SWP45-11-Liquid Cryo..

advertisement

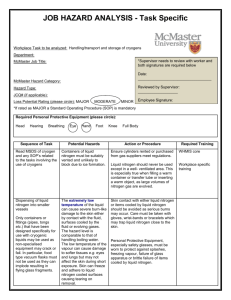

OHS026 Safe Work Procedure Faculty/Division Science Document number LG45-04 School/ Divisional Unit School of Physics/Optoelectronics Initial Issue date 01/11/2011 Current version 1.0 Current Version Issue date 21/3/2011 Next review date 21/3/2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Liquid Cryogen Dewars and General Liquid Cryogen Safety Description: Filling liquid nitrogen storage dewar. Transport of liquid nitrogen and use of liquid nitrogen in the laboratory. Transport and use of liquid helium dewars. Associated risk assessment title and location: RISK ASSESSMENT: Collection and use of liquid nitrogen and liquid helium. Describe the activity or process Background In the Optoelectronics labs, liquid nitrogen and liquid helium are used to cool experimental equipment. There are many safety issues associated with the use of liquid nitrogen and liquid helium as they have the ability to freeze living tissue and can also cause asphyxiation (suffocation). They must be used with extreme safety. The 50 L (Janis) Liquid nitrogen dewar and CF60 liquid helium dewars are usually stored in OMB LG45. The laboratory is fitted with air conditioning and oxygen level detector for your safety (see ‘suffocation danger’ for details). Handling of liquid cryogen dewars Do not enter room if the low oxygen level alarm is sounding. Contact the person on the emergency contact list for instructions. 1. 2. 3. 4. 5. 6. Liquid cryogens cannot be handled without proper training from a qualified person. This training can be obtained from the Area Supervisor (Peter Reece). After training your name will be added to a list of trained cryogen users. Appropriate personal protective equipment (gloves, face shield and long sleeve lab coat) is provided within the labs and must be worn prior to transferring liquid nitrogen or liquid helium. Be aware when handling cryogens that 1 litre of liquid will expand into approx. 740L of gas if warmed above its boiling point. Nitrogen gas is a similar weight to air and may collect at floor level. Helium gas is lighter than air and will tend to collect in higher locations. As the safety features vary from dewar to dewar, consult a trained user before use of cryogenic storage vessels. In general, when transporting a vessel, one of the gas pressure relief valves should be open to prevent gas buildup. All dewars must have at least two safety relief valves built into the dewar neck. When not in use, liquid helium dewars should be attached to the helium recovery system in a lab. This not only allows collection of the gas for liquefaction but keeps the room clear of helium gas. Please ensure this connection is secure as there can be a small pressure buildup (0.023bar or 0.33psi) in the collection line and this may blow the line off the connection, allowing helium gas into the room. If using an enclosed lift, the vessel should be sent unattended to the next level in case there is a failure of the lift or the vessel. This failure may allow cryogenic gas to build up in the enclosed space. This operation will require two people to prevent access to the lift at both levels. When transferring liquid be particularly careful not to move or bump the dewar as transfer tubes, particularly plastic and rubber tubes, can be brittle and fracture when cold, spraying liquid cryogen around the room. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Personal Protective Equipment (PPE) • Wear clean and dry clothing that covers arms and legs. • The clothing should be loose, so it is easy to remove it if an accident happens. • Avoid wearing open trouser pockets and wrapped sleeves. • Wear cryogenic gloves (provided) under the sleeves so no liquid can fall in the gloves. • Wear the face shield provided to ensure complete protection of the face and neck. • Wear non-slip closed footwear and a lab coat which has long sleeves (provided). ______________________________________________________________________________________________________________________ Page 1 of 3 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Suffocation danger • Make sure there is enough ventilation in the facility as liquid nitrogen and liquid helium immediately turn into a gas when exposed to room temperature and pressure. This displaces oxygen from the air resulting in low oxygen levels and an asphyxiation risk. • Avoid transporting liquid nitrogen in lifts carrying other persons. Damage to surfaces and footwear · Liquid nitrogen and liquid helium make floor coverings, normal shoe soles, and plastic materials brittle. Do not spill onto floors! · Do not use domestic glass lined vacuum thermos flasks for storing liquid nitrogen. These flasks are brittle and will break easily. A. FILLING LIQUID NITROGEN DEWARS FROM THE PHYSICS LARGE STORAGE TANK 1. All operators must be trained before using the large storage tank to dispense liquid nitrogen. 2. Dispense only into Dewars that are rated for liquid nitrogen. a. Never use a Dewar that does not have pressure relief valves. b. Never use Dewars with makeshift or homemade lids/stoppers. c. Use pressure venting lids/stoppers supplied by the Dewar manufacturer 3. Dispense only into Dewars that are: a. Equipped with carrying handles or wheels b. Stable/not in danger of tipping over easily 4. Persons filling Dewar(s) will be in constant attendance during filling. Keep entry gate OPEN. 5. Prevent Splashing. Place filling hose at or below the mouth of the receiving Dewar 6. Wear Required Personal Protective Equipment a. Cryogenic Gloves b. Lab Coat with sleeves pulled over cuffs of Cryogenic Gloves c. Liquid proof Shoe Covers/Spats d. Chemical Splash Goggles or Laboratory Face Shield B. TRANSPORTING LIQUID NITROGEN AND LIQUID HELIUM WITHIN LABORATORIES AND BETWEEN LABORATORIES IN THE SAME BUILDING 1. Use Dewars rated for liquid nitrogen or Liquid helium. 2. Do not transport Liquid Nitrogen in Open Containers. 3. Wear Required Personal Protective Equipment. 4. The Janis 50L liquid nitrogen dewar rests is not fixed to the dolly and can potentially be tipped up if one of the wheels gets stuck. 6. Never attempt to lift a filled dewar off the dolly – a full LN dewar can weigh in excess of 40kg. 5. If you are carrying a Dewar containing Liquid Nitrogen: a. Make sure Dewar is your ONLY load (no books, coffee, other items) b. Carry transport Dewar as far away from your face and body as possible c. Watch for other people who may run into or bump you List emergency shutdown instructions 1. Vacate the room. 2. Contact the Plant Custodian (Peter Reece x54998 or 0423 117 969 or other senior experimental staff who are authorized users on the emergency contact list below: 3. If unable to contact and there is a major emergency contact x56666 List clean up and waste disposal requirements Evacuate the area until the liquid has evaporated and oxygen levels are at normal atmospheric levels. This may require opening outside windows and doors if safe to do so. If spill occurs outside, keep up wind of the spill. If there is a large spill, or if a vessel is leaking, contact emergency services (UNSW Emergency, xn 56666) and notify the supplier. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australian Standard AS 1894 Code of Practice for the Safe Handling of Cryogenic Fluids Australian Standard AS 2243.2 Safety in Laboratories: Chemical Aspects Supervisory approval, training, and review Supervisor: Peter Reece Signature: Plant custodian: Peter Reece x54998 Signature ______________________________________________________________________________________________________________________ Page 2 of 3 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 List competency required – qualifications, certificates, licensing, training - eg course or instruction: UNSW/Physics Liquid Nitrogen Training. UNSW Laboratory Safety Awareness training. Hands-on training in cryogens transfer and the use of low temperature equipment by an authorized user. SWP review date: 14/3/2014 Responsibility for SWP review: Peter Reece ______________________________________________________________________________________________________________________ Page 3 of 3 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007