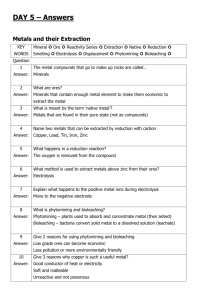

EXTRACTION OF METALS

advertisement

EXTRACTION OF METALS The extraction of metals is economically important, because metals are useful materials with a range of desirable properties, for example electrical and thermal conductivity, strength, malleability, ductility and shiny appearance. The way a particular metal is extracted depends on a number of factors. COMPOSITION OF THE EARTH’S CRUST Element Oxygen Silicon Aluminium Iron Calcium Sodium Potassium Magnesium Hydrogen Titanium Mass % 49.50 25.70 7.50 4.70 3.40 2.60 2.40 1.90 0.88 0.58 Element Chlorine Phosphorus Carbon Manganese Barium Sulphur Chromium Fluorine Nitrogen All others Mass % 0.19 0.12 0.09 0.08 0.05 0.05 0.03 0.03 0.03 0.15 Of the possible engineering metals, only aluminium and iron can be classed as abundant, with titanium, manganese and chromium being the next most common metals. Other metals which are widely used are relatively rare in the Earth’s crust, for example: zinc 0.0070% copper 0.0055% lead 0.0013% tin 0.0002% silver 0.000007% TOPIC 12.11: EXTRACTION OF METALS 1 USES OF METALS Metals have been used by Man for thousands of years. Today, more than 60 metallic elements are extracted and used by us. The use to which a metal is put depends on: its physical properties, such as tensile strength, compressive strength, density, hardness, appearance, electrical conductivity, thermal conductivity its chemical properties, such as resistance to corrosion, reactivity etc. its cost All metals are: ductile – they can be drawn into wires malleable – they can be hammered into shape without breaking Complete the table below by giving the property of each metal which is being made use of in the application which has been given in column 2. METAL USE REASON Silver Jewellery ................................................................................. Aluminium Aircraft construction ................................................................................. Aluminium Overhead power lines ................................................................................. Copper Electrical cables ................................................................................. Lead Roofing ................................................................................. Gold Gold leaf ................................................................................. Copper Saucepan bases ................................................................................. Titanium Artificial hip joints ................................................................................. Copper Coins ................................................................................. Aluminium Cooking foil ................................................................................. Aluminium Window frames ................................................................................. Zinc Galvanising steel ................................................................................. Tin Coating steel for use in food cans ................................................................................. TOPIC 12.11: EXTRACTION OF METALS 2 ORES Only metals with a low reactivity towards water and oxygen, such as gold and silver, occur uncombined (NATIVE) in the Earth’s crust. Most metals occur in the form of compounds. High grade ores, which exist in a few specific locations, are rocks which metal compounds metals in high enough concentrations for their extraction to be economic. The economic concentration of the metal compound will vary, depending on the value of the metal. Some useful metal ores have become concentrated by the movement of water through cracks deep in the Earth’s crust. Water which is at a high temperature and pressure can dissolve minerals which are not normally soluble. As the solution rises towards the surface, the temperature and pressure fall, and the minerals crystallise out forming mineral veins. Most metal ores are oxides or compounds which can easily be converted to oxides, like sulphides and carbonates. METAL PRINCIPAL ORE FORMULA TYPE Aluminium Chromium Copper Iron Iron Lead Mercury Tin Uranium Zinc Bauxite Chromite Malachite Haematite Magnetite Galena Cinnabar Cassiterite Carnotite Sphalerite Al2O3 FeO.Cr2O3 CuCO3.Cu(OH)2 Fe2O3 Fe3O4 PbS HgS SnO2 K2(UO2)2(VO4)2 ZnS Oxide Oxide Basic carbonate Oxide Oxide Sulphide Sulphide Oxide Oxide Sulphide The process of extracting a metal from its ore is reduction. Oxide ores are reduced directly to the metal, but sulphides are first converted to oxides by roasting them in air. For example: 2ZnS(s) + 3O2(g) 2ZnO(s) + 2SO2(g) The sulphur(IV) oxide produced in this process is a pollutant which contributes to acid rain. Sulphur(IV) oxide dissolves in water in the clouds, to form sulphurous acid, H2SO3. H2O(l) + SO2(g) H2SO3(aq) Some is oxidised by oxygen in the air to sulphur(VI) oxide. 2SO2(g) + O2(g) 2SO3(g) Sulphur(VI) oxide dissolves in water to form sulphuric acid H2O(l) + SO3(g) H2SO4(aq) When these acids fall to the ground in rain water, they damage plants and water courses by lowering the pH and by leaching toxic metals out of rocks. TOPIC 12.11: EXTRACTION OF METALS 3 EXTRACTION OF A METAL Metals can be extracted from their ores by reduction in several ways. The method chosen for a particular metal depends on a number of factors: 1. Energy Requirements of the Process Metal oxides are stable compounds and their reduction is usually endothermic. The cost of the energy used in the reduction process is an important factor. A process which is operated at a lower temperature will usually be cheaper. The energy required for electrolysis is high, and where possible, cheaper methods such as carbon reduction will be preferred. 2. Cost of the Reducing Agent Some reducing agents are easily obtained: carbon is readily available from coal; hydrogen can be obtained relatively easily by the reaction of natural gas with steam. These reducing agents will therefore be much cheaper than metals such as sodium and aluminium, which first have to be extracted from their ores in costly processes. 3. The Required Purity of the Metal If a metal is required in a high state of purity for a particular use, for example copper in electrical wiring, it may be necessary to use a more expensive reduction technique to achieve this result. Taking all the factors into account, the cheapest method capable of producing a saleable product will be used. CARBON REDUCTION Carbon is a cheap and plentiful reducing agent. The most common form of carbon used in metal extraction is coke, which is obtained from coal by heating it in the absence of air. Apart from its high carbon content, coke has the additional benefit of being structurally strong and porous. The reduction of a metal oxide with carbon: MO(s) + C(s) M(l) + CO(g) is endothermic (H is +ve) since a gas is produced in the process, the entropy change (S) is +ve The free energy change (G) is given by the equation: G = H -TS For a reaction to be feasible, G must be negative. G becomes negative when the value of TS is greater than H. Therefore, if the temperature is high enough, carbon reduction of any metal oxide is feasible. Carbon reduction is used to extract, among others, iron and zinc. The temperature required to extract aluminium by this method is too high to be practical and economic. TOPIC 12.11: EXTRACTION OF METALS 4 IRON & STEEL EXTRACTION OF IRON The most important example of carbon reduction is the manufacture of iron. This is a continuous process which is carried out in a blast furnace. The raw materials are: iron ore (haematite, Fe2O3) coke, which acts as a fuel and a reducing agent limestone, which removes impurities hot air, which is blown into the base of the blast furnace Haematite, coke and limestone are heated together strongly to produce a uniform mixture known as sinter, which is fed into the top of the blast furnace. Sinter is porous and structurally strong. Hot air is blown into the base of the furnace through jets called tuyeres. Carbon burns in air to form carbon dioxide: C(s) + O2(g) CO2(g) This reaction is highly exothermic and produces the heat needed for the reduction of iron(III) oxide. At the high temperature produced, carbon dioxide reacts with coke to form carbon monoxide: C(s) + CO2(g) 2CO(g) The carbon monoxide reduces most of the iron(III) oxide to iron at around 1200 oC: Fe2O3(s) + 3CO(g) 2Fe(l) + 3CO2(g) In the hotter part of the furnace, coke also reduces iron(III) oxide: Fe2O3(s) + 3C(g) 2Fe(l) + 3CO(g) The molten iron which is formed runs to the bottom of the furnace and is tapped off. The product, known as cast iron, is impure. It contains up to 4% carbon, together with sulphur, silicon, phosphorus and manganese in quantities which vary with the ore used and with the operating conditions. Limestone decomposes at the high temperatures in the furnace: CaCO3(s) CaO(s) + CO2(g) Calcium oxide is a basic substance which combines with the acidic impurities in the ore, mainly silicon dioxide, to form a molten slag, which runs to the bottom of the furnace and floats on the surface of the molten iron. CaO(s) + SiO2(s) CaSiO3(l) Slag is used: to make breeze blocks for the construction industry as road chippings. TOPIC 12.11: EXTRACTION OF METALS 5 waste gases EXTRACTION OF IRON RAW MATERIALS: iron ore (haematite) coke limestone stock line o 300 C o 600 C slag forms o 900 C o 1200 C 1500 oC ore reduced by CO melting zone ore reduced by C o 1900 C carbon burns hot air blown in through tuyeres TOPIC 12.11: EXTRACTION OF METALS slag iron 6 BLAST FURNACE Cowper stoves pre-heat the blast scrubber removes impurities THE BASIC OXYGEN STEEL-MAKING PROCESS Molten iron from the blast furnace is mixed with recycled scrap steel, then powdered magnesium is added. The magnesium reacts with sulphur impurities in the iron, forming magnesium sulphide, which floats as a slag on the surface of the iron. Mg + S MgS Pure oxygen is then blown into the molten iron through a water-cooled lance. Calcium oxide is also added. The non-metal impurities are converted into oxides. Carbon is oxidised to carbon monoxide, which is given off as a gas. The oxides of silicon and phosphorus, which are solid and acidic, react with calcium oxide to form a slag. Sulphur cannot be removed by treatment with oxygen, because iron would be oxidised in preference to the sulphur. Calculated quantities of carbon and/or other elements are then added to make a range of steels with particular properties. oxygen water cooled lance desulphurised, molten cast iron containing scrap steel TOPIC 12.11: EXTRACTION OF METALS 7 Steels are iron-carbon alloys containing 0.04 –1.0% carbon. The addition of small quantities of other metals or carbon alters the properties of steel. High carbon steel (~1% carbon) is hard and strong but brittle; it is used to make, for example, chisels. Mild steel (~0.1% carbon) is the commonest steel and is used, for example, to make car bodies. Low carbon steel (~0.04% carbon) is soft and easily shaped; it is used to make wire, nails and rivets. Stainless steel is an alloy containing chromium and nickel, which is hard and resistant to corrosion. It is used to make cutlery, sinks etc. PROBLEMS WITH THE CARBON REDUCTION PROCESS 1. Pollution A by-product of this process is carbon dioxide, which causes problems because it is a greenhouse gas and contributes to global warming. 2. Carbide Formation Instead of the oxide being reduced to the metal in this process, some metals form metal carbides instead. The method is therefore impractical for such metals. An important example is titanium; when titanium(IV) oxide is heated with carbon: TiO2 + 3C TiC + 2CO Other metals which give carbides are vanadium, tungsten and molybdenum. Carbides are, however, important materials, some of which can be used as catalysts. Tungsten carbide is very hard and is used as an abrasive and to tip drills. TOPIC 12.11: EXTRACTION OF METALS 8 ALUMINIUM Aluminium is the commonest metal in the Earth’s crust. It is a reactive metal which can only be reduced by carbon at impractically high temperatures. Instead, it is obtained by electrolysis of the molten metal oxide. ELECTROLYSIS When ionic substances, which are made of ions, are melted (or dissolved in water), the ions are free to move about. Therefore, the ions are able to carry charge from one place to another: this means that these substances can conduct electricity. When an electric current is passed through an ionic substance which has been melted (or dissolved in water), the substance is broken down (decomposed) into simpler substances through chemical reactions at the electrodes. This is the process called electrolysis. During electrolysis, positively-charged ions are attracted to the negative electrode, which is called the cathode. Here they gain electrons (reduction) and are converted to neutral atoms. Negatively-charged ions are attracted to the positive electrode, which is called the anode. Here they lose electrons (oxidation) and are converted to neutral atoms. THE EXTRACTION OF ALUMINIUM The raw material for the production of aluminium is the ore, bauxite. This is an impure form of aluminium oxide, the main impurity being iron(III) oxide. The ore is purified to give aluminium oxide (sometimes called alumina). For electrolysis to be carried out, the aluminium oxide must be molten, but because its melting point is so high (>2000oC), it is dissolved in molten cryolite (Na3AlF6). This lowers the melting point of the melt to 970oC. pipe for sucking out molten aluminium (+) graphite anodes crust of solid electrolyte molten electrolyte molten aluminium TOPIC 12.11: EXTRACTION OF METALS 9 (-) graphite cathode The process is run continuously. As aluminium oxide is used up, more is added at regular intervals from a hopper above the cell, after first breaking the crust of electrolyte. The molten aluminium oxide/cryolite mixture is electrolysed using graphite (carbon) electrodes. The positive aluminium ions (Al3+) are attracted to the cathode, where they gain electrons (reduction) to form aluminium atoms. Al3+ + 3e- Al The negative oxide ions (O2-) are attracted to the anode, where they lose electrons (oxidation) to form oxygen molecules. 2O2- - 4e- O2 At the high temperatures of the electrolysis, the oxygen produced at the anode reacts with the graphite (carbon) that the electrode is made of to form carbon monoxide and carbon dioxide. This means that the anode burns away and has to be replaced regularly. 2C + O2 2CO C + O2 CO2 The process consumes large amounts of electricity, both to melt the cryolite and to decompose the aluminium oxide, which makes aluminium an expensive metal. The process is economical only where relatively cheap electricity is available. Tiny amounts of fluorine are produced in the process, but great care is taken to ensure that this does not pollute the area around the plant. Waste cryolite could cause fluoride pollution. TOPIC 12.11: EXTRACTION OF METALS 10 TITANIUM Titanium is a relatively abundant metal in the Earth’s crust, but the difficulties in extracting it limit its uses, despite many desirable properties. It has high strength, low density and a high resistance to corrosion. It is non-toxic. Carbon reduction is not a feasible method of extracting titanium. Traces of carbon, oxygen and nitrogen in titanium render it brittle and unusable. The only practical way of extracting titanium is by the reduction of the metal halide with a reactive metal. This is an expensive method. Extraction Titanium is a reactive metal which is extracted from its ores by reaction with a more reactive metal. The raw material is the ore, RUTILE, which contains titanium dioxide, TiO2. The oxide is converted into titanium(IV) chloride, TiCl4, by heating it with coke and chlorine at about 900oC. TiO2 + 2C + 2Cl2 TiCl4 + 2CO Titanium(IV) chloride is a colourless liquid. It fumes in moist air as it is hydrolysed. It is purified from other chlorides, such as those of Fe, Si and Cr, by fractional distillation under an atmosphere or argon. Titanium(IV) chloride is heated with sodium under an inert atmosphere or argon, forming sodium chloride and titanium. The reaction begins at about 550oC, but because of the exotherm, the temperature rises to about 1000 oC during the reaction.(Magnesium could be used instead of sodium). TiCl4 + 4Na Ti + 4NaCl (H is -ve) During the reaction sodium, the more reactive metal, is oxidised (loses electrons to form Na+). Titanium(IV) chloride is reduced. Argon prevents the contamination of the titanium with oxygen or nitrogen. Sodium chloride is dissolved out in water to leave titanium as a grey, granular powder. The process is a batch process and is expensive because: chlorine and sodium have to be produced first by electrolysis high temperatures are involved in both steps an argon atmosphere is needed TiCl4 needs to be handled carefully because it reacts violently with cold water TOPIC 12.11: EXTRACTION OF METALS 11 TUNGSTEN Tungsten is the metal which has the highest melting point (3422oC). Like aluminium and titanium, it is protected from corrosion by a thin oxide layer on it's surface. However, this layer only protects is up to about 400oC after which it rapidly oxidises in the presence of air. Extraction of tungsten Tungsten is extracted from its ores Wolframite (Fe/Mn)WO4, Huebnerite MnWO4, Ferberite FeWO4 and Scheelite CaWO4 by reduction with hydrogen. The ores are processed to produce WO3 which is then heated with hydrogen gas at 850oC WO3 (s) + 3H2 (g)) → W (s)) + 3H2O (l)) This process is potentially dangerous to the very flammable nature of hydrogen. Tungsten could be extracted from its ore by carbon reduction but this also leads to the formation of tungsten carbide (WC) which is less useful and makes the metal brittle. Tungsten carbide is however extremely hard and is used to make drills, grinders, and cutting tools. TOPIC 12.11: EXTRACTION OF METALS 12 ECONOMIC FACTORS & RECYCLING The reserves of many important metals (e.g. Cu) are limited and recycling is necessary to prevent the depletion of ore deposits. Since the collection and transportation of scrap metal to the recycling plant have an energy requirement, it is not economic to recycle all metal, but in general, the greater the value of the metal, the more economic it is for even small pieces to be collected and recycled. Recycling of Iron Iron is extensively recycled, and up to 30% scrap steel is used in each batch in the basic oxygen process. Despite the abundance of iron, it is sensible to recycle it because: scrap iron and steel contain a higher percentage of iron than even high grade ores recycling uses less energy than the primary extraction process carbon dioxide, a greenhouse gas, is produced in the primary extraction process. Recycling, which involves only melting and re-shaping, does not produce carbon dioxide iron is magnetic and can easily be separated from other scrap metal a serious pollution problem is avoided. Without recycling, discarded iron and steel objects, which would include about 1.5 million cars per year in the U.K., would pollute the environment Scrap iron can also be used to extract copper from low grade copper ores. When these ores are processed the liquid waste still contains very small amounts of copper dissolved in it. Scrap iron can be used to reduce the dissolved copper ions to copper metal. Cu2+ (aq) + Fe (s) → Fe2+ (aq) + Cu (s) The cheaper iron dissolves in this process and the more expensive and increasingly scarce copper is obtained. This process is very efficient since little energy is needed compared to the high temperature carbon reduction process. Recycling of Aluminium Aluminium too is an abundant metal, but the large energy consumption makes up a high percentage of its extraction cost. It is therefore sensible to recycle, even if aluminium is harder to separate from other scrap metal than iron is, because: recycling uses much less energy than the primary extraction process. Since electrolysis uses so much energy, melting and re-shaping aluminium can save up to 95% of the energy used in extraction. carbon dioxide, a greenhouse gas, is produced in the primary extraction process, by the burning away of anodes. Recycling, which involves only melting and reshaping, does not produce carbon dioxide. scrap aluminium contains a higher percentage of aluminium than bauxite as with iron, recycling avoids pollution by dumped objects. TOPIC 12.11: EXTRACTION OF METALS 13