CE3503 – Environmental Engineering

advertisement

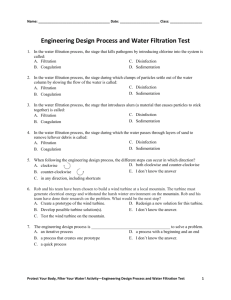

CE3503 – Environmental Engineering - Field Trip #2 C&EE Environmental Process Simulation Center This field trip will be to the C&EE Environmental Process Simulation Center (EPSC), located in Room 106 of the Dow Environmental Science & Engineering Building. The EPSC was designed to provide students with hands-on experience in working with environmental processes. A number of upper division undergraduate and graduate classes conduct experiments in the facility. Please visit – http://www.cee.mtu.edu/environ_proc_sim_center.html prior to the field trip to learn more about the EPSC. In this field trip, we will use the EPSC to provide a demonstration of a typical process train for drinking water treatment. We will begin with a raw water source and proceed through six unit operations. RAW WATER The raw water supply is derived from the Keweenaw Waterway and spiked with clay and food coloring to permit better visualization of the treatment process. COAGULATION FLOCCULATION SEDIMENTATION We will apply a bench scale jar test in which a chemical (coagulant) is added to the water in a ‘flash-mix’ and then agitated slowly (flocculated) to permit the formation of larger, more easily settled particles (flocs). We will then shut off the mixers and allow the flocs to settle out. Note that, while the water has become much clearer, significant cloudiness remains. We will demonstrate this by comparing turbidity measurements before and after settling. It is then necessary to remove the residual turbidity through filtration. FILTRATION We will pass the water through a multi-media filter containing anthracite, sand and gravel. The goal in filtration is to remove large particles at the top of the filter and progressively smaller particles as we move deeper into the bed. Anthracite is used at the top because this medium has large pores and thus captures only large particles. Sand is used next to capture smaller particles. Gravel serves as the base of the multi-media system and keeps the sand from moving out with the filtered water. The densities of the component media are such that they will re-sort as intended during backwashing (even though the anthracite medium has a larger diameter than the sand medium). We will evaluate the effectiveness of this treatment through additional turbidity measurements. ADSORPTION At this point we have been quite successful in removing particles, but have made little progress with color, a surrogate for potentially dangerous dissolved organic chemicals. We will remove these by passing the water through an activated carbon column. Note the reduction in color in the effluent. DISINFECTION Finally, the water is disinfected through the addition of chlorine. Here, we will use household bleach. The chlorine kills bacteria, protozoa and viruses through direct oxidation, i.e. it ‘burns them up’. In addition, chlorine oxidizes any dissolved organic matter remaining in the sample. Where large amounts of dissolved organic matter are present, much of the chlorine may be consumed and disinfection may be incomplete. Further, we need to maintain a residual to pass along to the distribution system. We will test for chlorine residual to insure that we have a safe water supply. NOTES: A Drinking Water Treatment Process Train Martin T. Auer – MTU Civil & Environmental Engineering Our demonstration of a drinking water treatment process train will be held in the Environmental Process Simulation Center, a teaching facility to supplement the unit operation theory learned in class. This oneof-a-kind facility provides students with hands-on opportunities to explore bench and pilot-scale processes for water treatment, wastewater treatment and air pollution control. Drinking water treatment seeks to make a water supply both potable (safe) and palatable (goodtasting) by removing pathogens (disease-causing organisms) and particles (that might shield pathogens from disinfection. → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection This is accomplished through a process train that includes coagulation, flocculation, sedimentation, filtration and disinfection. → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection In coagulation, aluminum sulfate (alum) is flash-mixed with the raw water. The aluminum ions form positively-charged hydroxy-metallic complexes that neutralize the negative charges of clay particles allowing them to clump together (coagulate) into larger, more easily sedimented flocs. The complexes also encourage floc formation by bridging. → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection In flocculation, the water is gently mixed encouraging particle contact and building larger flocs. The mixing rate is reduced as the water moves through a series of flocculation units to avoid breaking up the large particles. A Drinking Water Treatment Process Train → → Untreated Water Treated Water Coagulation Flocculation Sedimentation Filtration Disinfection In sedimentation, particles settle to the bottom of a tank and are removed to waste. It is not efficient to remove all particles in this way because small particles settle very slowly and thus an immense sedimentation tank would be required. → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection The water is then passed through a rapid sand filter to remove the remaining particles. After a period of operation, the filtration apparatus becomes clogged and must be backwashed. In this drinking water treatment demonstration, we are adding removal of organic chemicals by adsorption with granular activated carbon. → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection → → Untreated Water Coagulation Treated Water Flocculation Sedimentation Filtration Disinfection The final step prior to distribution is to insure that all pathogens have been destroyed and that residual disinfectant is present to protect the distribution system. This disinfection is typically accomplished by the addition of chlorine.