prepare value-added products at a composting facility

advertisement

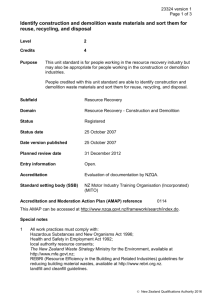

NZQA registered unit standard 23314 version 2 Page 1 of 5 Title Prepare value-added products at a composting facility Level 3 Purpose Credits 10 This unit standard is for people working in the composting sector of the resource recovery industry. People credited with this unit standard are able to: prepare for value-added product preparation; carry out initial preparation of value-added products; prepare value-added products; and conduct inspection on quality of completed value-added products, at a composting facility. Classification Resource Recovery > Composting Available grade Achieved Explanatory notes 1 All work practices must comply with: Health and Safety in Employment Act 1992; Resource Management Act 1991; Hazardous Substances and New Organisms Act 1996; NZS 4454:2005 Composts, soil conditioners and mulches; The New Zealand Waste Strategy: Reducing Harm, Improving Efficiency 2010 Ministry for the Environment, available at http://www.mfe.govt.nz; Material safety data sheets (MSDS); Approved Code of Practice for the Management of Substances Hazardous to Health in the Place of Work, Occupational Safety and Health Service, available at http://www.business.govt.nz/worksafe/ (WorkSafe NZ). 2 Personal protective equipment (PPE) must be used throughout operations in accordance with company procedures. PPE includes but is not limited to – gloves, eye protection, footwear, overalls, hearing protection, respirator or facemask, highvisibility clothing, fire extinguisher, first aid kit, eye wash kit, face shield/mask; hard hat. 3 Assessment against this unit standard must take place in a commercial scale composting facility or in a situation that reproduces and/or simulates operational conditions. 4 Definitions Company procedures mean the documented methods for performing work activities and include health and safety, environmental, site, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23314 version 2 Page 2 of 5 Organic in the resource recovery industry refers to materials that are putrescible or are of animal or vegetable origin. Value-added products may include – standard and specialised potting mixes; general and special purpose landscaping soils; composted and pasteurised mulches for various applications; composted and pasteurised soil conditioners for various applications; loose fill materials for playground surfacing or other applications; ornamental mulches; effluent, storm water or emission treatment products; products for erosion control or site remediation; products for agricultural disease suppression and other products for specialised applications. Outcomes and evidence requirements Outcome 1 Prepare for value-added product preparation at a composting facility. Evidence requirements 1.1 Job sheet and/or work order are reviewed to identify all product requirements in accordance with company procedures. Range 1.2 Equipment requirements for safe, effective, and efficient product preparation are identified in accordance with company procedures. Range 1.3 equipment may include but is not limited to – volume measuring, weight measuring. Hazards are identified, risk-assessed, reported, and managed in accordance with company procedures. Range 1.4 job sheet/work order may include but is not limited to – job number; batch number, pre-processed raw material preparation, product quantity and quality, compost batch recipe, product batch order, packaging. hazards may include but are not limited to – noise, dust, ergonomic hazards, hazardous substances, spills, bystanders, overhead power lines, mechanical malfunctions, exposed moving parts. Environmental impacts associated with machinery operation are identified, evaluated in terms of harm to the environment, and reported in accordance with company procedures. Range impacts may include but are not limited to – noise, exhaust emissions, organic dusts, hazardous substances, run-off. Outcome 2 Carry out initial preparation of value-added products at a composting facility. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23314 version 2 Page 3 of 5 Evidence requirements 2.1 Compost, materials, and other product additives are identified and confirmed against job sheet in accordance with company procedures. Range compost, materials, and other product additives may include but are not limited to – raw materials, finished compost of varying maturity and characteristics, product additives. 2.2 PPE is selected, used, maintained, and stored in accordance with the MSDS and company procedures. 2.3 Compost, materials, and other product additives are measured into the required quantities in accordance with job sheet and company procedures. 2.4 Compost, materials, and other product additives are monitored for quality in accordance with company procedures. 2.5 Variations and/or non-conformities in quality are identified and reported in accordance with company procedures. Range 2.6 Preparation method is selected in accordance with product type and company procedures. Range 2.7 evidence is required for two variations or non-conformities. preparation method may include but is not limited to – reduction, particle size screening, measuring of quantities, mixing and blending of materials, load shifting. Equipment and/or machinery are selected in accordance with product type and company procedures. Outcome 3 Prepare value-added products at a composting facility. Evidence requirements 3.1 Equipment and/or machinery are operated safely in accordance with manufacturer’s instructions and company procedures. 3.2 Equipment and/or machinery are monitored for performance and efficiency and defects or faults reported in accordance with company procedures. Range 3.3 may include but is not limited to – safety guards, operational techniques for the specific terrain, weather conditions, maintaining working loads within specifications. Compost, materials, and other product additives are blended and processed in accordance with company procedures. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23314 version 2 Page 4 of 5 3.4 Product outputs are monitored and adjustments to machinery operations are made to meet job sheet specifications. 3.5 Equipment and/or machinery and site are cleared and cleaned to avoid contamination between batches in accordance with company procedures. Outcome 4 Conduct inspection on quality of completed value-added products at a composting facility. Evidence requirements 4.1 Value-added products are inspected and checked to confirm compliance with job sheet and company procedures. 4.2 Quantity of product is confirmed and the product is labelled in accordance with company procedures. 4.3 Product details are documented in accordance with company procedures. 4.4 Supervisor and/or product dispatcher is informed of product readiness for dispatch in accordance with company procedures. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 23 April 2007 31 December 2017 Review 2 16 April 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23314 version 2 Page 5 of 5 CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016