professional experience

advertisement

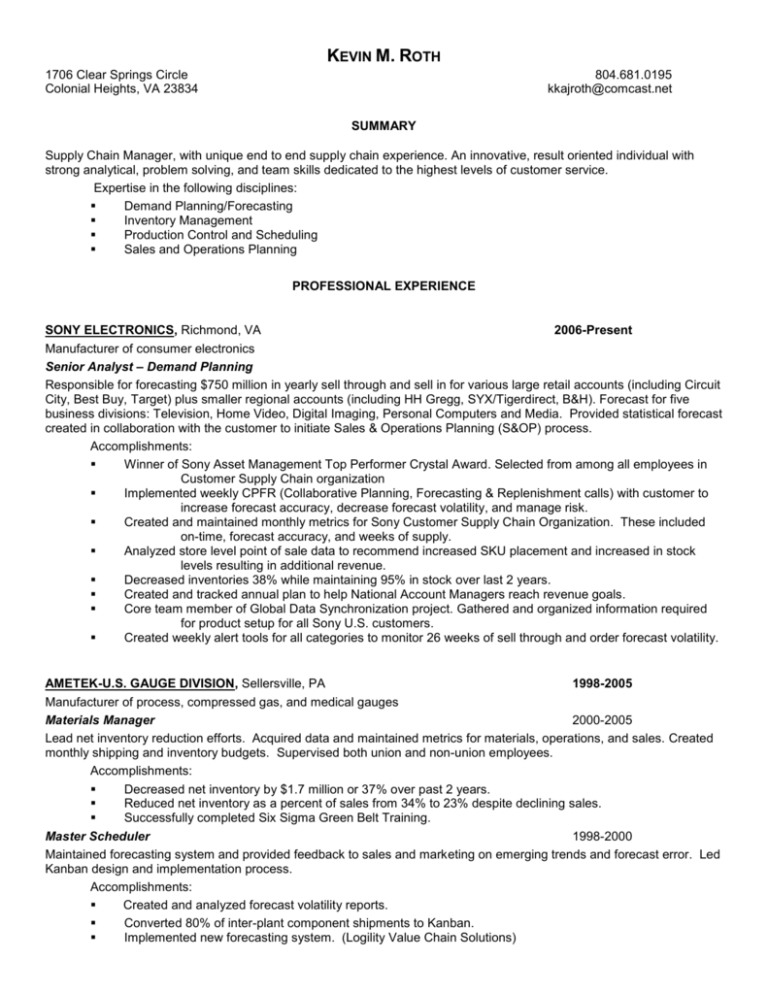

KEVIN M. ROTH 1706 Clear Springs Circle Colonial Heights, VA 23834 804.681.0195 kkajroth@comcast.net SUMMARY Supply Chain Manager, with unique end to end supply chain experience. An innovative, result oriented individual with strong analytical, problem solving, and team skills dedicated to the highest levels of customer service. Expertise in the following disciplines: Demand Planning/Forecasting Inventory Management Production Control and Scheduling Sales and Operations Planning PROFESSIONAL EXPERIENCE SONY ELECTRONICS, Richmond, VA 2006-Present Manufacturer of consumer electronics Senior Analyst – Demand Planning Responsible for forecasting $750 million in yearly sell through and sell in for various large retail accounts (including Circuit City, Best Buy, Target) plus smaller regional accounts (including HH Gregg, SYX/Tigerdirect, B&H). Forecast for five business divisions: Television, Home Video, Digital Imaging, Personal Computers and Media. Provided statistical forecast created in collaboration with the customer to initiate Sales & Operations Planning (S&OP) process. Accomplishments: Winner of Sony Asset Management Top Performer Crystal Award. Selected from among all employees in Customer Supply Chain organization Implemented weekly CPFR (Collaborative Planning, Forecasting & Replenishment calls) with customer to increase forecast accuracy, decrease forecast volatility, and manage risk. Created and maintained monthly metrics for Sony Customer Supply Chain Organization. These included on-time, forecast accuracy, and weeks of supply. Analyzed store level point of sale data to recommend increased SKU placement and increased in stock levels resulting in additional revenue. Decreased inventories 38% while maintaining 95% in stock over last 2 years. Created and tracked annual plan to help National Account Managers reach revenue goals. Core team member of Global Data Synchronization project. Gathered and organized information required for product setup for all Sony U.S. customers. Created weekly alert tools for all categories to monitor 26 weeks of sell through and order forecast volatility. AMETEK-U.S. GAUGE DIVISION, Sellersville, PA 1998-2005 Manufacturer of process, compressed gas, and medical gauges Materials Manager 2000-2005 Lead net inventory reduction efforts. Acquired data and maintained metrics for materials, operations, and sales. Created monthly shipping and inventory budgets. Supervised both union and non-union employees. Accomplishments: Decreased net inventory by $1.7 million or 37% over past 2 years. Reduced net inventory as a percent of sales from 34% to 23% despite declining sales. Successfully completed Six Sigma Green Belt Training. Master Scheduler 1998-2000 Maintained forecasting system and provided feedback to sales and marketing on emerging trends and forecast error. Led Kanban design and implementation process. Accomplishments: Created and analyzed forecast volatility reports. Converted 80% of inter-plant component shipments to Kanban. Implemented new forecasting system. (Logility Value Chain Solutions) PAGE 2 KEVIN M. ROTH 1706 Clear Springs Circle Colonial Heights, VA 23834 804.681.0195 kkajroth@comcast.net ACCU-SORT SYSTEMS, INC., Telford, PA Manufacturer of automatic bar code readers and systems Master Scheduler Loaded and maintained Master Production Schedule (MPS) for all products. Reviewed and adjusted Kanban inventory levels for all work cells based upon forecast. Measured and reported on-time performance, customer backlog, and material shortage information and impacts on lead-time of products. Coordinated implementation of engineering changes between manufacturing, purchasing, engineering, and customer service. Accomplishments: Coordinated successful on time introduction of two new products from design to production. Completed Facilitator Training for Process Improvement Teams (PIT). Completed PIT mission to improve the process for measuring vendor quality performance. KULICKE & SOFFA INDUSTRIES, INC., Willow Grove, PA Manufacturer of semi-conductor capital equipment Senior Production Coordinator/ Master Scheduler Maintained Master Production Schedule (MPS) demand for all product lines of $350 million company. Conducted monthly MPS meetings, between marketing, materials management, and production planning. Accomplishments: Improved production forecasting through integration of sales and marketing systems. Production Coordinator Planned subassemblies through shipment of $70K to $100K wire bonders in a flow line JIT manufacturing environment. Participated in team problem solving daily during production stoppages at red light events and weekly continuous improvement meetings. Accomplishments: Implemented Kanban system, reducing inventory and increasing inventory turns. Managed production at vendor’s facility to keep material delivery flow at an acceptable rate. Involved in implementing flow line assembly process that reduced cycle time in half. Participated in creating ISO 9001 procedures for successful certification. COMPUTER SKILLS SAP APO, BW, & R3 Logility Value Chain Solutions Forecasting Microsoft Office- Excel, Word, Powerpoint American Software/ 400 MRPII Crystal Reports Vista Query EDUCATION/TRAINING Virginia Polytechnic Institute and State University, Blacksburg, VA Bachelor of Science, Double Major - Management Science (Production and Ops)/Management University of Tennessee - Supply Chain Certification (5 courses, 80 hours) Penn State – Overview of Project Management (15 hours) Demand Flow College - Toyota Production System (40 hours) Six Sigma Green Belt Training APICS Member – currently pursuing CPIM certification