CL-03-01 HYTORC Spanner Checklist Template

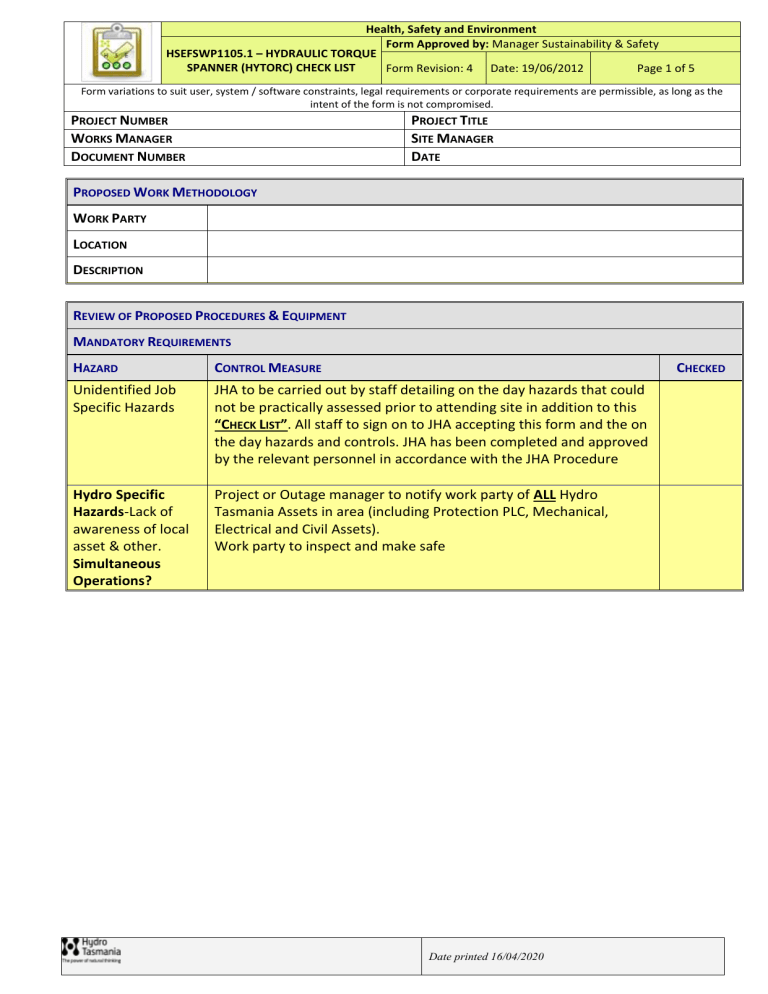

Health, Safety and Environment

Form Approved by: Manager Sustainability & Safety

HSEFSWP1105.1 – HYDRAULIC TORQUE

SPANNER (HYTORC) CHECK LIST Form Revision: 4 Date: 19/06/2012 Page 1 of 5

Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised.

P ROJECT N UMBER P ROJECT T ITLE

W ORKS M ANAGER

D OCUMENT N UMBER

S ITE M ANAGER

D ATE

P ROPOSED W ORK M ETHODOLOGY

W ORK P ARTY

L OCATION

D ESCRIPTION

P ROP

R EVIEW OF P ROPOSED P ROCEDURES & E QUIPMENT

M ANDATORY R EQUIREMENTS

H AZARD

Unidentified Job

Specific Hazards

Hydro Specific

Hazards-Lack of awareness of local asset & other.

Simultaneous

Operations?

C ONTROL M EASURE

JHA to be carried out by staff detailing on the day hazards that could not be practically assessed prior to attending site in addition to this

“C HECK L IST ”. All staff to sign on to JHA accepting this form and the on the day hazards and controls. JHA has been completed and approved by the relevant personnel in accordance with the JHA Procedure

Project or Outage manager to notify work party of ALL Hydro

Tasmania Assets in area (including Protection PLC, Mechanical,

Electrical and Civil Assets).

Work party to inspect and make safe

Date printed 16/04/2020

C HECKED

Health, Safety and Environment

Form Approved by: Manager Sustainability & Safety

HSEFSWP1105.1 – HYDRAULIC TORQUE

SPANNER (HYTORC) CHECK LIST Form Revision: 4 Date: 19/06/2012 Page 2 of 5

Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised.

P ROJECT N UMBER P ROJECT T ITLE

W ORKS M ANAGER

D OCUMENT N UMBER

S ITE M ANAGER

D ATE

G ENERAL R EQUIREMENTS

H AZARD

Incorrect selection of equipment

Unserviceable condition of

Hydraulic Torque

Spanner

C ONTROL M EASURE

Identify the type of work to be carried out and select the appropriate equipment for the task

Ensure that the torque (pressure setting) is known prior to selecting the appropriate equipment

Ensure all of the hydraulic fittings are of the correct pressure rating

The hydraulic hoses are of the correct pressure rating and are in good condition

The condition of the Hydraulic Torque Spanner head is good (no signs of cracks or fatigue)

The pump and pressure gauge are in good condition

N / A C HECKED

Socket / spanner selection

Torque setting selection

The reaction legs are in good condition (no signs of cracks or fatigue) and are the correct legs for the job

The pendant cable and pendant are in good condition

The pump motor electrical lead is in good condition and has been tested and tagged and is within the date range

Check pump oil level is correct and only use recommended hydraulic spanner oil for topping up and that the oil is clear and amber in colour.

Ensure that only approved and identified sockets

(marked with orange paint band) / spanners are used

Inspect for damage, cracks etc before use

Ensure that the approved and identified socket / spanner selected is the correct fit to the nut or bolt before applying pressure

Ensure that the correct torque conversion chart accompanies the hydraulic torque spanner prior to the spanner being used

Ensure that the torque required for the job is known from drawings, specifications, engineering etc

Convert the torque setting to a pressure setting using the correct torque conversion chart for the particular type of hydraulic torque spanner being used

Date printed 16/04/2020

Health, Safety and Environment

Form Approved by: Manager Sustainability & Safety

HSEFSWP1105.1 – HYDRAULIC TORQUE

SPANNER (HYTORC) CHECK LIST Form Revision: 4 Date: 19/06/2012 Page 3 of 5

Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised.

P ROJECT N UMBER P ROJECT T ITLE

W ORKS M ANAGER

D OCUMENT N UMBER

S ITE M ANAGER

D ATE

G ENERAL R EQUIREMENTS

H AZARD

Testing the

Hydraulic Torque

Spanner equipment with socket or spanner attached prior to use

Operation of

Hydraulic Torque

Spanner

(communication)

Use of Hydraulic

Torque Spanner on site, varied locations and manual handling

C ONTROL M EASURE

Connect the hydraulic torque spanner unit to the pump and check the security of the fittings

Set up the correct pressure in accordance with the hydraulic torque spanner operating manual instructions

Ensure the area around the hydraulic torque spanner is clear while the hydraulic torque spanner is being tested and all personnel in the area understands what is happening

Operate the hydraulic torque spanner on the floor to check correct mechanical operation, to set the correct pressure and check for oil leaks

The hydraulic torque spanner is to be operated by a minimum of two personnel who are authorised to use the hydraulic torque spanner

Where-ever practically possible the hydraulic torque spanner pump operator will be in line of sight with the hydraulic torque spanner head handler

Ensure all personnel not required during the hydraulic torque spanner operation are clear of area

The hydraulic torque spanner pump operator will not operate the hydraulic torque spanner equipment until given the “All Clear” command from the hydraulic torque spanner head handler

The hydraulic torque spanner pump operator will not operate the hydraulic torque spanner pump unit if they are not clear on the instructions that have been given by the hydraulic torque spanner head handler

The hydraulic torque spanner pump remote control operator will cease operation of the pump when given instruction by anyone who gives the command to stop

Ensure there is a thorough understanding (detailed planning stage) of the issues involved with using the hydraulic torque spanner

Ensure a JHA is developed on-site in consultation with personnel carrying out the work clearly identifying the manual handling issues associated with using the hydraulic torque spanner equipment

Date printed 16/04/2020

N / A C HECKED

Health, Safety and Environment

Form Approved by: Manager Sustainability & Safety

HSEFSWP1105.1 – HYDRAULIC TORQUE

SPANNER (HYTORC) CHECK LIST Form Revision: 4 Date: 19/06/2012 Page 4 of 5

Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised.

P ROJECT N UMBER P ROJECT T ITLE

W ORKS M ANAGER

D OCUMENT N UMBER

S ITE M ANAGER

D ATE

G ENERAL R EQUIREMENTS

C HECKED H AZARD

Incorrect PPE

C ONTROL M EASURE

Ensure a manual handling risk assessment is carried out for the work involved

The minimum requirement for PPE will be safety helmet with high impact full face visor, gloves and steel capped safety shoes or boots

S ITE R EGISTRATION (Note: Applies to all Work Parties and personnel working on site)

N / A

R EQUIREMENT

Permit To Work issued

Visitors register sheet or emergency board being used. Site Map issued (showing emergency assembly areas and fire equipment)

Hydro Tasmania Level 2 O H & S Induction complete

Hydro Tasmania Level 3 Site induction complete

S

A DDITIONAL P ERSONAL P ROTECTIVE E QUIPMENT (C OMPLIANT WITH A USTRALIAN S TANDARDS )

C HECKED

R EQUIREMENT C HECKED R EQUIREMENT C HECKED R EQUIREMENT C HECKED

C ERTIFICATION

I have personally checked and verified all items on all pages of this check list

Works Manager Name Signature Date

I acknowledge and agree that all items are detailed on all pages of this check list. I agree to ensure that all employees and sub-contractors engaged in this work will fully comply with all control measures indicated

Authorised Hydraulic Torque

Spanner User

Signature Date

Date printed 16/04/2020

Health, Safety and Environment

Form Approved by: Manager Sustainability & Safety

HSEFSWP1105.1 – HYDRAULIC TORQUE

SPANNER (HYTORC) CHECK LIST Form Revision: 4 Date: 19/06/2012 Page 5 of 5

Form variations to suit user, system / software constraints, legal requirements or corporate requirements are permissible, as long as the intent of the form is not compromised.

P ROJECT N UMBER P ROJECT T ITLE

W ORKS M ANAGER

D OCUMENT N UMBER

S ITE M ANAGER

D ATE

D AILY R EVIEW

I F T HERE IS A SIGNFICANT CHANGE IN W ORK AND OR C ONDITIONS A NEW C HECK L IST IS R EQUIRED

D ATE AND T IME R EVIEWED / C OMMENT N EW C HECK L IST R EQUIRED

Date printed 16/04/2020