QC - THE IDEA

James O. Westgard, Ph.D.

Outline of lesson

Need for QC?

A simple graphical tool - the QC chart

In the beginning, there was Shewhart

Learning the QC lingo?

Doing the deed

References

Please note: an updated version of this lesson is available in the Basic QC Practices, 2nd Edition.

Need for QC

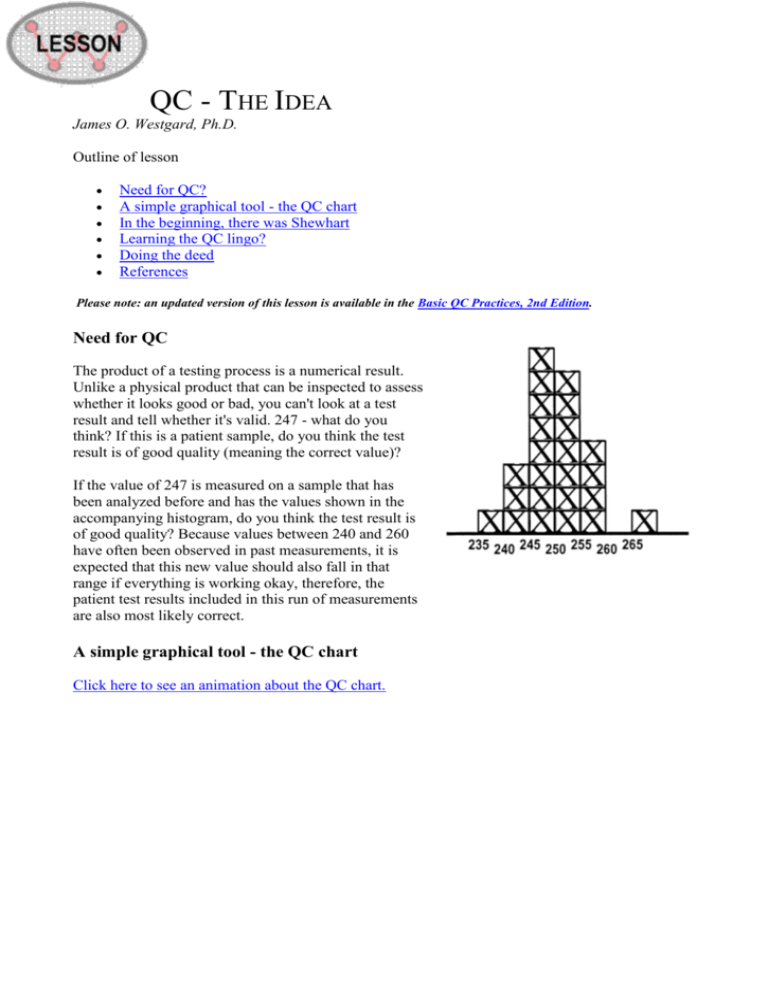

The product of a testing process is a numerical result.

Unlike a physical product that can be inspected to assess

whether it looks good or bad, you can't look at a test

result and tell whether it's valid. 247 - what do you

think? If this is a patient sample, do you think the test

result is of good quality (meaning the correct value)?

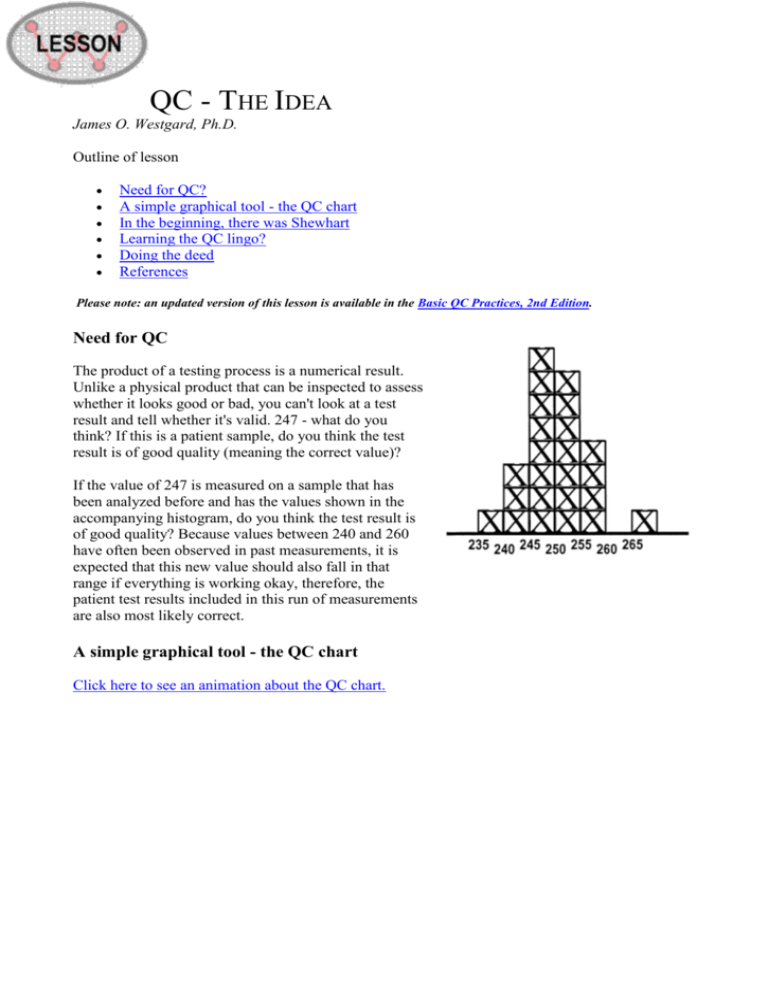

If the value of 247 is measured on a sample that has

been analyzed before and has the values shown in the

accompanying histogram, do you think the test result is

of good quality? Because values between 240 and 260

have often been observed in past measurements, it is

expected that this new value should also fall in that

range if everything is working okay, therefore, the

patient test results included in this run of measurements

are also most likely correct.

A simple graphical tool - the QC chart

Click here to see an animation about the QC chart.

In the laboratory, control charts

are used to make it simple to

compare today's observed value

with what is expected based on

past history. As shown in the

second figure, by turning the

histogram sideways and

spreading the results out

according to the time they were

collected, it is easy to see how

each observation compares to the

expected distribution of past

observations, which are shown by

the central line and certain limits

calculated from the mean and

standard deviation (SD) of the of

the past control data. In this

figure, the limit lines correspond

to the mean plus/minus 1 SD, 2

SD, and 3 SD. Assuming a

gaussian or normal distribution, it

would be expected that about

68% of the points fall within 1

SD of the mean, 95% within 2 SD of the mean and 99.7% within 3 SD of the mean. Therefore, it

would be very unexpected (0.3% chance) to observe a control value greater than 3 SD from the

mean and such an observation usually indicates there is a problem with the method. It is somewhat

unexpected to observe a control value greater than 2 SD from the mean, but this will happen at least

5% of the time when analyzing 1 control per run, so it may indicate a real problem or it may be a

false alarm. It is very common (32% chance) to see individual values beyond 1 SD from the mean,

therefore this control limit is of no value for making a judgment about method performance based

on a single control value.

That's the idea behind statistical quality control. See if you can get the right answer for a known

sample. The right answer is actually a range of values that are calculated from the mean and

standard deviation of past results. That mean and control limits can be shown on a control chart to

make it simple to plot new control measurements and see how they compare with the expected

range of values.

In the beginning, there was Shewhart

Walter A. Shewhart was a statistician at Bell Telephone Laboratories who developed the scientific

basis for statistical process control. Shewhart stated that "the object of industry is to set up

economic ways of satisfying human wants and in so doing to reduce everything possible to routines

requiring a minimum amount of human effort. Through the use of the scientific method, extended to

take account of modern statistical concepts, it has been found possible to set up limits within which

the results of routine efforts must lie if they are to be economical. Deviations in the results of a

routine process outside such limits indicate that the routine has broken down and will no longer be

economical until the cause of trouble is removed." Shewhart made this statement in the preface to

his book on the "Economic Control of Quality of Manafactured Product" that was published in

1931.

Statistical process control, from the beginning, has been concerned with achieving the desired

quality (satisfying human wants) at minimum cost (economic control). Shewhart identified critical

elements such as the expected variation of a routine process, a way to set limits that will identify

when the routine has broken down, and the need to eliminate causes of trouble when the process

was observed to exceed those limits.

Almost twenty years passed before Levey and Jennings introduced statistical control methods in

clinical laboratories in 1950 [2]. Shewhart's original recommendations called for making a group of

measurements, calculating the average and range (maximum difference), then plotting the average

and the range on two different control charts. Levey and Jennings proposed making duplicate

measurements on a patient specimen. Because the actual level of the measured constitutent varied

from specimen to specimen, this was a more difficult application. Henry and Segalove [3]

developed an alternative procedure in which a stable reference sample was analyzed repeatedly and

individual measurements were plotted directly on a control chart. This reference sample type of QC

in which individual values or single values are plotted directly is commonly known today as a

Levey-Jennings chart.

Since that time, industry has developed stable control products that mimic patient samples, thus

today there are safe QC materials readily available for most established tests. A better

understanding of the performance characteristics of QC procedures has been developed [4], which

has led to refinements such as the multirule procedure for evaluating and interpreting control data

[5]. Strategies for cost-effective operation have been further refined [6]. Computer programs have

been developed to implement statistical control procedures by performing the necessary

calculations, preparing graphical displays, applying the desired control rules, and alerting analysts

to problem situations. Today, support for handling control results is provided by most automated

analyzers, information systems, and even point-of-care devices.

Learning the QC linguage

Statistical process control is the general term used to describe those aspects of a control system in

which statistics are applied to determine whether observed performance is within the expected

variation of the process, in contrast to other components of a total control system such as preventive

maintainence, instrument function checks, operator training, etc., that are included in CLIA's broad

definition of quality control.

Statistical control procedure is used here to refer to a specific protocol for analyzing a specific

number of control materials and interpreting a specific number of test results. In healthcare

laboratories, a control procedure is usually implemented by collecting test results on stable control

materials, then plotting those control observations on a control chart that has specified control

limits, or by evaluating those control results by data calculations employing specified decision

criteria or control rules.

Control chart is a graphical method for displaying control results and evaluating whether a

measurement procedure is in-control or out-of-control. Control results are plotted versus time or

sequential run number; lines are generally drawn from point to point to accent any trends,

systematic shifts, and random excursions.

Control limits are lines drawn on a control chart to provide graphical criteria for assessing whether a

measurement procedure is in-control or out-of-control. These control limits are usually calculated

from the mean and standard deviation (SD, or s) determined for a given control material. Typically

the interpretation is based on a specified number of results or points exceeding a certain control

limit when in-control patient test results are reported. When out-of-control, the run is rejected and

no test results can be reported.

Control rule means a decision criterion for judging whether an analytical run is in-control or out-ofcontrol. It is commonly defined by a symbol of the form AL, where A is an abbreviation for a

statistic or represents a number of control measurements, and L identifies the control limits, often

specified as the mean plus or minus a multiple of the standard deviation (s) or sometimes by a

specified probability for false rejection (Pfr). Some examples follow:

13s refers to a control rule that is commonly used with a LeveyJennings chart when the control limits are set as the mean plus

3s and the mean minus 3s. A run is rejected when a single

control measurement exceeds the mean plus 3s or the mean

minus 3s control limit.

12s refers to the control rule that is commonly used with a LeveyJennings chart when the control limits are set as the mean

plus/minus 2s. In the original Westgard multirule QC procedure,

this rule is used as a warning rule to trigger careful inspection of

the control data by the following rejection rules.

22s - reject when 2 consecutive control measurements exceed the

same mean plus 2s or the same mean minus 2s control limit.

R4s - reject when 1 control measurement in a group exceeds the

mean plus 2s and another exceeds the mean minus 2s.

Run, analytical run, or run length refer to the interval, which could be a period of time or group of

samples, for which a decision on control status is to be made. CLIA defines a maximum run length

of 24 hours for chemistry analytes and 8 hours for hematology tests. Many laboratories define a

shorter period based on changes that may affect the performance of the testing process, such as

changing operators, changing reagents, recalibration, or other factors that may make the process

susceptible to problems. Run length varies from system to system and laboratory to laboratory. For

random access automated systems, a run is usually defined as the time interval at which controls are

reanalyzed. For manual systems and batch instruments, a run is often defined as a group (or batch)

of samples that are all analyzed at the same time.

Doing the deed

The idea is simple, but the application can be complicated.

First, you need to obtain control materials that are appropriate for the tests of interest and the

methods in use. See QC - the Materials for a discussion of important factors, such as matrix effects,

stability, vial to vial variation, assayed versus unassayed materials, analyte levels, and pre-treatment

problems.

Then you must assay the selected control materials under routine operating conditions to

characterize the expected measurement variation and establish the expected distribution of values.

This usually involves obtaining at least 20 values and calculating the mean and standard deviation.

There are a number of pitfalls from using bottle values or other estimates of the means, standard

deviations, and control limits, so you need to be careful with this step. See QC - the Calculations for

more information about data calculations.

Next you need to define appropriate control rules, numbers of control measurements (N), and the

analytical run length. See QC - the Regulations for the legal requirements for laboratory QC. See

QC - the Planning Process for a brief description of QC planning and links to other materials on this

website.

You must also define how you will implement these rules and Ns - manual plotting, or computer

assessment by the analyzer, a PC workstation, or a laboratory information system. For manual

implementation, see QC - the Levey-Jennings Control Chart for directions on how to prepare the

control chart, plot control results, and interpret control data.

Finally, you should prepare written guidelines to define the QC procedure in detail. This written

document is important for teaching laboratory analysts the QC procedure and establishing a uniform

practice. It is also necessary for meeting US regulatory requirements.

Now you're ready to implement QC. See QC - the Practice for a summary and review of the whole

approach. See FAQs about QC for additional information about some of the nitty- gritty problems

and issues with routine QC.

References

1. Shewhart WA. Economic Control of Quality of Manufactured Product. New York; D. Van

Hostrand Company, Inc., 1931.

2. Levey S, Jennings ER. The use of control charts in the clinical laboratory. Am J Clin Pathol

1950;20:1059-66.

3. Henry RJ, Segalove M. The running of standards in clinical chemistry and the use of the

control chart. J Clin Pathol 1952;27:493-501.

4. Westgard JO, Groth T, Aronsson T, Falk H, deVerdier C-H. Performance characteristics of

rules for internal quality control: probabilities for false rejection and error detection. Clin

Chem 1977;23:1857-67.

5. Westgard JO, Barry PL, Hunt MR, Groth T. A multi-rule Shewhart chart for quality control

in clinical chemistry. Clin Chem 1981;27:493-501.

6. Westgard JO, Barry PL. Cost-Effective Quality Control: Managing the Quality and

Productivity of Analytical Processes. Washington, DC:AACC Press, 1986.

Copyright © 2000. All rights reserved.

Westgard QC, Inc., 7614 Gray Fox Trail, Madison WI 53717

Call 608-833-4718 or e-mail westgard@westgard.com

A Message from JOW

QC Lessons | QC Applications | Questions | Multirule

CLIA Requirements | What's new? | Catalog | Demo Download

Home | Glossary | ARCHIVES | Links | Feedback

QC - THE MATERIALS

Elsa F. Quam, BS, MT(ASCP)

Control solutions, control materials

Matrix effects

Stability

Vial to vial variability

Assayed versus unassayed

Analyte levels

Pretreatment steps

Conclusions

References

PLEASE NOTE: An updated version of this lesson is available in Basic QC Practices, Second Edition

The purpose of a statistical quality control procedure is to monitor the analytical quality of the

measurement during stable operation, detect changes from the stable operation, and eliminate

reporting of results with medically important errors [1]. From the technologist’s standpoint, the

objectives of the control procedure are simply to "alert me when the method has a problem" and

"don't alert me when the method is working okay." These correspond to "true alarm" and "false

alarm" situations, which are characteristics of the QC procedure. In short, technologists want to

know about real problems, but can't afford to waste time when the method's working okay. Any

additional information that can aid in the troubleshooting the method is an "extra bonus."

Much has been written about how to perform the statistical calculations needed for quality control

procedures, how to choose control rules, how to apply the rules, how to construct control charts, and

how to interpret results from the control procedures, all of which assume we have found appropriate

stable control materials. We need to pay careful attention to the selection of the control materials.

Important attributes are the stability, vial to vial variability, assayed versus unassayed, appropriate

analyte levels, and pretreatment procedures. The very success of the control procedure depends

upon these attributes!

Control solutions, control materials

The International Federation of Clinical Chemistry defines a control solution or control material as

a "specimen or solution which is analyzed solely for quality control purposes, not for calibration"

[2]. We use the term control material or control product to refer to a control solution that is

available, usually commercially, in liquid, frozen, or lyophylized form, packaged in small bottles

suitable for use on a daily basis. Such control materials are widely available today for most

laboratory tests. They can be obtained from manufacturers who specialize in the production of

control materials, and also are often provided by the same companies who are selling you the

reagents, methods, and instrument systems. It is common today to purchase complete testing

packages that include the necessary control materials.

Matrix

Matrix refers to the substance or base from which the control material is prepared in addition to all

the additives such as spiking materials, preservatives, etc. added to make the product desirable to

the user. The American Society for Testing and Materials has defined matrix as " the principal

element or elements in a sample" and a matrix interference as "an effect due to the presence of a

constituent or characteristic."[3]

Ideally, control materials should have the same matrix as the specimens being tested so that they

will behave the same as the real specimen. For example, choose a whole blood control for point-ofcare blood glucose analyzers and for blood gas and whole blood electrolyte analyzers to maintain a

similar matrix; use a serum/protein based control for analyzers that perform tests on serum or

plasma. Control materials are also available having matrices of urine and spinal fluid. In general,

materials prepared from human sources have been preferred in the past, however because of the

potential biohazard risk today, bovine based control products have become more popular.

Control materials, even when selected to have the appropriate matrix, undergo a substantial number

of manipulations during their production which can alter the properties of the matrix. These

alterations include human and non-human additives for achieving specific concentrations and/or

stability as well as physical changes to the material such as freeze drying or lyophilization. These

alterations may in turn cause interferences in the testing process which may not be present in fresh

human samples.

Certain test methodologies may also influence the selection of control materials. For example, a

bovine based control material will usually assay low by a bromcresol purple albumin method,

which has been optimized for human albumin. In contrast, bovine controls are acceptable for use

with the less specific bromcresol green albumin method. For some assays, such as those used in

lipoprotein testing, fresh or frozen human pools may be the most appropriate control materials [4].

Careful consideration to the control material matrix is an important consideration in the QC

planning process.

Stability

When possible, it is desirable to purchase at least a one year supply of the same lot or batch number.

Many products are now available with expiration dates of more than two years. The desired

expiration date of the control product should be included in the specifications listed at the time of

purchase. This planning step will pay off in the ability to provide a continuous monitor of the

analytical process through many method and instrument changes, while reducing costs by

minimizing the crossover testing necessary during the checking out period of new control lot

numbers. It usually isn't necessary to purchase and store the entire lot for the duration of the

expected time of use because most vendors are willing to sequester specified lot numbers for the

desired period and set up automatic shipment and billing schedules at monthly, every other month,

or quarterly intervals. This strategy also has the advantage of not requiring payment or inventory

of the control materials until they are needed for use.

Vial to vial variability

The variation observed when monitoring a method is almost entirely due to measurement

imprecision and vial to vial variability of the control materials themselves, which is usually a small

part of the total variation observed. Commercial control materials that have been lyophilized or

freeze dried must be reconstituted with water or specialized diluent, therefore, it is very important to

standardize the reconstitution step. Use Class A volumetric pipettes, deonized Type 1 water, and

instructions that specify the mixing time and the reconstitution time to minimize the vial to vial

variability due to the preparation process.

Many liquid control products which eliminate the reconstitution process are now available. These

products are generally more expensive and sometimes contain additives or preservatives which

could introduce sources of error due to matrix problems with certain methods. Depending upon the

analytical methods to be monitored, the benefits of the reduced vial to vial variability may outweigh

any increased costs. In addition, liquid control products are generally stable for 14 to 30 days after

the vial has been opened whereas lyophilized products are usually only stable for less than 48 hours

after reconstitution. Liquid controls may therefore, in some cases, be a better buy because of

reduced waste due to stability, elimination of vial to vial to variability, and reduction in operator

errors due to the reconstitution process.

Assayed versus unassayed controls

Control products are available as assayed or unassayed materials. Assayed control materials

generally come with an assay sheet of expected values for analytes assayed by various methods and

instrument systems. These assay sheets usually list, for each constituent present, expected mean

values as well as expected ranges. Values may even be available for reference methods used to

measure certain analytes. These ranges are provided only as guidelines until the laboratory has

established its own statistical limits. Assayed controls are generally more expensive than unassayed

controls due to the cost incurred with the value-assignment process. They may, however, be

valuable for the smaller laboratory, for meeting CLIA regulations, and for troubleshooting method

problems.

Analyte levels

Constituent levels of quality control materials should be chosen at medical decision concentrations

and/or at critical method performance limits such as upper and lower linearity limits. Two or three

different concentrations are often needed for each analyte. Choosing control materials at critical

concentrations (medical and/or performance) will allow the analyst to estimate the random error at

critical levels of the method during stable operation and to provide a monitor at the most important

performance levels for that analyte. Statland has provided recommendations for decision levels for

many tests [5], which are summarized in tabular form on this website.

Vendors manufacture sets of materials to have critical concentration levels and also to monitor the

working range of a method. Purchase of these materials will often include the services of a quality

control program. Services provided by these quality control programs include statistical

calculations of your laboratory data, preparation of Levey Jennings plots using your mean and

standard deviation, and a comparison report which compares your monthly and cumulative statistics

to those of a peer group of users using same lot number of materials. Costs for these programs are

usually included in the cost of the control materials. An alternate option is to select materials from

different vendors in order to minimize possible matrix problems that may be inherent in all

materials from a single vendor.

Pretreatment steps

Many laboratory tests such as digoxin, hemoglobin A1C, and total iron binding capacity require

pretreatment of the specimen prior to determination by the analytical process. These procedures

often require manual pipetting and mixing steps which are more problem prone that the analytical

determination. It is best, for these procedures, to have control materials that are submitted to the

pretreatment steps and are therefore treated exactly as the specimen being tested. If the analytical

method is also problem prone, it may be advantageous to select one or two control materials which

do not undergo the pretreatment process in addition to the one or two materials which are included

in the pretreatment. This strategy will aid the analyst, when errors occur, by isolating the analytical

process from the pretreatment process.

Conclusions

The selection of appropriate control materials requires consideration of many factors and should be

part of the planning process for the selection and implementation of SQC. The process becomes

even more complicated when selecting control materials suitable for a multiconstituent analyzer.

Compromises may have to be made in order to limit the number of control materials used. There is

no right or wrong way to choose control materials for a given method, just as there is no perfect

control which behaves exactly the same as a fresh human sample. Selection of appropriate control

materials is a balancing act in which cost, stability, ease of use, performance due to matrix effects,

and constituent levels must be considered and weighted for each laboratory’s own application and

use.

Control materials being used should be reassessed yearly. Product vendors are continually making

changes and enhancements in their products so that these products are more marketable. Presently,

it is hard to keep abreast of all the changes in immunoassay control products as vendors are

scurrying to provide materials with constituents to fit the test menus of these new analyzers. Other

quality control services and enhancements are also being provided by instrument vendors. Some

instrument manufacturers will be offering quality control troubleshooting services by using a

modem hookup to review QC measurements from the instrument at the laboratory site. Of course,

control materials purchased from the instrument vendor must be used to obtain the service. The

selection of control materials is an important consideration in the statistical quality control planning

process and must be reviewed as our needs change.

References

1. Westgard JO, Barry PL. Cost-Effective Quality Control: Managing the Quality

andProductivity of Analytical Processes. Washington DC;AACC Press, 1986.

2. Buttner J, Borth R, Boutwell JH, Broughton PMG. International Federation of Clinical

Chemistry provisional recommendation on quality control in clinical chemistry. I. General

principles and terminology. Clin Chem 1976;22:532-40.

3. ASTM Committee on Terminology. Compilation of ASTM standard

definitions. Philadelphia, PA: American Society for Testing and Materials,

1990.

4. Handbook of Lipoprotein Testing, edited by Nader Rifai, G. Russell Warnick, Marek H.

Dominiczak, Chapter 11: Matrix Effects in the Measurement and Standardization of Lipids

and Lipoproteins written by W. Greg Miller.

5. Statland BE. Clinical Decision Levels for Lab Tests. Oradell, NJ;Medical Economic Books,

1983.

Copyright © 2000. All rights reserved.

Westgard QC, 7614 Gray Fox Trail, Madison WI 53717

Call 608-833-4718 or e-mail westgard@westgard.com

A Message from JOW

QC Lessons | QC Applications | Questions | Multirule

CLIA Requirements | What's new? | Catalog | Demo Download

Home | Glossary | ARCHIVES | Links | Feedback

QC - THE CALCULATIONS

James O. Westgard, Ph.D.

Outline of lesson

What calculations?!

Mean, SD, CV

Control Limits

Cumulative or lot-to-date calculations

Z-scores, SDI's

PLEASE NOTE: an updated version of this lesson is available in Basic QC Practices, 2nd Edition

What Calculations?

Are any calculations necessary if the control material has an assay sheet that

lists the range of acceptable values for my method?

Yes, you still need to collect your own control measurements and calculate the control limits that

apply in your own laboratory. Values and limits found on assay sheets often describe the

performance observed by a specific method in several different laboratories, which means that the

figures are likely to include variations that occur between laboratories. Therefore, those limits are

likely to be too wide for an individual method in your laboratory. If the control limits are too wide,

you won't be able to detect problems in your own laboratory.

Note that US CLIA regulations require that the laboratory determine it's own mean and standard

deviation. [493.1218(5d) "When calibration or control materials are used, statistical parameters

(e.g., mean and standard deviation) for each lot number of calibration material and each lot of

control material must be determined through repetitive testing."]

What statistics need to be calculated to establish my own control limits?

You need to calculate the mean and standard deviation from the control results that have been

collected for each control material. It's also common to express the standard deviation in percent by

calculating a coefficent of variation, or CV.

Mean, SD, CV

How many control measurements should be collected before making these

calculations?

The rule of thumb is to collect at least 20 measurements over at least 2 weeks or 10 working days,

and preferably over at least 4 weeks or 20 working days. You do this by including control materials

as part of your daily work for a long enough period to observe the variation expected in your

laboratory. Too short a period leads to too small an estimate of the standard deviation. Longer is

usually better because the estimates will include more operators and more method changes, such as

pre and post maintenance performance, changes in reagent lot numbers, sample probes or pipettes,

etc., thus even one month might be too short a period. In practice, calculations of the mean and

standard deviation are often made monthly and then the monthly data are added to data from

previous months to calculate the cumulative or lot-to-date mean and standard deviation that are then

used for setting control limits. These cumulative or lot-to-date control limits are a better

representation of long term test performance.

How many significant figures are needed in the control results that are used to

estimate the mean and standard deviation?

Control results should have at least one more significant figure than the values reported for patient

test results in order to get good estimates of the mean and standard deviation and to be able to set

appropriate control limits. With some instrument systems where test results are rounded for clinical

significance, only whole numbers end up being reported for control results, thereby giving a

discrete distribution of control values with only a few possible results, rather than the continuous

gaussian distribution that is expected. This may lead to some practical problems in setting control

limits because the calculated control limits may not correspond to the discrete integer values being

reported.

What is the equation for the mean?

The mean is determined by adding a group of measured values, then dividing the total by the

number of measurements in the group. This is often written as:

where the mean may be symbolized by, an x with a bar over it (hence the term x-bar), xi

represents an individual measurement, represents the operation of summation or addition of all

these xi values, and n is the number of xi values in the group. Using just 3 numbers for an example

(which is not sufficent data according to the current laboratory practice of obtaining a minimum of

20 results), for the values of 100, 105, and 98, xi is the total of these three or 303, and the mean or

average is 303/3 or 101.

What's a practical way to calculate the mean?

Hand held calculators can be used to easily calculate the total of a group of measurements, then

divide that total by the number of measurements included. Scientific calculators usually have a

built-in program for both the mean and standard deviation. Electronic spreadsheets, such as Lotus 12-3 and Excel, usually have built-in functions for calculating the mean and standard deviation from

a column of data. Statistical programs, such as Minitab, SPSS, SAS, and Systat have functions for

calculating the mean and standard deviation, as well as describing the population in terms of the

observed median, mode, range, lowest value, highest value, etc.

In most laboratories, the QC program in the laboratory computer system will calculate the control

data captured on-line or through manual entry. The QC programs incorporated in instrument

systems and some Point-of-Care devices have similar capabilities. Stand alone QC programs on

personal computers are also available and offer complete support for calculations, graphic displays

of control charts, and storage of results. Participants in external survey programs offered by

instrument or control manufacturers can also submit their control data for analysis by the vendors,

though the data analysis may require up to a month for return of the results.

What does the mean tell me about method performance?

The mean value for a control material provides an estimate of the central tendency of the

distribution that is expected if method performance remains stable. Any change in accuracy, such as

a systematic shift or drift, would be reflected in a change in the mean value of the control, which

would be shown by a shift or drift of the distribution of control results. Always keep in mind that

the mean is related to accuracy or systematic error and the standard deviation is related to precision

or random error. See QC - The Idea for a review of how the mean of the distribution of control

results is related to the mean and control limits on a control chart.

What is the equation for the standard deviation?

The standard deviation is determined by first calculating the mean, then taking the difference of

each control result from the mean, squaring that difference, dividing by n-1, then taking the square

root. All these operations are implied in the following equation:

where s represents the standard deviation, means summation of all the (xi - )2 values, xi is an

individual control result, is the mean of the control results, and n is the total number of control

results included in the group.

For computerized calculations and for estimating the cumulative standard deviation, the form of the

equation that is commonly used is:

where xi2 is the summation of

all the squared individual values,

and ( xi)2 is the square of the

sum of all the individual values.

What's a practical way to

calculate the standard deviation?

It is easy to use a scientific calculator, an electronic spreadsheet, or a statistics program, all of which

have built-in functions for calculating the standard deviation of a group of measurements. This

function for calculating the standard deviation is often labeled "SD". Specialized QC software in

laboratory information systems, instruments, and personal computer workstations will automatically

calculate the standard deviation for the data being accumulated. External quality assessment

programs offered by manufacturers of instruments and control materials will also process the data

of participants and provide reports that include the calculated results.

What does the standard deviation tell about method performance?

The standard deviation is related to the spread or distribution of control results about the expected

mean. Whereas the mean is an indicator of central tendency and therefore related to accuracy or

systematic error, the standard deviation is a measure of the width of the distribution and is related to

imprecision or random error. The bigger the standard deviation, the wider the distribution, the

greater the random error, and the poorer the precision of the method; the smaller the standard

deviation, the narrower and sharper the distribution, the smaller the random error, and the better the

precision of the method.

For a measurement procedure, it is generally expected that the distribution of control results will be

normal or gaussian, as shown above. For a gaussian distribution, the percentage of results that are

expected with certain limits can be predicted. For example, for control results that fit a gaussian

distribution, it would be expected that 68.2% of the observed results will be within plus/minus 1s of

the mean; 95.5% within plus/minus 2s of the mean, and 99.7% within plus/minus 3s of the mean.

What's a CV?

CV refers to the "coefficient of variation," which describes the standard deviation as a percentage of

the mean, as shown in the following equation:

CV = (s/ )100

where s is the standard deviation,

ratio to a percentage.

is the mean, and the multiplier of 100 is used to convert the s/

Why is a CV useful?

The standard deviation of a method often changes with concentration, i.e., the larger the

concentration, the larger the standard deviation, therefore it is usually necessary to estimate the

standard deviation at the concentration level of interest. Because the CV reflects a ratio of the

standard deviation to the concentration, it is often provides a better estimate of method performance

over a range of concentrations.

For example, you may be interested in planning a QC procedure on the basis of the performance

needed at a critical decision concentration of 200 mg/dL, but the nearest control available has a

mean of 190 mg/dL. Therefore, it is best to calculate the CV from the observed results at 190

mg/dL, then apply that CV to the 200 mg/dL decision level. This is the reason that QC planning

applications with the QC Validator program use a percentage figure for the imprecision of the

method.

Control limits

How do you calculate control limits?

Given the mean and standard deviation for a control material, control limits are calculated as the

mean plus and minus a certain multiple of the standard deviation, such as 2s or 3s. For cholesterol

where a control material has a mean of 200 mg/dL and a standard deviation of 4 mg/dL, the 2s

control limits would be 192 and 208 mg/dL, and the 3s control limits would be 188 and 212 mg/dL.

See a web-based Control Limit calculator in the lesson, QC - The Levey-Jennings Chart

How many significant figures should be used in control limit calculations?

As a rule of thumb, the control results and the calculated standard deviation should have at least one

more significant figure than needed for clinical significance of the patient test result; the mean of a

control material should include at least two more significant figures than needed for clinical

signficance of the patient test result. When in doubt, carry more significant figures than necessary

and round at the end when the control limits have been calculated. Most calculators and computers

carry plenty of extra figures so you can round at the end.

Cumulative or lot-to-date calculations

What's a cumulative or lot-to-date control limit?

Typically, control results are summarized by calculating the mean, standard deviation, CV, and N

on a monthly basis. In order to establish longer term estimates of the mean and standard deviation,

the control data or calculated results need to be accumulated to describe performance observed over

a longer periods of time. Longer term limits are often described as "cumulative limits," which

indicates they have been calculated from cumulative means and standard deviations. These may

also be referred to as "lot to date" limits when these calculated values are provided by a

manufacturer or supplier who processes the control data for a group of laboratories in order to

provide information about the comparative performance between laboratories and between

methods.

What's a cumulative standard or lot-to-date deviation?

This is a long term estimate of a method's precision performance based on a large number of control

measurements collected over a long period of time. A long period here is at least two months and

could be several months, even a year.

How is a cumulative or lot-to-date standard deviation calculated?

These calculations are often automatically performed by the QC programs in laboratory computer

systems, personal computer work stations, and in many automated instruments and even some

point-of-care devices.

If you need to perform these calculations yourself, one practical approach is to calculate monthly

statistics, then tabulate the month n's, xi and xi2, which can then be totaled and used in the

equation below to provide the cumulative estimate:

where nt( xi)t2 is the total of the sums of all the squared individual values, and ( xi)t2 is the square

of the total of the sums of all the individual values, and nt is the total number of measurements in

the time period of interest.

What's a cumulative or lot-to-date mean?

This is a long term estimate of the central tendency observed for a control material based on a large

a number of control measurements collected over a long period of time. A long period here is at

least two months and could be several months, even a year. Changes in the accuracy of a method

could lead to shifts or drifts in the mean observed for a control material.

How is a cumulative or lot-to-date mean calculated?

From the monthly statistics that are calculated, tabulate the monthly n's and xi's, which can then be

totaled for the period of interest (two months, several months), and used in the equation below to

provide the cumulative mean:

where ( xi)t is the total of the monthly sums of individual values and nt is the total of the monthly

ns for the period of interest.

How are cumulative or lot-to-date control limits calculated?

The estimates for the cumulative or lot-to-date mean and standard deviation, as calculated above,

are used to calculate cumulative or lot-to-date control limits. Here's a table that illustrates the whole

procedure.

(Cumulative results are show in parentheses.)

Monthly total (cumulative total)

Month

1

Calculated statistics

Control Limits

n

x

x2

Mean

s

Mean +/- 3s

20

3983

793465

199.15

3.63

188.3 - 210.0

20

3993

797537

199.65

4.20

187.1 - 212.2

2

(40)

20

(7976)

4002

(1591002)

801138

(199.40)

200.10

(3.86)

4.22

(187.8 - 211.0)

187.5 - 212.7

3

(60)

20

(11978)

4020

(2392140)

808182

(199.63)

201.00

(3.97)

2.92

(187.7 - 211.6)

192.2 - 209.8

4

(80)

20

(15998)

3995

(3200322)

798259

(199.96)

199.75

(3.77)

3.68

(188.7 - 211.3)

188.7 - 210.8

5

(100)

(19993)

(3998581)

(199.93)

(3.73)

(188.7 - 211.1)

See a web-based QC calculator that performs these calculations.

Z-scores and SDI's

What's a z-score?

A z-score is a calculated value that tells how many standard deviations a control result is from the

mean value expected for that material. It is calculated by taking the difference between the control

result and the expected mean, then dividing by the standard deviation observed for that control

material. For example, if a control result of 112 is observed on a control material having a mean of

100 and a standard deviation of 5, the z-score is 2.4 [(112- 100)/5]. A z-score of 2.4 means that the

observed control value is 2.4 standard deviations from its expected mean, therefore this result

exceeds a 2s control limit but not a 3s control limit.

Why is a z-score useful?

It is very helpful to have z-scores when you are looking at control results from two or more control

materials at the same time, or when looking at control results on different tests and different

materials on a multitest analyzer. You can quickly see if any result exceeds a single control limit,

for example, a z-score of 3.2 indicates that a 3s control limit has been exceeded. You can also look

for systematic changes or trends occurring across different control materials, for example,

consecutive z-scores of 2 or greater on two different control materials.

What's an SDI?

If you participate in an external quality assessment program or a proficiency testing program, you

are asked to analyze a series of unknown specimens and submit your test results for comparison

with those obtained by other laboratories. The data from all the laboratories are usually

analyzed to determine an overall average and standard deviation for the group. The program will

generally report your performance relative to the group. The difference between your test results

and the overall average is often expressed by a standard deviation index, or SDI, which expresses

the difference in terms of the number of standard deviations from the overall mean. For example, an

SDI of 1.0 would indicate your result fell one standard deviation from the mean. On a series of

specimens, if you observe SDIs such as +1.5, +0.8, +2.0, +1.4, and +1.0 (all positive), this suggests

that your method is generally running on the high side and is biased, on average, by +1.3 SDI. To

figure the size of this average bias in concentration units, you need to multiply by the actual value

of the group SD.

Note the similarity between the calculation of the SDI and the z-score. They're basically the same

thing, but the z-score tends to be used in internal QC programs to compare an individual QC result

with the expected values for that material, whereas the SDI tends to be used in external QC

programs to compare the performance of the lab with the overall mean for a defined comparative

group or with an established target value.

Why's an SDI useful?

One advantage is that it allows you to inspect results from many different tests at the same time,

without having to think about different units and the actual magnitude of the change in the units of

the test. In general, any SDI of 2.0 or greater deserves some special concern, regardless what the

test is. Any test whose average SDI is 1.0 or greater deserves some special attention because your

method shows a systematic difference from the group. In the future, this bias might lead to

unacceptable results.

Copyright © 2000. All rights reserved.

Westgard QC, 7614 Gray Fox Trail, Madison WI 53717

Call 608-833-4718 or e-mail westgard@westgard.com

A Message from JOW

QC Lessons | QC Applications | Questions | Multirule

CLIA Requirements | What's new? | Catalog | Demo Download

Home | Glossary | ARCHIVES | Links | Feedback

QC - THE REGULATIONS

Sharon S. Ehrmeyer, Ph.D.

HCFA and COLA

CLIA QC Requirements based on Test Complexity

Waived tests

Provider Performed Microscopy

Moderate Complexity Tests

High Complexity Tests

What if a control fails to meet criteria for acceptability?

JCAHO

Standards for Quality Control

CAP

Guidelines for Quality Control

References

If you perform laboratory tests in the US, the government's got you covered! One way or another,

you have to comply with the Clinical Laboratory Improvement Amendments of 1988 (CLIA’88),

which establish the minimum standards for all laboratory testing, including specific regulations for

quality control [1]. You can, however, select the organization that will administer these regulations

or administer professional standards that are equivalent to these regulations:

The Health Care Financing Administration (HCFA) will inspect any size laboratory,

including physician office laboratories, for adherence to the CLIA standards;

The Commission of Office Laboratory Accreditation (COLA) inspects only physicians

office laboratories for adherence to COLA standards which closely parallel the CLIA

regulations;

The Joint Commission on Accreditation of Healthcare Organizations (JCAHO) inspects

laboratories as part of an overall inspection of a hospital or healthcare organization;

The College of American Pathologists Laboratory Accreditation Program (CAP-LAP)

mainly inspects large laboratories directed by pathologists.

There are other government approved organizations that have standards for laboratories to follow

and some states impose specific requirements [2].

Health Care Financing Administration (HCFA) and Commission of Office

Laboratory Accreditation (COLA) Requirements for QC

The first part of this discussion focuses on CLIA’88 and COLA regulations [1,3] since COLA's 200

question checklist adheres to the CLIA’88 QC requirements almost exactly. Professional standards

administered via CAP and JCAHO are considered later.

CLIA QC Requirements based on Test Complexity

CLIA'88 regulations are based on four categories of test complexity: waived, provider performed

microscopy (PPM), moderate complexity, and high complexity. Current information on test

complexity can be obtained from the CDC’s web site (http://www.cdc.gov/phppo/dls/testcat.htm).

Each testing category has different regulatory requirements for personnel, quality control, quality

assurance, proficiency testing, etc.

Waived testing

This category requires the least regulation. Under CLIA and COLA, the minimum requirement for

anyone performing waived testing is to follow the manufacturers’ directions for QC, and if no

directions are included, to follow good laboratory practices. No specific QC requirements are

identified. Good laboratory practice would dictate that controls be run and results documented and

reviewed for correctness before reporting patient results. The tests that are waived include the

following (current September 29, 1997 list of Waived Tests):

Dipstick or tablet reagent urinalysis for bilirubin, glucose, hemoglobin, ketones, leukocytes,

nitrite, pH, protein, specific gravity, and urobilinogen

Fecal occult blood

Ovulation tests - visual color comparison tests

Urine pregnancy tests - visual color comparison tests

Erythrocyte sedimentation rates - non-automated

Blood glucose - all glucose monitoring devices cleared by FDA for home use; HemoCue BGlucose System, and Cholestech L.D.X.

Hemoglobin - (non-automated) by copper sulfate; (automated) by HemoCue Hemoglobin

System

Hematacrit - all spun microhematocrit procedures, Wampole STAT-CRIT, Separation

Technology STI HemataSTAT II and Model C70, StatSpin Technologies CritSpin, and

Vulcon Technologies Microspin 24, Protime - ITC (International Techidyne Corp.) and

BMC CoaguChek

H. pylori -- Serim Pyloritek Test Kit, GI Suppy HP-FAST, Quidel QuickVue One-Step for

whole blood, Delta West CLOtest, Abbott FlexPack HP, ChemTrak AccuMeter, and

SmithKline FlexSure

Strep A (throat only) Quidel QuickVue In-Line One-Step, Binax NOW, Abbott Signify and

SmithKline ICON Sx

Cholesterol -- Cholestech L.D.X., BMC Accu-Chek InstantPlus, ChemTrak AccuMeter, and

J & J ADVANCED CARE

HDL Cholesterol -- Cholestech L.D.X.

Triglyceride -- Cholestech L.D.X

Gastric occult blood -- SmithKline Gastroccult

Micro albumin -- BMC Chemstrip Micral

All qualitative color comparison pH testing for body fluid (other than blood)

To keep up to date with all the new test additions and new methodologies for waived tests, you can

check the CDC Web site [http://www.cdc.gov/phppo/dls/clia.htm].

Provider Performed Microscopy (PPM)

As of January 1993, the category "Physician-Performed Microscopy" was established under

CLIA’88. In the April 24, 1995 Federal Register, the category was renamed to "ProviderPerformed Microscopy." This category is a subset of moderate complexity and is exclusively for

physicians, dentists, nurse practitioners and midwives, and physician assistants performing the

testing as part of a patient examination. The primary instrument for performing the test(s) is the

microscope.

The 9 tests identified under a PPM CLIA certificate can be performed, as well as waived tests.

When these tests are provided, the practitioners are expected to follow the manufacturers’ directions

for QC or follow good laboratory practices. Good laboratory practice would dictate that controls be

run whenever possible and results documented and reviewed for acceptability before reporting

patient results. The PPM category includes:

all direct wet mount preparations (suspended in saline or water) for the presence or absence

of bacteria, fungi, parasites, and human cellular elements

KOH preps

pinworm exams

fern tests

post-coital direct qualitative exams of vaginal or cervical mucous

urine sediment exams

nasal smears for granulocytes

fecal leukocyte exams

qualitative semen analysis (limited to the presence or absence of sperm and detection of

motility).

Moderate Complexity Tests

Approximately 75% of all tests performed in laboratories today fall in the category of moderate

complexity. For this category, the QC requirements are identified in subpart K for CLIA’88 -Quality Control. Originally, in the February 28, 1992 Federal Register, HCFA stated that as of

September 1, 1994, laboratories would meet most of CLIA'88 QC requirements simply by

following manufacturers' labeling, provided the FDA approved manufacturers' QC instructions.

This never happened and the implementation date (9/1/94) has now been suspended, in the May 12,

1997 Federal Register, until at least 7/31/98.[5] Until HCFA implements new QC requirements,

laboratories performing moderate complexity tests will meet the CLIA QC requirement by

following sections §493.1201 and §493.1202(c) only.

Section §493.1201 (general QC: moderate or high complexity testing, or both) states: The

laboratory must establish and follow written QC procedures for monitoring and evaluating the

quality of the analytical testing process of each method to assure the accuracy and reliability of

patient test results and reports.

Section §493.1202(c) identifies the specific requirements for unmodified moderate complexity

tests: [1,4]

follow manufacturer directions;

have a procedure manual for the method that identifies how to perform the testing and

reporting of results;

perform and document calibration procedures or check calibration at least once every six

months;

assay at least two levels of control materials each day of testing (a run cannot exceed 24

hours) and keep records;

perform and document any applicable specialty and subspecialty control procedures;

perform and document remedial actions as specified in §493.1219;

maintain records of all QC activities for 2 years or 5 years for immunohematology and 10

years for pathology as specified in §493.1221.[4]

As you can see, CLIA QC includes a lot more than traditional statistical QC and defines standards

for calibration, procedure manuals, remedial actions and record keeping. Concerning statistical QC,

for most moderate complexity tests, the general requirement is to analyze two levels of QC

materials on each day of testing. However, for certain tests, i.e., blood gases, hematology and

coagulation tests, etc., CLIA requires additional QC:

Blood gases require, at a minimum, one control sample every 8 hours of testing and a

calibrator or control in each run unless the instrument "autocals" at least every 30 minutes.

Automated hematology and coagulation test systems require two levels of controls every 8

hours of testing and each time a change in reagent occurs.

Manual cell counts using a hemocytometer must be tested in duplicate and one control is

required every 8 hours of operation.

For manual coagulation testing, each analyst must perform two levels of controls before

testing patient samples and with each change in reagent. In addition, patient and control

samples must be tested in duplicate.

With electrophoresis, one control needs to be included in each electrophoretic cell and the

control must contain fractions representative of those routinely reported in patient samples.

For toxicology, each thin layer chromatogrophy (TLC) plate must be spotted with at least

one sample of calibration material containing all drug groups reported by the laboratory with

TLC, one control must be included in each chamber, and the sample must be processed

through each step of patient testing including extraction.

Qualitative tests with built-in controls are adequate provided the kit has been qualified with

at least one positive and negative control. CAP requires one positive (external) and one

negative (external) control per day.

For those methodologies where the manufacturer specifies, surrogate or electronic controls

may be used to fulfill the daily QC requirement. In all cases, the appropriate number of

controls (two levels per day for most analytes) must be included and the results must be

documented and reviewed to ensure the adequacy of the testing process.

In all cases, documentation of both the QC results and the specific remedial action to "out of control

results" must be available to the inspector.

High Complexity Tests

This category includes those tests that are modified by the laboratory, developed by a laboratory, or

a test classified as high complexity under CLIA. Laboratories under CLIA and COLA also must

comply with Section §493.1201 (general QC): The laboratory must establish and follow written QC

procedures for monitoring and evaluating the quality of the analytical testing process of each

method to assure the accuracy and reliability of patient test results and reports. Section §493.1202

states for each test of high complexity performed, the laboratory must meet all applicable standards

of this subpart (subpart K). For statistical QC, laboratories must be in compliance with the

following sections:

§493.1218: Control procedures are performed on a routine basis to monitor the stability of

the method or test system; control and calibration materials provide a means to indirectly

assess accuracy and precision of patient test results. Control procedures must be performed

as defined in this section unless otherwise specified in sections §493.1223 through

§493.1285 (these state specific QC requirements for blood gases, hematology, etc.).

§493.1218(b) for each method that is developed in-house, is a modification of the

manufacturer’s test procedure, or is a method that has not been cleared by the FDA as

meeting the CLIA requirements for general QC (all highly complex methods), the laboratory

must evaluate instrument and reagent stability and operator variance in determining the

number, type, frequency of testing calibration or control materials and establish criteria for

acceptability used to monitor test performance during a run of patient specimen(s).

§493.1218(d)(1) The stated values of an assayed control material may be used as the target

values provided the stated values correspond to the methodology and instrument employed

by the laboratory and are verified by the laboratory.

§493.1218(d)(2) Statistical parameters for unassayed materials must be established over

time by the laboratory through concurrent testing with calibration materials or control

materials having previously determined statistical parameters. (The statistical parameters,

e.g. mean and SD, for each lot number must be determined through repetitive testing).

§493.1218(e) Control results must meet the laboratory's criteria for acceptability prior to

reporting patient test results. Laboratory criteria for acceptability refers to the particular

control limits or control rules chosen by the laboratory.

What if a control fails to meet criteria for acceptability?

Regardless how a test has been classified, the regulations require "remedial action and

documentation of this activity. Section 493.1219(b) Remedial actions states that when: "Results of

controls and calibration materials fail to meet the laboratory's established criteria for

acceptability, all patient test results obtained in the unacceptable test run or since the last

acceptable test run must be evaluated to determine if patient test results have been adversely

affected and the laboratory must take remedial action necessary to ensure the reporting of accurate

and reliable patient test results.

Joint Commision on Accreditation of Healthcare Organizations (JCAHO)

Requirements for QC

The requirements identified for CLIA’88 and COLA also are applicable to JCAHO. Under JCAHO

[6], the goal of QC is to achieve quality in laboratory testing and produce the best possible test

results and outcomes. Additional JCAHO requirements are found for the different test classification

categories.

JCAHO and Waived Testing

JCAHO recognizes waived tests as defined by CLIA'88, but identifies additional QC requirements

that include:

Defined QC checks that at least meet the minimum manufacturer's recommendations (when

no QC requirement is specified, the testing institution must define a policy);

Maintenance of appropriate QC and test records;

Proof of training and continued competence of all testing personnel;

Proof all testing personnel have access to current written procedures for QC and remedial

actions.

Maintenance of QC records, including a mechanism to correlate or link analyst, QC records,

instrument and instrument problems, and individual patient test results.

For glucose, at a minimum two levels of controls are required each day a glucose is

performed. QC is focused on each meter used, not each individual performing the test.

Therefore, not all testing personnel need to routinely perform QC, but each meter must be

validated by QC before testing patient samples.

JCAHO and Moderate Complexity Tests

For moderate complexity tests, JCAHO, for the most part, follows CLIA'88 and mandates the same

seven QC requirements as CLIA’88 and COLA and also accepts electronic controls for now.

However, for use of electronic controls, JCAHO requires that the laboratory verify the

manufacturer’s QC claims and run external (usually liquid) controls periodically to validate that no

change occurred with the testing system.

JCAHO and High Complexity Testing

Testing sites must follow all the CLIA QC requirements for high complexity tests as well as for any

modified moderate complexity tests (this includes not following the manufacturer’s directions) and

tests developed in-house.

JCAHO Standards for Quality Control

In addition to the requirements identified above, JCAHO requires that all testing sites meet the

following standards associated with quality control.

General QC Requirements:

(QC.1) Each specialty and subspecialty (of testing) has a documented quality control

program.

(QC.1.3) The laboratory’s QC system includes daily surveillance of results by appropriate

personnel.

(QC.1.4) The laboratory takes remedial action for deficiencies identified through QC

measures or authorized inspections and documents such actions.

(QC.1.5) The laboratory ensures that QC results meet its criteria for acceptability before it

reports patient test results.

Clinical Chemistry QC Requirements:

(QC.6) Using appropriate controls, the laboratory verifies each procedure in clinical

chemistry at least once each day of use.

(QC.6.2) Using repetitive testing, the laboratory establishes control ranges with valid

statistical measurements for each procedure in chemistry.

(QC.6.3) The laboratory has established and makes available to its staff acceptable limits for

all standard and reference QC samples, as well as the action to take when results are outside

satisfactory control limits.

(QC.6.4) The laboratory established test control limits to provide results with meaningful

clinical applications.

Hematology and Coagulation QC Requirements:

(QC.7.1) The laboratory verifies each procedure and test parameter against known standards

or controls within the range of clinically significant values each day of use.

(QC.7.3) The laboratory has established and makes available to its staff acceptable limits for

all standard and reference QC samples, as well as the action to take when results are outside

satisfactory control limits.

(QC.7.4) The laboratory has established test control limits to provide results with

meaningful clinical applications.

College of American Pathologists Laboratory Accreditation Program

(CAP-LAP) Requirements for Quality Control

CAP-LAP's philosophy is that all clinical laboratory tests need to follow the requirements defined

for high complexity testing under CLIA'88 [7]. Requirements for routine analysis of QC follow the

CLIA requirements in terms of number and frequency, except controls must be included with all

tests (even those identified as waived tests under CLIA'88). For now, CAP only allows "acceptable"

alternative (electronic) QC for point of care testing. The latest POCT Checklist (Checklist 30,

1997.0) states that certain unit-use devices/kits may warrant some combination of instrument,

procedural, and/or electronic controls. Question 30.0550 (Checklist 30) states that POCT sites using

alternative QC must have scientifically acceptable evidence (documented information) that the

entire analytical process is being evaluated correctly. Except for electronic controls, CAP requires

that control specimens be tested in the same manner as patient samples.

Qualitative tests (even those with built-in controls) need to be evaluated with both a positive and

negative control each day of use. For all tests, CAP-LAP requires an audit trail that ties the patients’

results with the analyst, instrument and QC. In addition, the QC program should show evidence of

documented review on the next shift, if no supervisor is on site, and at least weekly review by the

technical supervisor and monthly secondary review by the director or director's designee.

CAP Guidelines for Quality Control

In the general requirements, CAP states in Checklist #1 1997.1 that the overall QC program for the

entire laboratory must be clearly defined and documented. It must include general policies and

delegation of responsibilities. The QC records should be well-organized with a defined system to

permit regular review by appropriate supervisory personnel.

01.3000) Does the QC program clearly define goals for monitoring analytic performance,

procedures, policies, tolerance limits, corrective action and related information?

Hematology QC Requirements (Checklist 2, 1996.2)

(02.2005) For numeric data generated by the hematology laboratory, are Gaussian or other

longitudinal process control statistics (S.D. and C.V.) calculated at least at monthly intervals

to define analytic precision?

(02.2010) Are tolerance limits (numeric and/or non-numeric) fully defined and documented

for all hematology and coagulation control procedures?

(02.2580) Does the laboratory use preserved or stabilized whole blood preparations for

longitudinal process control?

(02.2582) Does the laboratory use retained, previously analyzed patient whole blood

samples for longitudinal process control?

(02.2587) If assayed controls are used for CBC instruments, do control values correspond to

the methodology and have target values been verified by the laboratory for quantitative

tests?

(02.2588) If unassayed controls are used, has a statistically valid target range been

established for each lot by repetitive analysis in runs that include previously tested control

materials?

Automated/General Chemistry QC Requirements (Checklist 3, 1996.2)

(03.2600) For quantitative tests, are control specimens (with a matrix appropriate for the

method) at more than once concentration (when available) used for all tests with each

analytical run?

(03.2605) If assayed controls are used, do control values correspond to the methodology and

have target values been verified by the laboratory for quantitative tests?

(03.2610) If unassayed controls are used, has a statistically valid target range been

established for each lot by repetitive analysis in runs that include previously tested control

materials?

(03.2625) Are tolerance limits defined for control procedures? Note: For tests with numeric

results, recovery ranges supplied by manufacturers of assayed controls must not be

substituted for QC range limits determined the laboratory on its own equipment.

References

1. U.S. Department of Health and Human Services. Medicare, Medicaid and CLIA programs:

Regulations implementing the Clinical Laboratory Improvement Amendments of 1988

(CLIA). Final rule. Fed Regist 1992; 57:7002-186.

2. Laessig RH, Ehrmeyer SS: New Poor Man’s (Person’) Guide to Meeting the Regulations. R

& S Consultants, Madison WI. 1997.

3. Accreditation Manual. Commission on Office Accreditation (COLA). Columbia, MD, 1996.

4. U.S. Department of Health and Human Services. Medicare, Medicaid and CLIA programs:

Regulations implementing the Clinical Laboratory Improvement Amendments of 1988

(CLIA) and Clinical Laboratory Act program fee collection. Fed Regist 1993:58:5215-37.

5. U.S. Department of Health and Human Services. Medicare, Medicaid and CLIA Programs:

Extension of Certain Effective Dates for Clinical Laboratory Requirements Under CLIA.

Fed Regist 1997;62:25855-58.

6. Accreditation Manual for Pathology and Clinical laboratory Services. Joint Commission on

Accreditation of Healthcare Organizations (JCAHO). Oakbrook Terrace, IL, 1996.

7. Laboratory Accreditation Program. College of American Pathologists (CAP). Northfield,

IL, 1997.

Biography: Sharon S. Ehrmeyer, Ph.D.

Sharon Ehrmeyer, Ph.D., MT(ASCP) is Professor of Pathology and Laboratory Medicine and

Director of the Medical Technology Program at the University of Wisconsin in Madison,

Wisconsin. Dr. Ehrmeyer is active in the American Association for Clinical Chemistry, the

American Society for Clinical Laboratory Science and the National Committee Clinical Laboratory

Standards where she serves on the Board of Directors and chairs its pH/Blood Gas Committee. Dr.

Ehrmeyer gives numerous presentations on laboratory regulations (CLIA, JCAHO, CAP and

COLA), point of care testing and various quality issues. Her research interests focus on clinical

laboratory quality and the impact of government regulations on laboratory practices.

Copyright © 2000. All rights reserved

Westgard QC, 7614 Gray Fox Trail, Madison WI 53717

Call 608-833-4718 or e-mail westgard@westgard.com

A Message from JOW

QC Lessons | QC Applications | Questions | Multirule

CLIA Requirements | What's new? | Catalog | Demo Download

Home | Glossary | ARCHIVES | Links | Feedback

Lesson of the Month:

QC - THE PLANNING PROCESS

James O. Westgard, Ph.D.

What information is needed for QC planning?

What are some practical QC planning approaches?

1. Computer Supported Planning Process

2. Manual QC planning with a workbook of OPSpecs charts

3. Manual QC planning with normalized OPSpecs charts

4. Manual QC planning with QC Selection Grids

Which approach should you use?

Education and Training in QC Planning

References

PLEASE NOTE: An updated version of this lesson is now available in Basic QC Practices, 2nd Edition.

Many of you know about my Scandinavian heritage from my frequent references to one of my

ancestors, Hagar the Horrible, who is a source of both inspiration and practical advice. In one of my

favorite Hagar cartoons, Helga asks why girls mature faster than boys. This is a good example of a

process problem that all of us have experienced as teenagers and many of us also as parents. Hagar's

answer is "poor planning." That certainly rings true. And those of us who are parents of more than

one child have been repeatedly frustrated by this process, even though we supposedly gain

experience that should make it easier the next time. The difficulty is that we really aren't able to

change the process and just have to live through it again and again. Everyone in the future will also

have to endure this problem and live through a similar experience. What is really needed is to replan

the process to eliminate the problem, but that's something that only top management has the power

to do.

In many ways, this problem is analogous to the QC problems experienced in many laboratories.

Bench level analysts often have to live with QC problems because the testing process has not been

properly planned, particularly the selection of an appropriate statistical QC procedure. The people at

the bench can't generally change the process because management retains that power. Many of you

who are reading this are probably QC specialists, supervisors, managers, or directors, and you do

have the power to change the process. You need to be able to select QC procedures that will assure

the desired analytical or clinical quality is achieved, taking into account the imprecision,

inaccuracy, and instability observed for your methods. That's what QC planning is all about.

What information is needed for QC planning?

QC planning requires information about the quality requirements for different tests, the imprecision

and inaccuracy observed for a specific testing process, and the probabilities of rejection expected

for the QC procedures of interest. Information on quality requirements will be found in

recommendations in scientific literature, regulatory guidelines, and proficiency testing criteria. This

website provides a discussion of different types of quality requirements, as well as summary tables

of analytical quality requirements, clinical quality requirements, and biological goals.

Reliable estimates of method performance can be obtained initially by following established method

evaluation protocols and later from on-going estimates of imprecision from measurements

accumulated on control materials and estimates of bias from proficiency testing surveys.

Performance characteristics of commonly used QC procedures are available in the clinical

chemistry literature. QC simulation programs may be employed by laboratory analysts to estimate

the power of new control rules, including patient data algorithms. Probability calculations may also

be utilized by industrial statisticians and laboratory analysts with the necessary mathematical skills.

What are some practical QC planning approaches?

A systematic QC planning process is needed to consider all this critical performance information in

an orderly manner. The key to practicality is being able to do QC planning in a matter of a few

minutes, rather than a few hours or days. This means supporting data calculations, preparing

graphical tools and charts, and making it easy to document the QC recommendations.

Based on my experience with QC planning over the last several years, both in the laboratory and in

classrooms and workshops, there are four approaches that are practical today. These approaches

take advantage of tools and technology that make it simpler and faster to perform QC planning. It is

essential to recognize that new tools and technology will be needed if you are to perform QC

planning quickly and efficiently. As with any new tool or technology, you need to initially spend

some time understanding the principles and theory, satisfy yourself that the approach is

scientifically sound, and then implement the process steps and operations. The planning process can