Document 7846525

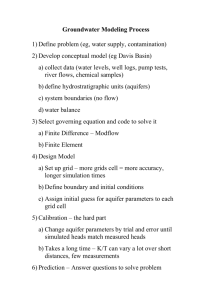

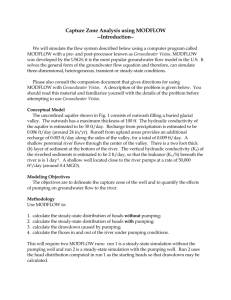

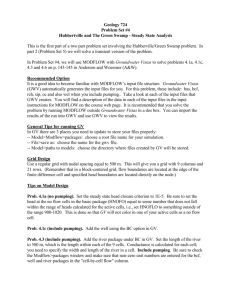

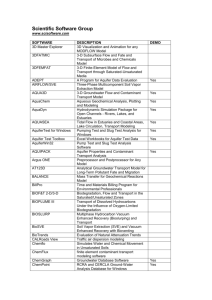

advertisement