Competencies for Next Generation Employability

advertisement

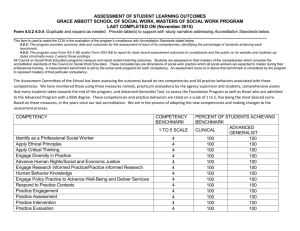

ENHANCING STUDENT EMPLOYABILITY: Higher Education and Workforce Development Ninth Quality in Higher Education International Seminar in collaboration with ESECT and The Independent. Birmingham 27th-28th January 2005 The Competencies for Next Generation Employability Eamonn McQuade, Deirdre Hogan, John O’Donoghue, Theresa Maguire, Eamonn Murphy. Programme for the University Industry Interface, University of Limerick Conference Theme 3: Working with employers Abstract It is generally accepted that employees will need to broaden their knowledge, skills and competencies through a lifetime of learning if they are to remain employable, and if enterprises are to maintain their competitiveness in a knowledge-based global economy. However, identifying and developing skills and competencies for next generation employability in Ireland is a challenging task. The Programme for University Industry Interface (PUII) is an action research project, established in 2003, to determine the skills and competencies required by Irish Industry and to develop learning models that will facilitate their delivery. This paper presents the outcomes of an action research methodology based on a Community of Practice model (COP), which addressed the issues surrounding competencies for next generation employability. It proposes a competency framework which integrates the four key categories of skills: Business, Technical, Interpersonal, Intrapersonal, and presents a set of recommendations for individuals, employers and higher education institutions. Introduction The Programme for University Industry Interface (PUII) is an action research project, established at the University of Limerick in 2003 to determine the next generation skills and competencies required by Irish Industry, and to develop learning models that will facilitate their delivery. PUII is committed to working with industry members from all sectors and industries and from all company sizes to achieve this task. The focus of PUII is on the graduate who has worked in industry for a number of years. It looks at their future employability and transferability between roles, industries and sectors. Of particular interest to PUII is the ICT manufacturing industry - Currently manufacturing industries employ approximately 282,800 people (111,200 in the indigenous sector and 171,600 in the multi-national sector). Of these, approximately 65,000 have a third-level qualification (approximately 45,000 in the multinationals and 20,000 in indigenous enterprises). It is clear that the future for Irish manufacturing will be vastly different from the past as the sector progresses and develops beyond its traditional roots. The outsourcing of manufacturing and service work to lower-labour-cost economies is a global trend. Europe has lost approximately 1.5 million manufacturing jobs since 2001. In Taiwan and Japan, there is significant migration of manufacturing jobs to China. The 1 challenge for Ireland is to conserve and grow the higher value-added activities such as logistics, supply-chain management, and customer-relations management. Many of the positive factors that previously existed in the Irish manufacturing environment still prevail today: high productivity, tax benefits, stable government, track record, English speaking etc. The causes for concern are that the previous consensus among social partners appears to be at risk and ‘hunger to prove’ oneself is no longer evident in the Irish workforce. These changes may be attributed to a successful, prosperous economy. We in Ireland must focus on the positive attributes, and build on these to sustain employment while continuing to attract new investment. Mindful of this insight, the initial PUII work included of a Community of Practice, entitled ‘The Competencies for Next Generation Employability’, that addressed: The Future Landscape of Manufacturing in Ireland. Identifying the Competencies for Next Generation Employment. How Competencies can be developed in the Workplace. This paper presents the deliberations and findings of this COP. COP Methodology PUII uses an action research methodology based on Communities of Practice (COPs). A COP consists of a group of people informally bound together by shared expertise and a passion for joint enterprise (Wenger and Synder, 2000). Members share knowledge and use their creativity and resourcefulness to address relevant problems and identify best practice. The strength of a COP is that it reflects the members’ own understanding of what is important. The Terms of Reference for the COPs allow for modifications of the aims and objectives as determined by the COP team. A PUII COP is generally made up of 7-9 individuals from industry, supported by an academic consultant (PhD Student), a research consultant (PostDoc. Fellow), a UL Patron and the PUII project manager. The first PUII Community of Practice, ‘The Competencies for Next Generation Employability’ 1, and had two principal aims: To identify the skills and competencies required for next generation employability in the manufacturing sector. To identify effective approaches to learning that could be used to enhance up-skilling in companies. 1 Key questions considered by the COP included: What are the skills and competencies that individuals in manufacturing will need to ensure next generation employability? How can we structure a Skills and Competencies Framework that will facilitate the development of learning models appropriate to their delivery? What learning opportunities exist in companies? How can these be used to enhance delivery of the relevant skills and competencies? How can an organisation create an environment that will encourage individuals to take control of their own learning for long-term employability? What are the latent skills and competencies that have been developed during the Celtic Tiger that are relevant to the growth of employment and employability in industry? The complete COP Report is available on the PUII website, www.ul.ie/~puii 2 The companies represented in the COP were Apple, Dell, DePuy Ireland, IBM, Intel, Lucent Technologies and Celestica. Participants were typically from the middle management of their company. Five full-day meetings were held during the period from 30 October 2003 to 7 May 2004. The COP used a number of formal and informal methodologies to gather and share information. These included presentations by key CEOs in the manufacturing sector and by COP members, case studies, analyses of significant documents, informal surveys, brainstorming sessions, discussions and formal written reports. To facilitate and expedite proceedings, COP1 subdivided into three sub-groups to address three key questions What is the Future Landscape of Manufacturing in Ireland? What are the Competencies for Next Generation Employment? How can Competencies be developed in the Workplace? Question 1: What is the Future Landscape of Manufacturing in Ireland? The first task of the COP was to consider the future landscape for manufacturing in Ireland. Future scenarios were constructed using a combination of the insights of the individual COP members and by extrapolating from the experiences of successful manufacturing companiesfor example Dell Ireland, Analog Devices, Abbot, Apple, DePuy Ireland, Hewlett Packard, Intel, Lucent etc. Two in-depth case studies were also conducted. Case Study 1 - Apple, Cork, Ireland Case Study 2 - Intel, Leixlip, Ireland A number of common themes emerged from all of these sources: The Irish Organisation must have a Strategic Plan centred on potential growth areas such as Supply Chain Management, R&D, Sales and Marketing or Shared Services. The term ‘manufacturing’ does not adequately identify the wider focus of activities that will be taking place. In this context the term ‘Extended Enterprise’ captures, more explicitly, the business of these organisations in the future. Opportunities exist within and beyond the ICT sector for ‘extended enterprises’ in new growth areas, e.g. Biotechnology, Medical Devices and logistics. The Irish Operation must be closely aligned with the ‘corporate heartbeat’. Strong local leadership is vital to the success of the company. The Irish workforce must have a strong willingness to accept change. Committed employees with a ‘Hunger to Prove’ are central to a successful company. Companies must build on their proven track record. Companies must have a culture of employee development. The COP findings support the national strategy for attracting new manufacturing into Ireland in the future. The proposed strategy focuses on clusters of excellence, improved competitiveness and growth in productivity, collaboration and partnerships (IDA Annual Report, 2003). The future landscape of the manufacturing sector will see fewer companies involved in core manufacturing. Most will have extended their enterprises to at least two of the key value-added areas. Flexible and responsive enterprises will deliver customised solutions. Customer-focused partnerships will evolve to deliver the best possible solution and may include the capacity to partner with companies in China/Eastern Europe effectively and seamlessly. 3 Profiling the Future for Manufacturing in Ireland The COP investigated possible landscapes for the future of the ICT sector (5 yrs +) in Ireland by looking at industry in terms of the different activities of the companies involved and making some assumptions about their future role. Assumption 1 (A) There will be a core of high-tech companies in Ireland, mostly (but not totally) subsidiaries of multinational ICT companies. (B) There will be a number of organisations loosely bound to (A), but with international customers: Specialised Operations and Services, Research, Consultancy, Logistics, Supply Chain Management, IT services. (C) A number of smaller indigenous companies will be in operation (outer layer C) – spin-offs, joint ventures and start-ups that may progress to become (A) or (B)-style companies. Assumption 2 The (A) sector will remain reasonably stableno major closures or start-ups, but perhaps some takeovers, or downsizing/ upsizing. Jobs will be lost, but equally jobs will be gained as companies shift their business priorities as they begin to realise new opportunities. (B) and (C) sectors will experience major activity, with innovation driving a new mix of products and services. Assumption 3 The policies and culture that support Assumptions 1 and 2 will be maintained and improved in Ireland and the EU. This is necessary to sustain the ICT sector and make it attractive for jobseekers. Individual Career Trajectory In the context of this possible future, an individual can have a number of career trajectories. Lifetime training and education will not be just an option; career planning by individuals will have to take this situation into account. Many individuals in the core (A) will be able to maintain career paths entirely within their own or similar companies. Individuals can move within the core (large multinational company) of a sector (ICT, Medical Devices, Biopharmaceutical etc.). They can have single or multiple roles within a company or indeed change core companies within a sector. Individuals can move within a sector from the core to the inner ring (B) to the periphery (C) (research spin-off, selfemployment, SME, further education, smaller organisations, younger companies, service companies etc.). Similarly individuals can move from the periphery to the core; move within the periphery, or change sectors altogether and begin the cycle again. All types of career migration must be supported from a Future Employability standpoint. Skills other than technical skills are critical for this migration; a ‘common denominator’ of competencies that support these movements exists. Towards Next Generation Employability – Key Insights Summary Irish manufacturing has an important role to play in the Irish economy now and in the future. Successful manufacturing companies in the future will have a well-executed Strategic Plan for Ireland that underpins a process for Building Strategic Value for the parent 4 company. These companies will also move closer to the customer and possibly become the European Headquarters for the US parent. Companies will become ‘extended enterprises’ that exploit development opportunities within and beyond the ICT sector. The manufacturing sector of the future will be characterised by building on existing strengths, having a partnership mentality and by being flexible and responsive. FDI companies who have active participation at corporate level will still be present but will have justified their existence by becoming Centres of Excellence for some key areas of the corporate business plan. Case Study 1: Apple’s Value Added Strategy Joe Gantly, Senior Director of Operations and Apple Care Eight years ago, it was decided that the future for Apple in Ireland was not in core manufacturing. It was clear that ‘brawn’ production had reached the end of its life cycle and that surviving and maintaining Apples’ presence in Ireland would depended on restructuring to more value-added ‘brain’ activities and integrating forward into the needs of its European customer base as much as possible. Apple in Ireland already had a long history of reviewing its infrastructure and had developed a leveraged manufacturing model that incorporated outsourcing as part of the model. As a result, it had developed strong and experienced technical resources and a strong workforce, capable of delivering on the Apple philosophy of ‘making and meeting commitments’. In a strategic environmental assessment conducted by the management team in October 1988, the following key strategic norms were identified: 1. People are our key asset. 2. Manufacturing will only survive if it is genuinely “World Class” and shows significant value-add. 3. There is a higher premium in the company on higher value-added activities. 4. Technology has enabled the geographic independence of corporate activities. Today, the centre in Cork is responsible for Operations and Service in Europe, employs 1400 people and had 1.3 billion dollars in revenue last year. It is now a World Class Customer Focused Operations and Service Centre. The operation is involved with all aspects of getting the product to the customer, including planning, procurement, manufacturing, logistics, service and support. The transformation brought up many challenges and Apple is continually learning lessons on how to survive in this area. ‘It’s one thing to move up the value chain and another to stay up there’. As part of this transformation, Apple underwent many changes including: In April 1999, re-engineered manufacturing process to 100% ‘Brain’ and outsourced ‘Brawn’ to the Far East and Eastern Europe. In September 2000, opened a European Call/Technical Centre with customer support, on-line sales, customer relations and back office capabilities. This now employs 420 people. European Telesales function centralised in Cork in January 2001. European Logistics, Order Management and Finance functions centralised in Cork. Data Centre was relocated from Holland to Cork in February 2002. With this transformation complete, 85% of the 1400 quality employees are engaged in value-added activities in comparison to 30% six years ago. Almost all ‘professional’ people made the transition. They were able to adapt their skills to the needs of the various new activities of the company. Manufacturing people tended to be expert in Supply Chain 5 Management (SCM) Thinking – Process – Logic – Control. Very few at the operator level (non-professional) made the transition. To succeed, as part of the change process, individuals had to think globally, not locally, which took time to bring into effect. The new operation required the individual to understand the organisation and their role in the customer experience. It also required a more complete understanding of SCM as a discipline which focused on ‘getting the product from raw material at the source to a transformed product with the customer in the fastest and most cost effective manner possible’. The HR focus is now on managing professional careers, identifying gaps in capabilities at an individual level, and managing development plans. Apple Cork considered diverging into Research and Development (R&D), but it was clear that this was not the path to follow. Apple’s R&D resources are mainly centred in the US and there is a tendency to keep R&D close to the corporate headquarters. The other focus was managing Customer centric activities and in this it did succeed. At present, there is some brawn in the call centres, however it is where manufacturing was 5 years ago. It may come under threat from countries such as India and particularly South Africa who are aggressively targeting these capabilities. Apple in Cork now manages the full customer experience in Europe, from Order Management to Manufacturing to Logistics to Service and Support. Its role and function now is about integrating and developing all elements of the customer experience in a manner that adds value to Apple and its customers. Case Study 2: Intel’s Innovation Strategy Jim O’Hara, General Manager, Intel Ireland & VP of TMG Intel is a capital-intensive business. A fundamental part of the business model is to generate enough cash to continue to invest significant capital expenditure in manufacturing facilities and technology. This is critical to business success in a highly innovative and dynamic marketplace such as Semiconductor manufacturing. Originally Intel located in Ireland because they needed an inlet into Europe, Ireland was English speaking, had a government that supported business, had moderate to low development costs, a large number of graduates and tax incentives. About two thirds of the employees have a third-level education in a technology discipline. Today, Ireland has become a high-cost environment, prescribed EU legislation is not helpful, we no longer have abundance of highly qualified graduates and Europe is now considered a mature market. Most global companies investing look at the balance between where they spend their money and where they get their revenue. ‘The wind is in our face now!’ However Intel places a huge value on performance and execution; Intel Ireland has proven it can execute well against world-class benchmarks and so will receive favourable consideration for the next investment. ‘We don’t have to be as low cost as China, just significantly better than the US. Equilibrium will happen eventually and there will need to be global companies with a presence in the three centres, US, Europe and Asia.’ Co-development to enable fast technology transfer is a key skill in Intel Ireland. Each time we advance into new areas of technology development, a contingent of engineers are sent to the US to participate in the development stage and transfer the expertise to Ireland. In Ireland Intel’s culture is one of transition and change. The site commenced production with a Systems Manufacturing business whose population was transitioned into an Assembly 6 and Test operation and after its closure the majority of employees found suitable employment within the Wafer Fabrication plants. Intel’s IT Innovation Centre provides an example of entrepreneurship. The centre responds to emerging needs and opportunities in the information technology space, striving to improve the internal competitive advantage for Intel, as well as providing a showcase for new ICT usage models. It concentrates on the combination of current or emerging technologies to provide innovative solution stacks. The centre has merged the diverse competencies from a number of internal development groups to achieve critical mass and has leveraged the combined skill sets for maximum effect, with significant focus on elearning, distributed computing and wireless initiatives. The group formally kicked off in mid 2003, with two or more years behind-the-scenes work. The concept started in Ireland, but the drive now is to expand into a worldwide operation. The centre has a corporate mandate and has benefited from R&D grant funding. Strategic Objectives of the centre are: 1) To reduce the cost of IT services to the organisation and put the savings towards new services and capabilities; 2) To move Intel into Business Partner role with the other business units across the corporation; 3) To be an Industry influencer and reference point for IT Innovation. Examples of the work of the centre include: www.skoool.ie, an education portal focused on the Junior and Leaving Certificate. This initiative builds on new technology and brings credibility in the area of e-learning. Other work under development includes; Idea Management Tools, Adaptive Learning Models and distributed/edge computing tools. Question 2: What are the Competencies for Next Generation Employability? The second area of interest to the COP was the competencies for next generation employability. Thirty-five competencies were identified. In doing this, it was assumed that the individual had already acquired the prerequisite technical and professional competencies to satisfy their job role. Each competency was defined according to its context in the working environment (Table 3). Competencies were classified according to 4 key headings, - Interpersonal Skills required to work effectively with others Intrapersonal Attitudes, beliefs, values, confidence inherent in the individual Business Understanding the mechanics of the organisation Technical Acquired core skills relevant to a particular area within an organisation During the categorisation process, it became evident that individual competencies could to be categorised under more than one heading, thus reflecting the complex nature of the modern workplace. On further reflection, competencies were considered along 3 axes, the horizontal axis representing personal skills, the emerging axis corresponding to technical skills and the vertical axis representing new ‘innovative’ skills. A number of skills overlap the three axes (Figure 1). 7 Figure 1 - The Competencies Space 8 Table 3 - The Competencies for Next Generation Employability Competencies Categorisation Definition Ability to adapt & change Interpersonal Intrapersonal Flexibility Ability to sell your skills in a client environment Interpersonal Intrapersonal Recognising & articulating personal and strengths Business Acumen Business Interpersonal Intrapersonal Technical Good appreciation and knowledge of business requirements Communication Skills Interpersonal Listening, writing, interpreting, verbalising Conflict Resolution Interpersonal Combination of negotiation and influencing to resolve conflict Creativity, Innovation, Intrapreneurship, Entrepreneurship, Vision Intrapersonal Design, development and implementation of new ideas or concepts Customer Centric Skills - Execution Interpersonal Intrapersonal Understanding, listening customer needs and implementing customer requirements Customer Centric Skills Relationships Interpersonal Intrapersonal Proactively addressing customer’s needs and requirements Decision Making under uncertainty Risk taking Technical Intrapersonal Ability to make a decision without all facts and information Effective Collaboration Interpersonal Intrapersonal Ability to work within and across teams HR Management Technical Developing processes to facilitate people management ICT Skills Technical Ability to use ICT, e-mail, spreadsheets, networking, collaboration, intranet, internet, manufacturing systems, learning management systems Individual Ownership of Career/Personal Social Development Interpersonal Intrapersonal Taking ownership for self development and progression Influencing Interpersonal Intrapersonal Ability to positively persuade groups of people to achieve a desired result Information Management Technical Processing and managing information Knowledge to customise a solution to a corporate customer Business Providing a tailored solution to meet the customer’s requirement Language skills Technical Foreign Language Leadership - Corporate Management Interpersonal Intrapersonal Leading people to achieve the Corporate Goal Negotiation skills Technical Interpersonal To reach a win/ win outcome Networking skills Interpersonal Building effective contacts and relationships Presentation Skills Technical Intrapersonal To effectively design, develop and present information to target audiences. Priority Setting Technical Differentiating and scheduling tasks based on business impact 9 competencies Problem solving Technical Intrapersonal To use tools and techniques to effectively and efficiently resolve problems. Project Management Technical To effectively manage projects from concept to implementation Proposal generation and ability to articulate Technical Interpersonal e.g. Business Plan, Project Outline Reflection Intrapersonal To review, evaluate and appraise one’s own work/learning/role Sociological - People Skills Interpersonal Intrapersonal Ability to work with people Strategic Planning Technical Looking and planning into the future Stress Management Intrapersonal Surviving pressure, managing self, balance Supply Chain Management Technical Managing all aspects of the Supply Chain purchasing, operations, logistics etc. Think Globally Act Locally Execution Excellence Business Interpersonal Intrapersonal Understanding the ‘Big Picture’ and the role played by each individual Understanding of supply chain and decision-making structures Business Understanding how to operate effectively within the corporate business environment Working in a virtual environment Interpersonal Intrapersonal World Class Manufacturing Standards Technical Working non face-to-face with teams/ individuals Incorporating all Quality and Productivity Improvement Methodologies A Competency Framework The competency framework was developed to integrate the four key categories identified (Business, Technical, Interpersonal, Intrapersonal), (Figure 2). The framework facilitates an individual or organisation: To assess existing competency levels against current and future needs. To consider each competency according to all relevant categories, recognising the composite nature of competency. Each competency identified by the COP is placed according to a scale of importance along the x-axis, set against an estimate of the current competency level set along the y-axis. Thus the relative urgency with which a particular skill needs to be developed within one of the categories is clearly identified. 10 Figure 2: Proposed Competency Framework The framework once completed is known as a competency map (Figure 3). The map can be personalised to each individual within an organisation or can be used as a tool to see where the organisation itself is positioned vis-à-vis its current ‘competency bank’ and to 11 identify the competencies that it will need for the future. The map is dynamic and changes with the individual’s progress or the changing requirements of the business. This classification is a considerable improvement on previous methods. Under this system not only can gaps in the competencies of an individual or organisation be clearly seen, but the relative importance and direct relevance of those gaps is also highlighted. Further because the map considers all the elements of a competency, it facilitates the subsequent process of matching that competency with the emerging National Qualifications Framework (NQAI, 2003). This will facilitate organisations to gain accreditation for courses developed to meet the identified competency needs in the future. Figure 3 - Identifying Focus Areas for Development using a Competency Map Question 3: What are the Key Competencies for Next Generation Employability? Thirty-five competencies were identified and defined by the COP. To gain an appreciation of the relative importance of these competencies, members of the participating organisations and their colleagues ranked them. This facilitated the identification of the top ten competencies for the current and future work environment. The results of this exercise are outlined in Table 4. Variations in competencies between the current and future work environments are bolded. 12 Table 4 – Ranking Current and Future Competencies Table 4 – Ranking Current and Future Competencies: Top ten Competencies Current Future 1. Ability to adapt and change 1. Ability to adapt and change 2. Supply Chain Management 2. Creativity, Innovation, Intrapreneurship, Entrepreneurship, Vision 3. Creativity, Innovation, Intrapreneurship, Entrepreneurship, Vision 3. Communication Skills 4. Customer Centric Skills – Execution 4. Networking skills 5. Problem solving 5. Customer Centric Skills - Execution 6. Communication Skills 6. Understanding of the supply chain corporate structures and decision making structures 7. Ability to sell your skills in a client environment 7. Knowledge to customise a solution to a corporate customer 8. World Class Manufacturing Standards 8. Supply Chain Management 9. Effective Collaboration 9. Effective Collaboration 10. Influencing Skills 10. Problem solving Three key themes emerged from this examination of competencies by the COP. 1. Almost all organisations reported that they had begun the evolutionary process of moving from current competencies to future competencies in their skills needs analyses in response to the dynamic nature of their manufacturing environment. 2. Intrapersonal and interpersonal skills, as defined by the COP, in both the current and future views were seen as being more important than specific technical or purely business competencies. The competencies that had the highest change in ranking from their position in the ‘current competencies’ table to the ‘future competencies’ table included the ability to network, to show ‘creativity, innovation, intrapreneurship, entrepreneurship and vision’, knowledge of supply chain corporate structures, decisionmaking structures, negotiation skills and the need to take individual ownership of one’s own career/personal social development. 3. COP members considered that World Class Manufacturing Standards and ICT skills could be taken ‘as a given’ in the future, consequently they reduced their relative importance from the current to the future situation. What was identified, as a key future competency, was the development of a mindset that allowed for customisation of corporate solutions to suit individual customer needs. A further analysis of the competencies ranked them within the four core categories for current and future contexts. Each competency was given a dual weighting in respect of the organisation’s skill level both now and in the future and of its relative importance to the organisation now and in the future. The results are displayed in Table 5. 13 Table 5 - The Top Ranked Future Competencies in each Category: Top Ten Competencies 1 2 3 4 5 Current Technical 1 World Class Manufacturing Standards 2 ICT Skills 3 Problem solving 4 Priority Setting 5 Supply Chain Management Interpersonal Skills Customer Centric Skills - Execution Ability to adapt & change Sociological - People Skills Customer Centric Skills - Relationships Leadership - Corporate Management 1 2 Intrapersonal Skills Problem solving Customer Centric Skills - Execution 3 4 Sociological - People Skills Effective Collaboration 3 4 5 6 Leadership - Corporate Management 5 6 Business An understanding of the supply chain corporate structures and decision making structures Knowledge of how to customise a solution to a corporate customer Think Globally Act Locally - Execution Excellence Future Technical 1 Project Management 2 Strategic Planning 3 Problem solving 4 Priority Setting 5 Information Management Interpersonal Skills 1 Ability to adapt and change 2 Customer Centric Skills - Relationships 3 Customer Centric Skills - Execution 4 Networking skills 5 Think Globally Act Locally - Execution Excellence Intrapersonal Skills 1 Effective Collaboration 2 Customer Centric Skills - Relationships Customer Centric Skills - Execution Creativity, Innovation, Intrapreneurship, Entrepreneurship & Vision Problem solving Business An understanding of the supply chain corporate structures and decision making structures Knowledge of how to customise a solution to a corporate customer Think Globally Act Locally - Execution Excellence The Competencies for Next Generation Employability – Key Insights Summary Ireland has a rich resource of people with competencies and skills that have been developed in manufacturing environments. Thirty-five competencies have been identified for next generation employability in the manufacturing sector. These competencies can be categorised as being: Technical, Business, Interpersonal and Intrapersonal. The Top ten competencies for next generation employability are: 1. Ability to Adapt and Change 2. Creativity, Innovation, Intrapreneurship, Entrepreneurship and Vision 3. Communication Skills 4. Networking Skills 5. Customer Centric Skills - Execution 6. An Understanding of the Supply Chain Corporate Structures and Decision-making Structures 7. Knowledge to Customise a Solution to a Corporate Customer 8. Supply Chain Management 9. Effective Collaboration 10. Problem Solving Interpersonal and intrapersonal competencies will have increased importance in the future. 14 Companies are already in transition and have initiated the development of the competencies identified for next generation employability. A competency framework that will facilitate the identification of training needs both at the individual level and the organisational level has been developed. Developing Competencies in the Workplace Having identified the competencies for Next Generation Employability, the COP considered how the competencies identified could be developed within organisations. As a result of group discussion and brainstorming, the following key points were raised. Individual and Employer Responsibilities In a knowledge economy, lifetime employment is not guaranteed and individuals need to be resigned to ‘involuntary career change’ at least once in a career. Individuals need to take responsibility for their own personal development, take ownership of their own employability and view their career in terms of wider employability. Employers must recognise the changing landscape of employability and make provision for and support the acquisition of non-critical competencies for their employees’ future employability. 15 Learning Models and Delivery of Competency in the workplace Learning models need to be described for each of the competencies identified. A range of coherent and inter-related course material should be developed to support the learning models identified. Acquisition of the key transferable competencies must begin early in the education cycle. To facilitate their delivery, key competencies should be described at different levels (This would facilitate the future mapping of the competencies onto the developing National Qualifications framework). The levels identified should be integrated progressively into the second-level education system (work experience, outreach from university/ industrial community, transition year). There is a requirement for generic third-level technical courses for broad applicability across industrial sectors. Individual specialisation should take place at the appropriate time. At third-level key personal competencies should be integrated into engineering, professional and business courses and also made available as elective courses. Facilitating the Acquisition of Competencies The acquisition of competencies will be facilitated through: Partnerships between third-level institutes, Industry, and Professional Bodies (e.g. Institute of Engineers in Ireland) The availability of graduate programmes such as the UK Graduate Programme, which allows Doctoral graduates to develop integrated people and business skills (http://www.grad.ac.uk/index.jsp) The availability of conversion courses within and between sectors – FÁS, Third-level and Professional Bodies (for example IEI) Third-level Institutions must focus on delivering learning modules that individual’s needs. Reflections and Recommendations Emerging Enterprise Models A central message emerging from COP1 is that manufacturing will continue to be a key element of the Irish economy in the future. This will be facilitated by a number of emerging enterprise models within the sector that were identified by the COP (Figure 3). The Control Tower (for example Apple) concept sees the FDI subsidiary in Ireland positioning itself as the controller of multiple manufacturing facilities in Europe and elsewhere. In this model, the Irish subsidiary builds on the cutting edge expertise developed in manufacturing and related skills. The Customer Centric concept (for example Hewlett Packard) sees the FDI subsidiary working closely with customers to identify technical solutions to problems that can lead on to the development of new products and services. This model demands considerable technical expertise from the subsidiary, allied to good interpersonal and negotiation skills and the ability to form lasting relationships with customers. 16 The Innovation model (for example Intel) is a good example of intrapreneurship, where a group internal to the subsidiary finds innovative ways of adding value to the products manufactured by the company. In this scenario, the internal group must have very significant technical capabilities combined with good innovative skills. Figure 4 - Emerging Enterprise Models The Future Landscape of Manufacturing Next generation manufacturing and service enterprises will emphasise innovation, flexibility, adaptability and customer focus. Manufacturing organisations are moving from core manufacturing to ‘Extended Enterprises’. FDI companies need a comprehensive, well-executed, strategic plan that is aligned with the corporate charter. Next Generation Skills and Competencies Individuals in the manufacturing sector have well-developed competencies that are transferable. Key skills for the future are identified as transferable interpersonal and intrapersonal skills, but these need to be built on a strong technical base. There is a need to recognise that interpersonal and intrapersonal skills can be developed through formal courses. Developing Competencies in the Workplace Organisations need to foster a learning culture that encourages continuing development by their employees. A blended approach to learning may be the way forward for successful delivery of the competencies. More interaction and collaboration is required between industry and university. COP General Recommendations There is a need to facilitate mobility between sectors through appropriate training, education and accreditation. 17 Companies should create more opportunities for inter-company learning, for example online/offline forums and Communities of Practice. Competencies for next generation employability should be aligned with the emerging NQAI framework. Flexible blended learning models and appropriate delivery mechanisms must be developed to meet the new needs of industry. More partnerships should be developed between semi-state organisations, industry and third-level education. The delivery and development of interpersonal and intrapersonal skills should be a focal point for a future COP. COP Recommendations to Education Providers Deliver education and training at the leading edge for all learners in terms of the staff, the curriculum, the facilities, the delivery systems and the general service provision. Provide a service to off-campus learners that is sensitive to the needs of people in industry and elsewhere who want access to the full range of services (library, ICT facilities, tutorial support, etc) at any time from anywhere. Put in place support services, such as registration, fee payment, course descriptions, schedules, contact names and contact details, etc sensitive to the needs of adult students who are busy and under pressure in the emerging global work environment. Provide a balanced portfolio of courses that include some modules that have immediate relevance to current issues in contemporary enterprises. At present these might include Sales and Negotiation, Project Management, Value Chain and Supply Chain Management, Safety and Health, Environmental Legislation and so on. Develop and implement procedures for the recognition of prior learning (APL) and prior experiential learning (APEL). Develop and implement procedure for accrediting and assigning credit weightings (ECTS credits) to in-company delivered learning material. Form partnerships with companies at the leading-edge of in-company and ICT enhanced learning. Pay particular attention to accommodating the needs of SMEs and Micro enterprises. Developing Competencies in the Workplace – Key Insights Summary Development of key competencies in the workplace will require a number of delivery strategies. In this context, a blended learning approach offers the most potential for meeting both individual and organisational needs. Individuals must take responsibility for their own personal development to ensure future employability. There is a need to reflect the changing emphasis of interpersonal and intrapersonal skills in curricula at all levels in the education system. Acquisition of the key competencies must begin early in the education life cycle. In-company learning must address the strategic needs of the corporation as well as the specific needs of individual employees. Bodies such as “Great Place to Work” have a role to play in assessing an organisation on the process they have in place to facilitate the acquisition of key competencies by their employees. 18 Conclusions The work described in this paper has address the issue of defining the competencies for next generation employability. The community of practice methodology, combined with some case studies, has had the aim of capturing the authentic voice of employers and enterprises in Ireland. The competency models and framework developed are very consistent with other major studies. In general, while emphasizing the importance of individuals developing good personal communication and behavioural assets, the so called soft skills, their future employability also depends on having good technical/professional assets. The technical/professional assets are an assumed base upon which future employability will depend. Enterprises in Ireland are changing in response to the challenges of the new realities of outsourcing, off-shoring, complex supply chains and developing customer relationships. The new environment requires that individuals need to be increasingly flexible, innovative, good communicators and team players, contributing to the strategic goals of the company and increasingly technically/professionally competent. This presents companies, education providers and development agencies with some significant challenges and the opportunity to be creative. References Dorgan S. (2003). http://www.idaireland.com/whyireland/case_studies_apple.asp (accessed on 23 April 2004). Forfás (2003). The Fourth Report of the Expert Group on Future Skills Needs. Dublin: Forfás Graduate Skills and the Role of Higher Education (2004). http://www.gradireland.com/ (accessed on 3 May 2004). IDA Ireland (2003). Annual Report (2003) National Qualifications Authority of Ireland (2003). A Framework for the Development, Recognition and Award of Qualifications in Ireland. Dublin: NQAI Wince-Smith, D. (2004). Deborah Wince-Smith, President, US Council on Competitiveness (in an interview with MIT Technology Review, April 2004). Wenger, E. and W. Synder (2000). Communities of Practice: The Organizational Frontier. Harvard Business Review, 78(1): 139-145. American Electronics Association. (2004) Report ‘Offshore Outsourcing in an Increasingly Competitive and Rapidly Changing World: A High Tech Perspective’. The American Electronics Association (AEA). Washington. Engineering Technology Board UK, (2004) ‘Developing Technicians in the Workforce’. Engineering Council UK. http://www.uk-spec.org.uk/ (accessed February 2004). Forfás, (2003). The Fourth Report of the Expert Group on Future Skills Needs. Dublin. Forfás. Forfás, (2004). Annual Report 2003. Dublin. Forfás. 19 Irish Council for Science, Technology and Innovation. (2004). http://www.forfas.ie/icsti/. (accessed February, 2004) Ministry of Education Finland, (1999). Education, Training and Research in the Information Society A National strategy for 2000-2004. Helsinki: Ministry of Education, 1999. http://www.minedu.fi/julkaisut/information/englishU/index.html. (accessed January 2004). Career Space. (2004) The EU Career Space Programme http://www.career-space.com/project_desc/serv.htm PUII, (2004). The Programme for University Industry Interface Interim Report, December 2004. 20