abstract68 - EUCOMC2011 Toulouse France

advertisement

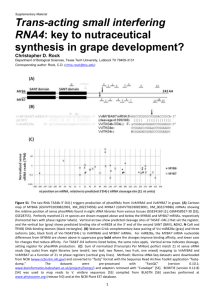

Screw pressing of grape seed: influence of process parameters on oil polyphenol content N. Rombaut*, R. Savoire**, E. Van Hecke*, J. Castello*, Lanoisellé* B. Thomasset***, J.-L. *Université de Technologie de Compiègne, EA 4297, Transformations Intégrées de la Matière Renouvelable, B.P. 20529 – 60205 Compiègne Cedex, France **Ecole Supérieure de Chimie Organique et Minérale, EA 4297, Transformations Intégrées de la Matière Renouvelable, 1 allée du réseau J.-M. Buckmaster – 60200 Compiègne, France ***Université de Technologie de Compiègne, UMR CNRS 6022, Génie Enzymatique et Cellulaire, B.P. 20529 – 60205 Compiègne cedex, France (E-mail : natacha.rombaut@utc.fr, r.savoire@escom.fr, jean-louis.lanoiselle@utc.fr) Abstract This paper focuses on the influence of process parameters on quality of screw pressed grape seed oil. Expression was carried out using a Komet screw press. In order to determine which of the four following process parameters (type of grape seeds (grape seed collected at different time), dye diameter, preheating of the barrel and screw rotation speed) could impact on oil yield and polyphenol content of the oil, a Taguchi L12 factorial design was used. Considering oil yield, both an effect of type of grape seeds and screw rotation speed were observed. Other results indicate that raw material had the major influence on temperature reached while pressing. Since temperature is expected to affect polyphenol content of oil, an effect of process parameters should be confirmed on polyphenol content of oil. Keywords. grape seed oil – screw pressing – Taguchi factorial design – total polyphenol INTRODUCTION Grape seed is one of the major by-product of wine production, by accounting for 38-52% of grape pomace on a dry matter basis. It benefits from a growing interest due to its high polyphenol content. These phenolic compounds, which are mostly known for their antioxidant properties, are also reported to be involved in a wide range of other biological activities (Maier et al., 2009). Grape seed contains around 13% of oil on a dry basis. Grape seed oil besides having a high level of linoleic and oleic acid is reported to contain phenolic acids. Bail et al., (2008) reported a total polyphenol content ranging from 59 to 115,5 µg/g Gallic Acid Equivalent (GAE) in grape seed oil samples. At industrial scale, oil is commonly expelled by a mechanical process: screw pressing (Zheng et al., 2005). Few to no researches report the effect of processing parameters on grape seed oil quality. The aim of our work was to evaluate the impact of process parameters (type of grape seeds, dye diameter, preheating temperature of the barrel and screw rotation speed) on the total polyphenol content of expelled grape seed oil and oil yield. METHODS Grape seeds (three types according to the time between grape pressing and drying), were air-dried prior to pressing. Table 1 states water, oil and polyphenol content of the different grape seeds samples. Table 1. Composition of grape seed samples : water, oil and polyphenol content Water content Oil content Polyphenol content Type of grape seeds (%) (% dry basis) (% dry basis GAE) Type 1 7,74 13,28 5,80 Type 2 6,09 13,54 9,50 Type 3 6,92 15,35 9,57 Oil expression was carried out on a Komet screw press (S87G model – 15 kg/h, IBG Monforts, Germany). A Taguchi experimental design L12 was used to study the effect of type of seeds, dye diameter (10 and 15 mm), preheating temperature of the screw head (90 and 120°C) and screw rotation speed (40 and 70 rpm) on oil polyphenol content and yield. In the result section, levels of factors listed are respectively coded 1, 2 and 3 in the case of grape seeds. Significance of factors was evaluated by ANOVA using the software XLSTAT (Addinsoft, France, 2010). Each experiment, consisting of a combination of type of seed, dye diameter, screw rotation speed, was performed once, sampling (oil and meal) being done during the steady state. During an experiment, temperature of the expelled oil as well as oil and cake flow rate were monitored. Screw pressed oils were centrifuged at 3079 g for 10 min, to recover sediments. Samples of oil, sediments and meal of each experiment were stored at -20°C until assessment of total polyphenol content in each fraction by Folin-ciocalteu assay (adapted method of Singleton et al., 1965). RESULTS 65 60 V2 55 50 45 1 2 3 1 2 1 V1 2 V1 Figure 1. Effect of significant screw pressing parameters on oil yield average oil temperature (°C) 70 V2 average oil yield (wt%, o/o) Figures 1 and 2 represent significant effects of process parameters on average oil yield and temperature of oil. The average oil yield is defined as the ratio of oil recovered from seeds as a percentage of oil originally present in the seeds. Each dot corresponds to the average response obtained for each process parameter: for example, around 53% (wt%) average oil yield was obtained for the experiments using the third type of grape seed. The medium line of each chart represents the average value for all experiments per parameter: an average oil yield of 56% (wt%) was achieved for the 12 experiments of the experimental design. Screw rotation Type of grape seed Dye diameter Type of grape seed speed 95 90 85 80 75 1 2 3 Figure 2. Effect of significant screw pressing parameters on oil temperature during expelling According to figure 1, the main effect on oil yield is due to the type of grape seeds, maximum yield is achieved with the first type of grape seeds at an average of 60% (wt%). Rotation speed also has a significant influence on the yield, the lowest speed (40 rpm) leading to the highest yield (average of 58% (wt%)). Dye diameter also has a significant influence, smallest diameter enables higher yield. The effect of type of grape seeds could be explained by composition of seed samples. On the one hand, differences between seed samples could be attributed to the variability due to the use of raw material, but on the other hand to a more or less efficient separation of grape seeds from pomace, leading to more dried grape skin in type 1 than in type 2 and 3. However, when compared to figure 2, screw pressing of the first type of grape seeds leads to the highest oil temperature (93°C). Statistical analysis shows no significant influence of the other factors, in the case of oil temperature. Although cold pressing was performed (no additional heating while processing), oil temperature are high, and might affect the polyphenol level of oil. Given those results, it could be concluded that the third type of grape seeds combined with the lowest rotation speed and smallest dye diameter would lead to the highest polyphenol content. The level of sediments in oil was also studied (results not presented here), indicating that the only significant parameter was the type of grape seeds: third type gave the lowest level of sediments. CONCLUSION Results indicate that raw material had the major influence on oil yield and temperature. To determine whether these parameters in turn affect the oil’s polyphenol level, results have to be compared to polyphenol content in oil. Polyphenol assay is currently in progress. The outcome of these trials will be a combination of factors expected to maximise both oil yield and polyphenol content in oil. The experimental design will be concluded by a confirmation trial to assess that no other parameters not considered in these experiments affect oil quality. REFERENCES Bail, S., Stuebiger, G., Krist, S., Unteweger, H., Buchbauer, G. (2008) Characterisation of various grape seed oils by volatile compounds, triacylglycerol composition, total phenols and antioxidant capacity. Food Chemistry, 108, 1122–1132. Maier, T., Schieber, A., Kammerer, D.R., Carle, R. (2009) Residues of grape (Vitis vinifera L.) seed oil production as a valuable source of phenolic antioxidants, Food Chemistry, 112, 551–559 Singleton, V. L., Rossi, J. A. (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungistic acid reagents. American Journal of Enology and Viticulture, 16, 144-158. Zheng, Y.L., Wiesenborn, D. P., Tostenson K., Kangas N., (2005) Energy analysis in the screw pressing of whole and dehulled flaxseed. Journal of Food Engineering, 66, 193–202.