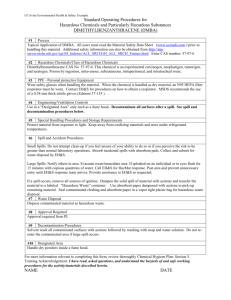

SWP Biological spill procedure

advertisement

OHS026 Safe Work Procedure Faculty/Division School/ Divisional Unit Medicine SOMS Document number Initial Issue date Current version Current Version Issue date Next review date SOMS_IIR_SWP32 March 2010 January 2014 January 2016 2.0 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Biological Spills Description: To describe the procedure how to clean up spills of potentially infectious biological materials and genetically modified organisms (GMOs) Describe the activity or process Spills of Biological Materials Hepatitis B vaccination is strongly recommended for workers handling human blood or tissues. Hepatitis B is a potentially fatal disease and is very contagious. Infection with blood-borne pathogens occurs through a direct route of entry e.g. cuts, burns, needle sticks, eyes, and mucous membranes. Treat any blood or body fluids as infectious. The basic principles of biological material spills management are: Standard precautions apply, including use of personal protective equipment (PPE) as applicable Spills should be cleared up before the area is cleaned (adding cleaning liquids to spills increases the size of the spill and should be avoided) Generation of aerosols from spilled material should be avoided. The risk controls we have in place for cleaning up spills in the Laboratory are:A. Laboratory training with respect to the use, safe handling and transport of biologicals B. An appropriate decontaminant for the biological agents present. (Note: the decontaminant MUST be used at the correct concentration and for the required contact time.) C. PPE - Always wear a long sleeve gown, double gloves (nitrile preferred), eye protection and a respiratory protection All biological spills should be dealt with as soon as possible Spill procedures (Eg Infectious, Biological, Clinical, GMO, human or animal blood and body fluids) Liquid spills generally form three fractions: the bulk of the liquid forms a puddle; small splashes of liquid escape; and a small portion of the liquid forms airborne particles. In the event of a spill, the following procedures should be observed: · Avoid breathing in aerosol and vacate the area. · Warn other people to keep away from the area (verbally and with signs). · Keep the area cleared for a minimum of 30 minutes to allow time for aerosols to settle or be diluted by air ______________________________________________________________________________________________________________________ Page 1 of 4 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 handling systems. · In case of splashing with infective agent or GMO · Remove any contaminated clothing. · Wash affected area, scrub with soap and water (use eyewash if applicable). · Wash exposed skin (hand, face). · Notify your supervisor. · Assemble a clean-up team consisting of three people: one observer, one person to clean and another to pass materials and disinfectants. · After waiting at least half an hour, the team should: · Put on protective clothing and equipment. · Wear double gloves (nitrile preferred) while decontaminating – make sure the gloves are over the cuffs of the gown. · Assess the extent of the contaminated area. · Lay paper towels impregnated with appropriate decontaminate over the spill. Cover the spill working from the outside to the centre. Wait for the appropriate time for the decontaminant to be affective. · Do not pour decontaminant directly onto a spill as this can produce more aerosols. · Use tongs to pick-up the contaminated paper towel. Also use tongs to pick-up any sharps in the spill such as broken glass or needles. · Dispose of contaminated materials in an approved PC2 waste bin or sharp bin. · Wipe over the contaminated area with appropriate decontaminant. · Re-wipe over the contaminated area with appropriate decontaminant. · Dry the area as wet areas attract contaminants. · Decontaminate the tongs by soaking in appropriate decontaminate for the required contact time or autoclave them. · Remove outside set of gloves and dispose of in PC2 waste bin. · Wash and dry hands · Take gown off and put it into bag for steam sterilization · Wash and dry hands · Remove eye protection and respiratory protection · Rewash hands and dry thoroughly. · Notify your supervisor. · Fill in an incident report. Procedure for Biological Spill in a Centrifuge Centrifuge tubes should be sealed closed. Always use sealed safety buckets or sealed rotors with O-rings. Examine O-ring and replace if worn, cracking or missing. Check tubes and bottles for cracks and deformities before each use. · If a tube breaks during centrifugation, immediately stop the centrifuge and allow the rotor to completely stop. · If a spill is identified after the centrifuge lid is opened, carefully close the lid and evacuate the laboratory and close the laboratory door. · Allow 30 minutes for any aerosols that were generated to settle before cleaning up the spill. · Post a sign on the laboratory door indicating there is a biohazard spill and do not enter. · Notify your supervisor and the plant custodian. · Don the proper PPE (double gloves, lab coat, respiratory protection and safety goggles). · Locate all the equipment you will need to clean up the spill · If possible, take the centrifuge into the biological safety cabinet. · If the spill is contained in the rotor, take the rotor into the biological safety cabinet. · Alternatively, transfer the buckets to a biological safety cabinet. · Use a mechanical device (eg. tweezers, tongs) to remove the tube top and any tube pieces into a biohazard sharps container. · Remove the tube adapter from the rotor, being careful not to spill the contents. · Add appropriate decontaminate to the adapter and let sit for the required contact time. · Pour the solution in the tube adapter onto absorbent material sufficient to absorb the fluid located within the tube adapter. · Place all contaminated absorbent material in the biohazard waste container. · Wash the tube adapter with appropriate decontaminate. · Intact tubes may be wiped down and placed into a new container. · If the centrifuge bowl has been contaminated, carefully wipe the inside of the centrifuge with appropriate ______________________________________________________________________________________________________________________ Page 2 of 4 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 decontaminant. · Rewipe the centrifuge bowl. · If there are areas of the centrifuge that are contaminated but can’t be disinfected without disassembly, get the custodian to directly contact the company · Remove one set of gloves and dispose of in the biohazard container and wash hands. · Take gown off and put it into bag for steam sterilization · Wash and dry hands · Remove eye protection and respiratory protection · Rewash hands and dry thoroughly. · Fill in an incident report. Procedure for Biological Spill Biological Safety Cabinet · Leave the biological safety cabinet blower on and begin cleanup immediately. · While wearing PPE cover the spill area with paper towels or decontaminant soaked paper towels. · Do not place your head in the cabinet to clean the spill, keep your face behind the viewscreen. · If necessary, flood the work surface as well as the drain pans and catch basins below the work surface, with appropriate decontaminant. Be sure the drain valve is closed before flooding the area under the work surface. · Wipe cabinet walls, work surfaces, and inside the viewscreen with appropriate decontaminant. · Lift the front exhaust grill and work surface; wipe all surfaces with appropriate decontaminate. Be sure no paper towels or soiled debris are blown into the area under the spill tray · If the work surface, as well as drain pans and catch basins under the work surface, have been flooded with appropriate decontaminant soak up the appropriant decontaminate in the work surface after required contact time. · Place a container under the drain valve and drain the appropriate decontaminate under the work surface into the container. · Wipe the areas under the work surface to remove residual decontaminant. · Wash hands and exposed skin with soap and water. · Autoclave all cleanup materials and protective clothing. · Notify your supervisor and the plant custodian. List all resources required including plant, chemicals, personal protective clothing and equipment, etc PPE - Always wear a long sleeve gown, double gloves (nitrile preferred), eye protection and respiratory protection Absorbent paper towel Tongs or tweezers Appropriate decontaminant for the microorganism or GMO present. Biohazard disposable waste bag PC2 waste bin List potential hazards and risk controls including specific precautions required Potential hazard of being exposed to infectious material or GMO through the skin, eyes, inhalation and ingestion. Potential hazard the unintentional release of a GMO All staff and students working in the Laboratory have been inducted into the Laboratory and orientated in the hazards that exist in the Laboratory. All staff and student working in the laboratory have undertaken UNSW PC2 training. ______________________________________________________________________________________________________________________ Page 3 of 4 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007 List emergency shutdown instructions For major spills, vacate the area and warn other people to keep away from the area (verbally and with signs). Notify your supervisor and the plant custodians. Dial x56666 if required List clean up and waste disposal requirements All laboratory gowns containing or potentially contaminated with live microorganisms must be decontaminated by pressure steam sterilisation (autoclaving) before being sent to the cleaning contractor. All biological or GMO waste that has been chemically treated must be disposed as chemical waste. All other biological or GMO waste must be place in the PC2 waste bins. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act and Regulation Australian/New Zealand Standards 2243.3:2002. Safety in laboratories - Microbiological aspects and containment facilities UNSW OHS Policy: OHS321 - Laboratory Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: UNSW UNSW UNSW UNSW Laboratory Safety Awareness training Occupational Health & Safety Awareness training PC2 training course Hazardous Substances training SWP review date: January 2014 Responsibility for SWP review: Ken Wyse (ext. 52456) ______________________________________________________________________________________________________________________ Page 4 of 4 Safe Work Procedure Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 1.2, 15/08/2007