paper-Verawan-joe-4-FINAL

advertisement

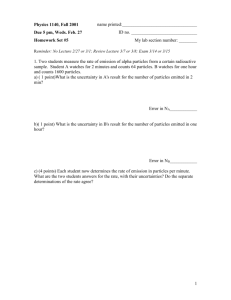

Swelling and Deswelling of Adsorbed Microgel Monolayers Triggered by Changes in Temperature, pH and Electrolyte Concentration. Verawan Nerapusri1, Joseph L. Keddie2 , Brian Vincent1,* and Ibraheem A. Bushnak2 1 2 School of Chemistry, University of Bristol, Bristol, BS8 1TS, UK Department of Physics, University of Surrey, Guildford, GU2 7XH, UK * author to whom correspondence should be addressed: brian.vincent@bris.ac.uk keywords: microgels, microgel layers, ellipsometry, streaming potential, poly(Nisopropylacrylamide), gel swelling. table of contents picture: 1 Abstract The formation and characterisation of close-packed monolayers of negative, poly (Nisopropylacrylamide)-based microgel particles onto positively charged silicon wafers is described. The silicon wafers were rendered positive, by first oxidising their surface to silica, and then adsorbing a layer of poly(ethyleneimine). The thickness of the deposited microgel monolayers (under aqueous conditions) has been determined, by spectroscopic ellipsometry, as a function of temperature (20 to 60 C), pH (3 to 8) and added NaCl concentration (0 to 1 M). No actual desorption of the microgel particles was evident on changing the conditions, but a swelling/deswelling transition was observed around 32 C. The thickness of the monolayer has been compared with the hydrodynamic diameter of the free microgel particles, dispersed in aqueous solution. For the poly(Nisopropylacrylamide) microgel particles, without any bulk ionisable co-monomer groups present, the temperature dependence of the ellipsometric thickness of the monolayer mirrors closely that of the hydrodynamic diameter of the free particles. When ionisable (-COOH) groups are introduced into the microgel particles, however, this correspondence is largely lost, because the microgel particles forming the deposited monolayer now contract strongly onto the oppositely-charged substrate surface. 2 Introduction Microgel particles, which swell or deswell with changes in their environmental conditions (e.g. temperature, pH or electrolyte concentration) have been widely studied [1-3], in particular, those based on poly (N-isopropylacrylamide) [poly(NIPAM)]. Such microgel particles have been proposed for uses in many applications, such as controlled uptake and release [1-3]. Indeed, this potential has been investigated in a number of earlier studies by the Bristol group, for various kinds of model “active” species, ranging from metal ions [4,5] and surfactants [6,7] to polymers [8] and nanoparticles [9]. In these studies the microgel particles were dispersed in solution, and the uptake or release of the active species concerned was monitored using some appropriate analytical method. In certain applications, it would be better to have the microgel particles tethered to a substrate, as a (mono)layer on the surface. Examples might be in the release of bactericides into food processing lines, or even from teeth and gum surfaces in the mouth. Microgel monolayers might even be deposited on larger, hard particles for use in packedcolumns for selective uptake and separation purposes. Such applications require fundamental studies to determine whether swelling and deswelling occur in microgel layers, restricted to a solid/liquid interface, as they do for free microgel particles. In this paper we describe a simple “dipping” procedure for the formation of closepacked monolayers of negative, poly (N-isopropylacrylamide)-based microgel particles onto positively-charged silicon wafers. Two types of microgel particles, both negatively charged, were studied. The first type of microgel was poly(NIPAM), where the particles possess negative surface charge groups. Such microgels exhibit a temperature response, i.e. they deswell with increasing temperature [1-3]. The second type of microgel was poly(NIPAM-co-AAc), where the carboxylic acid groups respond to pH changes, i.e. the particles (in addition to exhibiting a temperature response) swell with increasing pH, as a result of developing a bulk negative charge, in addition to the surface negative charge. The silicon wafers were rendered positive by first oxidising their surface to silica and then adsorbing a layer of poly(ethyleneimine). The thickness of the deposited microgel monolayers (under aqueous conditions) has been determined by spectroscopic 3 ellipsometry as a function of temperature (20 to 60 C), pH (3 to 8) and added NaCl concentration (0 to 1 M). The thickness of the monolayer has been compared with the hydrodynamic diameter of the free microgel particles, dispersed in aqueous solution, under similar environmental conditions. Experimental Section Materials N-isopropylacrylamide [NIPAM] (Aldrich, 97%) was purified by recrystallization from n-hexane prior to use. N,N’-methylenebisacrylamide [BA] (Aldrich, 99%) was used as the cross-linking monomer. Acrylic acid [AAc] (Aldrich, 99%) and the initiator, potassium persulfate [KPS] (Aldrich, 99%), were used as received. Water was Purite “Milli-Q” grade (with a resistivity of 18.2 M cm). Poly(ethyleneimine) [PEI] was obtained from BDH, as a 50 wt % aqueous solution. Preparation of the Microgel Dispersions Poly(NIPAM) particles were prepared by surfactant-free emulsion polymerisation, following the procedure described by Pelton and Chibanate [10]. In summary, NIPAM (4.2 g, 37.1 mM) and the cross-linking agent BA (0.042 g, 0.27 mM) were added to a 500 mL, three-necked, round-bottom flask, equipped with an overhead stirrer, condenser and nitrogen line. The monomer was dissolved in water (300 ml) and the solution purged with nitrogen, for approximately 10 min. The solution was then heated to 70 ± 1 oC and then KPS (0.21 g), dissolved in water (7 ml), was added. Within 10 minutes the solution turned slightly turbid indicating the nucleation of particles. The reaction was allowed to proceed for 16 h, under a nitrogen atmosphere, with stirring (350 rpm). At the completion of the polymerisation reaction, the dispersion was left to cool to room temperature. Poly(NIPAM-co-AAc) microgel particles were prepared by a similar process [11]. NIPAM (7 g) and BA (0.45 g) were added to a 1 L reaction vessel and dissolved in water (650 ml). Then AAc (0.5 g), dissolved in water (50 ml), was added to the reaction flask. The solution was purged with nitrogen for 20 min then heated to 70 ± 1 oC. KPS (0.21 g), 4 dissolved in water (50 mL), was added to the reaction flask. The reaction was left to proceed for a further 10 h and then left to cool to room temperature. Both microgel dispersions were purified by extensive dialysis against distilled water (for approximately 1 week) to remove any unreacted monomer and residual electrolyte. Characterisation of the Microgel Particles. The diffusion coefficients and electrophoretic mobilities of the various microgel particles were determined by dynamic light scattering [DLS] and phase analysis light scattering [PALS], respectively, using a Brookhaven Instruments Zeta Plus apparatus, fitted with a 15mW laser (λ = 678 nm). Samples were prepared at a particle concentration of 0.025 wt%, and were checked to ensure no multiple scattering was present The StokesEinstein equation was then used to calculate the hydrodynamic diameter (d) of the particles from the diffusion coefficient. The size of the microgel particles is expressed here in terms of the de-swelling ratio, S, defined as S = (d/do)3, where do is the diameter of the microgel particles in water at 20 oC. Preparation of Microgel Layers on Macroscopic Surfaces. The substrates used were silicon wafers, which, prior to use, were cleaned with HCl/H2O2 solution (70:30 vol %) at 80oC for 1 h (to remove organic residues from the surface), followed by rinsing with purified water 10 times. This procedure also leads to oxidization of the silicon surface, to give a thin silica layer at the surface, whose net surface charge is then pH-dependent (the iso-electric point for silica is generally in the pH range 2-3). In order to render the surface charge net positive at neutral pH, the silicon wafer was dipped into a 10 wt% PEI solution (for 5 min) and again thoroughly rinsed with water. The negatively charged microgel particles were then adsorbed onto this treated silicon wafer. Prior to adsorption the temperature of the microgel dispersion (1.5 wt %.) was raised to 50 oC and this was then left to equilibrate for 15 min, allowing the microgel particles to adopt their de-swollen state. The pre-coated wafer was dipped into this microgel dispersion, at 50 oC, for 5 min to allow maximum coating of the substrate 5 surface to occur. The wafer was then transferred to water, at room temperature, for a further 15 min. The microgel-coated wafer was allowed to dry in a clean air environment. Scanning electron microscopy. Scanning electron microscopy (SEM) was used to study the morphology and to estimate the thickness of the adsorbed microgel layer. SEM micrographs were obtained using a JEOL 6330F Field Emission instrument. Spectroscopic Ellipsometry. Ellipsometry is a technique that has been widely used to determine the thickness () and refractive index (n) of an adsorbed or deposited thin film on an optically-flat surface, for many types of soft matter [12], including adsorbed polymer films [13-16]. The principles of the technique may be found elsewhere [17,18]. In summary, ellipsometry measures the change in the polarization state of light caused by reflection from a single interface or parallel interfaces. The technique measures the two ellipsometry parameters and , as a function of wavelength. These values are related to the ratio of the Fresnel reflection coefficients, Rp and Rs, for p and s-polarized light, respectively, through tan .e i Rp Rs . [1] Then and n are derived from and using a model-dependent, fitting procedure [18]. In this work the data were fitted with software using a Marquardt algorithm [19]. In the model, each layer was treated as a planar slab with a uniform refractive index. Although this model is a simplification for a microgel layer, a more complex model with a gradient in refractive index with depth into the layer would introduce too many unknown parameters and cannot be justified. However, defects and vacancies in the microgel layer were considered in the model by assuming variation in the thickness of the film across the footprint of the beam. In this paper, only the average values for will be reported. Ellipsometry measurements were performed using a variable-angle spectroscopic instrument (J.A. Woollam Co. Inc., USA) with a rotating analyser configuration. The wavelength range chosen for this study was 400 to 800 nm, where poly(NIPAM) is non- 6 absorbing. The ellipsometry spectra of the silicon oxide layer, polyelectrolyte (PEI) layer, and dry microgel layer were initially obtained in air. The thickness and refractive index of each of these materials were thereby obtained for use in subsequent analysis. Then the silicon wafer, with the adsorbed microgel, was placed in a liquid cell, having permanent glass windows, less than 150 m in thickness, as described elsewhere [15]. The liquid cell was placed on a thermostating unit that allowed solution temperature control to within ± 0.1 oC. Measurements were performed with the incident light beam set at 72 o with respect to the sample normal, such that the light beam was normal to the glass windows. Streaming Potential. Streaming potential measurements were made with an EKA Electrokinetic Analyzer instrument (Anton-Paar, Graz, Austria) [20-21], using a rectangular cell constructed from parallel-sided glass slides to form a channel through which electrolyte solution could be passed, under a known pressure difference. Although not identical, of course, it was assumed that the surface of the glass was a reasonable approximation to the silica surface used in the ellipsometry experiments. Two Ag/AgCl electrodes are used to determine the streaming potential (U), as function of pressure difference (dp). U should, in principle, be a linear function of p. The zeta potential (ζ) for the surface, at a given electrolyte concentration, was then derived from the value for (dU/dp), using the Smoluchowski equation, dU dp r 0 [2] where η is the viscosity and κ the conductivity of the electrolyte solution, and ε r and εo are the relative permittivity (dielectric constant) of the solution and the permittivity of free space, respectively. 7 Results and Discussion Charge Properties of the Silicon Wafers and the Microgel Particles. Figure 1 shows the derived zeta potential, as function of pH, obtained using equation [2], for the bare glass surface and the PEI-coated surfaces. It may be seen that the latter surface is positive up to pH values of ~ 9.5. As stated earlier, we are assuming that the charge properties of the glass surfaces closely resemble those of the silicamodified silicon wafers. Figure 2 shows typical electrophoretic mobility data for the poly(NIPAM-coAAc) particles (containing 6 wt % AAc and also 6 wt % of the cross-linking monomer), as a function of temperature, in 10-3 M NaCl and at three pH values (3, 6 and 7.5). It may be seen that the mobility increases with temperature, at all three pH values. Similar results have been obtained by us before, but for PNIPAM microgel particles with no AAc present [22]. The basic reason why the mobility increases with increasing temperature is simply that the particles de-swell on raising the temperature, at these various pH values (see figure 4 later). Hence, their surface charge densities (and also their bulk charge densities, when AAc is present) increase correspondingly. No attempt has been made here to convert the mobility values (u) into zeta potentials (), because the soft, solventpenetrable microgel particles do not conform to the normal hard-sphere model assumed in the standard theories relating u to . It is not obvious why the dependence of u on temperature (over the range studied) appears to be stronger at pH 3, compared to the two higher pH values, in Figure 2. It may, however, simply reflect the fact that the transition in particle size, with increasing temperature, is much sharper at pH 3, than at pH 8, as shown later in figure 5. It is clear that, because the PEI-coated, silica-modified silicon wafer surfaces and the microgel particles are oppositely charged, under the all the conditions used in the current experiments, the microgel particles should adhere to the silicon wafers through electrostatic attraction forces. 8 Scanning Electron Microscopy. Some typical SEM images of the microgel particle layer adsorbed onto the silicon wafer surface are shown in figure 3. It would seem that the structure obtained does vary, depending on the electrolyte concentration in the dispersion medium. For figure 3(a) the particles were deposited in 10 mM KCl solution, so as to reduce lateral repulsion forces between neighboring adsorbed (de-swollen) particles. It may be seen that the particles have close-packed to form a fairly smooth, contiguous layer of approximately 300 ± 30 nm in thickness, on cooling (to effect swelling) and then drying. For figure 3(b), however, the particles were deposited without any added electrolyte present. Hence, the particles could not now entirely close-pack, because of significant lateral inter-particle repulsion forces. Under these conditions, the particles have clearly not formed such a coherent film (on cooling and re-swelling) as in (a), and, although the silicon surface seems to be covered with polymer, in this case the microgel film is rather rough. Figure 3(c) shows the corresponding top-view to (b), at lower magnification; this reveals that although the film is not as continuous and smooth, as in (a), there are very few “holes” per se, where particles are “missing”. There are local regions where the particles are in a hexagonal array, although the ordering does not extend across the whole surface. It is clear from these SEM studies that it is necessary to have sufficient electrolyte present in solution, during the particle adsorption stage, at 50 C, to obtain a final smooth microgel film, and this was the case in the ellipsometry studies reported below. Ellipsometry. The dry state Table 1. Refractive indices and layer thicknesses in the dry state. Substance refractive index ( = 550 nm) 1.49 1.52 1.53 silicon oxide PEI poly(NIPAM) Poly(NIPAM-co-AAc) 9 thickness / nm 2.71 0.04 6.5 0.1 334 6 194 4 Table 1 shows the results obtained for the various layers in the dry state. The dependence of the n of each material on the wavelength of light () was described through two fitting parameters in the Cauchy equation [18]. It would appear that, for the dry poly(NIPAM) layer, there is excellent agreement between the value found from ellipsometry (table 1) and that found by SEM (300 30 nm, see figure 3(a)). The smaller value obtained with the poly(PNIPAM-co-AAc) particles is interesting, since the hydrodynamic diameter of these particles in water is larger than that of the poly(NIPAM) particles. However, the values in Table 1 for the two dry microgel monolayers do follow the trend in the values found for the same monolayers in water at 60 C, i.e. 350 nm for the poly(NIPAM) particles and 140-220 nm (depending on the pH) for the poly(NIPAM-co-AAc) particles. We shall return to a discussion of this point later. Poly(NIPAM) particles in water: effect of temperature: In analyzing the ellipsometry data for layers in the liquid cell, the dependence of the refractive index of water on wavelength and on temperature was considered in the model by using standard values obtained from the literature [23]. It was assumed that the -dependence of the polymer layers’ n did not change with temperature, pH or electrolyte concentration. Any dimensional change in the PEI layer with changing temperature (or pH) was neglected. Hence, the only unknown parameters in modeling the data were the microgel layer thickness () and n. The dependence of n for the microgel layer on the wavelength () was described through two fitting parameters in the Cauchy equation [18]. It was assumed that the -dependence did not change with temperature, pH or electrolyte concentration. The values of the refractive index for the swollen microgel layers were always between that for water and the dry polymer, as expected. From the refractive index values, the polymer volume fraction was estimated to range from 20% when swollen up to 80% when de-swollen. Figure 4(a) shows the variation in (1) the hydrodynamic diameter of the dispersed poly(NIPAM) microgel particles in bulk water, and (2) the thickness of a corresponding monolayer of the same microgel particles attached to the silica substrate under water, both as a function of temperature. A rather abrupt swelling is observed upon cooling to 10 32 2 C, for both the dispersed microgel particles and the microgel monolayer. In fact, the two plots “mirror” each other quite closely. This fact becomes more evident in figure 4(b), where the two sizes values have each been normalized to unity at 20 C, as the deswelling ratio (S) in each case. It is interesting, however, that the absolute ellipsometric thickness values for the microgel monolayer are somewhat greater than the corresponding hydrodynamic diameters of the free microgel particles, at all temperatures. This suggests either that the value of the hydrodynamic diameter is less than the “real” diameter of the particles (i.e. the diameter of the spheres containing all the polymer segments belonging to the microgel particles), or that the particles in the monolayer are somewhat extended, normal to the surface, in the close-packed layer. The former explanation seems less plausible, since Routh has shown [24], from theoretical hydrodynamic considerations that the hydrodynamic diameter is indeed close in value to the “real” diameter. The latter explanation is possible since the microgel particles are adsorbed as a close-packed monolayer in the deswollen state (at 50 C), and the particles in this monolayer are then allowed to reswell, on cooling, possibly “squashing” them laterally, and causing the observed extension normal to the surface. Some entanglement formation between adjacent particles might then prevent them returning to their initial size on heating again to 60 C. Furthermore, the limitations of the slab model used in analyzing the ellipsometry data should be considered. The refractive index of the microgel layer is expected to vary with depth, and the interface with the water is expected to be somewhat broad. Of course, represents the average layer thickness interacting with the incoming light beam, and it is likely to be an under-estimation of the full extension of the layer into the aqueous solution. The swelling that was observed upon cooling of the microgel layer was found to be fully reversible. That is, if a swollen microgel layer was re-heated from a lower temperature, it collapsed to a thickness that was close to the original thickness. There was no evidence for desorption of the microgel particles from the substrate. Calculations of the total amount of microgel adsorbed at the interface (made through the application of standard procedures [16, 18]), however, found that the apparent total amount adsorbed 11 was lower when the layer was swollen. This finding is consistent with our belief that is an under-estimate of the true thickness of the swollen layer. Poly(NIPAM-co-AAc) particles in water: effect of temperature and pH Measurements of the n of the aqueous phase found that there was a negligible change when the pH was adjusted. Figures 5 (a) and 5 (b) show comparisons of the hydrodynamic diameter (d) of poly(NIPAM-co-AAc) microgel particles in aqueous dispersion, and the thickness () of a monolayer of these particles on the silica substrate, both as a function of temperature, at pH 3 and pH 8, respectively. In both cases, as with the pure poly(NIPAM) microgel particles, the hydrodynamic diameter decreases with temperature (see figure 4(a)). The most significant difference between the poly(NIPAMco-AAc) and the poly(NIPAM) microgel particles concerns the thickness values of the deposited monolayers. For the poly(NIPAM) microgel particles the values of this parameter were consistently higher than those for the corresponding hydrodynamic diameters of the free particles. With the poly(NIPAM-co-AAc) microgel particles the reverse is true, i.e. the ellipsometric thickness values are now very much lower than the corresponding hydrodynamic diameters. Indeed, at pH 8 (figure 5(b)), the thickness of the microgel monolayer hardly decreases at all over the temperature range 20 C to 60 C. At pH 8, the microgel particles are highly negatively charged and, thus, there is a strong electrostatic attraction between these particles and the (positively charged) substrate surface. The microgel particles are “contracted down” onto the surface. At pH 3 (figure 5(a)), on the other hand, where only the surface of the microgel particles carries any charge (from the persulfate initiator), and there is no bulk charge, this contracting force is much less, and, as a result, there is a somewhat more pronounced shrinkage with increasing temperature. The fact that this decrease in size with temperature is still not as large as with the poly(NIPAM) particles (figure 4(a)), which also carry a similar surface charge, simply reflects the greater degree of cross-linking (6 wt%) for the poly(NIPAMco-AAc) particles compared to the poly(NIPAM) particles (1 wt%). In figure 6(a) and 6(b) the hydrodynamic diameter of the free poly(NIPAM-co-AAc) microgel particles and the ellipsometric thickness of the deposited monolayer of these particles, respectively, are shown as a function of pH, at a fixed 12 temperature (25 C), where the microgel particles are already swollen. The hydrodynamic diameter (figure 6(a)) increases further with pH, because of the increasing bulk charge created inside the microgel particles as the pH increases; this leads to increased (osmotic) swelling due to the presence of the counter ions. This effect, at 25 C, is also evident from figures 5(a) and 5(b). However, from those figures it may be seen that this additional (counter-ion) swelling effect is suppressed at 60 C, where the (now deswollen) microgel particles have the same size at both pH 3 and pH 8. From figure 6(b) it may be seen that the layer thickness passes through a minimum value with increasing pH. This is due to a competition between two effects: (I) the tendency of the particles to expand with increasing pH, as the bulk charge within the particles increases; (II) the tendency for the particles to contract onto the positively charged surface. Between pH 3 and 5 effect (II) dominates. Above pH 5, the (positive) charge on the poly(ethyleneimine) layer decreases and effect (I) dominates. A further important conclusion from figure 6(b) is that there is no evidence that the microgel particles desorb at all from the substrate on raising the pH, even though the positive charge on the substrate decreases. Poly(NIPAM-co-AAc) particles in water: effect of NaCl concentration When analyzing ellipsometry data, the small change in the refractive index of the aqueous phase with changing salt concentration was considered in the data modelling. As may be seen from figure 7, at 25 C, the hydrodynamic diameter of the free, swollen poly(NIPAM-co-AAc) microgel particles decreases with increasing NaCl concentration, at both pH 3 and 8, as a result of charge screening. As expected, this effect is stronger at the higher pH value, where the particles have a bulk charge as well as a surface charge. The situation with the microgel particle monolayers is more complex, however. At pH 3, where the particles only have a surface charge, the decrease in thickness with increasing NaCl concentration approximately parallels the corresponding values for hydrodynamic diameter of the free particles, although as seen earlier (figure 5(a)- no added electrolyte), the monolayer thickness values are significantly smaller than the hydrodynamic diameter values. At pH 8 the thickness values actually increase with increasing NaCl concentration. This must mean that the electrostatic force, tending to contract the 13 (negative) microgel particles onto the (positive) substrate surface, is significantly weakened with increasing NaCl concentration. There was no evidence for particle desorption. When salted water was replaced with de-ionized water, the original layer thickness before salt addition was re-gained. Conclusions It has been shown that close-packed monolayers of microgel particles may be deposited onto oppositely charged substrate surfaces by a simple “dipping” procedure. Using microgel particles which are sensitive to temperature, or, in those cases where the particles contain bulk ionisable groups, such that they are also sensitive to pH and electrolyte concentration, then the thickness of the monolayer may be controlled using these parameters. A swelling/deswelling transition is observed in the adsorbed layers at a transition temperature. The response is also dependent on pH and salt concentration, as can be explained by considering charge effects. These microgel monolayers should therefore be capable of the controlled uptake and release applications, as suggested in the Introduction. This subject is currently under investigation in our laboratories. Acknowledgements We should like to thank SCIC Ltd (Thailand) for funding to enable VN to carry out her PhD studies in the UK. We also thank the Ministry of Higher Education of Saudi Arabia for providing a PhD scholarship for IB. References [1] Murray, M.J.; Snowden, M.J., Adv. Colloid Interface Sci., 1995.54, 73. [2] Saunders, B.R; Vincent, B, Adv. Colloid Interface Sci., 1999, 80, 1. [3] Saunders, B.R.; Vincent, B., Encyclopedia of Surface and Colloid Science, Marcel Dekker, USA, 2002, 4544. [4] Morris, G.E.; Vincent, B; Snowden, M.J., J.Colloid Interface Sci., 1997, 190, 198. [5] Morris, G.E.; Vincent, B; Snowden, M.J., Prog. Colloid Polymer Sci., 1997, 105, 16. [6] Bradley, M.; Vincent, B., Langmuir, 2005, 21, 8630. [7] Bradley, M. et al., Langmuir, 2006, 22,101. [8] Bradley, M.; Ramos, J.;Vincent, B., Langmuir, 2005, 21, 1209. [9] Bradley, M.; Bruno, N.;Vincent, B., Langmuir, 2005, 21, 2750. [10] Pelton, R.H.; Chibanate P, Colloids Surfaces, 1986, 20, 247. 14 [11] Routh, A.F.; Vincent, B., Langmuir, 2002, 18, 5366. [12] Keddie, J.L., Curr. Opin. Coll. Interf. Sci., 2001, 6, 102. [13] Shubin, V.; Linse P., J. Phys.Chem., 1995, 99, 1285. [14] Amiel, C.; Sikka, M.; Schneider, J.W., Macromolecules, 1995, 28, 3125. [15] Minko, S.; Sidorenko, A.; Stamm, M., Macromolecules, 1999, 32, 4532. [16] Styrkas, D.A. et al., Langmuir, 2000, 16, 5980. [17] Smith, T., J. Optical Soc. Amer., 1968, 58, 69. [18] Styrkas, D.A. et al.., Polymer Surfaces and Interfaces III, ed. Richards, R.W.; Peace, S.K., John Wiley, Chichester, 1999, 1. [19] Marquardt, D.W., J.Soc.Ind. Appl. Math., 1963, 11,431. [20] Ribitsch, C.; Jorde, J.; Schurz, H., Progr. Colloid Polymer Sci.,1998, 77, 49. [21] Grundke, K.; Uhlmann, P.; Simon, F., Composite Interfaces, 1996, 3, 293. [22] Rasmusson, M.; Vincent, B.; Marston, N., Colloid Polymer Sci., 2000, 278, 253. [23] Schiebener, P. et al., J. Phys. Chem. Ref. Data, 1990, 19, 677. [24] Routh, A.R.; Zimmerman, W.B., J. Colloid Interface Sci., 2003, 261, 547. Figure Captions Figure 1. Zeta potential of bare glass, and glass coated with 10% PEI solution, as a function of pH, in 10-3 M KCl solution, obtained from streaming potential measurements. Figure 2. Electrophoretic mobility, as a function of temperature, for poly(NIPAM-coAAc) particles, in 10-3 M KCl solution , at three pH values, as indicated. Figure 3. Scanning electron micrographs of close-packed layers of poly(NIPAM) particles (with 1 wt% cross-linker) adsorbed onto a PEI-treated silicon wafer: (a) crosssection, side-view image through the microgel layer (10 mM KCl present), scale bar =200 nm; (b) a second, side-view image of a different wafer (no added electrolyte), scale bar = 200nm; (c) a top-view image, corresponding to (b), taken at a lower magnification, scale bar = 1 m. Figure 4. (a) The hydrodynamic diameter of poly(NIPAM) microgel particles (1 wt% cross-linker) in aqueous dispersion, and the ellipsometric thickness of a monolayer of these particles at the silica interface, both as a function of temperature; (b) as in (a) but both sets of data are normalized to their respective values at 20 C. 15 Figure 5. The hydrodynamic diameter of poly(NIPAM-co-AAc) microgel particles (6 wt% AAC and 6 wt% cross-linker) in aqueous dispersion, and the ellipsometric thickness of a monolayer of these particles at the silica interface, both as a function of temperature: (a) at pH 3; (b) at pH 8. Figure 6. (a) The hydrodynamic diameter of the poly(NIPAM-co-AAc) microgel particles as a function of pH (25 C and 10-3 M NaCl); (b) the ellipsometric thickness of the corresponding monolayer as a function of pH (25 C and 10-3 M NaCl). Figure 7. The hydrodynamic diameter of the poly(NIPAM-co-AAc) microgel particles and the ellipsometric thickness of the corresponding monolayer, as a function of NaCl concentration, at pH 3 and at pH 8 (25 C). 16 45 bare glass Zeta Potential (mV) 30 glass coated with PEI 15 0 2 4 6 8 10 -15 -30 -45 -60 pH Figure 1 17 12 0 pH 3 pH 6 pH 7.5 electrophoretic mobility 10-8 (m 2s-1v -1) -1 -2 -3 -4 -5 -6 20 30 40 50 60 o temperature ( C) Figure 2 18 (a) (b) (c) Figure 3 19 1500 thickness hydrodynamic dia. (a) 1250 size (nm) 1000 750 500 250 0 10 20 30 40 50 60 temperature (oC) 1.2 (b) thickness hydrodynamic dia. deswelling ratio(d/d o)3 1 0.8 0.6 0.4 0.2 0 10 20 30 40 50 o temperature ( C) Figure 4 20 60 900 (a) thickness 750 hydrodynamic dia. size (nm) 600 450 300 150 0 20 30 40 50 60 o Temperature ( C) 1100 (b) thickness 900 size (nm) hydrodynamic dia. 700 500 300 100 20 30 40 50 o Temperature ( C) Figure 5 21 60 70 1100 hydrodynamic diameter (nm) (a) 1000 900 800 700 600 0 2 4 6 pH 8 10 500 (b) Thickness (nm) 400 300 200 100 2 3 4 5 6 7 pH Figure 6 22 8 9 1100 pH 3,thickness pH 8,thickness pH 3,diameter pH 8,diameter size (nm) 900 700 500 300 1.0E-04 1.0E-03 1.0E-02 1.0E-01 log ([NaCl]/M) Figure 7 23 1.0E+00